文章编号: 1004-0609(2005)03-0358-05

纳米SrCe0.95Y0.05O3-x陶瓷粉的制备与烧结

孟 波1, 2, 谭小耀2, 杨乃涛2, 张宝砚1

(1. 东北大学 理学院, 沈阳 110004; 2. 山东理工大学 化工学院, 淄博 255049)

摘 要: 采用基于Pechini法的低温燃烧工艺制备了SrCe0.95Y0.05O3-x (SCY)前驱物。 前驱物在900℃经0.5h的煅烧处理即可得到纯的粒度在7~25nm范围内的SrCe0.95Y0.05O3-x 固体电解质纳米粉。 将煅烧的粉体在18MPa压力下压成片状的素坯, 在900~1500℃的温度范围内于空气中烧结素坯10h。 用X射线衍射(XRD)表征煅烧粉体的晶体结构, 用扫描电镜(SEM)和透射电镜(TEM)表征了煅烧粉体和烧结体的形貌和粒度, 采用阿基米德法测量了烧结体的密度。 结果表明: 温度达到1000℃时, 烧结体的径向收缩率和密度随着温度的升高而显著增加; 温度达1300℃时烧结体的径向收缩率和密度趋于恒定, 得到相对密度高于96%、 平均粒径约为3.68μm 的SrCe0.95Y0.05O3-x 固体电解质陶瓷体。

关键词: 固体电解质; SrCe0.95Y0.05O3-x; 纳米陶瓷粉; 烧结; 低温燃烧

中图分类号: TQ174.758; O614.3 文献标识码: A

Preparation and sintering behavior of nanosized pure SrCe0.95Y0.05O3-x powders

MENG Bo1, 2, TAN Xiao-yao2, YANG Nai-tao2, ZHANG Bao-yan1

(1. College of Science, Northeastern University, Shenyang 110004, China;

2. College of Chemical Engineering and Technology,

Shandong University of Technology, Zibo 255049, China)

Abstract: Precursors for SrCe0.95Y0.05O3-x (SCY) were synthesized by sol-combustion process based on the Pechini method. Pure SrCe0.95Y0.05O3-x nanosized powders with the size range of 7-25nm were obtained after calcining the precursors at 900℃ for 0.5h. The calcined powders were pressed into pellets at 18MPa. These pellets were sintered at the temperature range of 900-1500℃ for 10h in air. The crystal structure of the calcined powders was analyzed using XRD. The morphology and crystallite sizes of the calcined powders and the sintered pellets were observed using SEM and TEM. The densities of the sintered pellets were measured using Archimedes method with water. The results indicate that, at 1000℃ and above, the radial shrinkage and the density of the sintered pellets obviously increase; at a temperature as high as 1300℃, nearly fully dense SrCe0.95Y0.05O3-x ceramic (relative density larger than 96%) with a mean grain size of 3.68μm can be obtained.

Key words: solid electrolyte; SrCe0.95Y0.05O3-x; nanosized ceramic powder; sintering; low temperature combustion

由于钙钛矿结构的材料如BaCeO3和SrCeO3在较高温度和含氢气氛中具有高的质子导电性[1, 2], 特别是掺杂稀土元素的钙钛矿结构材料显示出极好的质子传导性[3, 4], 因此常被用于氢气或湿度传感器、 固体氧化物燃料电池材料、 加氢或脱氢反应器、 从含氢混合气中分离氢气以及水蒸汽电解生产氢气等[5-9]。 但是它们也存在着质子导电率偏低和稳定性的问题, 所以寻找稳定性好、 离子导电性更高的体系, 以及对现有体系开发操作方便、 成本低的材料制备工艺和薄膜化组件制备新工艺一直是研究的热点[10]。

BaCeO3和SrCeO3基陶瓷粉体主要是采用传统的固相反应煅烧法制备[11, 12]。 固相反应法中, 由于物理混合的不均匀性, 很难制备具有组成单一、 粒度分布均匀的粉体, 因而更难以制备致密、 具有精细粒度的烧结体[13]。 因此湿化学法如溶胶-凝胶法[14]、 柠檬酸法[15]、 Pechini法[16]、 甘氨酸燃烧法[17]、 共沉淀法[6]以及低温燃烧法[18]等得到了广泛关注。 其中低温燃烧法利用强放热的氧化还原反应制得超细粉体, 方法简单、 快捷, 又可针对不同的体系采用不同的燃料控制粒度的大小[19]。 本文作者将低温燃烧法和Pechini法结合起来, 在低温下(900℃)合成了组成为SrCe0.95Y0.05O3-x、 均匀单相的固体电解质陶瓷粉末, 并考察了粉体的烧结性能。

1 实验

1.1 试剂

实验过程中所用试剂均为分析纯。 主要试剂为: 硝酸锶(Sr(NO3)2), 硝酸亚铈(Ce(NO3)3·6H2O), 硝酸钇(Y(NO3)3·6H2O), 柠檬酸(C6H8O7·H2O), 乙二醇(C2H6O2), 硝酸(HNO3), 氨水(NH3·H2O)。 使用前用化学法标定硝酸盐中金属离子含量。

1.2 粉体的制备和性能检测

采用基于Pechini法的硝酸-氨水低温燃烧合成SrCe0.95Y0.05O3-x纳米晶。 首先将化学计量的各种金属硝酸盐依次溶于最小量的蒸馏水中, 完全溶解后, 加入计量的柠檬酸和乙二醇, 柠檬酸的加入量参照Pechini法为金属离子总物质的量的1.5倍, 乙二醇的用量是柠檬酸物质的量的1.2倍; 搅拌加热形成透明的溶液; 加入计量的硝酸, 硝酸的加入量根据有机物总量来确定; 最后滴加氨水, 氨水的加入量由硝酸的量决定。 继续搅拌加热, 在80℃左右保温进行酯化和络合反应形成金属和高分子网络的复合物, 并除去多余的水形成溶胶。 当溶胶内有气泡产生时, 迅速将温度升高到230℃左右, 这时溶胶内有大量气体产生, 体积迅速膨胀, 并发生燃烧得到淡黄色毛绒状疏松的固体粉末。 将燃烧粉末进行热处理即得所需粉体。 将粉体在18MPa下压成直径为25mm、 厚度为1~3mm的片状素坯, 然后在900~1500℃空气中烧结10h得到SCY陶瓷体。 烧结过程中, 控制升温速率为2℃/min。

用X射线衍射仪(日本理光, D/max 2200)检测燃烧粉末及热处理产物的物相组成, 铜靶(λ=0.154178nm), 电压35kV, 扫描速率0.1(°)/s, 2θ范围10°~80°。 用扫描电子显微镜(SEM, 荷兰, Philips, XL30&DX-4i)和透射电子显微镜(TEM, 日本, H-800)考察粉体和烧结体形貌和粒度大小。 采用阿基米德法测量烧结体的密度。

2 结果与讨论

2.1 粉体的物相组成和形貌

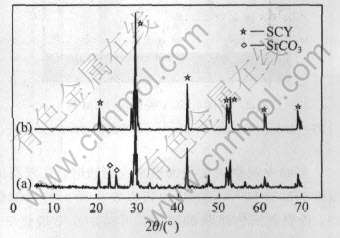

图1所示是所制备的燃烧粉末和经过900℃煅烧0.5h的SrCe0.95Y0.05O3-x(SCY)纳米粉体的XRD谱图。 由图1(a)可见, 燃烧粉末中除SCY外, 只含有部分碳酸盐杂质, 说明燃烧反应很完全。 图1(b)中所有衍射峰都为SrCeO3的峰, 同时根据反应认为是SCY。 这与JCPDS-ICDD标准卡片(23-1412)稍有偏差, 应为Y部分取代了SrCeO3中的Ce或粉体粒度的不同引起的。 可见该方法合成的粉体为纯的具有斜方钙钛矿结构的SCY粉。

图1 燃烧粉末(a)和900℃煅烧0.5h粉末(b)的XRD谱图

Fig.1 XRD patterns of combustion powders before(a) and after(b) calcined at 900℃ for 0.5h

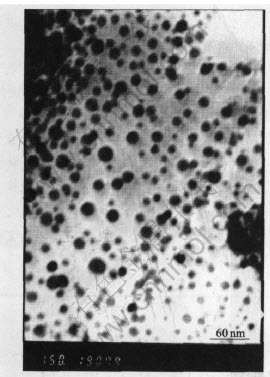

图2所示是煅烧的粉体经过研磨分散后的透射电镜照片。 可见, 900℃煅烧0.5h得到的SCY是颗粒形貌完整且基本为球形、 粒度分布在7~25nm之间的纳米粉体。 该方法比文献[11]中采用传统的固相反应法降低了650℃。 低温燃烧法能在900℃的低温下完成SCY相的形成, 是由于柠檬酸的络合作用使各组分均匀分散在溶胶中, 其机理见文献[16]。 溶胶燃烧过程中生成大量的气体抑制了粒子间的团聚, 并且燃烧放出的热量促进了物相的形成[18]。 特别是在有硝酸和氨水存在的条件下, 氨水的助络合与助燃作用, 硝酸的氧化作用更促进了离子的均匀分布以及燃烧反应的进行。 有硝酸和氨水存在下的燃烧反应表示为

Sr(NO3)2+0.95Ce(NO3)3+0.05Y(NO3)3+

3C6H8O7+3.6C2H6O2+40NH3·H2O+

40HNO3→SrCe0.95Y0.05O3-δ+25.2CO2+

103.8H2O+40.75N2+3.5NO2

图2 研磨后SCY粉体的TEM像

Fig.2 TEM photograph of SCY after milling

实验中观察到在不加氨水或硝酸时, 在较高的温度(450~500℃之间)也可以发生无火苗状的燃烧, 得到灰黑色块状的固体, 再经900℃煅烧3h也可以得到团聚较重的SCY超细粉末(如图3(a)), 图3(b)所示是加硝酸和氨水时所得到粉末的SEM照片。 由图可见氨水和硝酸的加入使团聚粒子呈松散的毛绒状, 很容易被分散为如图2所示的球形的超细粉体。

图3 900℃煅烧后没有研磨的SCY粉末的SEM照片

Fig.3 SEM micrographs of SCY powders calcined at 900℃ for 0.5h before milling

2.2 粉体的烧结性能

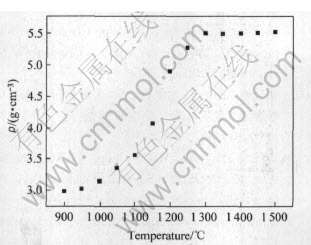

图4所示是经900℃煅烧0.5h的粉体经过18MPa干压成型后, 试样的径向收缩率随烧结温度的变化。 由图可见, 试样的径向收缩率在1000℃开始迅速增大, 高于1300℃后趋于稳定, 在13.6%左右, 说明烧结体内部骨架和孔隙的分布已经稳定。 图5所示是各烧结温度下的试样密度。 可见试样密度随烧结温度的变化与径向收缩率趋势相同。 1000℃烧结体的密度比950℃烧结体的密度增加了0.13g/cm3, 说明材料开始烧结并发生致密化。 温度高于1300℃烧结体的密度趋于定值(5.48g/cm3), 高于理论密度的96%。 表明烧结体内部颗粒堆积已经趋于恒定, 形成紧密的堆积结构。

图4 烧结温度对径向收缩率的影响

Fig.4 Effect of temperature on radial shrinkage

图5 烧结温度对烧结体密度的影响

Fig.5 Effect of temperature on density

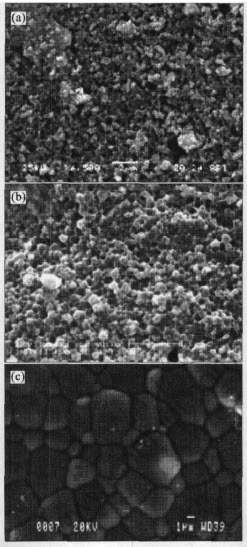

1100℃、 1200℃和1300℃烧结10h后样品的SEM照片如图6所示。 由6(a)可见, 1100℃烧 结10h的样品内存在分布比较均匀的开口孔。 随着温度的升高, 孔的大小和数目都下降。 当温度达到1300℃时, 所有的孔都消除了, 形成了致密的烧结体。 烧结体内颗粒的平均直径约为3.68μm。 表明用低温燃烧法制备的SCY纳米粉体能够在1300℃烧结致密, 比文献[11]中的烧结温度低了300℃。 SCY纳米粉体具有很好的烧结性能, 是因为溶胶低温燃烧法合成的粉体具有球形结构和粒度分布窄的优点。

图6 空气中烧结10h 得到的SrCe0.95Y0.05O3-x陶瓷烧结体的显微结构

Fig.6 Microstructures of SrCe0.95Y0.05O3-x ceramics sintered at 1100℃(a), 1200℃(b) and 1300℃(c) for 10h in air

3 结论

1) 采用基于Pechini 法改进的低温燃烧法制备了SrCe0.95Y0.05O3-x纳米陶瓷粉。 在硝酸和氨水存在的条件下溶胶燃烧所得粉末经过900℃, 0.5h的煅烧即可得到粒度在7~25nm之间、 形状为球形的SrCe0.95Y0.05O3-x纳米陶瓷粉。 该方法比传统的固相反应法降低了650℃。

2) 制备的SrCe0.95Y0.05O3-x粉体在1000℃即发生烧结, 当温度高于1300℃时烧结体的密度达5.48g/cm3, 高于理论密度的96%。 烧结体内颗粒平均直径为3.68μm。 表明SrCe0.95Y0.05O3-x粉体具有很好的烧结性能, 比传统的固相反应法制备的粉体烧结温度降低了300℃。

REFERENCES

[1]Iwahara H. Technological challenges in the application of proton conducting ceramics[J]. Solid State Ionics, 1995, 77: 289-298.

[2]Iwahara H. Oxide-ionic and protonic conductors based on perovskite-type oxides and their possible applications[J]. Solid State Ionics, 1992, 52: 99-104.

[3]Reichel U, Arons R R, Schilling W. Investigation of n-type electronic defects in the protonic conductor SrCe1-xYxO3-x[J].Solid State Ionics, 1996, 86-88: 639-654.

[4]He T, Ehrhart P. An optical in-situ study of BaCeO3 at high temperatures[J]. Solid State Ionics, 1996, 86-88: 633-638.

[5]Marnellos G, Sanopoulou O, Rizou A, et al. The use of proton conducting solid electrolytes for improved performance of hydro- and dehydrogenation reactors[J]. Solid State Ionics, 1997, 97: 375-383.

[6]Schneller T, Schober T. Chemical solution deposition prepared dense proton conducting Y-doped BaZrO3 thin films for SOFC and sensor devices[J]. Solid State Ionics, 2003, 164: 131-136.

[7]Song S J, Wachsman E D, Rhodes J, et al. Hydrogen permeability of SrCe1-xMxO3-δ[J]. Solid State Ionics, 2004, 167: 99-105.

[8]Alberti G, Casciola M. Solid state protonic conductors, present main applications and future prospects[J]. Solid State Ionics, 2001, 145: 3-16.

[9]Grover Coors W. Protonic ceramic fuel cells for high-efficiency operation with methane[J]. J Power Sources, 2003, 118: 150-156.

[10]郑文君, 庞文琴. 钙钛矿型复合氧化物氢离子导体研究现状[J]. 功能材料, 1997, 28(3): 242-246.

ZHENG Wen-jun, PANG Wen-qin. Recent developments of protonic conductors with perovskite-type structure[J]. J Functional Materials, 1997, 28(3): 242-246.

[11]Reichel U, Arons R R, Schilling W. Investigation of n-type electronic defects in the protonic conductor SrCe1-xYxO3-δ[J]. Solid State Ionics, 1996, 86-88: 639-645.

[12]QIU Li-gan, MA Gui-lin, WEN Di-jiang. Ionic conduction in BaxCe0.8Er0.2O3-α[J]. Solid State Ionics, 2004, 166: 69-75.

[13]Takatori K, Tani T, Watanabe N, et al. Preparation and characterization of nano-structured ceramic powders synthesized by emulsion combustion method[J]. J Nanoparticle Research, 1999, 1: 197-204.

[14]耿树江, 邵忠宝, 牛盾, 等. 溶胶-凝胶法合成La1-xSrxCoO3粉末[J]. 中国有色金属学报, 1998, 8(S2): 61-63.

GENG Shu-jiang, SHAO Zhong-bao, NIU Dun, et al. Synthesizing La1-xSrxCoO3 powders by sol-gel process[J]. The Chinese Journal of Nonferrous Metals, 1998, 8(S2):61-63.

[15]张建敏, 王吉德, 王疆英, 等. 致密SrCe0.95Y0.05O3-δ在含氢气氛下的电化学性质研究[J]. 无机材料学报, 2001, 16(3): 559-562.

ZHANG Jian-min, WANG Ji-de, WANG Jiang-ying, et al. Electrochemical research of dense SrCe0.95Y0.05-O3-δ under atmosphere contained hydrogen[J]. Journal of Inorganic Materials, 2001, 16(3): 559-562.

[16]LIU S M, TAN X Y, LI K, et al. Synthesis of strontium cerates-based perovskite ceramics via water-soluble complex precursor routes[J]. Ceramics International, 2002, 28: 327-335.

[17]LIU M L, WANG D S. Preparation of La1-z-SrzCo1-yFeyO3-x thin films, membranes, and coatings on dense and porous substrates[J]. J Mater Res, 1995, 10(12): 3210-3221.

[18]Purohit R D, Tyagi A K, Mathews M D, et al. Combustion synthesis and bulk thermal expansion studies of Ba and Sr throats[J]. J Nuclear Materials, 2000, 280: 51-55.

[19]李汶霞, 殷声.低温燃烧合成陶瓷微粉[J]. 硅酸盐学报, 1999, 27(1): 71-78.

LI Wen-xia, YIN Sheng. Low temperature combustion synthesis of ultrafine ceramic powder[J]. J Chin Ceram Soc, 1999, 27(1):71-78.

(编辑袁赛前)

基金项目: 国家自然科学基金资助项目(20076025)

收稿日期: 2004-07-20; 修订日期: 2005-01-14

作者简介: 孟 波(1963-), 女, 博士研究生, 副教授.

通讯作者: 孟 波, 副教授; 电话及传真: 0533-2786292; E-mail: mb1963@126.com