面齿轮磨削仿真及齿面误差分析

何国旗1, 2,严宏志1,何瑛3,舒陶量2,任行丽2

(1. 中南大学 机电工程学院,高性能复杂制造国家重点实验室,湖南 长沙,410083;

2. 湖南工业大学 机械工程学院,湖南 株洲,412007;

3. 湖南理工职业技术学院 资源工程系,湖南 湘潭,411104)

摘要:为了研究经蜗杆砂轮磨削后的面齿轮齿面误差对其啮合性能的影响,运用CATIA二次开发设计面齿轮插齿及磨齿的仿真流程,并对面齿轮插齿及齿面磨削进行加工仿真,得到经插齿和磨齿的面齿轮齿面,并对磨齿后面齿轮齿面接触和误差进行仿真。同时,加工出一定参数的面齿轮,对其啮合性能进行实验测试。通过传动误差分析,发现经蜗杆砂轮磨削的面齿轮比经插齿得到的面齿轮啮合性能要优越,因此,磨削后的齿面误差对其啮合性能影响可以忽略。

关键词:面齿轮加工仿真;齿面磨削;齿面接触;传动误差

中图分类号:TH132.4 文献标志码:A 文章编号:1672-7207(2014)07-2193-08

Face-gear grinding simulation and tooth surface error analysis

HE Guoqi1, 2, YAN Hongzhi1, HE Ying3, SHU Taoliang2, REN Xingli2

(1. State Key Laboratory of High-Performance Complex Manufacturing,

School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China;

2. School of Mechanical Engineering, Hunan University of Technology, Zhuzhou 412007, China;

3. Department of Resources Engineering, Hunan Vocational Institute of Technology, Xiangtan 411104, China)

Abstract: In order to study the influence of ground face-gear tooth surface error on meshing performance, the simulation procedure of face-gear’s shaping and grinding was designed using the further development of CATIA. And a machining simulation on face-gear shaping and tooth surface grinding with the use of CATIA was conducted. A tooth surface can be obtained through shaping and grinding, and then simulations were conducted on the tooth contact and error of ground face-gear. A face-gear was manufactured with certain parameters, and then an experiment test on its meshing performance was conducted. Through analyzing transmission errors, it is found that the meshing performance of the ground face-gear is superior to that manufactured by gear shaper. Therefore, the impacts of tooth surface errors due to grinding on meshing performance can be ignored.

Key words: machining simulation of face-gears; tooth surface grinding; tooth contact; transmission error

面齿轮在分流-汇流传动方面的独特性,使其将逐步替代螺旋锥齿轮而成为武装直升机传动系统中最重要的核心零件[1-2]。国内外学者对面齿轮在切齿及磨齿加工等方面进行了相关的研究工作[3-7]。20世纪中期,Miller等[2, 4]最早提出采用滚齿的方法来加工面齿轮,该方法虽然保证了面齿轮滚刀的齿廓截面为渐开线,但并不能保证滚刀基蜗杆曲面的准确性,加工得到的面齿轮齿形与理论偏差较大。Litivin等[3, 5-9]发明插齿及磨齿的方法。李政民卿等[10-12]对面齿轮进行研究,并且成功研制出我国第一台直齿面齿轮插齿机床。姬存强等[13-16]也在进行面齿轮加工试验的研究。由于面齿轮齿面方程复杂,直接由面齿轮齿面方程来推导蜗杆砂轮齿面方程难以实现。磨削前的面齿轮齿面先由加工面齿轮的圆柱齿轮插齿刀(以下简称为插齿刀)经展成法而成,而面齿轮磨削加工过程中受径向进给和展成运动2个因素的影响,因此,通过包络磨削后得到的面齿轮与通过插齿原理得到的面齿轮理论齿廓产生一定的偏差。那么,经蜗杆砂轮磨削后的面齿轮齿面误差有多大?对面齿轮啮合性能有多大的影响?到目前为止,还没有相关报道。本文作者通过对面齿轮的插齿和磨齿加工的仿真研究,并对磨削后的面齿轮齿面进行接触仿真分析,同时对经插齿和磨齿的面齿轮进行啮合实验,就面齿轮磨削齿面误差对其啮合性能的影响进行分析。

1 面齿轮加工理论基础

1.1 面齿轮插齿理论基础

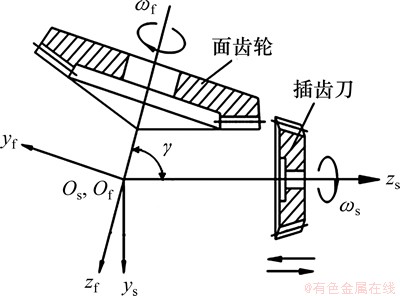

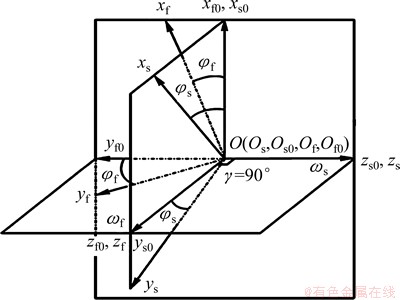

面齿轮插齿加工示意图如图1所示,当面齿轮轴线与插齿刀轴线夹角γ=90°时,得到面齿轮加工坐标系示意图如图2所示。图中:z f0(zf)与zs0(zs)分别为面齿轮与插齿刀具的旋转轴,两轴线的交点为坐标原点;坐标系Sf0:Of0xf0yf0zf0与坐标系Sf:Ofxfyfzf分别为面齿轮的固定坐标系和转动坐标系;坐标系Ss0:Os0xs0ys0zs0与坐标系Ss:Osxsyszs为插齿刀具的固定与转动系;φf与φs分别为运动中面齿轮和插齿刀转过的角度。

图1 面齿轮插齿加工示意图

Fig. 1 Schematic diagram for face-gear shaping

图2 插齿加工面齿轮坐标系示意图

Fig. 2 Schematic diagram of coordinate system for face-gear shaping

通过坐标转换,最终可得到面齿轮的齿面方程如下[3-7]:

(1)

(1)

式中:rbs为插齿刀基圆半径;m为插齿刀模数; 为插齿刀渐开线上一点的角度参数。

为插齿刀渐开线上一点的角度参数。

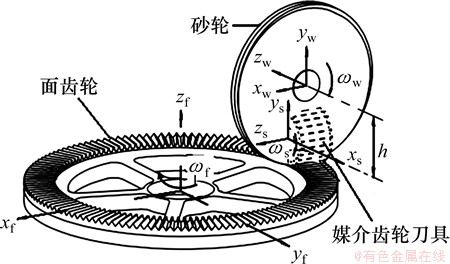

1.2 面齿轮齿面磨削理论基础

图3所示为面齿轮、蜗杆砂轮及媒介齿轮啮合示意图。

图3 面齿轮、蜗杆砂轮及媒介齿轮啮合示意图

Fig. 3 Schematic diagram of meshing of face-gear, worm grinding wheel and media gear

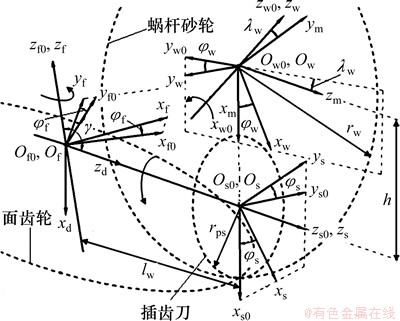

图4所示为蜗杆砂轮、插齿刀、面齿轮运动时的坐标系。对加工面齿轮所用的刀具S和砂轮W建立4个坐标系:两者在初始固定位置时的2个固定坐标系Ss0:Os0xs0ys0zs0和Sw0:O w0xw0yw0zw0;两者传动时的2个运动坐标系Ss:Osxsyszs和Sw:Owxwywzw。

图4 面齿轮与蜗杆砂轮、插齿刀三者的啮合坐标系

Fig. 4 Coordinate system of meshing of face-gear, worm grinding wheel and shaping cutter

蜗杆砂轮与刀具间的啮合方程为:

(2)

(2)

刀具齿面方程为:

(3)

(3)

可得圆柱齿轮刀具齿面单位法向量为:

(4)

(4)

式中:rm为插齿刀具分度圆半径; 和um为插齿刀具渐开线齿面参数。

和um为插齿刀具渐开线齿面参数。

结合式(2),(3)及(4)得蜗杆砂轮的导程角[4]:

(5)

(5)

式中:h为基蜗杆轴线与插齿刀具轴线的最短距离;nm为插齿刀具齿数。

2 面齿轮加工几何仿真

2.1 面齿轮插齿加工几何仿真

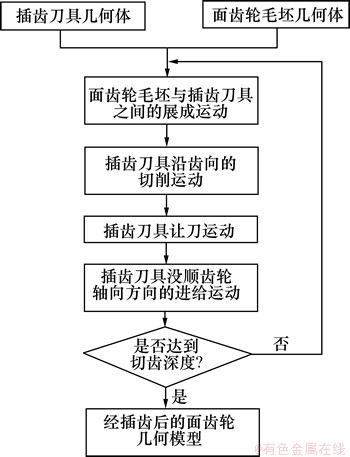

用CATIA二次开发进行面齿轮的插齿加工仿真时,保留一定的轴向加工余量,得到磨齿加工面齿轮的初始工件模型。实际加工过程中,刀具分多次沿面齿轮轴向进给达到所需切削深度,为了方便,将刀具一次性进给到所需的轴向深度。

面齿轮插齿仿真流程图如图5所示。首先建立插齿刀具几何体模型,可以在CATIA中直接建模,也可以通过导入外部数据得到刀具实体模型,对刀具几何体绕其轴旋转1个角度k×40/20。然后插入几何体,创建面齿轮毛坯,采用CATIA创成式外形设计,在面齿轮毛坯模型中生成一根几何中心轴,并将面齿轮毛坯绕轴旋转1个角度k。然后对毛坯几何体和刀具几何体进行布尔差运算,去除刀具几何体。进行第2个布尔运算时,新建1个刀具几何体,将刀具几何体绕其轴旋转1个角度2×k×40/20,将第一个布尔切齿得到的毛坯模型旋转1个角度k,然后再进行布尔差运算,按此方法,在进行第i个布尔运算时,将第i次新建的刀具几何体绕其轴旋转一个角度i×k×40/20,将第i-1次布尔切齿得到的面齿轮毛坯模型绕其轴旋转1个角度k,每次都用面齿轮毛坯模型移除新建刀具几何体,这样可以实现连续切齿运动,去除面齿轮毛坯上与刀具重合的材料。

图5 面齿轮插齿仿真流程图

Fig. 5 Simulation procedure schema of face-gear shaping

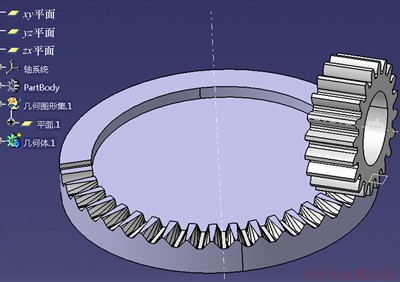

循环切齿可以在CATIA的宏中运用循环语句得以实现,首先启动CATIA中的宏录制,在第1个布尔运算完后终止宏的录制,然后对得到的宏进行编辑,将旋转角度k作为离散变量,采用for......next循环语句便可实现循环切齿,插齿仿真示意图如图6所示。

图6 面齿轮插齿仿真示意图

Fig. 6 Schematic diagram of simulation of face-gear shaping

2.2 面齿轮磨齿加工几何仿真

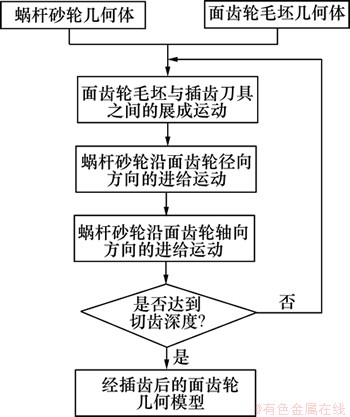

磨齿加工仿真也是运用了布尔运算进行运动切齿,砂轮与面齿轮工件在展成运动的同时,工件相对砂轮还有2个方向的进给,一个是相对于面齿轮的径向方向,另一个相对于面齿轮的轴向方向。为了方便,可将刀具一次性进给到所需的面齿轮轴向深度,这样在编辑切齿程序时,只需要离散2个变量,一个是角度变量d,另一个是径向进给变量i,磨齿加工仿真流程如图7所示。

图7 面齿轮磨齿仿真流程图

Fig. 7 Simulation procedure schema of face-gear grinding

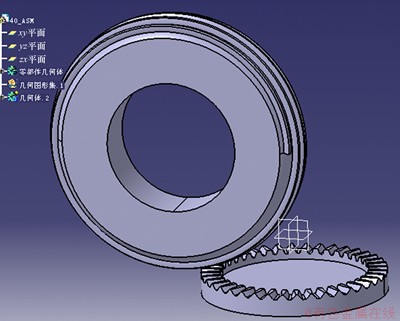

面齿轮工件及蜗杆砂轮几何体的生成:面齿轮与蜗杆砂轮在磨齿加工之前具有一定的位置关系,因此可先将插齿得到的面齿轮与蜗杆砂轮按一定的位置关系进行装配,得到面齿轮与蜗杆砂轮的啮合模型如图8所示。将装配后的组件保存为CATIA能读取的数据格式(如IGS格式),在CATIA软件中打开该组件后,分别新建几何体,然后复制组件中的面齿轮和砂轮实体作为切齿的毛坯和刀具。

图8 蜗杆砂轮与面齿轮啮合装配模型

Fig. 8 Assembly model of worm grinding wheel and face-gear meshing

磨齿布尔切齿的实现:磨齿布尔切齿与插齿一样,在进行切齿时,运用2个嵌套的for......next语句控制进给和角度变量。设一次进给条件下,进行一次转动的全循环,这样便可实现循环切齿。每次布尔去除刀具几何体后,新建几何体,然后复制组件中的刀具实体。面齿轮与蜗杆砂轮的旋转角度成一定的比例

,即面齿轮工件旋转角度为d,蜗杆砂轮的旋转角度为

,即面齿轮工件旋转角度为d,蜗杆砂轮的旋转角度为 。

。

3 面齿轮磨削齿面接触及误差分析

3.1 面齿轮加工齿面接触仿真

设加工面齿轮的插齿刀具模数m=5 mm,齿数为ns=20,压力角 ;蜗杆头数Nw=1,右旋,导程角

;蜗杆头数Nw=1,右旋,导程角 ,面齿轮齿数为40,面齿轮轴线与插齿刀轴线交角

,面齿轮齿数为40,面齿轮轴线与插齿刀轴线交角 。

。

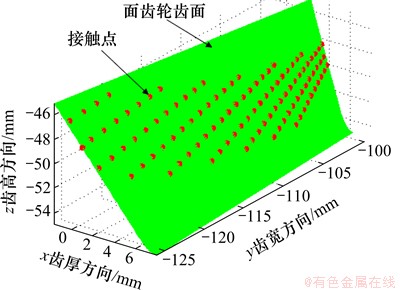

磨齿时蜗杆与面齿轮齿面的接触轨迹仿真如图9所示,图9中“面齿轮齿面”为通过插齿刀包络所得的曲面,“接触点”为蜗杆砂轮磨削齿面过程中与齿面的接触点。

从图9可以看出:面齿轮与蜗杆砂轮的啮合点都位于通过插齿刀包络所得的面齿轮齿面上,说明通过以蜗杆砂轮为基础进行磨齿加工所得的面齿轮齿面与插齿加工所得的面齿轮齿面是一致的。

图9 蜗杆砂轮磨削面齿轮齿面的接触轨迹

Fig. 9 Contact trace of face-gear ground by worm grinding wheel

3.2 面齿轮齿面磨削误差分析

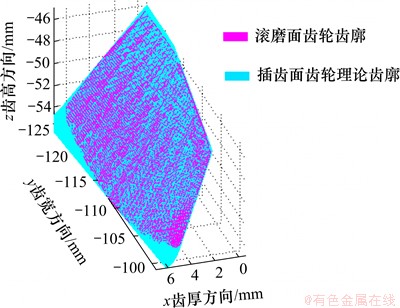

将磨削面齿轮齿廓与前面根据插齿原理得到的面齿轮齿廓进行比较,得到的结果如图10所示。由图10可以看出:基于磨削加工得到的面齿轮工作齿面非常接近于插齿理论齿廓,磨削面齿轮齿廓位于插齿理论齿廓一侧,两齿面没有相交并且间距非常小,因此,仅仅从图10中两者的差距看,其视觉效果并不容易判别。

图10 磨削与插削面齿轮齿面比较

Fig. 10 Comparison of face-gear tooth surface grinding and shaping

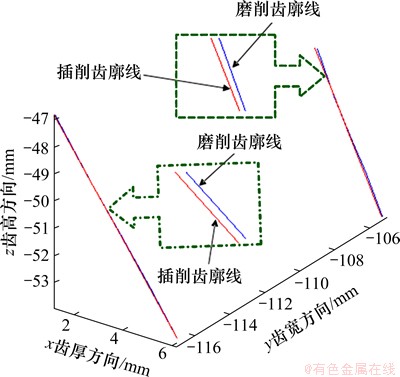

为了更准确地将两齿廓进行比较,得到磨削面齿轮齿面与插齿理论面齿轮齿廓之间的偏差,可提取齿面数据点进行比较,根据齿面计算方法可以取不同的径向参数(齿宽方向)下的齿面系列点进行比较,可以得到2种方法下齿面数据点的偏差。

本文选取沿齿宽方向的2个不同y值上的系列点,每一个系列选取5个点。得到的点如下:

第一系列(y=-105):

在插削面齿轮齿廓上的点:A1(5.979 8,-105,-53.974 0),B1(5.290 9,-105,-52.604 5),C1(4.658 2,-105,-51.342 9),D1(4.033 5,-105,-50.091 5),E1(3.270 5,-105,-48.552 2)。

在磨削面齿轮齿廓上的点:A1′(5.998 4,-105,-53.974 5),B1′(5.383 7,-105,-52.603 4),C1′(4.704 8,-105,-51.342 6),D1′(4.052 7,-105,-50.116 3),E1′(3.349 6,-105,-48.551 6)。

第二系列(y=-117)

在插削面齿轮齿廓上的点:A2(6.184 4,-117,-53.651 3),B2(5.058 7,-117,-52.130 1),C2(3.845 0,-117,-50.483 3),D2(2.746 8,-117,-48.987 4),E2(1.176 2,-117,-46.838 4)。

在磨削面齿轮齿廓上的点:A2′(6.193 2,-117,-53.650 8),B2′(5.094 6,-117,-52.130 9),C2′(3.875 3,-117,-50.484 1),D2′(2.751 3,-117,-48.988 1),E2′(1.180 2,-117,-46.837 9)。

从齿廓上系列点进行比较看出:磨削面齿轮齿廓与插齿理论齿廓偏差很小,将系列点组成的空间曲线在MATLAB7.0中进行可视化得到的结果如图11所示。

图11 磨削与插削面齿轮齿廓线误差

Fig. 11 Errors of face-gear tooth profile grinding and shaping

4 面齿轮传动误差实验分析

4.1 实验准备

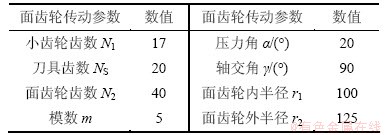

为了验证以上理论分析和有限元计算的正确性,对面齿轮啮合性能进行实验测试。为此,加工出如表1所示参数的面齿轮,加工好的面齿轮如图12所示。图13所示为经插齿后的面齿轮局部图,图14所示为经蜗杆砂轮磨削后的面齿轮局部图。

表1 实验用面齿轮参数

Table 1 Face-gear parameters in experiments

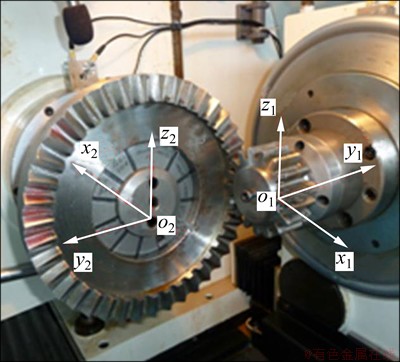

将小齿轮及面齿轮安装在面齿轮啮合检测机上,调整检测机Y轴,使主动轮和从动轮轴线位于同一水平面,夹紧工件,然后根据计算的安装距调整机床X轴和Z轴,面齿轮检测安装如图15所示。

图12 加工好的面齿轮

Fig. 12 A machined face-gear

图13 经插齿得到的面齿轮

Fig. 13 Face-gear machined by shaping

图14 经磨齿得到的面齿轮

Fig. 14 Face-gear machined by grinding

图15 小齿轮和面齿轮安装图

Fig. 15 Installation of pinion and face-gear

4.2 传动误差分析

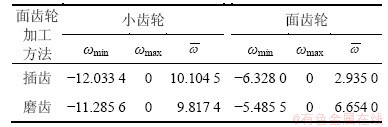

小齿轮齿数为17,面齿轮齿数为40,在不加载荷情况下调节转速,当速度稳定后开始采集数据。分别对经插齿和磨齿的面齿轮进行啮合实验,测试结束后,可以直接从数据采集面板上读出测试结果,通过对插齿和磨齿的面齿轮进行啮合实验后所得的小齿轮和面齿轮角速度的测量值如表2所示。

表2 面齿轮啮合角速度测试结果

Table 2 Test results of face-gear meshing angular velocity rad/s

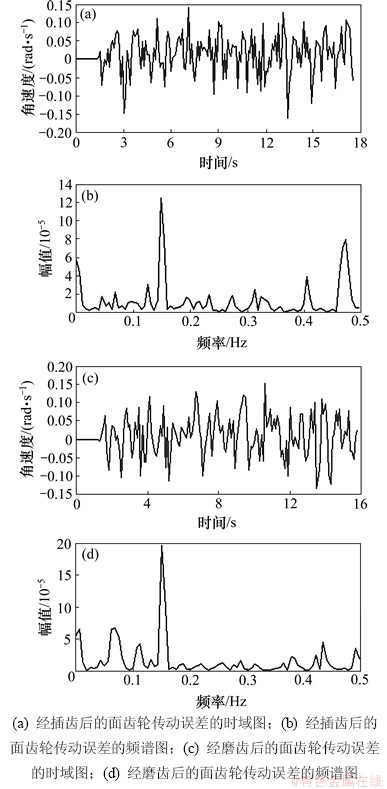

测试系统根据测得的角速度自动计算传动误差,经插齿后的面齿轮传动误差的时域图和频谱图,分别如图16(a)和(b)所示。根据测得的数据,传动误差的最大值和最小值分别为0.164 4和-1.954 6,其平均值为 0.064 7。传动误差的基频为1.487 4,1次谐波、2次谐波和3次谐波分别为0.033 9,0.008 9和0.004 7。

更换经磨齿后的面齿轮,面齿轮齿数仍为40,此时小齿轮和面齿轮角速度的测量值如表2所示。根据测得的数据,此时传动误差的最大值和最小值分别为0.152 6和-1.133 5,其平均值为0.043 5。传动误差的基频为1.525 2,1次谐波、2次谐波和3次谐波分别为0.042 1,0.015 9和0.006 1。图16(c)和(d)所示分别为经磨齿后的面齿轮传动误差的时域图和频谱图。通过计算可得,经插齿和磨齿的面齿轮传动误差平均值分别为0.065 5和0.042 6,由此可见,经过磨齿后的面齿轮比经过插齿后的面齿轮传动误差有所降低。因此,通过蜗杆砂轮磨削后面齿轮造成的齿面误差对其啮合性能的影响可以忽略。

图16 传动误差时域图和频谱图

Fig. 16 Transmission error waves in time domain and frequency domain

5 结论

(1) 通过对面齿轮的插齿、磨齿进行加工仿真及蜗杆砂轮与面齿轮的接触分析,并对磨削后的面齿轮齿面误差进行分析。同时用插齿和磨齿的方法加工出相应参数的面齿轮,分别对经插齿和磨齿的面齿轮进行啮合实验,并对磨削后齿面误差对其啮合性能的影响进行分析。

(2) 经过磨齿后的面齿轮比经过插齿后的面齿轮传动误差不但没有增加,反而有所降低。由此说明,通过蜗杆砂轮磨削后的面齿轮造成的齿面误差对其啮合性能的影响可以忽略不计。

参考文献:

[1] 朱如鹏, 高德平. 在面齿轮设计中避免根切和齿顶变尖的设计方法的研究[J]. 中国机械工程, 1999, 10(11): 1274-1276.

ZHU Rupeng, GAO Deping. Study on the method of avoiding dedendum undercutting and addendum pointing in face gear design[J]. China Mechanical Engineering, 1999, 10(11): 1274-1276.

[2] Miller E, Sturmfels B. Combinatorial commutative algebra[M]. Heidelberg: Springer Verlag, 2005: 112-124.

[3] Litvin F L, Wang J C, Bossler R B Jr, et a1. Application of face-gear drives in helicopter transmissions[J]. ASME Journal of Mechanical Design, 1994, 116(3): 672-676.

[4] Guing M, de Vaujany J P, Jacquin C Y. Quasi-static analysis of a face gear under torque[J]. Compute Methods Appl Mech Engrg, 2005, 194: 4301-4318.

[5] Litvin F L, Fuentes A, Zanzi C, et al. Design, generation, and stress analysis of two versions of geometry of face-gear drives[J]. Mechanism and Machine Theory, 2002, 37: 1179-1211.

[6] Litvin F L, Gonzalez-Percz I, Fuentes A, et al. Design, generation and stress analysis of face-gear drive with helical pinion[J]. Compute Methods Appl Mech Engrg, 2005, 194: 3870-3901.

[7] Litvin F L, Zhang Y, Wang J C, et a1. Design and geometry of face-gear drives[J]. ASME Journal of Mechanical Design, 1992, 114(4): 642-647.

[8] Litvin F L, Fuentes A, Zanzi C, et al. Face-gear drive with spur involute pinion: Geometry, generation by a worm, stress analysis[J]. Computer Methods in Applied Mechanics and Engineering, 2002, 191(25/26): 2785-2813.

[9] Taburdagitan M, Akkok E. Determination of surface temperature rise with thermoelastic analysis of spur gears[J]. Wear, 2006, 261: 656-665.

[10] 李政民卿, 朱如鹏. 面齿轮插齿加工过程包络面和理论齿面的干涉[J]. 重庆大学学报(自然科学版), 2007, 30(7): 55-58.

LI Zhengminqing, ZHU Rupeng. Process method of face-gear drive with spur involute pinion with the shaping machine[J]. Journal of Chongqing University (Natural Science Edition), 2007, 30(7): 55-58.

[11] 朱如鹏, 潘升材, 高德平. 正交面齿轮传动中齿宽设计的研究[J]. 机械科学与技术, 1999, 18(4): 566-569.

ZHU Rupeng, PAN Shengcai, GAO Deping. Study of the design of tooth width of right shaft angle face gear drive[J]. Mechanical Science and Technology, 1999, 18(4): 566-569.

[12] 沈云波, 方宗德, 赵宁, 等. 斜齿面齿轮几何传动误差的设计[J]. 航空动力学报, 2008, 23(11): 2145-2152.

SHEN Yunbo, FANG Zongde, ZHAO Ning, et al. Design of geometry transmission errors of helical face gear drive[J]. Journal of Aerospace Power, 2008, 23(11): 2147-2152.

[13] 姬存强, 魏冰阳, 邓效忠, 等. 正交面齿轮的设计与插齿加工试验[J]. 机械传动, 2010, 34(2): 58-61.

JI Cunqiang, WEI Bingyang, DENG Xiaozhong, et al. Design and gear shaping experiment on orthogonal face gear[J]. Journal of Mechanical Transmission, 2010, 34(2): 58-61.

[14] 高金忠. 面齿轮滚磨刀具设计与修整方法研究[D]. 南京: 南京航空航天大学机电学院, 2011: 20-30.

GAO Jingzhong. Research on structure design and dressing method of hobbing or grinding worm for manufacturing face gear[D]. Nanjing: Nanjing University of Aeronautics and Astronautics. College of Mechanical and Electrical Engineering, 2011: 20-30.

[15] 邓效忠, 徐爱军, 张静, 等. 齿距啮合偏差对准双曲面齿轮传动误差的影响[J]. 航空动力学报, 2013, 28(3): 595-602.

DENG Xiaozhong, XU Aijun, ZHANG Jing, et al. Effect of meshed pitch deviation on transmission error in hypoid gears[J]. Journal of Aerospace Power, 2013, 28(3): 597-602.

[16] 聂少武, 邓效忠, 苏建新, 等. 摆线齿锥齿轮齿面修形仿真及高阶传动误差设计[J]. 机械设计, 2013, 30(5): 32-37.

NIE Shaowu, DENG Xiaozhong, SU Jianxin, et al. Flank modification simulation and high-order transmission error design for epicycloid bevel gears[J]. Journal of Machine Design, 2013, 30(5): 32-37.

(编辑 杨幼平)

收稿日期:2013-07-29;修回日期:2013-10-16

基金项目:国家重点基础发展计划(“973”计划)项目(2011CB706800);国家自然科学基金资助项目(51375159);教育部高等学校博士学科点专项科研基金资助项目(20120162110004);湖南省高等学校科学研究项目(12A038,13C379)

通信作者:严宏志(1964-),男,湖南安乡人,教授,博士生导师,从事数字化制造理论与技术研究;电话:0731-88876612;E-mail: yhzcsu@163.com