文章编号:1004-0609(2012)08-2253-07

不锈钢表面激光合金化Mn-Al2O3强化层的组织及性能

李 鹏1,孙桂芳1,张 尉2,刘卫祥2,张永康3,张满奎1

(1. 江苏大学 机械工程学院,镇江 212013;

2. 江苏联冠科技发展有限公司,张家港 215624;

3. 东南大学 机械工程学院,南京 210000)

摘 要:基于高速混合机桨叶所用奥氏体不锈钢的失效情况,利用激光合金化技术在奥氏体不锈钢上制备合金化强化耐磨层。利用光学显微镜、扫描电镜、X射线衍射仪、显微硬度计和光学分析仪研究合金化层的显微组织、成分、物相、横截面的硬度分布,同时利用正交试验得到激光合金化技术的优化参数。结果表明:当硬质相Al2O3的含量为70%,激光功率为2 kW,扫描速度为15 mm/s时,合金化层的显微硬度最大,达到440.8 HV0.1;所制备的合金化层无裂纹和气孔等缺陷,与基体形成冶金结合;合金化层由枝晶和枝晶间共晶组成,其相组成为奥氏体、Al2O3、Cr7C3、Mn7C3和Mn2O3;合金化层的耐磨损性能较基体的显著提高。

关键词:桨叶;激光合金化;不锈钢;磨损

中图分类号:TG174.445;TG113.25;TG115.5 文献标志码:A

Microstructure and properties of

laser alloyed Mn-Al2O3 layer on stainless steel

LI Peng1, SUN Gui-fang1, ZHANG Wei2, LIU Wei-xiang2, ZHANG Yong-kang3, ZHANG Man-kui1

(1. School of Mechanical Engineering, Jiangsu University, Zhenjiang 212013, China;

2. Jiangsu Lianguan Science and Technology Development Co., Ltd, Zhangjiagang 215624, China;

3. School of Mechanical Engineering, Southeast University, Nanjing 210000, China)

Abstract: Based on the failure of austenitic stainless steel used in high-speed mixing blades, the laser alloying technique was used to fabricate the alloyed layer on stainless steel. The microstructure, composition, phases, microhardness of the cross-section of the alloyed layer were analyzed by OM, SEM, XRD, microhardness tester, optical profiling system, and the optimal parameter is obtained by the use of orthogonal. The results indicate that, the highest hardness is 440.8 HV0.1 when the content of Al2O3, the laser power and laser scanning speed are 70%, 2 kW and 15 mm/s, respectively. The alloyed layer is free of cracks with good processability, the alloyed layer is composed of dendrites and eutectic, the phases are austenite, Al2O3, Cr7C3, Mn7C3 and Mn2O3. The wear resistance of alloyed layer increases significantly.

Key words: blade; laser alloying; stainless steel; wear

浆叶和桶体是塑料混料设备的主要结构部件,其耐磨、耐腐性能的高低直接影响到设备的使用寿命。桨叶和筒体的工作温度为100~300 ℃,并且在高速旋转过程中承受磨料的摩擦力和冲击力,加之工作环境中产生的氯气的腐蚀作用,其在工作过程中会产生疲劳、裂纹和剥落,乃至失效[1]。目前,国内混料设备的浆叶和桶体基本采用普通奥氏体不锈钢,奥氏体不锈钢是含有Cr和稳定奥氏体的元素Ni、Mn、N等使钢在室温条件下为单相奥氏体的钢,具有耐蚀性高,塑性高、韧性和低温韧性好[2],但是硬度较低,耐磨性不好,使用寿命较短。目前,利用表面技术对零部件进行强化和修复已成为机械部件延寿的发展方向之一。

激光表面合金化(Laser surface alloying, LSA)利用高能激光束将基体金属表面与加入的合金化元素熔化,在以基体为溶剂,合金化元素为溶质的基础上制备耐磨损、耐腐蚀、耐高温抗氧化等特殊性能的强化层[3],常用以避免零部件整体使用贵重金属材料,近年来在工程领域得到越来越多的应用[4-7]。国内外学者在利用激光合金化提高奥氏体不锈钢性能方面做了许多工作。LO等[8]在已预涂WC粉末的AISI 316不锈钢表面实现激光合金化,显著提高不锈钢抗空蚀性能。许长庆和李贵江[9]采用激光合金化在AISI 321不锈钢表面制得TiC增强复合涂层,涂层表现出良好的耐磨性。JAGDHEESH等[10]采用激光合金化成功制备了以奥氏体不锈钢为基体的Ni和TiC颗粒增强合金化层。此外,花国然等结合激光技术与喷涂技术制备了纳米改性Al2O3复合陶瓷涂层,其耐磨性能改善,且优于等离子喷涂所制备涂层的耐磨性[11-12]。

当前制备的Al2O3陶瓷涂层具有高耐磨性、耐蚀性,且耐高温[12],同时陶瓷材料原料丰富,价格较金属材料有明显优势。Mn和Ni一样是能和Fe形成无限互溶固溶体的元素,而且Mn有比Ni大的固溶强化效应[2]。基于此,本文作者利用激光合金化技术在奥氏体不锈钢表面制备耐磨Al2O3陶瓷合金化层,采用Mn加Al2O3陶瓷粉末,在预涂层粉末中添加Mn元素,从而达到锰钢加硬质相增强耐磨损性能的作用[13],以期获得具有高耐磨性能的浆叶。

为了得到所需的材料性能,必须对诸如激光功率、光斑尺寸、扫描速度等对所制备合金化层影响较大的工艺参数进行精确控制。采用正交实验方法确定优化工艺参数研究优化参数下得到的合金化层的组织和物相,测试合金化层的硬度和耐磨性,并进行相应的分析。

1 实验

1.1 试样制备

基体由江苏联冠科技发展有限公司提供的1Cr18Ni9Ti奥氏体不锈钢的高速混合机的桨叶切割而成,每块试样的尺寸为20 mm×30 mm×10 mm,试样化学成见表1。试样打磨去掉表面氧化层,然后用酒精和去离子水清洗。

表1 1Cr18Ni9Ti奥氏体不锈钢的化学成分

Table 1 Chemical composition of 1Cr18Ni9Ti austenite stainless steel (mass fraction, %)

1.2 制备工艺

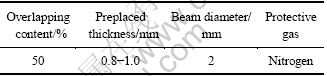

实验使用武汉金石凯的GS-TFL-10k型CO2激光器,采用预置粉末法,激光合金化粉末由Mn(粒度<48 μm)和Al2O3(粒度<75 μm)粉末混合研磨组成。硬质相Al2O3颗粒添加比例、激光功率和激光扫描速度3个定量因素对最后的合金化层的性能的影响将被考察,在正交实验中,分别将硬质相颗粒添加含量、激光功率、激光扫描速度记为因素A、B、C,每个因素取3个水平,分别为A1=70%,A2=50%,A3=30%(质量分数);B1=1 kW,B2=1.5 kW,B3=2 kW;C1=10 mm/s,C2=15 mm/s,C3=20 mm/s。预涂层厚度、激光光斑直径和保护性气体等激光工艺参数如表2所示。利用正交实验参数扫描试样表面涂层,然后空冷至室温,观察其组织,测量其硬度,确定最佳工艺参数。

表2 激光合金化工艺参数

Table 2 Parameters for laser alloying technique

1.3 性能测试

对优化后的最佳工艺参数下制备的激光扫描试样,沿激光扫描方向的垂直方向切取试样,经打磨抛光腐蚀制取金相试样。腐蚀剂使用王水甘油(VHCl:VHNO3:VC3H8O3=3:1:2)。采用HV-1000显微硬度计沿合金层的深度方向测量合金化层的显微硬度,载荷为1 N,加载时间为10 s,测量点间隔0.05 mm。采用D/max2500VB3+/PC型X射线衍射仪分析检测合金化层的物相组成,采用Co靶,扫描角度范围为30°~120°,扫描速度为6 (°)/min。采用LEICA DM2500M型光学显微镜进行合金化层的显微组织的观察和厚度的测量。利用JEOL JSM-7001F型扫描电镜及附带的能谱分析仪,观察并分析合金化层的组织形貌及组织成分。利用WYKO NT1100光学分析仪,观察基体与合金化层磨损后的形貌。

磨损实验机为高温高速摩擦磨损试验机。磨损方式为球盘式室温空气中干滑移磨损。磨损盘为激光合金化层表面,试样尺寸20 mm×15 mm×10 mm。磨损前,试样表面经过打磨抛光。载荷为10 N,旋转角速度为300 r/min,磨损时间为600 s。摩擦副为440-C不锈钢钢珠(其硬度为HRC62)。实验前后经酒精超声波清洗后称取质量。

2 正交实验结果分析

采用正交实验方法确定优化工艺参数,根据表3所示正交工艺参数进行实验,测得显微硬度结果列于表3之后,用以分析工艺参数。

表3 正交实验与结果分析

Table 3 Orthogonal experiment and results analysis

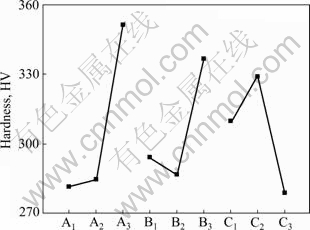

从9组实验结果来看,试样1-9的最大显微硬度值最高,其相应的工艺参数组合(A3=30%;B3=2 kW;C2=15 mm/s)是当前的最优工艺参数组合。下面通过数学分析寻找在所有工艺参数组合中的最优参数。

表3中“T1”行所示为在Al2O3硬质相颗粒添加比例为70%(A1=70%)时3次实验显微硬度之和:T1= 309.7+281.7+253.8=845.2,其均值T1/3=845.2/3= 281.7列于“m1”行。同理,将在A2=50%和A3=30%时的平均硬度为284.8和351.4。3个平均值的极差是R= max{281.7, 284.8, 351.4}-min{281.7, 284.8, 351.4}= 69.7,列在表的最后一行。同理计算应用于因素B和C,列于表3。

将3个工艺参数的平均显微硬度值列于图1,由图1可直观看到:1) Al2O3的含量越高,显微硬度越高;2) 功率为2 kW时,显微硬度最高;3) 激光扫描速度为15 mm/s时,显微硬度最高。综合来看,仍是A3=30%;B3=2 kW;C2=15 mm/s的工艺参数组合效果最优。

图1 显微硬度与3个工艺参数的关系

Fig. 1 Relationship between microhardness and three process parameters

在正交实验中,因素对响应的影响是有主次分别的,影响大小通过极差的大小来表现。3个因素的极差分布分别为69.7、49.6、50,由此可见,工艺参数对显微硬度的影响的重要性从大到小依次是A、C、B。下面以最优工艺参数组合所制备的(Al2O3硬质相颗粒添加比例为30%,激光功率为2 kW,激光扫描速度为15 mm/s)试样为例研究不锈钢表面经激光处理后的变化,以揭示不锈钢表面整体性能的变化。

3 涂层微观形貌及机理分析

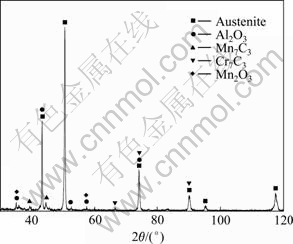

3.1 物相分析

图2所示为激光合金化层的XRD谱。由图2可见,激光合金化层主要由奥氏体(A)、Al2O3、Cr7C3、Mn7C3和Mn2O3组成,激光表面合金化后在奥氏体不锈钢表面形成了以奥氏体为基体,以Al2O3、Cr7C3、Mn7C3和Mn2O3为增强相的复合涂层。

图2 激光合金化层的XRD谱

Fig. 2 XRD pattern of LSA layer

ANTHONYSAMY等[14]提出的公式(1)为计算温度为973~1 173 K时,Cr7C3的吉布斯自由能提供了依据。可见,在任何高于0 ℃的温度下,其吉布斯自由能都为负值,该反应都有自发发生的趋势。本研究中,利用该公式计算2 000 K温度下Cr7C3的吉布斯自由能。计算数值为-175 067 J/mol,由于该值为负值,所以C和Cr有自发反应生成Cr7C3的趋势,如公式(2)所示。

=-92 067-41.5T (J/mol) (1)

=-92 067-41.5T (J/mol) (1)

3C+7Cr=Cr7C3 (2)

Mn7C3和Mn2O3的反应方程式分别如式(3)和(4)所示。

7Mn+3C=Mn7C3 (3)

2Mn+3O=Mn2O3 (4)

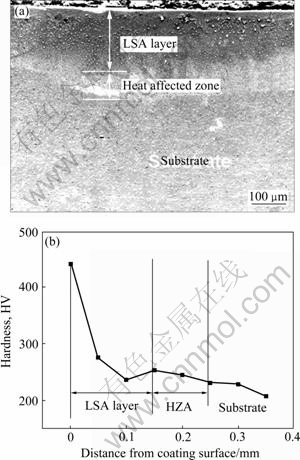

3.2 硬度和显微组织分析

图3(a)所示为试样横截面的照片,图3(b)所示为沿横截面的硬度分布。由图3(a)可见,试样分为激光合金化区、热影响区和基体3个部分。合金化区组织致密,晶粒细化,无裂纹、气孔等缺陷,同时,合金化层中可见到树枝晶分布,并且其平均厚度为140 μm。试样显微硬度分别对应激光合金化层、热影响区、基体分为3个级别,由表及里依次降低。其中基体的硬度为204 HV0.1,合金化层的最大硬度达到440.8 HV0.1,是基体的2.1倍。

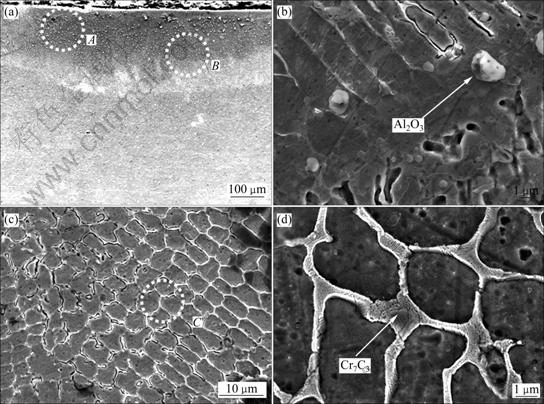

图4所示为激光合金化层的SEM像。图4(a)显 示的是合金化层整体的组织形貌。由图4(b)(图4(a)的A区域)可以看出,在合金化层的搭接区域处形成约为4 μm厚的平面晶,平面晶的生长形态是由热流方向决定的,平面晶的形成使得相邻道次之间形成良好的冶金结合。材料熔池表面的径向拉力分布是中心强、边缘弱,使熔液形成径向朝外的流动,从而带动了熔池内部的对流运动[15],结合XRD可以看出,随着对流一部分未融化的Al2O3颗粒分布在平面晶上。搭接扫描由于存在二次扫描过程,致使合金化层组织和性能呈现周期性的变化。枝晶的生长方向基本上垂直于熔池壁, 这主要是由于金属凝固时朝着垂直于熔池壁方向的散热速度较快所致。受熔池搭接和“二次加热”效应的影响,搭接区内的组织出现不均匀,在二次熔化区出现较多的胞状组织。

图3 试样横截面的形貌及沿试样横截面的硬度分布

Fig. 3 Microphology of cross-section(a) and microhardness distributions along cross-section(b) of sample

由图4(c)(图4(a)中B区域)所示:合金化层中下部分是具有方向性生长的胞晶和树枝状晶。这是因为熔池中底部吸热相对于熔池上部吸热较少,温度较低,涂层熔化不充分,而且在主要依赖基体传导热量的冷却过程中,冷却速度相对较快,晶核没有足够时间长大。

图4 激光合金化层的SEM像

Fig. 4 SEM images of cross-section of LSA layer

预涂Mn-Al2O3合金粉末在激光辐照下,基材与合金熔化形成一个具有较高Mn、Al含量的Ni-Cr-Mn-Al复杂合金化熔池。该熔池主要依靠基体的快速热传导和向外界空气的辐射传热作用而快速非平衡凝固。如图4(d)(见图4(c)中C区域)所示,合金化层是典型的枝晶组织,由奥氏体枝晶和沿枝晶析出的碳化物共晶组织组成Al2O3具有较高的熔点,首先从熔池中析出,存在于奥氏体枝晶中。Cr7C3[16]、Mn7C3和Mn2O3在枝晶边界析出,形成共晶。

3.3 磨损试验结果分析

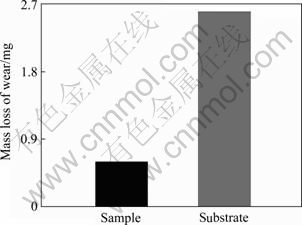

图5所示为激光合金化层和基体在相同磨损参数下的磨损量的对比。由图5中可以知,激光合金化层的耐磨性较基体显著提高,是基体的4倍,这是因为在基体表面合金化Mn和Al2O3硬质相后,其硬度得到了提高,因而耐磨性明显提高。

图6所示为基体与优化试样磨损后的表面形貌。由图6可知,基体的磨损较为严重,且不均匀,而工艺参数优化后的试样磨损损失均匀。由图6(a)可见,基体的磨损并不均匀,粘着磨损非常严重,黑色区域为基体被撕裂或者脱落的部分,磨损形式为研磨磨损,粘着磨损和氧化磨损的混合磨损机制。由图6(b)可见,磨损后的表面高度均匀,没有脱落或者撕裂的部分,主要磨损形式为研磨磨损。由于在磨损中作为硬质相的Al2O3和Cr7C3可以作为主要的承载体承受外界载荷的力学作用,减小磨粒对奥氏体基体的犁削作用,而塑性优良的奥氏体基体可以牢牢固定硬质相颗粒,防止其从合金化层中脱落。

图5 基体和激光合金化层的磨损性能

Fig. 5 Wear properties of substrate and LSA layer

图6 基体和优化试样磨损后的表面形貌

Fig. 6 Morphologies of substrate(a) and optimization sample(b) after wear

4 结论

1) 1Cr18Ni9Ti奥氏体不锈钢激光表面合金化Mn-Al2O3得到性能良好且与基体是冶金结合的合金化层。合金化层是典型的枝晶组织,由奥氏体枝晶和共晶组织组成。

2) 激光合金化层的最大硬度为440.8 HV0.1,是基体的2.1倍。XRD分析表明,激光合金化层主要由奥氏体(A)、Al2O3、Cr7C3、Mn7C3和Mn2O3组成。

3) 合金化层的耐磨损性能较基体有显著提高,是基体的4倍,这是硬质相和基体协同作用的结果,主要磨损形式为研磨磨损。

REFERENCES

[1] 韩 勇. 国产塑料混合机的技术现状及对策[J]. 橡塑技术与装备, 2002(5): 14-18.

HAN Yong. The present technical status and improving suggestion of domestic plastic mixer[J]. China Rubber Technology & Equipment, 2002(5): 14-18.

[2] 黄乾尧, 李汉康. 高温合金[M]. 北京: 冶金工业出版社, 2000.

HUANG Gan-yao, LI Han-kang. Superalloy[M]. Beijing: Metallurgical Industry Press, 2000.

[3] 李贵江, 许长庆, 孟 丹, 穆志宏. 材料表面激光合金化研究进展[J]. 铸造技术, 2008(8): 1136-1139.

LI Gui-jiang, XU Chang-qing, MENG Dan, MU Zhi-hong. Research progress on laser surface alloying[J]. Foundry Technology, 2008(8): 1136-1139.

[4] SUN Gui-fang, ZHOU Rui, LI Peng, FENG Ai-xin, ZHANG Yong-kang. Laser surface alloying of C-B-W-Cr powders on nodular cast iron rolls[J]. Surface and Coatings Technology, 2011, 205(8/9): 2747-2754.

[5] YAO Jian-hua, WANG Liang, ZHANG Qun-li, KONG Fan-zhi, LOU Cheng-hua, CHEN Zhi-jun. Surface laser alloying of 17-4PH stainless steel steam turbine blades[J]. Optics & Laser Technology, 2008, 40(6): 838-843.

[6] TONG Xin, ZHOU Hong, REN Lu-quan, ZHANG Zhi-hui, CUI Ren-dong, ZHANG Wei. Thermal fatigue characteristics of gray cast iron with non-smooth surface treated by laser alloying of Cr powder[J]. Surface and Coatings Technology, 2008, 202(12): 2527-2534.

[7] BLANCO-PINZON C, LIU Z, VOISEY K, BONILLA F A, SKELDON P, THOMPSON G E, PIEKOSZEWSKI J, CHMIELEWSKI A G. Excimer laser surface alloying of titanium with nickel and palladium for increased corrosion resistance[J]. Corrosion Science, 2005, 47(5): 1251-1269.

[8] LO K H, CHENG F T, KWOK C T, MAN H C. Improvement of cavitation erosion resistance of AISI 316 stainless steel by laser surface alloying using fine WC powder[J]. Surface and Coatings Technology, 2003, 165(3): 258-267.

[9] 许长庆, 李贵江. 激光表面合金化TiC增强复合涂层及性能研究[J]. 材料热处理学报, 2009(4): 160-163.

XU Chang-qing, LI Gui-jiang. Investigation on TiC-reinforced composite coating on stainless steel prepared by laser surface alloying[J]. Transactions of Materials and Heattreatment, 2009(4): 160-163.

[10] JAGDHEESH R, SASTIKUMAR D, MUDALI U K, NATH A K. Laser processed metal-ceramic coatings on AISI type 316L stainless steel[J]. Surface Engineering, 2004, 20(5): 360-366.

[11] 花国然, 黄因慧, 赵剑峰, 王 蕾, 田宗军, 张建华, 张永康. 激光熔覆纳Al2O3等离子喷涂陶瓷涂层[J]. 中国有色金属学报, 2004, 14(2): 199-203.

HUA Guo-ran, HUANG Yin-hui, ZHAO Jian-feng, WANG Lei, TIAN Zong-jun, ZHANG Jian-hua, ZHANG Yong-kang. Plasma-sprayed ceramic coating by laser cladding of Al2O3 nano-particles[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(2): 199-203.

[12] 花国然, 罗新华, 黄因慧, 赵剑峰, 田宗军, 王 蕾, 张永康. 激光重熔改性等离子喷涂陶瓷涂层的组织及其耐腐蚀性能[J]. 中国有色金属学报, 2004, 14(6): 934-938.

HUA Guo-ran, LUO Xin-hua, HUANG Yin-hui, ZHAO Jian-feng, TIAN Zong-jun, WANG Lei, ZHANG Yong-kang. Microstructure and corrosion characteristics of plasma-sprayed ceramic coating by laser remelting of nano-Al2O3 modifying[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(6): 934-938.

[13] KIVIKYT?-REPONEN P, ALA-KLEME S, HELLMAN J, LIIMATAINENA J, HANNULAB S P. The correlation of material characteristics and wear in a laboratory scale cone crusher[J]. Wear, 2009, 267(1/4): 568-575.

[14] ANTHONYSAMY S, ANANTHASIVAN K, KALIAPPAN I, KALIAPPAN I, CHANDRAMOULI V, VASUDEVA RAO P, MATHEWS C, JACOB K. Gibbs energies of formation of chromium carbides[J]. Metallurgical and Materials Transactions A, 1996, 27(7): 1919-1924.

[15] 孙承纬. 激光辐照效应[M]. 北京: 国防工业出版社, 2002.

SUN Cheng-wei. Laser radiation effects[M]. Beijing: National Defence Industry Press, 2002.

[16] BETTS J C. The direct laser deposition of AISI316 stainless steel and Cr3C2 powder[J]. Journal of Materials Processing Technology, 2009, 209(11): 5229-5238.

(编辑 李艳红)

基金项目:中国博士后科学基金资助项目(20100471383);中国博士后科学基金特别资助项目(201104513);国家教育部博士点专项基金资助(20113227120006);江苏大学高级专业人才科研启动基金资助项目(10JDG048)

收稿日期:2011-07-26;修订日期:2011-12-26

通信作者:孙桂芳,讲师,博士;电话:0511-88797898;E-mail: gfsun82@gmail.com