文章编号: 1004-0609(2004)11-1906-06

Mn对Al-Mg-Si-Cu铝合金结晶相的影响

刘 宏1, 2, 刘艳华1, 赵 刚1, 刘春明1, 左 良1

(1. 东北大学 材料与冶金学院, 沈阳 110004; 2. 山东轻工业学院 机电工程学院, 济南 250100)

摘 要: 通过扫描电镜/能谱、 X射线衍射以及金相分析, 针对含0.3%Fe(质量分数)的Al-Mg-Si-Cu铝合金, 研究了Mn含量对其结晶相的影响。 研究表明: 合金在铸造过程中形成的结晶相为Al1.9CuMg4.1Si3.3, Al5(FeMn)Si, Al8(FeMn)2Si以及少量的Mg2Si; 增大含Mn量, 合金中AlFeMnSi型结晶相数量增多; 对合金进行均匀化处理时, Al1.9CuMg4.1Si3.3相完全溶解, 发生Al5(FeMn)Si向Al8(FeMn)2Si相的转变; 对合金进行轧制及最终热处理后, 结晶相碎化且沿轧向呈纤维状分布, 但结晶相的类型不变。

关键词: Al-Mg-Si-Cu铝合金; 结晶相; Al1.9CuMg4.1Si3.3; Al5FeSi; Al8Fe2Si 中图分类号: TG146.21

文献标识码: A

Effects of Mn on constituents of Al-Mg-Si-Cu alloys

LIU Hong1, 2, LIU Yan-hua1, ZHAO Gang1, LIU Chun-ming1, ZUO Liang1

(1. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China;

2. School of Mechanical and Electrical Engineering,Shandong Institute of Light Industry, Jinan 250100, China)

Abstract: By means of scanning electron microscope/energy spectrum, X-ray diffraction and metallographic analysis, the effect of Mn content on the constituents of Al-Mg-Si-Cu aluminium alloys containing 0.3%Fe (mass fraction) was studied. The results indicate that the constituents formed during cast of alloys are Al1.9CuMg4.1Si3.3, Al5- (FeMn)Si, Al8(FeMn)2Si and a little Mg2Si. With increment of Mn content, the number of the constituents of Al(FeMn)Si is increased. During homogenizing treatment, the Al1.9CuMg4.1Si3.3 phase dissolves completely, and the phase transformation of Al5(FeMn)Si to Al8(FeMn)2Si occurs. But the morphology and distribution have not variation. After rolling and final heat treatment, the constituents are crushed and distribute in continuous lines along rolling direction. However, types of the constituents vary no longer.

Key words: Al-Mg-Si-Cu aluminium alloys; constituents; Al1.9CuMg4.1Si3.3; Al5FeSi; Al8Fe2Si

工业Al-Mg-Si-Cu铝合金中常添加锰元素, 目的是在铸锭均匀化处理过程中形成细小的(粒径约0.1μm)弥散相粒子, 以阻碍合金的再结晶, 细化晶粒, 并且使滑移变形均匀, 提高合金的塑性[1, 2]。 而工业用Al-Mg-Si-Cu铝合金通常含有约0.3%(质量分数)的Fe, 铸造时极易形成粗大的(粒径大于1μm)结晶相, 对合金的塑性产生不利影响[3]。 但这类合金中若同时含有Mn , 则Mn会进入含Fe的结晶相中, 形成含Mn和Fe的结晶相[4]。 虽然关于Mn在铝合金中的作用已进行过大量的研究[5-7], 但Mn含量的变化对Al-Mg-Si-Cu铝合金结晶相影响的研究还不多见。

本工作的目的是针对工业用Al-Mg-Si-Cu铝合金通常的含Fe量范围, 研究Mn含量的变化对其结晶相的影响, 以便控制Mn与 Fe的配比, 从而有效地控制结晶相粒子的变化, 为提高合金的性能奠定基础。

1 实验

熔炼合金的原料为99.9 %高纯铝、 电解铜、 Mg-1纯镁以及Al-9.5%Si和Al-9%Mn中间合金, 并采用高纯铁箔增铁。 将上述原料按一定的添加顺序放入电阻坩埚炉中熔化, 然后在水冷铜模中浇铸成220mm×120mm ×20mm的铸锭, 其化学成分见表1。 其中4#合金为未增铁的合金。

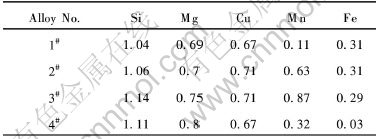

表1 合金的化学成分

Table 1 Chemical compositions of alloys (mass fraction, %)

铸锭经过470℃, 5h以及540℃, 16h的双级均匀化处理, 然后热轧和冷轧成1.2mm厚的薄板。 冷轧薄板的最终热处理为550℃、 30min固溶水淬, 170℃、 30min时效。

采用LEICA MPS30型金相显微镜观察合金组织中结晶相的分布, 用SSX-550扫描电镜及附带的DX-4型能谱仪研究合金中结晶相的形貌和成分, 并通过日本理学D/Max-YX射线衍射仪进行结构分析, 以确定结晶相的类型。

2 结果与分析

2.1 铸态组织中的结晶相

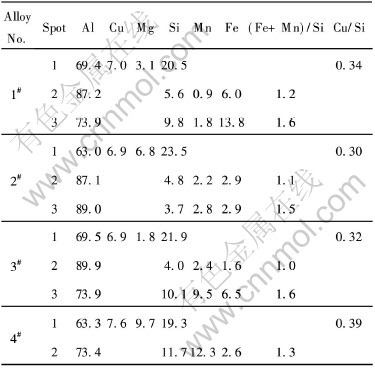

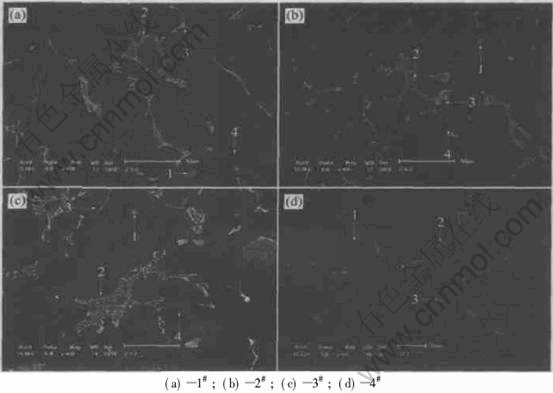

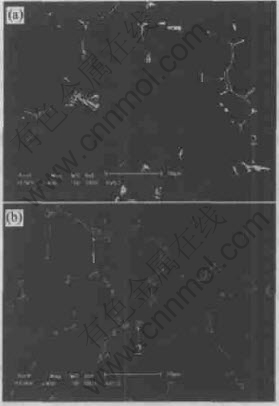

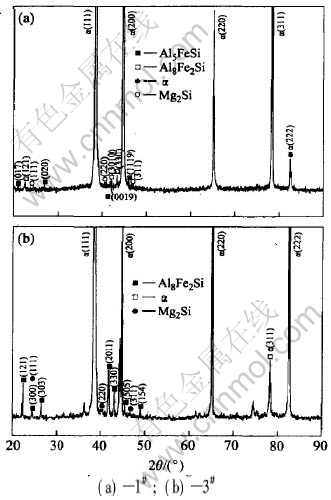

合金的铸态组织中存在大量的结晶相, 其数量随含Mn量的增加而增多。 结晶相的形态如图1所示, 具有不规则的条块状、 粒状和鱼骨状, 形成枝晶网。 表2中所列为图1所示的组织中具有代表性探测点的能谱分析结果, 合金的结晶相可大致分成含AlCuMgSi和含AlFeMnSi两大类。 X射线衍射分析结果(见图2)进一步证明, 它们主要为Al1.9CuMg4.1Si3.3以及Al5FeSi、 Al8Fe2Si 和Al4Mn3Si2型晶体相, 此外合金的铸态组织中还有极少量的Mg2Si相。

表2 合金铸态结晶相成分的扫描电镜能谱分析结果

Table 2 EDS analysis results of as-cast alloys(mole fraction, %)

根据能谱(EDS)分析及X射线衍射结果, 含AlCuMgSi型的结晶相为Al1.9CuMg4.1Si3.3, 也称作Q相(Al5Cu2Mg8Si6)[8, 9], 其形态呈颗粒状, 见图1(a)~(d)中的1点所示。 Mn含量的变化对这类结晶相的影响不大。

由图2可见, 1#~3#合金的X射线衍射谱中出现Al5FeSi和Al8Fe2Si相的特征峰, 这两种相中的Fe、 Si比值分别为1.0和2.0。 能谱分析结果证明, 1#~3#合金中不存在不含Mn的Al5FeSi和Al8Fe2Si结晶相, 所有含Fe、 Si结晶相均含Mn, 是含AlFeMnSi型结晶相。 这些结晶相中的Fe、 Si比值与Al5FeSi和Al8Fe2Si相的Fe、 Si比值相差较大, 但这些结晶相中的(Fe + Mn)与Si比值与Al5FeSi和Al8Fe2Si相的Fe、 Si比值接近, 说明在形成结晶相时, Mn有替代Fe的作用。 因此, 按(Fe+Mn)、 Si比值又可将1#~3#合金的结晶相分为两类: 一类为比值在1.5~2.2之间, 与报道的Al8Fe2Si相的Fe、 Si比值(1.5~2.0)[10, 11]相近, 可认为是Al8(FeMn)2Si相, 其形态呈不规则的条块状, 如图1(a)~(c)中的3点所示; 另一类为比值在1.0~1.3之间, 与Al5FeSi相的Fe、 Si比值相近的Al5(FeMn)Si相, 具有明显的共晶形态鱼骨状特征, 见图1(a)~(c)中的2点。

4#合金的Fe含量低于纯铝中的溶解度极限, 其铸态组织中未出现共晶形态鱼骨状结晶相, 其结晶相的形态为条状和小块状(见图1(d)中的2点)。该合金的X射线衍射谱中出现Al4Mn3Si2相的特征峰, 其中Mn/Si比值分别为1.5。 能谱分析结果证明, 4#合金中不存在不含Fe 的Al4Mn3Si2结晶相, 均为含AlMnFeSi型结晶相。 这些结晶相中的Mn/Si比值与Al4Mn3Si2相的Mn/Si比值相差较大, 但这些结晶相中的(Mn + Fe)与Si比值和Al4Mn3Si2相的Mn/Si比值接近, 说明在形成结晶相时, Fe有替代Mn的作用, 铸造时微量Fe溶入Al4Mn3Si2形成Al4(MnFe)3Si2相。 综合Mn在Al5FeSi和Al8Fe2Si型结晶相以及Fe在Al4Mn3Si2型结晶相中的作用, 可以证明在形成结晶相时, Mn与Fe有相互替代作用。

图1 合金铸态组织的扫描电镜照片

Fig.1 SEM photographs of microstructures of as-cast alloys

图2 合金铸态下的X射线衍射结果

Fig.2 X-ray diffraction profiles of as-cast alloys

对于4#合金, 由于在共晶温度下, Mn和Si在Al中均有较高的溶解度, 形成Al4Mn3Si2型结晶相的体积分数较小, 铸造时容易产生离异共晶, 因此合金中结晶相未表现出共晶的鱼骨状形态。

合金中只有极少量的Mg2Si结晶相, 但X射线衍射谱中存在Mg2Si衍射峰, 这可能是由于在铸造过程中析出了Mg2Si强化相, 尺寸较小, 在500倍放大倍数下观察不到该析出相的存在。

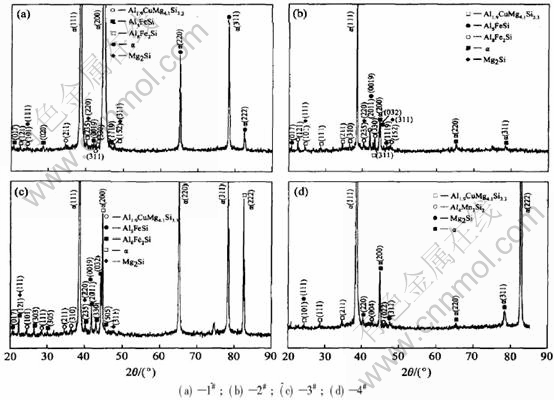

2.2 均匀化组织中的结晶相

1#和3#合金铸锭经均匀化处理后的扫描电镜组织如图3所示。 可见, 圆点状Q相完全溶解, 具有共晶形态的鱼骨状结晶相明显细化。 能谱分析结果证明剩余的结晶相主要为含AlFeMnSi型结晶相(如图3(a)和(b)中的1点)。 均匀化处理后, 部分剩余结晶相的(Fe+Mn)与Si比值发生变化, 由铸态的1.0~1.3变成了1.5~2.2, 但具有不规则条块状的含AlFeMnSi型结晶相(见图3(a)和(b)中的2点)的(Fe+Mn)与Si比值没有改变。 结合X射线衍射结果(见图4), 含AlFeMnSi型结晶相仍为Al5(FeMn)Si和Al8(FeMn)2Si, 此外还有少量的Mg2Si相。 与铸态相比1#合金Al5FeSi相的(017)和(020)特征峰在均匀化处理后减弱, 3#合金Al5FeSi相的特征峰消失, 且只出现Al8Fe2Si相特征峰, 说明在均匀化处理过程发生了Al5(FeMn)Si向Al8(FeMn)2Si的转变, 而且具有较高Mn含量的3#合金的Al5(FeMn)Si相完全转变为Al8(FeMn)2Si相。

根据Al-Fe-Si系富Al角处的液相面投影图[12]可知, FeSiAl5结晶相是比Fe2SiAl8温度更低的结晶产物。 由于铸造过程冷却速度较快, 合金发生非平衡凝固, 使合金中出现较多的低温结晶产物, 即Al5FeSi型结晶相。 随Fe、 Si比值升高其体积分数变小, 当Fe与Si比值升高到一定程度时, 合金的平衡组织中将不出现Al5FeSi结晶相。

图3 合金均匀化处理后的扫描电镜照片

Fig.3 SEM photographs of alloys after homogenization

图4 合金均匀化处理后的X射线衍射结果

Fig.4 X-ray diffraction profiles of alloys after homogenization

由于Mn有替代Fe的作用, 在讨论结晶相类型时, 可以用 (Mn+Fe)与Si的比值代替Fe与Si的比值。 在均匀化处理过程, 非平衡的Al5FeSi型结晶相要向平衡的Fe2SiAl8型结晶相状转变, 导致1#合金的Al5(FeMn)Si型结晶相数量减少。 3#合金的Mn含量较高, (Mn+Fe)与Si的比值较高, 合金的平衡组织中可能不出现Al5FeSi型结晶相。 因此该合金铸锭均匀化处理后组织中的Al5FeSi型结晶相基本消失, 转变成Al8Fe2Si型结晶相(即Al5(FeMn)Si转变成Al8(FeMn)2Si相)。

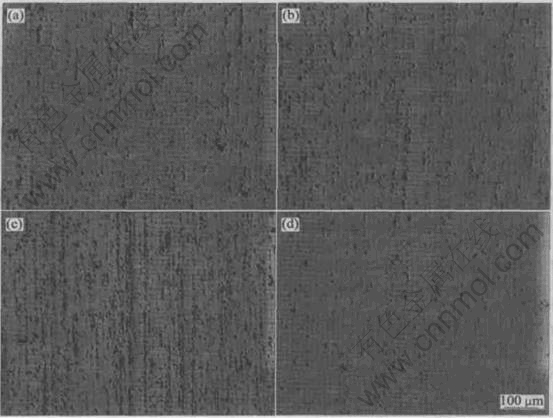

2.3 最终热处理后的结晶相

将均匀化处理后的铸锭经过热轧和冷轧加工制成板材, 再进行最终的550℃、 30min固溶水淬和170℃、 30min时效处理。 其金相显微组织如图5所示。 可见板材中的结晶相完全碎化, 并沿轧向呈纤维状分布。 扫描电镜能谱分析结果表明: 与均匀化处理后铸锭中的结晶相相比, 合金经轧制和最终热处理后, 其结晶相的类型未发生变化。

3 结论

1) Al-0.7 Mg-1.0 Si-0.7 Cu-(0.1 ~0.9 )Mn-0.3%Fe (质量分数)铝合金在铸造过程中形成的结晶相为Al1.9CuMg4.1Si3.3、 Al5(FeMn)Si、 Al8- (FeMn)2Si以及少量的Mg2Si。 在均匀化处理过程中, Al1.9CuMg4.1Si3.3相完全溶解, 并且发生Al5(FeMn)Si向Al8(FeMn)2Si相的转变, 当Mn含量很高时, Al5(FeMn)Si结晶相可完全消失。

2) 铸态组织中的Al1.9CuMg4.1Si3.3结晶相呈颗粒状, Al5(FeMn)Si具有共晶形态鱼骨状特征, 而Al8(FeMn)2Si则为不规则的条块状。

3) 在形成结晶相时, Mn与Fe有相互替代作用, 随Mn含量增加, 合金中含AlFeMnSi型结晶相增多。

4) 合金经热轧和冷轧加工后, 结晶相碎化且沿轧向呈纤维状分布。 在随后的固溶处理和时效过程中, 其结晶相的类型不发生变化。

(a)—1#; (b)—2#; (c)—3#; (d)—4#

图5 合金板材经最终固溶处理时效后的金相组织

Fig.5 Optical microstructures of alloy sheets after aging and solution treatment

REFERENCES

[1]潘青林, 李绍禄, 邹景霞, 等. 微量Mn对Al-Mg-Si合金微观组织与拉伸性能的影响[J]. 中国有色金属学报, 2002, 12(5): 972-976.

PAN Qing-lin, LI Shao-lu, ZOU Jing-xia, et al. Effect of minor manganese addition on microstructures and tensile properties of Al-Mg-Si alloys[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(5): 972-976.

[2]Burger G, Gupta A K, Sutak L, et al. Recrystallization in A 6000-series automotive sheet alloy during solution heat treatment practice[J]. Materials Science Forum, 1996, 217-222: 471-478.

[3]Hidetoshi U, Sei-ichi H, Hideo Y. Effect of manganese on n value of Al-Mg-Si alloys[J]. Sumitomo Light Met Tech Rep, 1997, 38(1): 1.

[4]Zhuang L, Bottema J, Kaasenbrood P, et al. The effect of small particles on annealed grain size and texture of Al-Mg-Si Alloys [J]. Materials Science Forum, 1996, 217-222: 487-492.

[5]Lee D H, Park J H, Nam S W, et al. Enhancement of mechanical properties of Al-Mg-Si alloys by means of manganese dispersoids [J]. Materials Science and Technology, 1999, 15 (4): 450-455.

[6]Dowling J M, Martin J W. The influence of Mn additions on the deformation behaviour of an Al-Mg-Si alloy [J]. Acta Metallurgica, 1976, 24: 1147-1153.

[7]Lodgaard L, Ryum N. Precipitation of dispersoids containing Mn and/or Cr in Al-Mg-Si alloys [J]. Matter Sci Eng A, 2000, A283: 144-152.

[8]Vaumousse D, Cerezo A, Warren P J, et al. An atom probe study of fine scale structure in AlMgSi(Cu) alloys [J]. Materials Science Forum, 2002, 396-402: 693-698.

[9]Chen X G, Langlais J. Solidification behavior of AA6111 automotive alloy[J]. Materials Science Forum, 2002, 331-337: 215-222.

[10]Claves S R, Elias D L, Misiolek W Z. Analysis of the intermetallic phase transformation occurring during homogenization of 6XXX aluminum alloys [J]. Materials Science Forum, 2002, 396-402: 667-674.

[11]Kulunk B, Zuliani D J. Application for the strontium treatment of wrought and die-cast Al [J]. JOM, 1996, 48 (10): 60.

[12]王祝堂, 田荣璋. 铝合金及其加工手册 [M]. 长沙: 中南工业大学出版社, 1988. 9-57.

WANG Zhu-tang, TIAN Rong-zhang. Aluminium Alloys and Their Machining Handbook [M]. Changsha: Central South University of Technology Press, 1988. 9-57.

基金项目: 教育部科学技术研究重大项目(0208); 国家高技术研究发展计划资助项目(2002AA331050); 国家教育部高等学校优秀青年教师教学科研奖励计划资助项目

收稿日期: 2004-02-00; 修订日期: 2004-09-03

作者简介: 刘 宏(1959-), 女, 博士研究生, 副教授.

通讯作者: 赵 刚, 教授; 电话: 024-83681685

(编辑龙怀中)