DOI: 10.11817/j.issn.1672-7207.2019.01.012

基于轧制界面表面粗糙度特征的板带轧机混合润滑特性研究

王桥医,朱媛,过山,张秋波,池冰冰

(杭州电子科技大学 机械工程学院,浙江 杭州,310018)

摘要:综合运用平均雷诺方程、Christensen随机粗糙峰分布理论、摩擦润滑理论和金属轧制变形理论,建立考虑表面粗糙度特征影响的轧制工作界面混合润滑模型,并采用该模型系统分析基于不同表面粗糙度方向、压下率、轧制界面膜厚比、接触载荷比、界面流体压力和接触面积比等混合润滑摩擦性能参数随润滑油卷吸速度或工作区位置变化的情况。研究结果表明:粗糙度横向分布更有利于润滑性能的提高;在相同表面粗糙度下,随着压下率增大,接触面积比和膜厚比减小;在相同压下率下,膜厚比随工作界面润滑油卷吸速度的增大而增大,而接触载荷比和接触面积比随之减小;工作界面表面粗糙度对界面流体压力分布有较大影响,在表面粗糙度最小处流体压力最小。

关键词:轧制界面;混合润滑;表面粗糙度特征;压下率

中图分类号:TH117.2 文献标志码:A 文章编号:1672-7207(2019)01-0083-08

Research on mixed lubrication characteristics of strip mill based on surface roughness features of rolling interface

WANG Qiaoyi, ZHU Yuan, GUO Shan, ZHANG Qiubo, CHI Bingbing

(School of Mechanical Engineering, Hangzhou Dianzi University, Hangzhou 310018, China)

Abstract: With the comprehensive application of average Reynolds equation, Christensen random rough peak distribution theory, friction lubrication theory and metal rolling deformation theory, the mixed lubrication model of rolling interface considering the influence of surface roughness characteristics was established. Based on different roughness directions, amplitudes and reduction rates, the changes of film thickness ratio, contact load ratio, distribution of fluid pressure and contact area ratio were systematically analyzed when lubricant entrainment speed and workspace location changed. The results show that the transverse distribution of roughness is more conducive to the improvement of lubrication performance. With the surface roughness amplitude being same, the contact area ratio and the film thickness ratio decreases with the increase of the reduction rate. For the same reduction rate, the film thickness ratio increases with the increase of the lubricant entrainment speed, while the contact load ratio and the contact area ratio decrease. At the same time, the surface roughness of the interface has great influence on the fluid pressure distribution of the interface, and the pressure at the minimum amplitude is the smallest.

Key words: rolling surface; mixed lubrication; surface roughness characteristics; reduction rate

在实际生产中,板带轧制塑性成形过程一般是在混合润滑[1-3]状态下进行,即轧辊与轧件一部分通过润滑油接触,一部分通过轧辊轧件表面微凸体接触。金属轧制变形过程是一个不断变化的过程,润滑油性能[4]、轧制条件[5]或轧制界面表面粗糙度[6-8]的轻微改变均会导致轧制工作界面间的润滑状态发生改变。YOUNES等[9-10]研究了轧制表面粗糙度对界面载荷分布的影响;KIJIMA等[11]用有限元分析法研究了轧辊表面粗糙度、润滑条件对轧制界面接触条件的影响;YANG[12]编写了摩擦润滑有限元程序预测接触面积比、应变分布等,分析了轧制表面粗糙度对流体润滑的影响;陈金山等[13]提出了考虑轧辊表面微凸体影响的塑性区油膜厚度模型;徐冬等[14-15]建立了真实接触的表面粗糙度生成模型并予以验证;刘乐民等[16]得出了不同表面形貌下的轧制力及摩擦力与轧制润滑膜厚度之间的具体关系;张晓峰等[17]考虑轧件、轧辊粗糙表面相互作用得出表面形貌生成规律。上述研究虽考虑了轧制界面粗糙度在板带轧制润滑过程中的重要作用,但均未考虑粗糙度分布特征和对流体润滑性能参数的影响。为此,本文作者综合运用平均雷诺方程、Christensen随机粗糙峰分布理论[18]、摩擦润滑理论和金属轧制变形理论,建立考虑表面粗糙度特征影响的轧制工作界面混合润滑模型。系统分析基于不同表面粗糙度方向、压下率、轧制界面膜厚比、接触载荷比、接触面积比和界面流体压力分布等混合润滑摩擦性能参数随润滑油卷吸速度或工作区位置变化的情况,以便为板带轧制过程中混合润滑性能参数研究提参考。

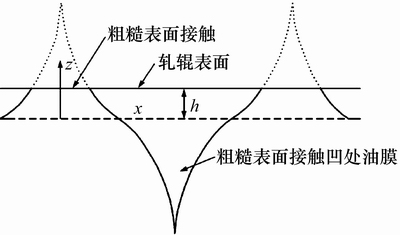

1 轧制界面表面特征表征

在早期的轧制润滑机理研究中,常假设轧辊和板带的表面是光滑的,这在实际生产中是不存在的。为了建立更加真实精确的数学计算模型,必须考虑板带粗糙度对轧制工作界面润滑剂流动的影响。实际上,板带与轧辊的表面均是凹凸不平的,存在表面波峰和波谷,而且是随机分布,如图1所示。Christensen随机粗糙峰分布理论[18]认为板带和轧辊的表面粗糙度呈高斯分布,因此,高斯表面的概率密度 可以描述为:

可以描述为:

(1)

(1)

(2)

(2)

式中:x为沿测量方向的距离; 为表面中线以上的高度;

为表面中线以上的高度; 为表面均方根粗糙度;z为微凸体中线到表面的距离;L为测量间距。

为表面均方根粗糙度;z为微凸体中线到表面的距离;L为测量间距。

图1 表面粗糙峰接触示意图

Fig. 1 Sketch map of surface roughness profile

为了对高斯分布表面进行近似表征,将多项式概率密度函数用于表示高斯表面的近似分布,使用较简便,其定义为

(3)

(3)

但均方根粗糙度不能反映微凸体分布方向,可用自相关函数对高斯表面粗糙度的分布方向进行表征。引入表面方向因子 :

:

(4)

(4)

其中: 和

和 分别为平行和垂直于表面运动方向的自相关长度。表面方向因子

分别为平行和垂直于表面运动方向的自相关长度。表面方向因子 >1表示高斯表面粗糙度的分布方向呈纵向分布,

>1表示高斯表面粗糙度的分布方向呈纵向分布, 表示呈各向同性分布,

表示呈各向同性分布, <1表示呈横向分布。对于高斯表面,平均油膜厚度ht可表示为

<1表示呈横向分布。对于高斯表面,平均油膜厚度ht可表示为

(5)

(5)

式中:hn为两变形表面中线间的距离。平均油膜厚度的量纲一形式为

(6)

(6)

(7)

(7)

(8)

(8)

Hn为膜厚比,其表达式为

(9)

(9)

接触面积比A可表示为

(10)

(10)

2 轧制界面混合润滑数学模型

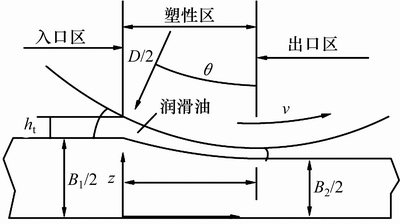

在实际轧制过程中,变形区复杂的几何形状、多变的轧制速度、温度、压力等工艺参数、变形区内复杂的物理化学反应使得轧制变形区润滑状态较复杂。但由于轧件进入变形区后受到的轧制力较大,轧辊与轧件表面间的微凸体接触发生塑性变形,因此,通常认为轧制工作界面处于混合润滑状态。图2所示为考虑润滑油膜的轧制变形区示意图,其中,D为轧辊直径, 为咬入角,v为轧辊转速。

为咬入角,v为轧辊转速。

图2 轧制变形区示意图

Fig. 2 Sketch map of rolling deformation

在混合润滑机制中,界面压力一部分由轧辊与轧件间润滑油膜承担,另一部分由表面微凸体承担。在流体动压润滑区域,通常采用PATIR等引入的平均雷诺方程[19]计算油膜压力:

(11)

(11)

式中:x为变形区任意位置; 为润滑油黏度;

为润滑油黏度; 为润滑油卷吸速度;U为板带表面速度;Ur为轧辊表面速度;

为润滑油卷吸速度;U为板带表面速度;Ur为轧辊表面速度; 为压力流量因子;

为压力流量因子; 为剪切流量因子;

为剪切流量因子; 为微凸体表面流体压力;

为微凸体表面流体压力; 为粗糙度,

为粗糙度,

(12)

(12)

Rqr为轧辊表面均方根粗糙度;Rqs为板带表面均方根粗糙度。

式(11)中的 和

和 用于减少表面粗糙度对轧件生成质量的影响。通过数值模拟,PATIR等给出了全膜润滑机制下流量因子的半经验表达式[19]:

用于减少表面粗糙度对轧件生成质量的影响。通过数值模拟,PATIR等给出了全膜润滑机制下流量因子的半经验表达式[19]:

(13)

(13)

(14)

(14)

(15)

(15)

式中:R为轧制压下率;B1为轧件入口厚度;B2为轧件出口厚度。

3 轧制界面压力分布模型

由图2可知轧制变形区分为3部分:入口区、塑性区和出口区。通常使用卡尔曼微分方程[20]来计算在塑性变形区的流体压力分布:

(16)

(16)

式中:k为工件平面变形下的剪切强度;B为变形区内任一点板带厚度; 为平均摩擦应力;p为轧制压力。

为平均摩擦应力;p为轧制压力。

经研究发现,在表面粗糙度纵向分布时,为得出微凸体自由表面流体压力pb,需考虑轧件塑性变形对量纲一微凸体等效硬度Ha的影响。Ha可以定义为

(17)

(17)

式中:Pa和Pb分别为量纲一微凸体接触载荷比和微凸体表面流体压力;pa为微凸体接触载荷比。

将润滑表面上总的界面压力p、微凸体接触载荷比pa、流体压力pb和接触面积比A联系起来,表示如下:

(18)

(18)

将式(18)写成量纲一形式:

(19)

(19)

式中:P为量纲一轧制界面压力,

(20)

(20)

4 轧制界面摩擦系数模型

在微凸体接触区域,微凸体顶部的边界油膜由于黏附和剪切产生边界摩擦应力,边界摩擦应力 根据牛顿黏性流体摩擦定律计算,为

根据牛顿黏性流体摩擦定律计算,为

(21)

(21)

式中:c为黏附系数。

因此,对于给定的卷吸速度,存在1个临界剪切厚度:

(22)

(22)

平均摩擦应力 的表达式为:

的表达式为:

(23)

(23)

(24)

(24)

式中:Ap为塑性剪切比;l为微凸体半间距;xc为剪切长度,对于锯齿状表面,有

(25)

(25)

r为微凸体高度,与未变形前的表面均方根粗糙度有关, 。运用式(24)和(25),塑性剪切比Ap可表达为

。运用式(24)和(25),塑性剪切比Ap可表达为

(26)

(26)

式中:Hc为量纲一临界剪切油膜厚度, ;

; 为平均黏性摩擦应力,

为平均黏性摩擦应力,

(27)

(27)

(28)

(28)

摩擦因数m定义为

(29)

(29)

将式(14),(22),(25)和(26)代入式(28)可得

(30)

(30)

5 数值仿真与结果分析

为了便于讨论表面粗糙度特征对混合润滑的影响,仿真时,采用总粗糙度来表征轧辊和板带的粗糙度,将粗糙度完全等效到板带上。鉴于表面粗糙峰通常呈现随机分布,通过使用四阶龙格-库塔法在Matlab上对式(11)和(16)进行迭代求解。为表达方便,用工作区位置表示变形区任意位置的量纲一形式:X=x/x1(其中,x1为入口区边界到轧辊中心连线的距离)。由于油膜厚度、界面压力和接触面积比在一定程度上相互影响,所以,分别研究在不同粗糙度分布方向和压下率下混合润滑参数随卷吸速度或工作区位置变化时的分布情况。计算时采用单变量法即某一轧制参数(如粗糙度、方向因子、压下率、卷吸速度)取不同值,其他轧制参数为定值,研究不同条件下轧制界面混合润滑情况。仿真初始数据来源于四辊板带轧机轧制实验:工作辊半径为110 mm,润滑油黏度为0.042 Pa·s,轧制速度为0.2~7.0 m/s,带钢入口厚度为1 mm/s,黏附系数为0.2;轧件材料为工业常用铝合金板带材1050A,屈服应力为125 MPa。

5.1 混合润滑轧制界面油膜厚度分布

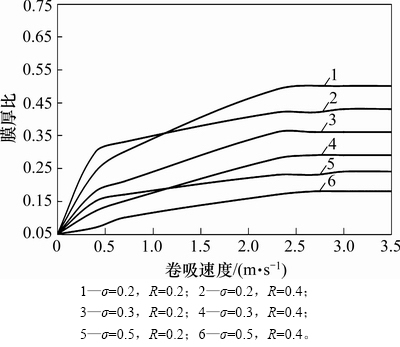

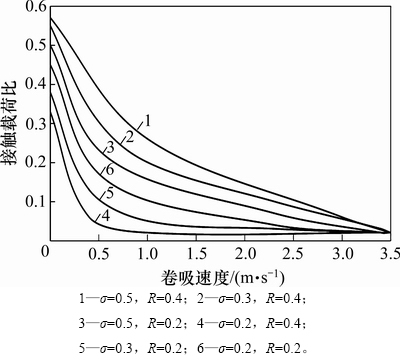

图3所示为在粗糙度横向分布时( <1)不同粗糙度

<1)不同粗糙度 (0.2,0.3和0.5)和压下率R(0.2和0.4)下膜厚比Hn随卷吸速度变化的分布情况。从图3可知:由于流体动压作用,膜厚比Hn随卷吸速度

(0.2,0.3和0.5)和压下率R(0.2和0.4)下膜厚比Hn随卷吸速度变化的分布情况。从图3可知:由于流体动压作用,膜厚比Hn随卷吸速度 的增大而增大,在低速时增加迅速,而当速度较大时虽有增加,但变化不大;当压下率R为0.4时,膜厚比Hn在表面粗糙度

的增大而增大,在低速时增加迅速,而当速度较大时虽有增加,但变化不大;当压下率R为0.4时,膜厚比Hn在表面粗糙度 为0.5时最低。

为0.5时最低。

图3 粗糙度横向分布时不同粗糙度σ和压下率R下的膜厚比分布

Fig. 3 Distribution of film thickness ratio for different roughnesses and reduction rates with transverse distribution of roughness

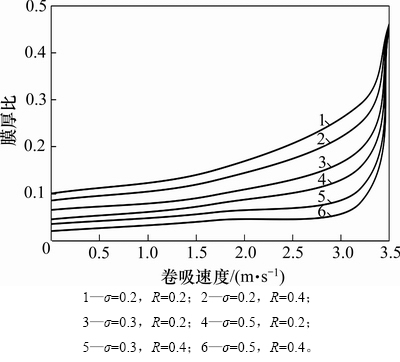

图4所示为在粗糙度纵向分布时( >1)不同粗糙度

>1)不同粗糙度 (0.2,0.3和0.5)和压下率R(0.2和0.4)下膜厚比随卷吸速度变化的分布情况。由图4可知:膜厚比Hn在粗糙度纵向分布时随卷吸速度

(0.2,0.3和0.5)和压下率R(0.2和0.4)下膜厚比随卷吸速度变化的分布情况。由图4可知:膜厚比Hn在粗糙度纵向分布时随卷吸速度 的增大而增大,且在卷吸速度大于3 m/s时,膜厚比迅速增大。

的增大而增大,且在卷吸速度大于3 m/s时,膜厚比迅速增大。

图4 粗糙度纵向分布时不同粗糙度σ和压下率R下的膜厚比分布

Fig. 4 Distribution of film thickness ratio for different roughnesses and reduction rates with longitudinal distribution of roughness

对比图3和图4可知:无论轧制界面粗糙度如何分布,在相同压下率下,膜厚比Hn随粗糙度 增大而减小;在相同粗糙度

增大而减小;在相同粗糙度 下,Hn随压下率R的增大而减小;在卷吸速度达到3.5 m/s的过程中,在相同压下率下,粗糙度横向分布下膜厚比比纵向分布时的大。

下,Hn随压下率R的增大而减小;在卷吸速度达到3.5 m/s的过程中,在相同压下率下,粗糙度横向分布下膜厚比比纵向分布时的大。

5.2 混合润滑轧制界面压力分布

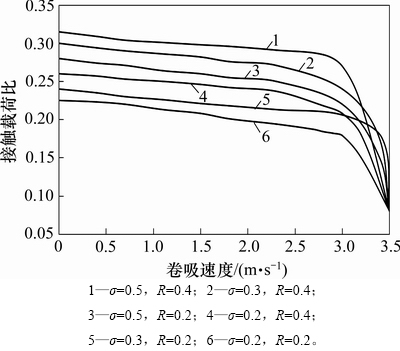

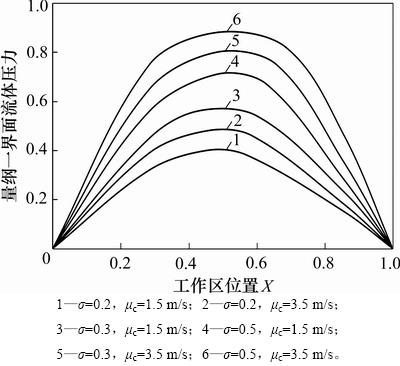

当粗糙度横向分布时( <1),不同条件下混合润滑轧制界面压力即量纲一接触载荷比Pa和量纲一流体压力Pb的分布情况分别见图5和图6。从图5可知:当润滑油卷吸速度

<1),不同条件下混合润滑轧制界面压力即量纲一接触载荷比Pa和量纲一流体压力Pb的分布情况分别见图5和图6。从图5可知:当润滑油卷吸速度 较小时,轧制界面流体压力主要由表面凸峰承担,压力梯度较大,量纲一接触载荷比Pa较大;随着

较小时,轧制界面流体压力主要由表面凸峰承担,压力梯度较大,量纲一接触载荷比Pa较大;随着 增大,油膜厚度增加,界面流体压力转为主要由油膜承担,导致量纲一接触载荷比Pa下降。粗糙度

增大,油膜厚度增加,界面流体压力转为主要由油膜承担,导致量纲一接触载荷比Pa下降。粗糙度 和压下率R较小的量纲一接触载荷比Pa下降较快。

和压下率R较小的量纲一接触载荷比Pa下降较快。

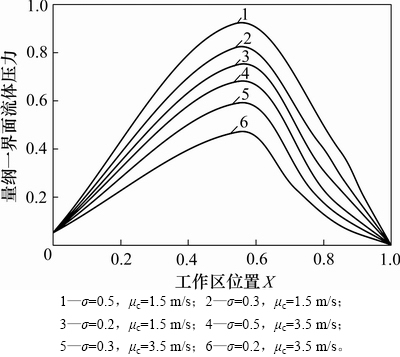

给定压下率R为0.2时,量纲一流体压力Pb在轧制界面的分布见图6。从图6可见:由于采用了卡尔曼微分方程来计算流体压力,在表面粗糙度横向分布时,Pb呈现“摩擦峰”形式;当卷吸速度增大时,流体压力Pb下降。这是因为高速下流体动压作用显著,使膜厚比增加,从而导致界面摩擦水平下降。

图5 粗糙度横向分布时不同粗糙度σ和压下率下R的接触载荷比分布

Fig. 5 Distribution of contact load ratio for different roughnesses and reduction rates with transverse distribution of roughness

图6 粗糙度横向分布时不同粗糙度σ和卷吸速度μc下界面流体压力分布(R=0.2)

Fig. 6 Distribution of fluid pressure for different roughnesses and suction speeds with transverse distribution of roughness (R =0.2)

当粗糙度呈纵向分布时( >1),不同条件下混合润滑轧制界面压力即量纲一接触载荷比Pa和量纲一流体压力Pb的分布情况分别见图7和图8。从图7可知:量纲一界面接触载荷比Pa变化趋势与横向分布时不同;当润滑油卷吸速度较小时,轧制界面量纲一接触载荷比Pa下降较快,在卷吸速度较大时,下降较缓慢。

>1),不同条件下混合润滑轧制界面压力即量纲一接触载荷比Pa和量纲一流体压力Pb的分布情况分别见图7和图8。从图7可知:量纲一界面接触载荷比Pa变化趋势与横向分布时不同;当润滑油卷吸速度较小时,轧制界面量纲一接触载荷比Pa下降较快,在卷吸速度较大时,下降较缓慢。

图7 粗糙度纵向分布时不同粗糙度σ和压下率R下的接触载荷比分布

Fig. 7 Distribution of contact load ratio for different roughnesses and reduction rates with longitudinal distribution of roughness

图8 粗糙度纵向分布时不同粗糙度σ和卷吸速度μc下界面流体压力分布(R=0.2)

Fig. 8 Distribution of fluid pressure for different roughnesses and suction speeds with longitudinal distribution of roughness (R =0.2)

从图8可知:与粗糙度横向分布相比,粗糙度纵向分布未出现明显“摩擦峰”。这是由于轧制板带的整体塑性变形减少了表面粗糙度纵向分布的有效硬度,使得流体压力在中性面处的变化较平缓。

对比图5和图7可知:在一定范围内,粗糙度分布情况对量纲一接触载荷比Pa与压下率R和粗糙度 的关系没有影响;在相同粗糙度下,压下率R越大,量纲一接触载荷比Pa越大;在相同压下率R下,粗糙度

的关系没有影响;在相同粗糙度下,压下率R越大,量纲一接触载荷比Pa越大;在相同压下率R下,粗糙度 越大,量纲一接触载荷比Pa越大。对比图6和图8可知:粗糙度分布对界面流体压力与粗糙度的关系无影响,在相同卷吸速度下,粗糙度

越大,量纲一接触载荷比Pa越大。对比图6和图8可知:粗糙度分布对界面流体压力与粗糙度的关系无影响,在相同卷吸速度下,粗糙度 越小,量纲一界面流体压力Pb越小;但粗糙度分布对量纲一界面流体压力与卷吸速度的关系有影响,在相同粗糙度

越小,量纲一界面流体压力Pb越小;但粗糙度分布对量纲一界面流体压力与卷吸速度的关系有影响,在相同粗糙度 下,当粗糙度横向分布时,卷吸速度越大,量纲一界面流体压力Pb越小;粗糙度纵向分布时则相反。

下,当粗糙度横向分布时,卷吸速度越大,量纲一界面流体压力Pb越小;粗糙度纵向分布时则相反。

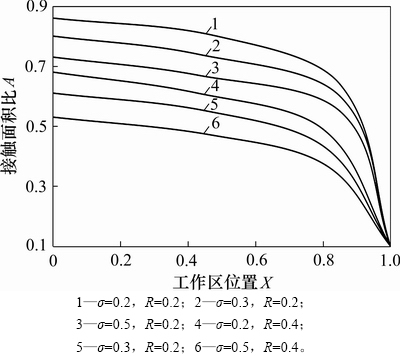

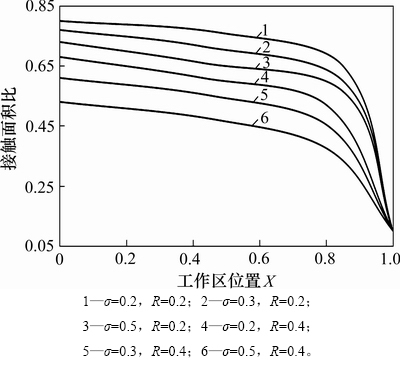

5.3 混合润滑轧制界面接触面积比分布

图9所示为粗糙度横向分布时( <1),在不同条件下轧制界面接触面积比A的分布情况。从图9可见:接触面积比A与膜厚比的变化趋势相反;在进入变形区的初始阶段,A增加迅速,在变形区剩余区域内变化不大。这是由于在变形区入口处,带钢表面微凸体被压平,此时,过大的轧制力和油膜压力抑制微凸体被压平,因此,微凸体不变形,接触面积比A基本恒定。

<1),在不同条件下轧制界面接触面积比A的分布情况。从图9可见:接触面积比A与膜厚比的变化趋势相反;在进入变形区的初始阶段,A增加迅速,在变形区剩余区域内变化不大。这是由于在变形区入口处,带钢表面微凸体被压平,此时,过大的轧制力和油膜压力抑制微凸体被压平,因此,微凸体不变形,接触面积比A基本恒定。

粗糙度纵向分布时不同粗糙度和压下率下的接触面积比分布见图10。从图10可见:在粗糙度纵向分布( >1)下,接触面积比A的变化趋势与横向分布时基本一致,但与粗糙度横向分布相比,在变形区入口时,粗糙度纵向分布具有更小的接触面积比。这是因为粗糙度纵向分布时工作界面入口处油膜厚度更大,导致接触面积比减小。

>1)下,接触面积比A的变化趋势与横向分布时基本一致,但与粗糙度横向分布相比,在变形区入口时,粗糙度纵向分布具有更小的接触面积比。这是因为粗糙度纵向分布时工作界面入口处油膜厚度更大,导致接触面积比减小。

对比图9和图10可知:粗糙度分布情况对接触面积比A无太大影响,粗糙度和压下率越大,A越小。

图9 粗糙度横向分布时不同粗糙度σ和压下率R下的接触面积比A分布

Fig. 9 Distribution of Contact area ratio for different roughnesses and reduction rates with transverse distribution of roughness

图10 粗糙度纵向分布时不同粗糙度σ和压下率R下的接触面积比分布

Fig. 10 Distribution of contact area ratio for different roughnesses and reduction rates with longitudinal distribution of roughness

这是由于粗糙度和压下率的增大使得轧制界面轧制压力减小,从而导致接触面积比有所减小。

6 结论

1) 膜厚比随工作界面润滑油卷吸速度的增大而增大,随压下率的增大而减小,粗糙度越大,膜厚比越小。在卷吸速度达到3.5 m/s的过程中,在相同压下率下,粗糙度横向分布时膜厚比比纵向分布时的大。在相同条件下,粗糙度横向分布更有利于润滑性能的提高。

2) 当润滑油卷吸速度较小时,界面流体压力梯度较大,接触载荷比较大。卷吸速度增大,油膜厚度增加,界面流体压力转为主要由油膜承担,导致接触载荷比下降。

3) 在表面粗糙度横向分布时,界面流体压力分布呈现“摩擦峰”形式。卷吸速度增大,膜厚比增加,流体压力下降。同时,表面粗糙度越小,流体压力越小。与粗糙度横向分布相比,粗糙度纵向分布界面流体压力在中性面处的变化较平缓,未出现明显“摩擦峰”。

4) 接触面积比与膜厚比的变化趋势相反。在进入变形区的初始阶段接触面积比增加迅速,而此后虽有增加,但是变化不大。压下率越大,接触面积比越小。

参考文献:

[1] LO S W, YANG T C, LIN H S. The lubricity of oil-in-water emulsion in cold strip rolling process under mixed lubrication[J]. Tribology International, 2013, 66(7): 125-133.

[2] WU Jianqing, LIANG Xiaoping, PAN Fusheng. Parametric analysis of mixed lubrication characteristics in work zone of strip rolling[J]. Journal of Central South University, 2016, 23(12): 3153-3159.

[3] 王悦昶, 刘莹, 黄伟峰, 等. 混合润滑理论模型进化与工程应用[J]. 摩擦学学报, 2016, 36(4): 520-530.

WANG Yuechang, LIU Ying, HUANG Weifeng, et al. The progress and engineering application of theoretical model for mixed lubrication[J]. Tribology, 2016, 36(4): 520-530.

[4] 朱作鑫, 孙建林, 高雅, 等. 热轧变形区润滑条件与板带钢表面质量关系试验研究[J]. 机械工程学报, 2012, 48(2): 133-137.

ZHU Zuoxin, SUN Jianlin, GAO Ya, et al. Experiment and search of the relationship between hot-rolling lubrication in deforming zone and surface quality of steel strip[J]. Journal of Mechanical Engineering, 2012, 48(2): 133-137.

[5] 李长生, 李有元, 余涛, 等. 四辊可逆冷轧机轧制润滑工艺实验研究[J]. 东北大学学报(自然科学版), 2010, 31(8): 1117-1120.

LI Changsheng, LI Youyuan, YU Tao, et al. Experimental research on rolling-lubricating process on 4-high reversing cold rolling mill[J]. Journal of Northeastern University(Natural Science), 2010, 31(8): 1117-1120.

[6] 陈金山, 李长生, 曹勇. 轧辊粗糙度对不锈钢板带表面和工艺参数的影响[J]. 机械工程学报, 2013, 49(4): 30-36.

CHEN Jinshan, LI Changsheng, CAO Yong. Effects of roll roughness on surface and process parameters for stainless-steel strip[J]. Journal of Mechanical Engineering, 2013, 49(4): 30-36.

[7] 王桥医, 黄海军, 李志华. 金属塑性加工工作界面非稳态润滑轧机振动控制[J]. 中南大学学报(自然科学版), 2010, 41(4): 1418-1423.

WANG Qiaoyi, HUANG Haijun, LI Zhihua. Control of mill vibration for unsteady lubrication based on metal-forming process[J]. Journal of Central South University(Science and Technology), 2010, 41(4): 1418-1423.

[8] MINET C, BRUNETIERE N, TOURNERIE B, et al. Analysis and modeling of the topography of mechanical seal faces[J]. Tribology Transactions, 2010, 53(6): 799-815.

[9] YOUNES M A, SHAHTOUT M, DAMIR M N. A parameters design approach to improve product quality and equipment performance in hot rolling[J]. Journal of Materials Processing Technology, 2006, 171(1): 83-92.

[10] MASJEDI M, KHONSARI M M. On the effect of surface roughness in point-contact EHL: formulas for film thickness and asperity load[J]. Tribology International, 2015, 82(2): 228-244.

[11] KIJIMA H, NIELS B. Influence of tool roughness and lubrication on contact conditions in skin-pass rolling[J]. Journal of Materials Processing Technology, 2009, 209(10): 4835-4841.

[12] YANG T S. Investigation of the strain distribution with lubrication during the deep drawing process[J]. Tribology International, 2010, 43(5): 1104-1112.

[13] 陈金山, 李长生. 冷轧过程热滑伤缺陷预报与控制软件[J]. 东北大学学报(自然科学版), 2014, 35(4): 524-528.

CHEN Jinshan, LI Changsheng. Forecasting and controlling software of thermal scratch defect in cold rolling process[J]. Journal of Northeastern University(Natural Science), 2014, 35(4): 524-528.

[14] 徐冬, 张杰, 李洪波, 等. 冷轧带钢表面粗糙度影响因素及控制策略[J]. 中南大学学报(自然科学版), 2017, 48(1): 112-118.

XU Dong, ZHANG Jie, LI Hongbo, et al. Influence factors and control strategy of cold rolled strip surface roughness[J]. Journal of Central South University(Science and Technology), 2017, 48(1): 112-118.

[15] 徐冬, 杨荃, 王晓晨, 等. 冷轧界面油膜厚度对表面形貌转印过程的影响[J]. 哈尔滨工业大学学报, 2017, 49(1): 160-165.

XU Dong, YANG Quan, WANG Xiaochen, et al. Influence of lubrication film thickness on transfer of surface topography at cold rolling interface[J]. Journal of Harbin Institute of Technology, 2017, 49(1): 160-165.

[16] 刘乐民, 臧勇, 陈园园, 等. 基于平均流量理论的轧制润滑动力学数值分析[J]. 机械设计与制造, 2011, 35(4): 182-184.

LIU Lemin, ZANG Yong, CHEN Yuanyuan, et al. Based on average flow theory of rolling lubricating dynamic numerical analysis[J]. Machinery Design and Manufacture, 2011, 35(4): 182-184.

[17] 张晓峰, 李瑞, 张勃洋, 等. 平整轧制过程中带钢表面形貌的生成模型[J]. 机械工程学报, 2013, 49(14): 38-44.

ZHANG Xiaofeng, LI Rui, ZHANG Boyang, et al. Model for the generation of surface topography in steel strip temper rolling[J]. Journal of Mechanical Engineering, 2013, 49(14): 38-44.

[18] 付括, 臧勇, 郜志英. 冷轧过程中的混合润滑特性[J]. 东北大学学报(自然科学版), 2014, 35(7): 1005-1009.

FU Kuo, ZANG Yong, GAO Zhiying. Mixed lubrication characteristics of cold rolling process[J]. Journal of Northeastern University(Natural Science), 2014, 35(7): 1005-1009.

[19] 轧制技术及连轧自动化国家重点实验室(东北大学). 冷轧润滑系统设计理论及混合润滑机理研究[M]. 北京: 冶金工业出版社, 2015: 106-107.

National Key Laboratory of Rolling Technology and Rolling Automation, Northeastern University. Study on lubrication design theory and mixed lubrication mechanism of cold rolling[M]. Beijing: Metallurgy Industry Press, 2015: 106-107.

[20] 付括, 臧勇, 郜志英. 轧制界面非稳态流体润滑轧制特性[J]. 北京科技大学学报, 2014, 36(1): 97-103.

FU Kuo, ZANG Yong, GAO Zhiying. Fluid lubrication rolling characteristics of unsteady rolling interfaces[J]. Journal of University of Science and Technology Beijing, 2014, 36(1): 97-103.

(编辑 陈灿华)

收稿日期:2018-03-19;修回日期:2018-05-21

基金项目(Foundation item):国家自然科学基金资助项目(51875146) (Project(51875146) supported by the National Natural Science Foundation of China)

通信作者:王桥医,博士,教授,从事复杂系统动力学性能及其控制技术、摩擦润滑等研究;E-mail: wangqiaoyi1989@163.com