基于PLC的灌浆压力自动控制系统设计与试验研究

王超1,徐力生1,徐蒙1,姚翠霞1,黄辉1, 2

(1. 中南大学 地球科学与信息物理学院,有色金属成矿预测教育部重点实验室,湖南 长沙,410083;

2. 云南华电怒江水电开发有限公司,云南 昆明,650228)

摘要:针对灌浆压力易受被灌地层复杂地质条件、灌浆设备结构形式和人工控制滞后性等因素影响而发生大范围波动的问题,为了实现灌浆压力的动态检测和自动控制,以可编程逻辑控制器(PLC)、压阻式压力传感器、伺服电机、驱动器、减速机和电动调节阀等作为核心部件,基于参数自整定模糊PID控制算法编写控制程序,设计灌浆压力自动控制系统。该系统通过对压力传感器的反馈压力进行闭环周期修正,控制伺服电机的正、反转来调整阀门开度使压力保持稳定。研究结果表明:当灌浆压力在0~5 MPa内变化时,灌浆压力自动控制系统可在5~6 s的响应时间内实现压力自动控制,并将控制精度保持在压力设定值的5%以内,稳定性良好,其控制性能优于现行人工控制模式,满足现场灌浆施工的需要。

关键词:灌浆;压力波动;可编程逻辑控制器;模糊PID控制

中图分类号:TV736 文献标志码:A 文章编号:1672-7207(2013)10-4055-08

Design and experimentation of grouting pressure automatic control system on PLC

WANG Chao1, XU Lisheng1, XU Meng1, YAO Cuixia1, HUANG Hui1, 2

(1. Key Laboratory of Metallogenic Prediction of Nonferrous Metals, Ministry of Education,

School of Geoscience and Info-Physics, Central South University, Changsha 410083, China;

2. Yunnan Huadian Nujiang River Hydropower Development Co. Ltd., Kunming 650228, China)

Abstract: Aimed at large-scale fluctuations of grouting pressure caused by complex geological conditions of grouting strata, grouting equipment structure, manual control hysteresis and other factors, in order to achieve dynamic detection and automatic control on grouting pressure, the grouting pressure automatic control (GPAC) system was designed based on the control program written by parameter self-tuning fuzzy-PID control algorithm, with core components of programmable logic controller (PLC), piezoresistive pressure transducer, servo motor, driver, reducer and electric control valve. Measured feedback values of piezoresistive pressure transducer can be closed-loop cycle corrected, and the valve opening can be adjusted by servo motor reversing to keep the grouting pressure stable under GPAC system control. The simulation results show that grouting pressure can be automatic controlled in 5-6 s and control precision can be kept on less than 5% of designed pressure value by grouting pressure automatic control system when the grouting pressure changes in the range of 0-5 MPa. Control performances of GPAC system are better than manual control mode, so the need of grouting construction can be well fulfilled.

Key words: grouting; pressure fluctuation; programmable logic controller; fuzzy PID control

基础灌浆是水工建筑物地基防渗和加固处理的主要方法之一,但灌浆施工是地下隐蔽工程,在施工过程中应对各主要技术参数进行实时监控和记录,以确保工程的安全和质量[1-2]。随着工程技术的进步和发展,浆液密度和流量等参数的动态检测技术得到进一步完善,但灌浆压力的检测和控制一直是未解决的工程难题[3]。灌浆压力是浆液在地层中扩散的动力,它直接影响灌浆的质量和加固效果。若灌浆压力过高,则会造成有害的水力劈裂和扩缝效应,从而引发地层抬动或其他对主体工程造成严重破坏的灌浆事故;若灌浆压力偏低,则浆液将无法有效充填被灌岩体的细小裂隙和空洞,影响灌浆质量,造成安全隐患[4-7]。目前,在国内工程中对灌浆压力多采用开环控制策略,即当灌浆压力发生波动并超过灌浆设计容许误差时,指定专人调节安装在返浆管道上调节阀的阀芯开度进行控制。由于被灌地层地质条件的复杂性和灌浆设备的结构形式等因素造成灌浆压力变化不确定,人工控制存在滞后性和控制精准度差等缺陷,极易造成灌浆压力的急剧升高和大范围波动[8]。为了实现灌浆压力的动态检测和自动控制,作者结合传感器技术、微机技术和自动控制技术,基于可编程逻辑控制器(PLC),研发了灌浆压力自动控制系统(简称GPAC系统),并通过室内模拟灌浆试验验证设备可靠性和控制精度,以期满足实际工程的检测和控制需要。

1 灌浆压力波动机理和系统设计

1.1 灌浆压力波动机理

灌浆压力通常是受灌浆泵活塞运动的驱使而发生,并通过连续前进的浆液本身而传递[9]。在系统设计中,主要考虑以下3个因素对灌浆压力的影响。

(1) 灌浆孔地层的阻尼特性。灌浆孔内是施加了高压的固液两相流体,因此,被灌地层的裂隙开度、走向、延伸范围、连通情况、裂隙中的充填物及裂隙面的粗糙程度等几何特征均会使孔内的流体运动状况发生复杂变化,进而造成灌浆压力波动[10]。这里以无量纲阻尼系数ξK综合描述灌浆孔地层的阻尼特性。在泵量一定的情况下,当阻尼系数ξK增大时,压降增大,孔内灌浆压力下降;当ξK减少时,压降减小,孔内灌浆压力上升至接近泵送压力。

(2) 电动调节阀的运行状况。当调节阀的阀芯开度不同时,其前、后压降不一样,这里用无量纲广义阻尼系数ξT来描述这种压降特征。在调节阀流量给定时,压降大,表示ξT大;压降小,表示ξT小。而灌浆压力随调节阀ξT的改变会发生具有复杂线性关系的波动变化。其原因是:当ξT增大时,灌浆压力将会上升;当ξT减小时,灌浆压力下降。ξT可根据下式计算得到:

(1)

(1)

式中:pT1为调节阀前压力,MPa;pT2为调节阀后压力,MPa;ξT为调节阀的广义阻尼系数;Q为通过调节阀的流量,L/min;AT为调节阀进口的阀口截面积,m2。

(3) 灌浆泵的脉动特性。当ξK或ξT发生变化时,灌浆泵的运行工作点将发生变化,泵的压力-流量特性将产生压力脉动,使流体流速突然增大或减小,形成管道内水击现象,进而造成管道内液体压强大幅度振荡波动、压力和流速反向,引起灌浆压力发生变化[11]。

地层阻尼特性是随机不确定的,调节阀的开度可以人为或电动调节,而灌浆泵脉动特性可以反映这3种因素对灌浆压力影响的相关程度。

1.2 灌浆压力自动控制系统

1.2.1 系统硬件组成

灌浆压力自动控制系统(GPAC系统)是基于灌浆压力波动机理进行设计,将可编程逻辑控制器(PLC)、压力传感器、伺服电机、驱动器和电动调节阀等进行有效组合,使所有元件和执行机构按照预设程序运行,从而实现灌浆压力的自动控制。在灌浆施工中,GPAC系统必须与灌浆自动记录设备如LJ-IV型灌浆测控系统等[12]有机组合,才能协同实现灌浆参数的检测和压力自动控制。系统主要由以下4个功能模块组成。

(1) 检测模块,为压阻式压力传感器。利用单晶硅压阻效应对灌浆压力进行动态检测[13],压力传感器测量范围为0~10 MPa,检测精度为0.2%。

(2) 控制模块,为S7-400系列PLC,采用模块化设计,模板扩展和配置功能使其能够按照每个不同的需求灵活组合[14]。

(3) 执行模块,包括伺服电机、驱动器和减速机等。功能为将PLC发送的电信号转换成电动机轴上的角位移或角速度输出,从而调整压力控制阀门的开度实现压力控制。驱动器选用ASDA-A2高解析开放型伺服驱动器,其利用具有高速运算能力的数字信号处理器反馈控制绝缘栅双极型晶体管产生精确的电流输出,以驱动伺服电机从而实现精准定位。伺服电机采用ECMA-C10807ES三相永磁交流伺服电机,功率为0.75 kW,额定转矩为2.39 N·m。减速机采用蜗杆减速机,速比为5,中心距为35 mm,举升力为1×104 N,输入功率为0.3 kW。根据阀芯尺寸计算,减速机调整压力范围为0~38.5 MPa,满足灌浆压力控制的要求。

(4) 压力调整模块,为控制阀门总成,包括电动调节阀和手动调节阀。其功能是根据执行模块指令,调节电动阀的开度,从而控制压力波动。手动阀用于紧急状况下的人工控制。

1.2.2 压力自动控制原理

GPAC系统是通过PLC对压力传感器的反馈压力进行闭环周期修正,控制伺服电机的正、反转来调整阀门开度进而控制压力波动。压力传感器安装在灌浆孔返浆管路的压力控制阀进口端,反映灌浆孔的孔底压力。传感器将灌浆压力转换成4~20 mA的电流发送至数据采集控制卡,经过A/V转换后,控制卡将模拟信号转换成数字信号由PLC程序处理。PLC对比实测压力与灌浆压力设定值,根据分析结果产生相应的脉冲或模拟信号给伺服电机驱动器;驱动器根据接收的信号驱动伺服电机正转或反转,从而带动电动调节阀阀杆上下移动以改变阀门的开度。当实时检测值(孔内实际灌浆压力)大于设定值时,增大阀门开度进行卸荷;反之,则阀门开度减小,减少卸荷流量以起到加压的作用;当孔内吸浆量较大不能产生压力时,阀门将完全关闭,所有浆液均灌入孔内;当孔内压力超过设定压力并快速增长时,阀门将迅速完全打开使灌浆压力卸荷,防止抬动事故发生。此过程循环执行,进而实现压力的自动控制。

1.2.3 控制算法和软件设计

(1) 控制算法。系统控制程序的编写采用了参数自整定模糊PID控制算法,即运用常规PID控制消除静态耦合和稳态误差,利用模糊控制较强的自适应能力消除动态耦合[15-16]。程序设计思想是:当压力偏差较大时,采用模糊控制,加快响应速度;当压力偏差较小时,进入稳态过程后,切换到PID控制,消除静差,提高控制精度。

将常规PID控制器的控制规律[17-18]中的积分和微分项进行离散化处理,得到适用于GPAC系统采样控制的离散PID控制表达式:

(2)

(2)

式中:u(k)为第k次采样时刻的计算机输出值;e(k)为第k次采样时刻输入的偏差值;e(k-1)为第(k-1)次采样时刻输入的偏差值;Kp为比例系数;Ki为积分系数;Kd为微分系数; ;

; ;Ti为积分时间常数;Td为微分时间常数;T为采样周期;k为采样序号。

;Ti为积分时间常数;Td为微分时间常数;T为采样周期;k为采样序号。

对于采样控制, ,且根据递推原理可得:

,且根据递推原理可得:

(3)

(3)

式中:△e(k)=e(k)-e(k-1);控制增量 只与最近采样偏差值e(k),e(k-1)及e(k-2)有关,算式不进行大量累加,计算误差对控制量影响小,控制效果较好。但控制算法中的Kp,Ki和Kd必需与被控对象结构及参数相匹配。而由于被灌地层地质条件的复杂性,灌浆管路的精确数学模型无法得到,因此,将无法调和提高响应速度和降低超调量之间的矛盾,此时,需要结合模糊控制来消除动态耦合。

只与最近采样偏差值e(k),e(k-1)及e(k-2)有关,算式不进行大量累加,计算误差对控制量影响小,控制效果较好。但控制算法中的Kp,Ki和Kd必需与被控对象结构及参数相匹配。而由于被灌地层地质条件的复杂性,灌浆管路的精确数学模型无法得到,因此,将无法调和提高响应速度和降低超调量之间的矛盾,此时,需要结合模糊控制来消除动态耦合。

参数自整定模糊PID控制算法以误差e及其误差变化率ec为输入,PID控制器参数的调整量△Kp,△Ki和△Kd为输出值。在运行中,通过不断检测e和ec,根据模糊控制原理对3个PID参数进行在线修改,以满足不同e和ec时对控制参数的不同要求,而使被控对象有良好的动态和静态性能。算法取e和ec和模糊判决输出值△Kp,△Ki和△Kd的模糊集合为{NB,NM,NS,ZO,PS,PM,PB} = {负大,负中,负小,零,正小,正中,正大}共7个语言值[19];e,ec,△Kp,△Ki和△Kd采用同一隶属函数,采用产生式规则来描述,其一般形式为

其中:An为偏差;Bn为偏差变化率;PC(△Kpn&△Kin&△Kdn)代表具有比例作用Kpn、积分作用Kin及微分作用Kdn的PID控制器,其在偏差An和偏差变化率Bn下对应的输出值分别为△Kpn,△Kin和△Kdn。

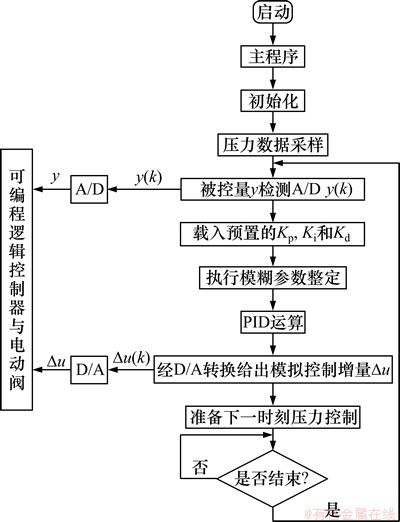

(2) 软件采用模块化设计,人机交互界面良好,指示性强,由主程序、功能子程序及中断程序构成。启动后先调用主程序,完成初始化(数据区、变量初始化,时钟设置等),然后,主程序进入等待循环,直至发出中断指令或调用子程序为止。程序流程如图1所示。软件包括以下功能。

1) 灌浆功能。配合LJ-IV型灌浆测控系统完成灌浆操作,设定包括灌浆工程有关参数(孔号、日期等)、灌浆压力、波动范围(上限和下限)、电机转数等系统参数。

图1 灌浆压力自动控制系统程序流程图

Fig. 1 Flow chart of grouting pressure automatic control system program

2) 通讯功能。实现与LJ-IV型灌浆测控系统、数据转存器串行通讯(RS-232C)功能。

3) 数据处理功能。分析灌浆压力实测值和设定值之间差值的“正”、“负”,根据参数自整定模糊PID控制算法,计算并输出压力调整量。

4) 指令执行功能。根据压力调整指令,控制伺服电机正、反转以调节电动阀的阀芯开度。

2 仿真试验

2.1 试验设备

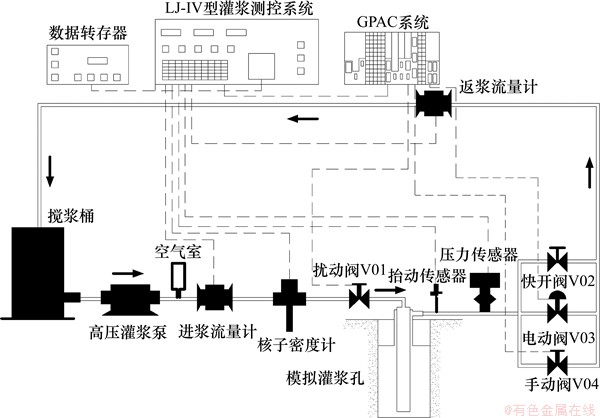

模拟灌浆试验按照DL/T 5148—2012(《水工建筑物水泥灌浆施工技术规范》)[20]要求,在一般灌浆工况下实施。试验设备包括:SGB6-10型往复式灌浆泵,LJ核子密度计,K300型电磁流量计,KELLER压阻式压力传感器,容栅地层抬动传感器,LJ-IV型灌浆测控系统主机,扰动阀V01,快开阀V02,电动阀V03和手动阀V04组成的阀门组,GPAC系统。仿真试验管路布设和设备组成如图2所示。试验中,GPAC系统与LJ-IV型灌浆测控系统主机实时连接,主机用于各传感器检测指标的分析、记录和打印,并传输实时检测数据。

2.2 试验内容和步骤

(1) 灌浆泵脉动特性试验。确定灌浆泵的稳定工作点,通过计算灌浆泵脉动带来的压力波动误差,分析灌浆泵脉动特性对压力自动控制的影响。为了防止浆液流动受管道阻力影响带来的试验误差,此部分采用自来水作为灌浆材料。

图2 模拟灌浆试验设备组成和管路设计

Fig. 2 Equipment composition and pipeline design of simulated grouting experiment

(2) 电动调节阀阻尼特性试验。采用水灰比为1:1的水泥浆液,设定不同压力下进行灌浆试验,通过GPAC系统控制阀门开度,检测并记录不同开度下电动阀前后压力、液体流量,根据式(1)计算其阻尼系数,分析电动阀阻尼特性对压力波动的影响。

(3) 灌浆压力自动控制试验。按设计要求改变电动阀V01的阀芯开度来产生扰动,从而模拟实际灌浆孔地层的阻尼系数ξK,采用水灰比1:1的水泥浆液灌浆。当压力不足或超限时,GPAC系统控制电动阀V03的开度来自动控制灌浆压力。快开阀V02和手动阀V04用来模拟灌浆管道阀门的切换控制。由于泵的脉动特性,在进浆流量计之前增加1个空气室,用于稳定试验时的浆液泵送流量,减小泵送压力变化带来的检测误差。

2.3 试验结果分析

2.3.1 灌浆泵脉动特性

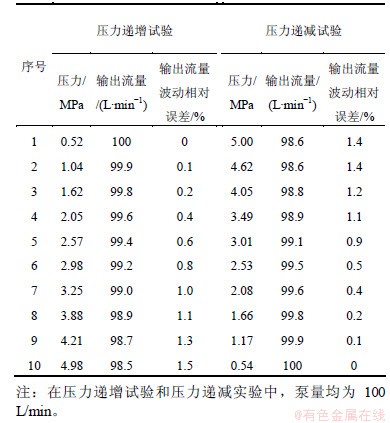

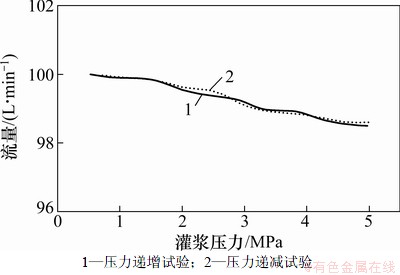

表1所示为灌浆泵脉动特性试验结果,灌浆泵p-Q性能曲线如图3所示。从表1和图3可知:灌浆泵的脉动特性使排浆量随着压力的增大而逐渐减小。这是因为在灌浆过程中,随着排出压力的提高,加大了浆量漏损;当灌浆压力为1~5 MPa时,灌浆泵的输出流量波动相对误差在1.5%以内,这表明SGB6-10型灌浆泵选型合适,可以稳定工作,其脉动特性对灌浆压力自动控制的影响较小。

表1 灌浆泵脉动性特性试验数据表

Table 1 Pulsation performance test result of grouting pump

图3 灌浆泵压力p-流量Q特性曲线图

Fig. 3 Pressure-flow performance of grouting pump

2.3.2 电动调节阀阻尼特性

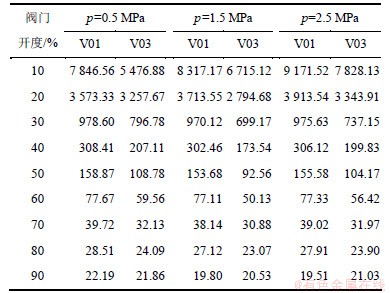

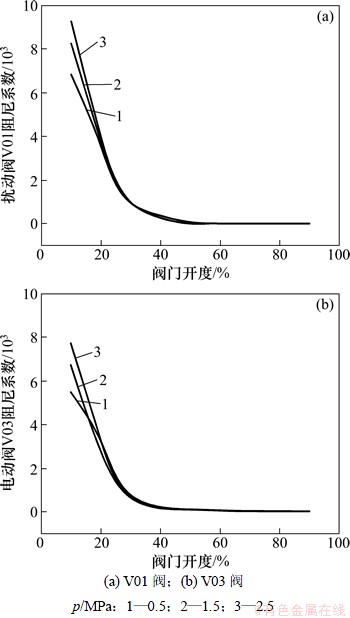

表2所示为0.5,1.5和2.5 MPa压力下,电动阀V01和V03的阻尼系数随阀门开度的变化情况。分析表2可知:在不同压力下,对于给定的开度,阀V01和V03的阻尼系数变化较小;当阀V01和V03在阀芯开度较小时,开度增大将大大减小阀门的阻尼系数;在开度大于40%时,阀门的阻尼系数下降幅度减小,相对稳定;当开度大于80%时,阻尼系数很小;随着开度的继续增大,阻尼系数几乎保持不变,直至接近于0。因此,使阀门开度在40%~80%之间变化对灌浆压力的稳定控制最有效。

表2 电动阀V01和V03的阻尼系数

Table 2 Damping coefficients of electric control valves V01 and V03

图4(a)和图4(b)所示为不同压力下,阀V01和V03的阻尼系数随开度的变化趋势。分析图4可知:阻尼系数是阀门的固有特性,与阀门开度有关;V01和V03为同一类型阀,但灌浆管道中布设位置不同,其阻尼系数发生了变化。这是因为在灌浆管路的扰动下,不同位置动态检测的压力不同。阀门阻尼系数试验结果为修正GPAC系统控制程序提供了计算依据。

图4 调节阀V01和V03阻尼系数变化曲线

Fig. 4 Tendency charts of damping characteristic of valves V01 and V03

2.3.3 灌浆压力自动控制

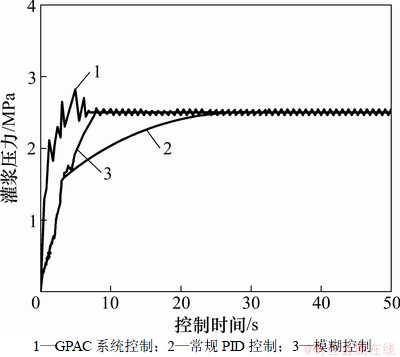

图5所示为设定2.5 MPa压力进行仿真试验时,灌浆压力的阶跃响应曲线。分析图5可知:在GPAC系统自动控制下,灌浆压力从0很快升到设定值左右;经过短时间的波动后,趋于平衡,稳定停留在设定压力上。这说明GPAC系统控制比常规PID控制具有更小的超调量和更短调节时间,而且消除了模糊控制在工作点附近的小范围振荡,没有稳态误差,其响应时间很短,且自动控制精度较高。

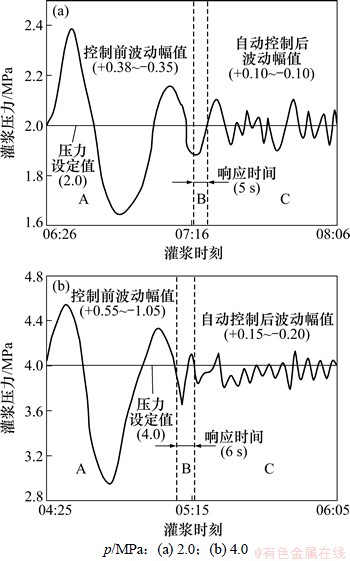

图6所示为以2.0 MPa和4.0 MPa压力灌浆时,管路中实测灌浆压力的变化过程。其中:A区为模拟扰动下灌浆压力超值波动的阶段;B区为GPAC系统自动控制的响应阶段;C区为压力在GPAC系统控制下趋于稳定的阶段。

图5 灌浆压力设定为2.5 MPa时的阶跃响应曲线

Fig. 5 Step response curves of grouting pressure of 2.5 MPa

图6 灌浆压力设定为2.0 MPa和4.0 MPa时压力波动的情况

Fig. 6 Changes of pressure fluctuations under designed grouting pressure of 2.0 MPa and 4.0 MPa

由图6(a)和图6(b)可知:改变扰动阀V01开度以模拟不同阻尼系数ξK的灌浆孔地层。在管路扰动下,灌浆压力发生超值波动,对应于2.0 MPa和4.0 MPa的压力设定值,其最大波动幅度分别达到0.38 MPa和1.05 MPa,为压力设定值的19%和26%,压力极不稳定。GPAC系统进行分析计算后,开始自动控制,分别经过5 s和6 s的控制响应时间,压力波动分别被控制在-0.100~0.100 MPa和-0.200~0.200 MPa范围内(均为压力设定值的5%),压力在自动控制后不再超值波动,逐渐趋于稳定。若采用人工调节来控制压力波动,则实测最好结果可在30~60 s的操作反映时间内将压力波动稳定在设定值的15%~20%。可见:人工控制误差很大,控制时滞较长,而且严重依赖操作人员的实际操作经验和工作效率。

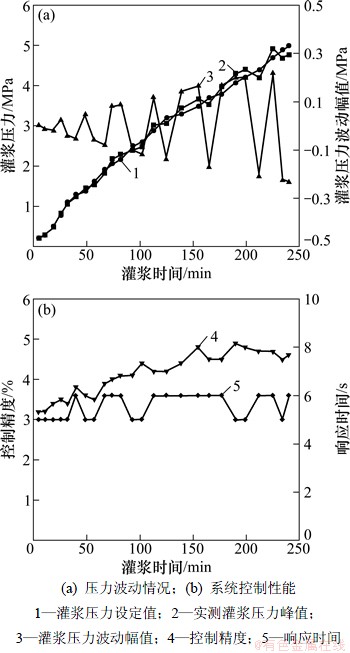

图7所示为多组压力自动控制的试验结果。由图7(a)可知:当灌浆压力在0~5 MPa范围内变化时,GPAC系统控制下不同压力设定值与实测压力峰值十分接近,压力波动小,且变化较稳定;随着压力设定值增大,波动幅度有所增大,但最大波动幅值没有超过压力设定值的5%。图7(b)所示为GPAC系统控制精度和响应时间的变化曲线。分析图7(b)可知:对于任意时间段的灌浆,系统均能在5~6 s内完成压力自动控制,其控制精度保持在压力设定值的5%以内,且稳定性较好;GPAC系统的控制性能指标远远优于人工控制的最优指标,满足灌浆施工对压力控制的要求。

图7 灌浆压力自动控制试验结果

Fig. 7 Results of grouting pressure automatic control test

3 结论

(1) 灌浆压力的波动主要受被灌地层阻尼特性和调节阀开度的影响。对于不同的灌浆工况,只要灌浆泵的选型合适且稳定工作,其脉动特性对压力自动控制的影响就较小。

(2) 基于参数自整定模糊PID算法的控制程序对灌浆压力的变化有较强的自适应能力,当压差较大时,模糊控制加快响应速度;当压差较小时,进入稳态后,切换PID控制,消除静差,提高控制精度。控制程序将PLC、伺服电机、驱动器和电动调节阀进行了有效结合,实现了根据计算控制量的主动加压和卸荷,有效控制了压力的波动。

(3) GPAC系统可将0~5 MPa范围内的压力自动控制精度保持在压力设定值的5%以内,控制响应时间为5~6 s,其响应快,精度高,稳定性好,满足灌浆施工的压力控制要求,可以有效取代人工压力控制。

参考文献:

[1] 张景秀. 坝基防渗与灌浆技术[M]. 北京: 中国水利水电出版社, 2002: 75-103.

ZHANG Jingxiu. Technology of base of dam permeate proof and grouting[M]. Beijing: Chinese Water Resources and Hydropower Press, 2002: 75-103.

[2] Kutzner C. Grouting of rock and soil[M]. Rotterdam, Brookfield: A.A. Balkema, 1996: 26-52.

[3] 李凤玲. 灌浆压力控制系统的关键技术研究[D]. 长沙: 中南大学信息科学与工程学院, 2009: 15-19.

LI Fengling. Research on key technologies of grouting pressure control system[D]. Changsha: Central South University. School of Information Science & Engineering, 2009: 15-19.

[4] 谭靖夷. 我国坝工技术的发展[J]. 水力发电, 2004, 30(12): 60-63.

TAN Jingyi. The development of dam construction technology in China[J]. Water Power, 2004, 30(12): 60-63.

[5] ZHANG Min, WANG Xinghua, WANG You. Numerical evaluation of uplifting effect for upper structure by grouting[J]. Journal of Central South University of Technology, 2012, 19(2): 553-561.

[6] YANG Xiaoli, ZOU Jinfeng. Estimation of compaction grouting pressure in strain softening soils[J]. Journal of Central South University of Technology, 2009, 16(4): 653-657.

[7] 李凤玲, 徐力生, 申群太. 基于快速支持向量计算法的灌浆地层识别[J]. 中南大学学报: 自然科学版, 2009, 40(2): 478-483.

LI Fengling, XU Lisheng, SHEN Quntai. Grouting stratum identification with fast support vector machine[J]. Journal of Central South University: Science and Technology, 2009, 40(2): 478-483.

[8] 陈伟. 裂隙岩体灌浆压力及其稳定性控制方法研究[D]. 长沙: 中南大学地学与环境工程学院, 2008: 15-20.

CHEN Wei. Study on grouting pressure and its stabilization controlling method in fractured rock mass[D]. Changsha: Central South University. School of Geoscience and Environmental Engineering, 2008: 15-20.

[9] 邹金峰, 徐望国, 罗强, 等. 饱和土中劈裂灌浆压力研究[J]. 岩土力学, 2008, 29(7): 1802-1806.

ZOU Jinfeng, XU Wangguo, LUO Qiang, et al. Study on grouting pressure of fracture grouting in saturated soil[J]. Rock and Soil Mechanics, 2008, 29(7): 1802-1806.

[10] Eriksson M, Stille H, Andersson J. Numerical alculations for prediction of grout spread with account for filtration and varying aperture[J]. Underground Space Technology, 2000, 15(4): 353-364.

[11] 张宁, 杨敏官, 李忠, 等. 侧壁式压水离心泵的压力脉动特性[J]. 机械工程学报, 2012, 48(14): 164-168.

ZHANG Ning, YANG Minguan, LI Zhong, et al. Pressure pulsation of centrifugal pump with tilt volute[J]. Journal of Mechanical Engineering, 2012, 48(14): 164-168.

[12] 徐蒙, 彭振斌, 陈珣, 等. 四参数灌浆与压水检测系统的设计[J]. 传感器与微系统, 2010, 29(9): 107-109.

XU Meng, PENG Zhenbin, CHEN Xun, et al. Design of four-parameter detection system for grouting and water-pressing[J]. Transducer and Microsystem Technologies, 2010, 29(9): 107-109.

[13] XIONG Jijun, ZHENG Shijun, HONG Yingping, et al. Measurement of wireless pressure sensors fabricated in high temperature co-fired ceramic MEMS technology[J]. Journal of Zhejiang University: Science C, 2013, 14(4): 258-263.

[14] 李德英. 基于PLC的液压实验台监控系统的开发与研制[D]. 长沙: 中南大学信息科学与工程学院, 2010: 26-48.

LI Deying. The development and research of the hydraulic test stand monitoring system based on PLC[D]. Changsha: Central South University. School of Information Science & Engineering, 2010: 26-48.

[15] 郭伟, 倪家健, 李涛, 等. 基于时域的分数阶PID预测函数励磁控制器[J]. 仪器仪表学报, 2011, 32(11): 2461-2467.

GUO Wei, NI Jiajian, LI Tao, et al. Improved fractional-order PID predictive function excitation controller based on time domain[J]. Chinese Journal of Scientific Instrument, 2011, 32(11): 2461-2467.

[16] 修智宏, 任光. T-S模糊控制系统的稳定性分析及系统化设计[J]. 自动化学报, 2004, 30(5): 731-741.

XIU Zhihong, REN Guang. Stability analysis and systematic design of T-S fuzzy control system[J]. Acta Automatica Sinica, 2004, 30(5): 731-741.

[17] Etedali S,Sohrabi M R, Tavakoli S.Optimal PD/PID control of smart base isolated buildings equipped with piezoelectric friction dampers[J]. Earthquake Engineering and Engineering Vibration, 2013, 12(1): 39-54.

[18] 王耿, 官春林, 张小军, 等. 应变式微型精密压电驱动器的一体化设计及其PID控制[J]. 光学精密工程, 2013, 21(3): 709-716.

WANG Geng, GUAN Chunlin, ZHANG Xiaojun, et al. Design and control of miniature piezoelectric actuator based on strain gauge senser[J]. Optics and Precision Engineering, 2013, 21(3): 709-716.

[19] 文乐,高林,戴义平. 透平压缩机组的模糊PID控制与特性研究[J]. 西安交通大学学报, 2011, 45(7): 76-81.

WEN Le, GAO Lin, DAI Yiping. Study on fuzzy PID control of turbine-driven centrifugal compressor[J]. Journal of Xi’an Jiaotong University, 2011, 45(7): 76-81.

[20] DL/T 5148—2012, 水工建筑物水泥灌浆施工技术规范[S].

DL/T 5148—2012, Technical specification for construction for cement grouting of the hydraulic structures[S].

(编辑 陈灿华)

收稿日期:2013-04-20;修回日期:2013-06-22

基金项目:国家自然科学基金资助项目(51208514);国家中小企业创新基金资助项目(12C26214304879);中南大学中央高校基本科研业务费专项资金资助项目(2011QNZT007)

通信作者:徐蒙(1981-),男,湖南长沙人,讲师,从事地质工程和灌浆工程仪器仪表等研究;电话:13975809372;E-mail:x1950217@126.com