Au-Ag-Si系钎料合金与Ni的润湿性

崔大田1,王志法1,莫文剑2,姜国圣1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 上海交通大学 材料科学与工程学院, 上海 200030)

摘要:通过分析相图,采用中频感应真空熔炼制成液相点温度在450~500 ℃之间Au-10.22Ag-3.25Si,Au-14.02Ag-3.28Si和Au-18.47Ag-3.27Si 3种不同成分的Au-Ag-Si系钎料合金。分别在其液相点以上20,40和60 ℃及流动氢气保护下进行钎料在Ni板上的铺展试验,通过分析铺展面积及润湿角,研究其与Ni的润湿性;采用背散射电子相观察钎料与Ni润湿后的界面组织。研究结果表明:Au-Ag-Si系钎料合金与Ni润湿性良好, 随着钎焊温度的增加,铺展面积增加,浸润角减小;钎料合金与Ni润湿后,出现润湿环现象;润湿环主要由Au元素组成; 钎料与Ni润湿后,在界面处形成Ni3Si金属间化合物,Ni3Si的形成在一定程度上可提高钎料焊接强度。

关键词:Au-Ag-Si;钎料;润湿性;润湿环;Ni3Si

中图分类号:TG146.3 文献标识码:A 文章编号:1672-7207(2007)01-0036-05

Wettability of Au-Ag-Si brazing filler metal series with Ni

CUI Da-tian1, WANG Zhi-fa1, MO Wen-jian2, JIANG Guo-sheng1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Shanghai Jiaotong University, Shanghai 200030, China)

Abstract: Based on the phase diagram, three kinds of Au-Ag-Si brazing filler metal with three different constituents, i.e., Au-10.22Ag-3.25Si,Au-14.02Ag-3.28Si and Au-18.47Ag-3.27Si were prepared by using the vacuum melting method in a medium-frequency induction furnace. The spreading-out experiment of the Au-Ag-Si brazing filler metal on Ni sheet was done at 20, 40 and 60 ℃ above its liquidus temperature respectively with flow H2 as protective gas. The wettability of the Au-Ag-Si brazing filler metal with Ni was studied by measuring and analyzing the area-of-spread and wetting angle. The interface structure of the brazing filler metal with Ni after its spreading was observed by backscattered electron images. The results show that the Au-Ag-Si brazing filler metal series have a good wettability with Ni. When brazing temperature increases, the area-of-spread increases and the wetting angle decreases, there are wetting rings when brazing filter metal is wetted with Ni. The wetting rings principlely consist of Au element. The intermetallic of Ni3Si is formed at the interface, and the formation of Ni3Si can improve the brazed joint strength to some degree.

Key words: Au-Ag-Si; brazing filler metal; wettability; wetting ring; Ni3Si

由于贵金属及其合金钎料具有流散性好、化学稳定性强、导电性高等优良性能,在工业中得到广泛应用,主要用于电器与电子工业、航空航天工业、冶金与化工工业和军事工业等重要工业部门。随着航天技术的发展,许多航天用电子器件都采用密度较低的材料,如铝基热沉材料(表面镀Ni)。这些电子器件都要求封装焊接。为保证有关材料的性能在焊接时不受影响,要求焊接温度必须低于铝基热沉材料的熔点(660 ℃);同时,这些电子器件的壳体与芯片的焊接多采用Au-Si和Au-Ge等低熔点焊料,其焊接温度多为400

℃左右,故钎料熔点应控制在450~550 ℃。目前,在450~600℃ 温区内,还缺乏相应的具有满意性能的贵金属合金钎料[1-4]。因此,迫切需要开发出一种熔点在500 ℃左右的共晶合金,同时还要能满足焊料的其他性能要求,具有一定的可加工性,与镀Ni层浸润良好,流动性好。研究结果表明[3-4],采用中频感应真空熔炼可制备符合上述熔点要求的Au-Ag-Si系钎料合金。本文作者在此基础上,通过对铺展面积和浸润角的测量以及对界面的观察[5-8],研究钎料合金与Ni板的润湿性情况。

1 试验方法

1.1 钎料合金的熔铸

通过对Au-Ag-Si系三元相图的分析,制定液相点温度在450~500 ℃,成分分别为Au-10.22Ag- 3.25Si,Au-14.02Ag-3. 28Si和Au-18.47Ag-3.27Si的3种合金,编号依次为1号、2号、3号。合金原料含99.99% Au,99.99% Ag和单晶硅,在中频感应真空炉中熔炼,熔炼时的载体为石墨坩埚,采用铜模冷却铸锭。经差热分析可知[4],其液相点依次为450,452和498 ℃。

1.2 钎料合金在Ni板上的铺展试验

铺展实验在流动氢气保护管式电阻炉中进行。将质量相等的钎料铸锭分别在其液相点以上20,40和60 ℃及流动氢气保护下进行润湿性测试,基板采用经过热轧以后的纯Ni板材,Ni板表面磨掉一层后用盐酸清洗再用水冲洗。当炉腔达到设定温度时,将样品放入加热区中,保温一段时间后推入冷却区,后取出并对其浸润角及铺展面积进行测量。

1.2.1 钎料合金与Ni润湿后的铺展面积测定

由于钎料铺展后的形状很不规则,故设计如下测量方案:将铺展开的钎料成像,放大10倍后打印。将打印出来的铺展像剪下来,用精度为1/万 g的分析天平测出其质量,记为mi;同时用分析天平测出面积为100 cm2的同一种打印纸张的质量,记为m。则钎料铺展面积Si可通过下式进行计算并加以比较;

有关此实验具体试验过程可参照GB 11364—89进行。

1.2.2 钎料合金与Ni的浸润角测定

浸润角测定的实验条件与铺展面积测量的实验条件相同,具体实验过程见文献[9]。

2 结果与讨论

2.1 钎料合金与Ni的润湿性

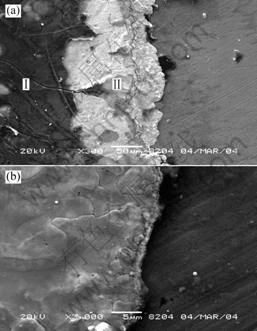

将1号、2号、3号钎料分别在其液湘点以上20,40和60 ℃及流动氢气保护下进行润湿性测试,基板采用经过热轧以后的纯Ni板材(厚度为1.0 mm)。图1所示为2号钎料铺展后的表面形貌及在不同温度下与Ni润湿后的浸润角截面图,表1所示为2号钎料铺展面积和浸润角的测量值。

t/℃: (a) 472; (b) 492; (c) 512

图 1 2号钎料合金铺展后的表面形貌及润湿角截面图

Fig.1 The surface topographies of the No.2 solder alloy and the sectional drawings of the wetting angle after wetting

表1 2号钎料铺展面积和浸润角测量值

Table 1 Values of wetting angle and area-of-spread

从钎料合金在Ni板上铺展后的表面形貌可以看出,钎料铺展后表面质量较好,无块状物残留,这表明钎料在液相线以上均已熔化,这也是合金流动性良好的体现。

钎料在Ni板上凝固后,其浸润角均小于90?,这表明钎料与Ni 浸润较好。浸润实验是在氢气气氛下进行的,还原性气氛有利于降低固体的表面张力(其实是固-气的界面张力),这可提高钎料与母材的浸润性。从不同温度下的铺展面积和浸润角测量值可知,随着钎焊温度的提高,铺展面积增大,浸润角减小,这表明钎焊温度提高有利于钎料与母材间的润湿。液体的表面张力随温度的升高呈线性下降,是润湿性提高的原因之一。由于液态金属不同于固体金属,其点阵排列不规则,以原子或分子的形态做布朗运动,它将借助于毛细管现象产生的毛细管力,沿着固体金属表面上的微小凸凹面和结晶的间隙向四方扩散,其扩散方式有晶间扩散、晶内扩散和表面扩散3种方式。由于表面扩散所需的能量最低,所以,其扩散以表面扩散为主,随着温度升高,扩散运动越明显,这也是铺展面积随温度升高而增大的另一原因。

2.2 钎料合金铺展后的表面形貌分析

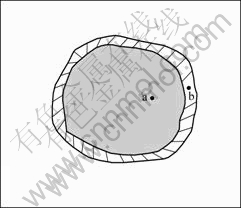

在钎料铺展过程中还发现,在熔化钎料的前沿总产生1个润湿环,从其宏观外形特征来看,如同在钎料外侧镶有一金边,这一特征称为润湿环现象。图2所示为润湿环现象示意图。其中:a表示铺展后的钎料主体;b表示润湿环。

图 2 润湿环现象示意图

Fig. 2 Diagrammatic sketch of the wetting ring

图1(c)中润湿环最明显,其他样品也均存在不同程度的润湿环现象。N.K.Batra等[5-6]认为,在950 ℃时Au的蒸汽压为1 mPa,在此温度下Au可能蒸发,在钎焊过程中,金部分挥发之后沉淀于母材上,当达到铺展温度后钎料整体开始流动覆盖于沉淀的Au上,而未覆盖的部分就构成了润湿环。

本次润湿性实验是在H2保护下进行的,实验温度为500 ℃左右,在此温度下Au的蒸汽压极低,不易挥发,这与文献中润湿环由于元素挥发而形成的机理不符合。因此,为了分析这种现象,对铺展后的钎料进行表面形貌观察和能谱分析。图3(a)中颜色较深的Ⅰ部分为钎料铺展后的主体,颜色较浅的Ⅱ部分为润湿环。在Ⅰ和Ⅱ之间可看到明显的分层。经能谱分析发现:Ⅰ部分表面以Si为主,Ⅱ部分由Au组成(含有少量的Ag)。根据这种结果可对钎料熔化后的铺展过程进行如下假设:当钎焊温度达到固相点以上时,钎料中的α(Au(Ag))相由于具有更好的流动性,将优先于主体部分开始向四周沿母材上的裂纹和沟槽扩展(或者可以说扩散速度更快),这也是钎料铺展前沿不整齐的原因。随后,钎料的主体部分也开始沿母材上的裂纹和沟槽流动,并汇集在一起。钎料在铺展过程中完全覆盖母材的那个区域就是钎料的润湿区;钎料虽已汇集,但尚未覆盖钎料呈分支铺盖的区域就形成润湿环。

(a) 钎料与母材的表层结合界面;(b) 润湿环的表面形貌

图 3 钎料铺展后的表面形貌

Fig. 3 The surface topograph of the solder alloy after wetting

以上关于润湿环的形成及钎料的铺展过程与高温钎焊时润湿环的形成机理[6]不同,与文献[5]中钎料中的元素优先铺展形成润湿环的机理相似。对润湿环的形成及钎料的铺展过程,还需要通过实验(如钎料熔化过程中高温下摄影,高温金相显微镜观察)进一步证实,从熔体的粘度、表面张力进行分析。关于润湿环的存在对钎料润湿性的影响,庄鸿寿[6]认为,不论是高温钎焊还是低温钎焊过程,润湿环的出现都有利于钎料与母材间的润湿。其原因主要是优先铺展的部分发生传质作用降低了钎料与母材间的表面张力。

在实验过程中,钎料的冷却是在空气中进行的,因此,钎料中的Si发生了氧化,形成一层致密的氧化层,这应该是图2中a部分表面含Si较多的原因。

2.3 钎料合金与Ni润湿后的界面组织分析

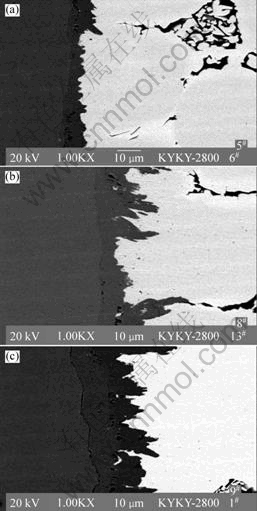

对2号钎料合金在不同温度下铺展后的截面在扫描电镜下进行背散射电子相观察,其界面形貌如图4所示。

t/℃: (a) 472; (b) 492; (c) 512

图 4 钎料合金与Ni板润湿后界面的背散射电子像

Fig. 4 The backscattered electron images of the interface

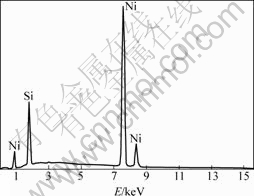

从钎料与母材润湿后的界面组织可以看出,钎料与镍板之间形成了一条明显的不均匀过渡层。线扫描结果显示,在此过渡层上Ni和Si产生明显台阶,而Au和Ag的含量明显减少,表明Au和Ag未向Ni侧发生扩散。对过渡层进行能谱分析(如图5所示),结果表明其中Ni原子数分数为71.8%,Si原子数分数为28.2%,初步推断该过渡层为Ni3Si金属间化合物。当钎料升温至液态后,固相Ni开始向液相溶解,随着温度升高,溶解速度加快,致使Ni在靠近界面处的局部浓度很高,当温度达到一临界值时,就促使金属间化合物Ni3Si形成,并向液相深处生长。温度越高,该金属间化合物生长速度越快,这也是随着钎焊温度的升高,过渡层增厚(见图4)的原因。实验所取的固相金属是多晶的轧制板材,不同取向晶粒的晶面其反应势垒不同,原子密度较大的晶面势垒较低,溶解速度较快。同时它也抑制了其他取向晶面的溶解。这应该是金属间化合物Ni3Si存在地点不均匀的原因。

图 5 过渡层的能谱分析图

Fig.5 The energy spectrum analysis of the transition layer

钎料与母材之间形成冶金结合将有利于钎料在母材间的润湿[10-15]。金属间化合物Ni3Si像无数钉子一样嵌入钎缝,有利于增强钎缝接头的强度。但由于Ni3Si为脆性相,若此过渡层太厚,则会降低接头强度。因此,优化钎焊温度和保温时间,控制升温速度,对提高钎焊接头强度都具有重要意义。

3 结 论

a. 根据相图,采用中频感应真空熔炼可制成液相点温度在450~500 ℃之间的Au-Ag-Si系钎料合金。

b. Au-Ag-Si系钎料合金与Ni具有良好的润湿性。铺展面积和浸润角测量值表明:在液相点以上60 ℃以内,Au-Ag-Si系钎料合金与Ni的润湿角θ≤30?,随着钎焊温度的升高,钎料在Ni板上铺展后的铺展面积增加,润湿角减小。

c. Au-Ag-Si系钎料合金与Ni润湿后,会出现润湿环现象。能谱分析结果表明,润湿环主要由Au元素组成,润湿环的出现有利于钎料与母材的润湿。

d. 从界面显微组织来看,Au-Ag-Si系钎料合金与Ni润湿后,在界面处形成Ni3Si金属间化合物,Ni3Si的形成在一定程度上可提高钎焊接头强度。

参考文献:

[1] 黄伯云, 李成功, 石力开, 等. 中国材料工程大典[M]. .北京: 化学工业出版社, 2006: 471.

HUANG Bai-yun, LI Cheng–gong, SHI Li-kai, et al. Chinese material engineering dictionary[M]. Beijing: Chemical Industry Press, 2006: 471.

[2] 张启运, 庄鸿寿. 钎焊手册[M]. 北京: 机械工业出版社, 1999: 14-16.

ZHANG Qi-yun, ZHUANG Hong-shou. Manual of brazing and soldering[M]. Beijing: Mechanical Industry Press, 1999: 14-16.

[3] 莫文剑, 王志法, 王海山, 等. Au-Ag-Si钎料合金的初步研究[J]. 贵金属, 2004, 25(5): 45-51.

MO Wen-jian, WANG Zhi-fa, WANG Hai-shan, et al. A primary study of Au-Ag-Si solder[J]. Precious Metals, 2004, 25(5): 45-51.

[4] 莫文剑, 王志法, 姜国圣, 等. Au-Ag-Si新型中温共晶钎料的研究[J]. 稀有金属材料与工程, 2005, 34(3): 497-500.

MO Wen-jian, WANG Zhi-fa, JIANG Guo-sheng, et al. Study of a new-type of Au-Ag-Si intermediate temperature eutectic solder[J]. Rare Metal Material and Engineering, 2005, 34(3): 497-500.

[5] Batra N K, See J B, King T B. Flux reactions in soldering[J]. Welding Journal, 1974, 53: 10.

[6] 庄鸿寿. 高温钎焊[M]. 北京: 国防工业出版社, 1989.

ZHUANG Hong-shou. High temperature brazing[M]. Beijing: National Defence Industry Press, 1989: 121-123.

[7] Shieu F S, Chen C F, Sheen J G, et al. Intermetallic phase formation and shear strength of a Au-In microjoint[J]. Thin Solid Films, 1999, 346: 125-129.

[8] LIU Xing-sheng, XU Shuang-yan, LU Guo-quan, et al. Stacked solder bumping technology for improved solder joint reliability[J]. Microelectronics Reliability, 2001, 41: 1979- 1992.

[9] Hosking F M, Stephensand J J, Rejent J A. Intermediate temperature joining of dissimilar metals[J]. Welding Research, l 999, 4(Suppl): l27.

[10] 吴文云, 邱小明, 殷世强, 等. Bi、Ag对Sn-Zn无铅钎料性能与组织的影响[J]. 中国有色金属学报, 2006, 16(1): 158-163.

WU Wen-yun, QIU Xiao-ming, YIN Shi-qiang, et al. Influence of Bi, Ag on microstructure and properties of Sn-Zn lead-free sdder[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(1): 158-163.

[11] 王 烨, 黄继华, 张建纲, 等. Sn-3.5Ag-0.5Cu/Cu界面的显微结构[J]. 中国有色金属学报, 2006, 16(3): 495-499.

WANG Ye, HUANG Ji-hua, ZHANG Jian-gang, et al. Microstructure of Sn-3.5Ag-0.5Cu/Cu interface[J]. The Chinese Journal of Nonferrous metals, 2006, 16(3): 495-499.

[12] 岳译新, 谭澄宇, 郑子樵, 等. 新型Ag-Cu-Ge钎料的性能及钎焊界面特征[J]. 中国有色金属学报, 2006, 16(10): 1793-1798.

YUE Yi-xin, TAN Cheng-yu, ZHENG Zi-qiao, et al. Properties and interface microstructure of new type Ag-Cu-Ge solder[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(10): 1793-1798.

[13] Pang H L J, Tan K H, Shi X Q, et al. Microstructure and intermetallic growth effects on shear and fatigue strength of solder joints subjected to thermal cycling aging[J]. Materials Science and Engineering, 2001, A307: 42-50.

Hassam S, Agren J, Gaune-eseard M, et al. The Ag-Au-Si system: Experimental and calculated phase diagram[J]. Metallurgical Transactions A, 1990, 21A: 1877.

收稿日期:2006-05-16

基金项目:国家高新工程重点项目(DZ-2002-021)

作者简介:崔大田(1983-),女,河南南阳人,博士研究生,从事中温共晶钎料的研究

通讯作者:崔大田,女,博士研究生;电话:0731-8877698(O); E-mail: ct_cui@126.com