DOI: 10.11817/j.issn.1672-7207.2017.11.036

分解窑混煤富氧燃烧研究

徐顺生1, 2,杨易霖1,时章明2,刘飞虹1,武浩1,肖逸奇1,黄碧漪3

(1. 湘潭大学 机械工程学院,湖南 湘潭,411105;

2. 中南大学 能源科学与工程学院,湖南 长沙,410083;

3. 浙江大学 能源工程学院,浙江 杭州,310058)

摘要:以2 500 t/d带四通道煤粉燃烧器的水泥分解窑为研究对象,通过理论分析和数值仿真方法,对分解窑内混煤富氧燃烧特性和燃烧规律进行研究,并通过实验验证仿真计算结果的可靠性。研究结果表明:随着燃烧器一次风O2摩尔分数增加,煤粉着火温度逐渐降低,燃烧温度、窑内传热速率逐渐增加;应用富氧燃烧技术能显著改善分解窑混煤燃烧特性,大幅提高无烟煤掺混比;与一般空气助燃相比,当一次风O2摩尔分数提高到27%时,火焰平均温度提高97 K,焦炭燃尽率提高5.09%,在此O2摩尔分数下,无烟煤掺比增至60%时,混煤仍能高效稳定燃烧,火焰温度和形状仍能满足熟料煅烧要求。

关键词:分解窑;富氧燃烧;混煤;数值模拟

中图分类号:TQ172.1 文献标志码:A 文章编号:1672-7207(2017)11-3116-10

Research on oxy-fuel combustion of blended coal in precalciner kiln

XU Shunsheng1, 2, YANG Yilin1, SHI Zhangming2, LIU Feihong1, WU Hao1, XIAO Yiqi1, HUANG Biyi3

(1. School of Mechanical Engineering, Xiangtan University, Xiangtan 411105, China;

2. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

3. Department of Energy Engineering, Zhejiang University, Hangzhou 310058, China)

Abstract: The oxy-fuel combustion of blended coal characteristics and rule were studied in the 2 500 t/d precalciner cement kiln with a four-channel burner via experiment and simulation, and the reliability of simulation results was verified by experiments. The results show that as the oxygen mole fraction of primary air rises, the combustion temperature and heat transfer rate both increase while the coal ignition temperature gradually reduces. The numerical calculation indicates that the blended coal combustion characteristics in the precalciner kiln are considerably improved using the technology of oxy-fuel combustion. Besides, the blending ratio of anthracite suitable for the kiln greatly increases in the oxy-mode combustion. Compared with the traditional air-mode combustion, the average flame temperature and char burnout ratio increase by 97 K and 5.09%, respectively, when the oxygen mole fraction of primary air is 27%. Meanwhile, even at the anthracite-blended ratio of up to 60%, the efficient and stable combustion are still obtained, and the flame property including temperature and shape can meet the requirements of clinker calcinations.

Key words: precalciner kiln; oxy-fuel combustion; blended coal; numerical simulation

我国水泥工业用煤量巨大,仅次于火电和冶金行业。设法提高无烟煤掺量和燃尽率,是实现其可持续发展必须解决的重要问题,人们为此进行了大量研究[1-5],取得了显著成效,但仍不能满足进一步节能减排和降低成本的需要。富氧燃烧技术能显著改善煤燃烧特性,已在锅炉、工业炉上进行了大量研究与应用[6-10]。为降低水泥生产用能成本,已有研究者对分解窑开展富氧燃烧技术研究。MARIN等[11]对分解窑富氧燃烧进行了数值模拟研究,表明富氧燃烧有助于改善低挥发或低热值煤燃烧特性;宗滇[12]通过数值模拟方法完成了劣质煤富氧燃烧器仿真设计;李明飞等[13-14]通过试验研究了O2摩尔分数与提高旋窑产量、降低能耗关系,合理确定了O2摩尔分数范围;范潇等[15-16]通过实验和数值模拟方法研究了旋窑煤粉富氧燃烧对NO排放特性的影响,研究表明在 CO2/O2气氛下O2摩尔分数的增加会促进NO生成。目前,未见对分解窑混煤富氧燃烧技术进行系统的研究报道。本文在理论定性分析O2摩尔分数对燃烧速度、着火温度、火焰温度、传热速度等影响的基础上,通过数值模拟定量研究O2摩尔分数对窑内“三场”、混煤配比、燃尽率、出口NOx浓度等的影响,以便为分解窑混煤富氧燃烧技术应用提供理论参考。

1 分解窑富氧燃烧理论分析

1.1 富氧燃烧对分解窑内混煤燃烧速的影响

煤粉燃烧属于非均相反应,实验测定的燃烧反应级数 1[17],建立煤粉燃烧反应速度模型为

1[17],建立煤粉燃烧反应速度模型为

(1)

(1)

式中:W为反应速率; 和

和 分别为氧气与煤粉浓度;k为反应速度常数。

分别为氧气与煤粉浓度;k为反应速度常数。

反应速度常数与温度、物性的关系用Arrhenius定律描述,其表达式为

(2)

(2)

式中:T为反应温度;E为活化能;R为通用气体常数;k0为频率因子。

将式(2)代入式(1)得

(3)

(3)

由式(3)可知:煤粉燃烧速度与O 2浓度、煤粉浓度成正比;与温度指数函数成正比(随温度变化显著)。

1.2 富氧燃烧对烧成带火焰温度的影响

忽略煤粉不完全燃烧损失和壁面的散热损失,通过热平衡建立燃烧温度方程

(4)

(4)

式中:Q为燃料低位热值,J/g; 为单位燃烧理论氧气体积,N·m3/kg;

为单位燃烧理论氧气体积,N·m3/kg; 为常规燃烧产生的烟气体积,N·m3/kg;

为常规燃烧产生的烟气体积,N·m3/kg; 为空气系数;

为空气系数; 为环境温度,K;

为环境温度,K; 为烟气平均比热容,J/(g·K)。

为烟气平均比热容,J/(g·K)。

由式(4)可知:燃烧温度随O2摩尔分数增大而增大。

1.3 富氧燃烧对煤粉着火温度的影响

煤粉燃烧放热速度和燃烧区域散热速度的计算方法分别为:

(5)

(5)

(6)

(6)

式中: 为燃烧放热速度,J/s;

为燃烧放热速度,J/s; 为散热速度,J/s;V为燃烧区体积,m3;K为散热系数,W/(m2·K);F为散热表面积,m2。

为散热速度,J/s;V为燃烧区体积,m3;K为散热系数,W/(m2·K);F为散热表面积,m2。

令 ,

, ,

, ,得

,得

(7)

(7)

令 ,对T求导得

,对T求导得

(8)

(8)

令 ,得

,得 ,

, 。在

。在 温度范围内,

温度范围内, ,

, 是T的减函数,即当B增加或D减少时,着火温度下降。由B与O2摩尔分数成正比,D与散热系数成正比不难得出:煤粉着火温度随O2摩尔分数增加及散热系数减小而降低。

是T的减函数,即当B增加或D减少时,着火温度下降。由B与O2摩尔分数成正比,D与散热系数成正比不难得出:煤粉着火温度随O2摩尔分数增加及散热系数减小而降低。

1.4 富氧燃烧对窑内传热效率的影响

富氧燃烧通过影响火焰温度来影响窑内传热速度。为简化分析,结合分解窑实际情况进行如下假设:

1) 烧成带火焰、物料、窑墙内表面温度分布均匀,分别采用平均温度Tf,Tm和Tw;

2) 视火焰为灰体( ), 并充满整个炉膛空间,设物料和炉壁黑度为定值

), 并充满整个炉膛空间,设物料和炉壁黑度为定值 和

和 ;

;

3) 基于窑墙保温好,具有重辐射特性,设回转窑表面散热损失等于窑内烟气与窑墙间的对流传热量;

4) 设物料、窑墙表面积分别为Fm和Fw,窑墙对物料角系数为 (简记为

(简记为 ),

), ,窑墙自身角系数

,窑墙自身角系数 。

。

1.4.1 窑墙的有效的热量辐射热量

由假设3)及窑墙吸、放热热平衡得到窑墙的有效辐射热量 为

为

(9)

(9)

式中: 为火焰投射到窑墙表面热量,

为火焰投射到窑墙表面热量, ;

; 为物料表面通过火焰空间辐射给窑墙的热量,

为物料表面通过火焰空间辐射给窑墙的热量, ;

; 为窑墙自身辐射热量,

为窑墙自身辐射热量, ;

; 为物热表面有效辐射热量。经整理后可得

为物热表面有效辐射热量。经整理后可得

(10)

(10)

1.4.2 投射到物料表面的热量

投射到物料表面的热量计算公式为

(11)

(11)

式中: 为由火焰投射到物料表面的辐射热量,

为由火焰投射到物料表面的辐射热量, ;

; 为窑墙通过火焰空间辐射给物料表面的辐射热量,

为窑墙通过火焰空间辐射给物料表面的辐射热量, 。

。

1.4.3 物料表面有效辐射热量

物料表面有效辐射热量的计算公式为

(12)

(12)

式中: 为料表面自身辐射热量,

为料表面自身辐射热量,

;

; 为物料表面反射的火焰辐射热量,

为物料表面反射的火焰辐射热量, ;

; 为物料表面反射的窑墙辐射热量,

为物料表面反射的窑墙辐射热量,

。

。

1.4.4 火焰对物料的净辐射热量

(13)

(13)

整理式(13)可得

(14)

(14)

将 和

和 代入式(14)得火焰与物料间净辐射热量为

代入式(14)得火焰与物料间净辐射热量为

(15)

(15)

令 ,

, 为火焰与物料之间的辐射系数,其值为

为火焰与物料之间的辐射系数,其值为 ,

, 和

和 的线图函数。分解窑烧成带内对流换热量远小于辐射传热量,忽略其影响。

的线图函数。分解窑烧成带内对流换热量远小于辐射传热量,忽略其影响。

整理可得分解窑烧成带传热量 计算公式为

计算公式为

(16)

(16)

由式(16)可见:燃烧温度的高低对传热速度有重要影响。基于前述研究所得燃烧温度随O2摩尔分数增加而提高,得出:窑内传热速度随O2摩尔分数增加而快速提高。

2 分解窑混煤燃烧数值模拟

2.1 物理模型

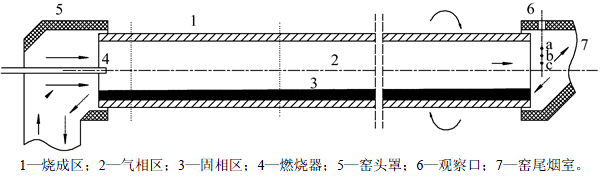

以某公司2 500 t/d分解窑为研究对象,分解窑模型如图1所示。模型计算域直径×长度为3.6 m×60 m。

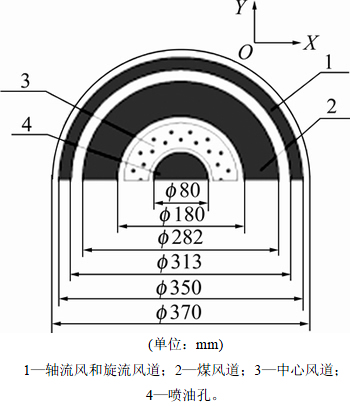

分解窑附带的四通道Duoflex DBC燃烧器结构参数如图2所示。煤粉及一次风经由燃烧器各通道进入窑内,来自于篦冷机的高温二次风经窑头罩进入窑内,与煤粉气流混合着火、燃烧。通过一次风各风道阀门调节火焰形状并适应原料、燃料成分的变化。

图1 分解窑模型示意图

Fig. 1 Schematic diagram of precalciner kiln model

图2 燃烧器结构示意图

Fig. 2 Schematic diagram of burner structure parameters

窑内多相流动、燃烧、传热、传质及固相反应过程复杂,为简化研究,进行如下假设:

1) 将窑内气相区作为模型计算域,窑内残余碳酸盐分解吸热与熟料烧成放热抵扣,物料表面按壁面函数处理。

2) 分解窑转动缓慢,窑筒体转动过程对煤粉燃烧、烟气流动的影响甚小,忽略不计。

2.2 网格划分

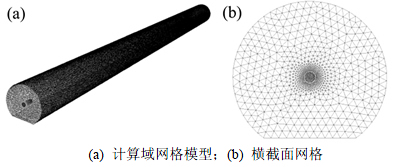

燃烧器通道尺寸与窑体尺寸相差较大,本文采用非均匀网格,燃烧器区域局部加密,窑长方向采用尺寸函数调整网格数量。网格总数约为120万个,计算区域网格划分如图3所示。

图3 计算域网格模型及横截面网格

Fig. 3 Mesh model and mesh distribution on cross-section of computational domain

2.3 数学模型

2.3.1 气相湍流模型

分解窑燃烧器形状复杂、气流速度较高,窑内气流呈湍流流动。为兼顾计算速度、稳定性及收敛性,采用对旋流流动模拟能力较强的RNG 模型来模拟窑内气固两相湍流流动。RNG

模型来模拟窑内气固两相湍流流动。RNG 模型传输方程为:

模型传输方程为:

(17)

(17)

(18)

(18)

式中: 为气体密度;U为速度矢量;k为湍流动能;

为气体密度;U为速度矢量;k为湍流动能; 为湍流耗散率;

为湍流耗散率; 为分子黏性系数;

为分子黏性系数; 为湍流黏性系数;

为湍流黏性系数; ;

; 为常数;

为常数; 为流体黏性力产生的湍流动能,

为流体黏性力产生的湍流动能, ;

; ,

, ;

; ,

, ,均为常数。

,均为常数。

2.3.2 煤粉颗粒运动模型

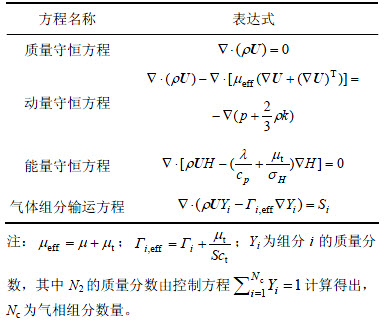

基于炉内煤粉颗粒特性,选用基于欧拉-拉格朗日方法的随机轨道模型,模型通过包含速度、位移、温度、各组分质量传输关系的控制方程组描述。采用的耦合气相流场的随机轨道模型方程组见表1。表1中: 为有效黏性系数;P为压力;H为总热焓;

为有效黏性系数;P为压力;H为总热焓; 为导热系数;Cp为比热容;

为导热系数;Cp为比热容; 为

为 与总焓输运系数之比;

与总焓输运系数之比; 为组分i输运系数;

为组分i输运系数; 为组分i有效输运系数;Si为组分i源项;Sct为湍流施密特数。

为组分i有效输运系数;Si为组分i源项;Sct为湍流施密特数。

表1 气相流场控制方程

Table 1 Control equation of gas flow

2.3.3 煤粉燃烧模型

基于本文研究重点是燃烧热效应及不稳定中间产物、稳定热解产物的生成规律,燃烧气相反应采用组分运输模型,焦炭燃烧采用扩散/动力模型。

2.3.4 辐射换热模型

辐射换热模型采用考虑辐射散射作用、对较大光学厚度适应性较好且计算速度快的P1模型。

2.3.5 NO生成模型

燃料燃烧过程产生的NOx主要由热力型NOx、燃料型NOx、快速型NOx组成。在分解窑条件下,主要由前两类组成,且NOx主要由NO组成,其他组分可忽略不计。采用广义Zeldovich机理,N2形成热力型NO的反应途径为:

(19)

(19)

(20)

(20)

(21)

(21)

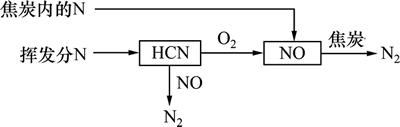

燃料型NO的生成机理比较复杂,本文采用的燃料型NO生成机理如图4所示,煤粉中焦炭内的氮直接转化为NO,挥发分氮首先生成中间产物HCN,然后氧化成NO。

图4 燃料型NO生成机理示意图

Fig. 4 Schematic diagram of Fuel-NO generating mechanism

将按以上反应机理得到的NO生成速率作为NO输运方程源项,再模拟计算分解窑内NO生成情况。

2.4 仿真计算边界条件

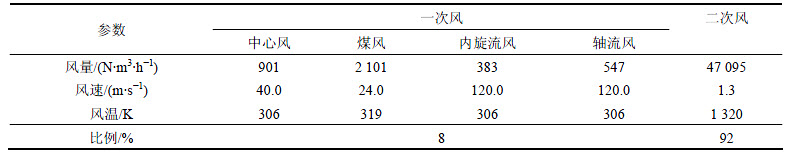

边界条件由热平衡测试及合理假设确定。在典型运行工况下,混煤中无烟煤A与烟煤B的质量比(mA:mB)为4:6,煤粉流量为1.36 kg/s,窑尾压力为 -430 Pa。通过测试窑筒体外表面散热损失推算内壁温度,沿窑体Z+方向冷却带、烧成带、放热反应带及碳酸盐分解带所对应窑内壁面温度分别取1 530,1 643,1 473及1 123 K,空气系数取1.20。煤粉颗粒粒径为R(60<R<100 μm),分布规律服从Rosin-Rammler方程,平均粒径为80 μm,燃烧器旋流风通道叶片角度为30°。

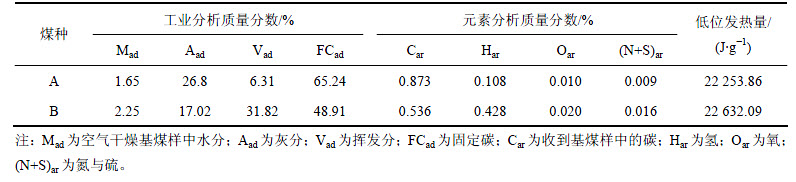

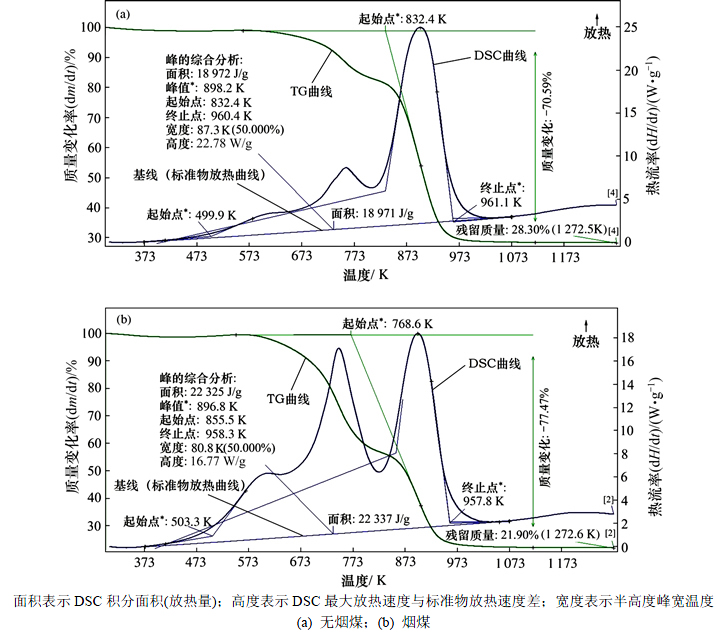

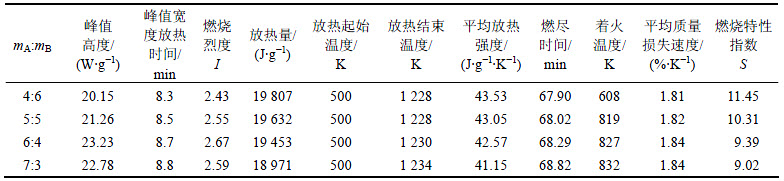

在仿真计算中,基于熟料充分冷却用风量控制原理(冷却后风温预设值保持不变),设入窑二次风温恒定为预定的运行温度;基于所研究的O2摩尔分数低(21%~30%),且摩尔分数变化小,处于反应速度常数随O2摩尔分数变化指数曲线的平缓变化区,为简化计算,设反应速度常数k保持初值不变。本文所用无烟煤A、烟煤B的工业分析和元素分析数据如表2所示;其TG-DSC综合热分析曲线如图5所示,通过对不同配比(mA/mB)时混煤TG-DSC综合热分析曲线计算得到的混煤燃烧性能数据如表3所示;燃烧器运行参数如表4所示。

3 混煤燃烧数值仿真模型验证

3.1 运行工况下温度场和浓度场仿真

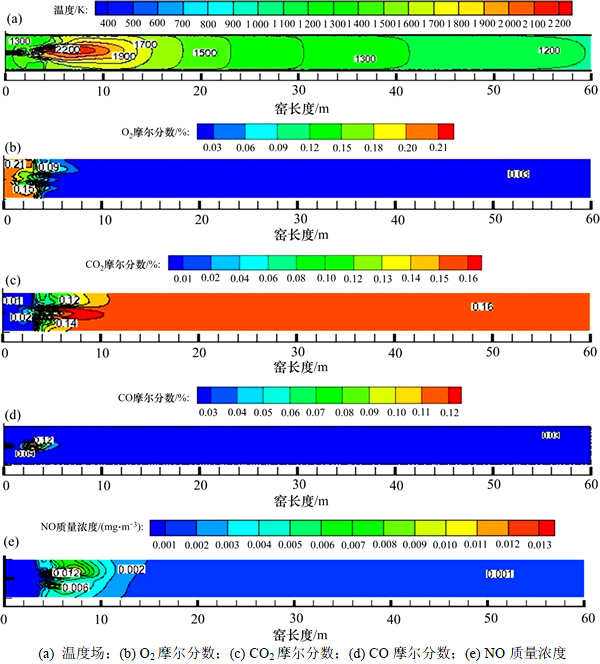

典型工况下温度场、浓度场仿真结果如图6所示。由图6(a)可知:分解窑内火焰呈“棒槌”型,长度为10~12 m,中心最高火焰温度为2 200 K,烧成带平均烟气温度为1 840 K,窑内火焰填充度较好,火焰形状及温度分布基本满足熟料煅烧工艺要求,火焰高温区后,温度逐渐下降,至窑尾出口温度降至1 200 K。由图6可知:燃烧器出口煤粉燃烧剧烈,氧气被迅速消耗,CO2摩尔分数快速增加并伴有CO生成,烟气流过火焰高温区后O2摩尔分数降至3%,窑尾出口CO2摩尔分数增至16%,CO摩尔分数稳定在3%,焦炭燃尽率仅为94.89%。过高的无烟煤掺比、不适配的燃烧器参数,是导致混煤燃烧效率低下,煅烧区域温度稍低的主要原因。由图6(e)可知:窑内NO在煤粉着火阶段伴随挥发分的热解开始大量生成,在窑内高温区质量浓度达到峰值6 400 mg/m3,其后,NO质量浓度迅速下降至出口的1 440 mg/m3,质量浓度分布符合热力型NO生成规律。

表2 煤样工业分析及元素分析

Table 2 Element and industry analysis of coal

图5 无烟煤和烟煤TG-DSC曲线

Fig. 5 TG-DSC curves of anthracite coal and bituminous coal

表3 混煤燃烧性能数据

Table 3 Data of mixed coal combustion performance

表4 燃烧器运行参数

Table 4 Operation parameters of burner

3.2 实验验证

基于实验测试的易行性,选择内窑出口附近烟室截面布置测点,测试方案如图1所示。为避免漏风及筒体散热对仿真结果验证的影响,测点a,b和c 与烟道中心距离分别为0,0.6和1.2 m。为提高测试精度,分解窑出口烟气温度采用自行研制的高精度双层套管抽气热电偶进行测试(专利号ZL201320572100.2)。由于烟气组分浓度在窑尾出口截面分布梯度极微,自行研制的高保真高纯烟气采样系统(专利申请号201410201082.6)对测点a,b和c进行烟气等比采样,取样后,采用英国KM940烟气分析仪测试烟气组分浓度。为保证测试可靠性,测前先对测试用仪器进行校验。所有测量数据经过多次测量取平均值,测试值和仿真计算值结果如表5所示。

图6 分解窑运行工况数值模拟

Fig. 6 Numerical simulation results of precalciner kiln

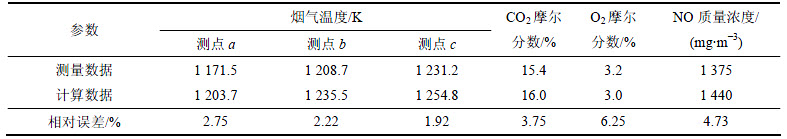

表5 实测数据与模拟计算数据对比

Table 5 Comparison of measured data and simulated data

从表5可知:烟气温度实测值与计算值相对误差小于3%,组分浓度相对误差小于7%,其相对误差在工程允许误差范围内,模型计算可靠。O2摩尔分数计算值与实测值误差较大,估计是窑尾漏风所致。

4 混煤富氧燃烧数值模拟结果与分析

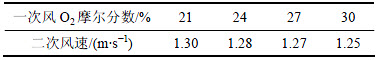

保持燃烧器一次风体积流量不变,一次风O2摩尔分数由21%逐步增至30%,对应二次风风速通过氧平衡计算如表6所示,其他参数与典型运行工况时相同。为方便对比,只选取窑头前30 m计算域(包括冷却带、烧成带、部分固相反应区)的结果进行分析。

表6 不同一次风O2摩尔分数时的二次风速

Table 6 Speed of secondary air with different oxygen mole fractions of primary air

4.1 温度场仿真结果及分析

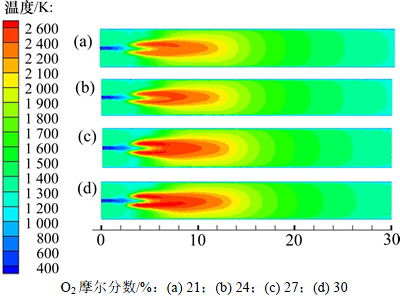

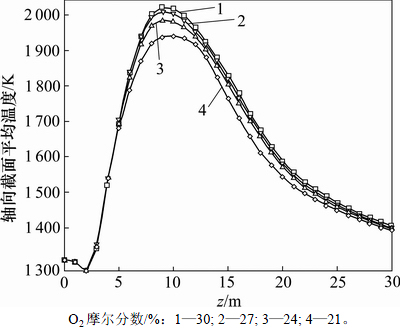

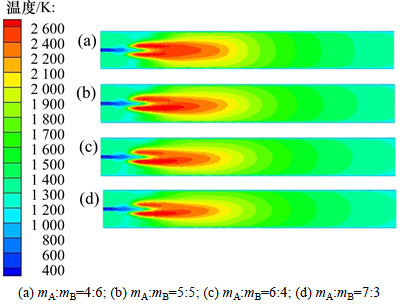

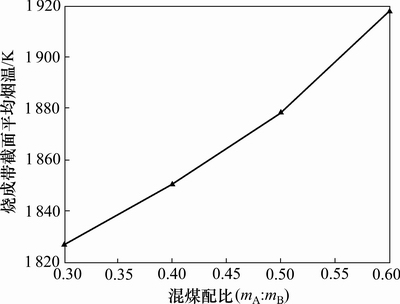

图7和图8所示分别为不同O2摩尔分数下窑内温度仿真计算云图、轴向截面平均温度分布云图。由图7可知:随着O2摩尔分数增大,混煤着火点不断向窑头方向移动,黑火头缩短,窑内火焰温度、长度及填充度均有明显提高;由图8可知:伴随O2摩尔分数增大,窑内平均温度升高,混煤燃烧稳定性提高,当O2摩尔分数达到27%时,烧成带烟气平均温度对比普通空气助燃提高97 K。图9和图10所示分别为当O2摩尔分数为27%时,保持其他参数与典型工况数值模拟相同,窑内温度云图及烧成带截面平均烟温随混煤配比改变的变化情况。由图9和图10可知:当一次风O2摩尔分数提高到27%,无烟煤配比提高至60%时,燃成带平均温度仍高达1 850 K以上,其火焰的形状、温度分布仍能满足水泥煅烧工艺要求。

4.2 浓度场仿真及分析

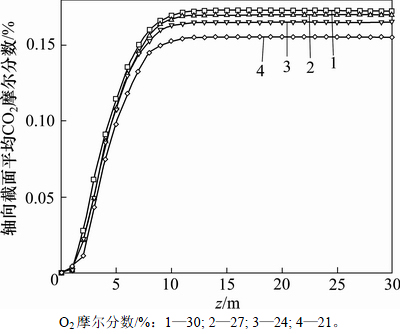

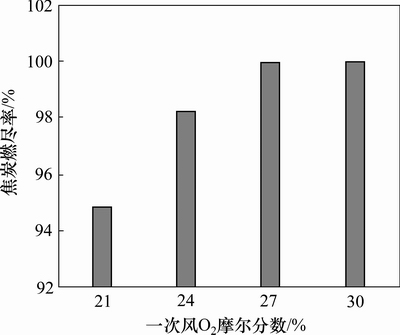

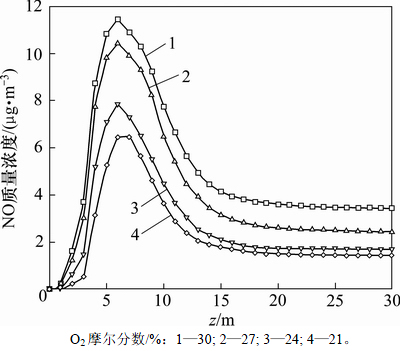

窑内CO2摩尔分数、焦炭燃尽率、NO浓度随一次风O2摩尔分数的变化如图11~13所示。由图11可以看出:随一次风O2摩尔分数增大,CO2摩尔分数快速增加,当一次风O2摩尔分数达27%时,窑尾烟气CO2摩尔分数较正常燃烧提高1.7%。由图12可知:焦炭燃尽率随一次风O2摩尔分数增加有所提高;当一次风O2摩尔分数由21%分别增至24%和27%时,焦炭燃尽率由94.89%分别增加到98.32%和99.98%,分别提高了3.43%和5.09%;当一次风O2摩尔分数增至30%时,焦炭燃尽率近100%。由图13可知:NO质量浓度随一次风O2摩尔分数增加而增加;当一次风O2摩尔分数达27%时,窑尾出口NO质量浓度较正常燃烧提高982 mg/m3。

图7 不同一次风O2摩尔分数对应窑内温度分布云图

Fig. 7 Contours of static temperature with different oxygen mole fractions of primary air

图8 轴向截面平均温度随一次风O2摩尔分数的变化

Fig. 8 Average temperature of axial cross section as a function of oxygen mole fractions of primary air

图9 一次风O2摩尔分数27%时窑内温度随混煤配比变化云图

Fig. 9 Contours of static temperature with different ratios of inferior coal at 27% oxygen mole fractions of primary air

图10 一次风O2摩尔分数27%时烧成带截面平均烟温随混煤配比变化

Fig. 10 Sectional average temperature of burning zone as a function of coal-blended ratio at 27% oxygen mole fraction of primary air

图11 轴向截面平均CO2摩尔分数随一次风O2摩尔分数的变化

Fig. 11 Average mole fractions of cross section of CO2 as a function of O2 mole fractions of primary air

图12 焦炭燃尽率随一次风O2摩尔分数变化

Fig. 12 Char burnout ratio with different oxygen mole fractions of primary air

图13 轴向截面平均NO质量浓度随一次风O2摩尔分数的变化

Fig. 13 Average mass concentrations of cross section of NO as a function of O2 mole fractions of primary air

5 结论

1) 理论研究表明,富氧燃烧能有效改善煤粉燃烧特性。在富氧条件下,煤粉燃烧速度、燃烧温度显著提高,着火温度降低,传热效率提高。

2) 在数值计算条件下,随分解窑内一次风O2摩尔分数的增加,窑内火焰温度明显提高,当O2摩尔分数达27%时,烧成带平均烟气温度较工况燃烧时温度高97 K。

3) 富氧燃烧能有效改善燃烧条件,大幅提高混煤中无烟煤的掺量。当一次风O2摩尔分数为27%,无烟煤掺比提高至60%时,窑内仍能实现稳定燃烧,火焰形状、温度分布仍能较好地满足水泥煅烧工艺要求。

4) 焦炭燃尽率随一次风富氧浓增加明显提高。当一次风O2摩尔分数分别上升到24%和27%时,焦炭燃尽率由工况下94.89%分别上升到98.32%和99.98%;当一次风O2摩尔分数增至30%以上时,理论上焦炭燃尽率近100%。

5) 富氧燃烧在改善煤粉燃料燃烧条件的同时也会造成窑内局部高温,促进窑内NO生成,增加分解炉出口脱硝负荷。当一次风O2摩尔分数由21%增至27%时,窑尾出口NO质量浓度提高了 982 mg/m3。鉴于富氧燃烧时窑内NO生成量增加较多,为减少分解窑烟气脱硝还原剂用量,建议此项技术应与分解炉分级燃烧降氮技术匹配使用。本文研究的对象即为分解炉采用了分级燃烧降氮技术的分解窑。

参考文献:

[1] 马爱纯. 熟料窑内流动、传热和煤粉燃烧的数值模拟和优化研究[D]. 长沙: 中南大学能源科学与工程学院, 2007: 2-13.

MA Aichun. Numerical simulation and optimization of fluid flow, heat transfer and coal combustion in alumina clinker rotary kiln[D]. Changsha: Central South University. School of Energy Science and Engineering, 2007: 2-13.

[2] 马仑, 汪涂维, 方庆艳, 等..混煤燃烧过程中的交互作用:掺混方式对混煤燃烧特性的影响[J].煤炭学报, 2016, 41(9): 2340-2346.

MA Lun, WANG Tuwei, FANG Qingyan. et al. Interaction in mixed coal combustion: effects of mixing modes on combustion characteristics of blended coals.[J]. Journal of Coal Industry, 2016, 41(9): 2340-2346.

[3] 谢峻林, 何峰, 宋彦保. 水泥分解炉工况下煤焦的燃尽动力学过程研究[J]. 燃料化学学报, 2002, 30(3): 223-228.

XIE Junlin, HE Feng, SONG Yanbao. Study on combustion dynamics of char in cement calciner[J]. Journal of Fuel Chemistry and Technology, 2002, 30(3): 223-228.

[4] 豆海建, 陈作炳, 毛娅. 分解炉内无烟煤燃烧优化的数值模拟研究[J]. 武汉理工大学学报, 2008, 30(3): 139-142.

DOU Haijian, CHEN Zuobing, MAO Ya. Numerical simulation study of the optimization for anthracite combustion in a precalciner[J]. Journal of Wuhan University of Technology, 2008, 30(3): 139-142.

[5] LIN Yunhou, WEI Bianfu, YONG Junzhang. A theoretical analysis on combustion intensification for blended coal in rotary cement kiln[J]. Fuel, 2001, 80(1): 1645-1650.

[6] 郭军军, 黄晓宏, 柳朝晖, 等. 3 MWth富氧燃烧煤粉锅炉的数值模拟研究[J]. 工程热物理学报, 2014, 35(5): 1007-1010.

GUO Junjun, HUANG Xiaohong, LIU Zhaohui, et al. Numerical simulation of oxy-fuel combustion on 3 MWth coal-fired boiler[J]. Journal of Engineering Thermophysics, 2014, 35(5): 1007-1010.

[7] MURPHY J J, SHADDIX C R. Combustion kinetics of coal chars in oxygen-enriched environments[J]. Combustion and Flame, 2006, 144(4): 710-729.

[8] 王鹏, 柳朝晖, 廖海燕, 等. 200 MW富氧燃煤锅炉传热特性研究[J]. 动力工程学报, 2014, 34(7): 507-511.

WANG Peng, LIU Zhaohui, LIAO Haiyan, et al. Study on heat-transfer characteristics of a 200 MW oxy-fuel coal-fired boiler[J]. Journal of Chinese Society of Power Engineering, 2014, 34(7): 507-511.

[9] 葛学利,乌晓江,张建文,等. 富氧燃烧条件下炉内数值模拟研究[J].动力工程学报,2016, 36(3): 172-177.

GE Xueli, WU Xiaojiang, ZHANG Jianwen. et al. Numerical simulation of furnace under oxygen enriched combustion condition. [J]. Journal of Chinese Society of Power Engineering, 2016, 36(3): 172-177.

[10] 张振扬, 闫红杰, 刘方侃, 等. 富氧底吹熔炼炉内氧枪结构参数的优化分析[J]. 中国有色金属学报, 2013, 23(5): 1471-1478.

YANG Zhenyang, YAN Hongjie, LIU Fangkan, et al. Optimizationanalysisoflance structure parameters inoxygen enrichedbottom blown furnace[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1471-1478.

[11] MARIN O, CHARON O,  J. Simulating the impact of oxygen enrichment in a cement rotary kiln using advanced computational methods[J]. Combustion Science and Technology, 2001, 164(1): 193-207.

J. Simulating the impact of oxygen enrichment in a cement rotary kiln using advanced computational methods[J]. Combustion Science and Technology, 2001, 164(1): 193-207.

[12] 宗滇. 水泥回转窑劣质煤富氧燃烧器设计及数值模拟研究[D]. 北京: 北京工业大学环境与能源工程学院, 2012: 1-2.

ZONG Dian. The design and simulation of oxygen-enriched inferior coal burner for rotary cement kiln[D]. Beijing: Beijing University of Technology. School of Energy and Environmental Engineering, 2012: 1-2.

[13] 李明飞, 陶从喜, 李小金, 等. 富氧燃烧技术在水泥窑的应用[J]. 水泥技术, 2014(4): 17-20.

LI Mingfei, TAO Congxi, LI Xiaojin, et al. Application of oxygen-enriched combustion technology in cement kiln[J]. Cement Technology, 2014(4): 17-20.

[14] 朱文尚, 颜碧兰, 齐砚勇, 等. 富氧燃烧技术在1 100 t/d生产线应用试验[J]. 水泥, 2014(9): 6-8.

ZHU Wenshang, YAN Bilan, QI Yanyong, et al. Oxygen-enrich combustion pilot test on 1 100 t/d cement production kiln[J]. Cement, 2014(9): 6-8.

[15] 范潇, 李辉, 段永华. 水泥工业煤粉富氧燃烧NO释放特性实验研究[J]. 硅酸盐通报, 2014, 33(9): 2375-2380.

FAN Xiao, LI Hui, DUAN Yonghua. The NO release characteristics of coal in oxy-fuel combustion in cement industry[J]. Bulletin of the Chinese Cement Society, 2014, 33(9): 2375-2380.

[16] 崔凯. 煤粉的富氧高温空气燃烧及其NOx生成特性研究[D]. 北京: 清华大学热能工程系, 2013: 91-110.

CUI Kai. Study on pulverized coal combustion and NOx emission characteristics in high-temperature air and enriched-oxygen environment[D]. Beijing: Tsinghua University. Department of Thermal Engineering, 2013: 91-110.

[17] 张松寿, 童正明, 周文铸. 工程燃烧学[M]. 北京: 中国计量出版社, 2008: 92-93.

ZHANG Songtao, TONG Zhengming, ZHOU Wenzhu. Combustion engineering[M]. Beijing: China Metrology Publishing House, 2008: 92-93.

(编辑 刘锦伟)

收稿日期:2016-11-03;修回日期:2016-12-21

基金项目(Foundation item):国家自然科学基金资助项目(51590891);郴州市科技计划重点项目(CZ2013163) (Project(51590891) supported by the National Natural Science Foundation of China; Project(CZ2013163) supported by the Science and Technology Key Project of Chenzhou Municipal)

通信作者:徐顺生,博士,副教授,从事动力工程及工程热物理研究;E-mail: csuxss@163.com