DOI:10.19476/j.ysxb.1004.0609.2018.02.09

Si-Mo-Zr反应熔渗改性C/C复合材料的微观结构与烧蚀性能

郝安林1,郝振华2, 3,孙 威2,熊 翔2,陈招科2,王雅雷2

(1. 安阳工学院 机械工程学院,安阳 455000;

2. 中南大学 粉末冶金国家重点实验室,长沙 410083;

3. 郑州大学 河南省资源与材料工业技术研究院,郑州 450000)

摘 要:为了提高C/C复合材料的抗烧蚀能力,采用不同配比的Si-Mo-Zr混合粉末反应熔渗改性C/C复合材料。利用X射线衍射分析仪(XRD)、扫描电镜(SEM)和透射电镜(TEM)分析改性C/C复合材料的物相组成和微观结构。利用氧乙炔焰烧蚀仪检测分析样品的烧蚀性能。结果表明:当混合粉末的成分配比为n(Si):n(Mo):n(Zr)=10:1:4时,样品熔渗效果最佳,密度和孔隙率分别为2.66 g/cm3和8.1%。熔渗效果较差的样品仅在靠近样品表面有SiC和ZrC陶瓷相共存的区域,样品内部仅含有少量SiC;熔渗较好的样品可以在样品内部观察到SiMoZrC固溶相以及环状ZrC相。熔渗效果较差的样品由于内部陶瓷相含量较少,其烧蚀性能随着烧蚀时间从300 s提高到600 s而急剧下降。

关键词:C/C复合材料;陶瓷基复合材料;SiC;反应熔渗;烧蚀性能

文章编号:1004-0609(2018)-02-0285-09 中图分类号:TB332 文献标志码:A

C/C复合材料自1958年被美国 Chance Vought 公司发现以来,由于其具有低密度、高热导、高温下保持优异的力学性能等一系列优良性能,已被广泛应用于航天航空领域[1]。然而,C/C复合材料在高温有氧条件下极易氧化[2],大大降低了其抗烧蚀性能,难以长时间服役于现代高超声速飞行器高温高速氧化性气流的烧蚀环境。因此,提高C/C复合材料抗烧蚀性能的研究具有极其重要的意义。

目前,提高C/C复合材料抗烧蚀性能常采用的方法是利用基体改性或涂层技术在C/C复合材料内部或表面引入高熔点耐烧蚀化合物,如SiC[3-5]、HfC[6-7]、ZrC[8-11]、ZrO2[12]等。其中SiC由于其与C/C材料具有良好的物理和化学相容性,常被用于C/C复合材料防护体系中[13-15]。SiC-MoSi2涂层体系已被证明在1700 ℃以下可以有效保护C/C复合材料[16-18]。ESFEHANIAN等[19]利用反应熔渗法制备了C/XSi2- SiC(X=Mo,Ti)复合材料,并且熔渗所得复合材料在1600 ℃条件下具有良好的力学性能。然而若要彻底改善C/C复合材料的烧蚀性能,必须结合基体改性和涂层技术,对C/C复合材料进行从内到外的一体化耐烧蚀防护[20-21]。目前,结合基体改性与涂层技术的研究通常涉及多个制备过程[22-23],工艺复杂,耗时长,涂层与基体之间结合能力较差。

前期研究结果表明[24-25],采用Si-Mo-Ti粉末对C/C复合材料进行反应熔渗所得到的材料结构致密并具有良好的力学性能与烧蚀性能。此外,利用这种反应熔渗方法可以在基体改性的同时在材料表面得到具有抗烧蚀能力的陶瓷涂层,实现基体改性与涂层技术的有机结合,并且工艺简单、耗时较少、涂层与基体结合良好。Zr的碳化物和氧化物均具有良好的抗烧蚀能力,在该种方法的基础上添加Zr元素,采用Si-Mo-Zr粉末对C/C复合进行反应熔渗,有望进一步提高C/C复合材料的抗烧蚀能力。在此,本文作者即采用此种粉末反应熔渗的方法,利用Si-Mo-Zr混合粉末对C/C复合材料进行反应熔渗改性,得到具有良好抗烧蚀能力的一体化改性(基体改性结合涂层技术)C/C复合材料,并分析了工艺参数对材料的微观结构、烧蚀性能的影响,在此基础上探究了材料的熔渗机理与烧蚀行为。

1 实验

1.1 材料的制备

实验采用多孔C/C复合材料为基体,Si-Mo-Zr混合粉末为熔渗剂,石墨坩埚为反应容器,在高温真空烧结炉(FH W-90,FCT,德国)中进行反应熔渗。其中,多孔C/C复合材料由整体针刺毡预制体经CVI(化学气相渗透)过程增密得到,熔渗用多孔C/C复合材料的密度约为1.3 g/cm3,孔隙率约为22%。整体针刺毡预制体由无纬布和网胎层交替堆叠后(无纬布按0°和90°交替堆叠)利用针刺技术经Z向纤维针刺而成。Si-Mo-Zr混合粉末由纯度99.9%的Si(兴荣源科技有限公司,北京)、Mo(兴荣源科技有限公司,北京)、Zr(昊天钛粉加工有限公司,锦州)单质粉末与酒精混合经行星式球磨机(XQM,科析实验仪器研究所,南京)球磨12~24 h后烘干制得。多孔C/C复合材料与Si-Mo-Zr混合粉末一起放置于特制的石墨坩埚后置于烧结炉中在2000~2200 ℃保温2 h以完成熔渗过程,整个过程烧结炉采用Ar保护。

1.2 材料的分析与表征

采用X射线衍射光谱分析仪(D/max 2550,Rigaku,日本)分析材料的物相组成。采用带有能谱分析仪的扫描电子显微镜(Nova Nano 230, Fei,美国) 观察材料的界面形貌与物相分布。采用带有能谱分析仪和球差校正仪的透射电子显微镜(Titan G260-300,Fei,美国)观察材料的微区形貌与元素分布。透射电子试样采用聚焦离子束(Helios Nanolab 600i,Fei,美国)制备得到。

1.3 烧蚀性能的检测

样品烧蚀性能的检测采用DR6130氧乙炔焰烧蚀仪(按GJB 323A-96设计)进行。烧蚀枪喷嘴内径2 mm,烧蚀火焰和样品角度90 ℃,试样初始表面到火焰喷嘴距离为20 mm,烧蚀温度约为2500 ℃,氧气压力和流量分别为0.4 MPa和1.960 L/s,乙炔压力和流量分别为0.095 MPa和0.696 L/s。烧蚀时间根据实验需要由控制柜控制,烧蚀试样的尺寸为直径30 mm×10 mm,样品的质量烧蚀率和烧蚀率分别由式(1)和(2)计算:

(1)

(1)

(2)

(2)

式中:Rm和Rl分别是样品质量烧蚀率和线烧蚀率;  是样品烧蚀前后的质量变化;

是样品烧蚀前后的质量变化; 是样品烧蚀前后的厚度变化;t是烧蚀时间。

是样品烧蚀前后的厚度变化;t是烧蚀时间。

2 结果与讨论

2.1 熔渗效果分析

表1所列为用4种不同配比粉末熔渗所得样品的密度与孔隙率。样品的密度随Zr含量的增加呈现先增加后减小的趋势,孔隙率随Zr含量的增加呈现先减小后增大的趋势,当熔渗粉末组成为n(Si):n(Mo):n(Zr)= 10:1:4时,样品熔渗效果最佳。熔渗效果随熔渗粉末中Mo含量增加而急剧下降。4种样品按熔渗效果由优到弱的顺序依次为Z4、Z1、Z10、M3。

表1 不同配比Si-Mo-Zr粉末熔渗所得样品密度与孔隙率

Table 1 Density and porosity of samples infiltrated by Si-Mo-Zr mixed powder with different chemical compositions

2.2 微观结构表征

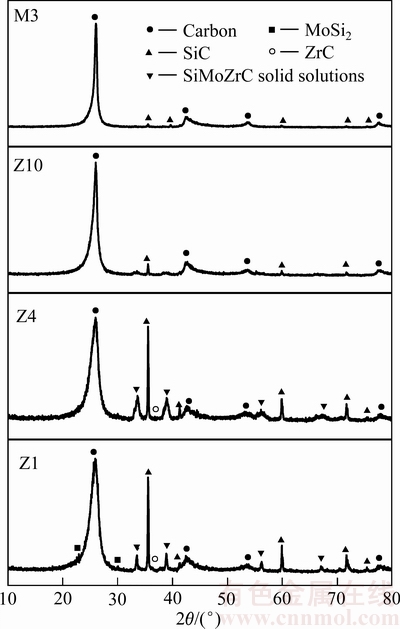

图1所示为不同配比粉末熔渗所得样品截面XRD谱。从图1可以看到,样品Z1和Z4的陶瓷相含量明显大于Z10和M3的,表明在熔渗过程中有更多的陶瓷相可以渗入基体内部,因而熔渗效果好,密度高,孔隙率较低。样品Z1由C、SiC、ZrC、MoSi2以及SiMoTiC固溶相组成。样品Z4的XRD谱中可以观察到C、SiC、ZrC以及SiMoTiC固溶相的特征峰,和Z1相比较,MoSi2的衍射峰消失,这是由于Zr含量的增加,影响了MoSi2的析出所致。样品Z10和M3仅能观察到微弱的SiC特征峰,表面可能仅在前期有部分Si渗入样品内部生成SiC,其后熔渗反应受条件限制而无法继续进行。

对熔渗效果较差的两个样品Z10和M3的截面采用SEM观察(见图2),可以发现两者均只有在表面有一定量的SiC和ZrC共存陶瓷相存在。随着熔渗方向的深入,样品中陶瓷相含量急剧下降,在样品内部仅有少量SiC相存在。样品Z10和M3的截面SEM形貌进一步证明:本实验采用的粉末反应熔渗过程为一个多步反应的过程,熔渗效果较差的样品通常是在过程中受条件限制而中止,致使后续熔渗反应过程无法继续进行。Si的单独渗入反应可以在熔渗过程早期进行,而Si与Zr的共同渗入则在Si的单独渗入反应之后进行。

图1 不同配比Si-Mo-Zr粉末熔渗所得样品截面XRD谱

Fig. 1 XRD patterns of samples infiltrated by mixed powder of Si-Mo-Zr with different chemical compositions

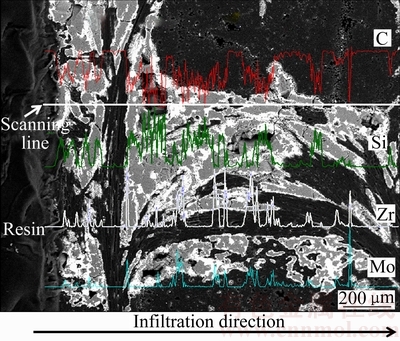

对熔渗效果最高的样品Z4的截面(见图3)观察可以发现,样品Z4中陶瓷相含量明显高于Z10和M3中的,并且陶瓷相含量随着熔渗方向没有明显减少,在熔渗方向深度1 mm处仍有多种陶瓷相存在。经能谱分析样品中存在的主要陶瓷相为SiC和SiMoTiC固溶体。并且,线扫描能谱分析显示样品中Zr元素与Mo元素的分布高度一致,说明在Zr元素的熔渗与Mo元素的熔渗过程是同一个过程。而样品Z10与M3熔渗效果较差的原因正是由于这一过程的缺失所导致的,这也是Z10与M3中未发现含有Mo的陶瓷相的原因。这一过程的缺失正是由于Z10与M3样品中高熔点元素Zr或Mo的过量导致整个体系熔点升高,粉末在熔渗温度(2000 ℃)下未能完全熔化,因而后续熔渗反应无法继续进行。

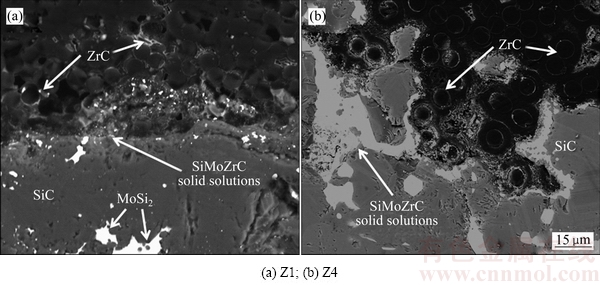

图4所示为熔渗效果较好的样品Z1和Z4 碳纤维束附近区域的SEM像。从图4可以看出,SiC(灰色相) 在陶瓷相中含量较高,广泛分布于C纤维附近的区域。

图2 不同配比Si-Mo-Zr粉末熔渗所得样品截面SEM像

Fig. 2 SEM images for cross section of samples infiltrated by Si-Mo-Zr mixed powder with different chemical compositions

图3 样品Z4截面SEM照片及线扫描能谱分析

Fig. 3 SEM images and line scanning EDX for cross section of sample Z4

然而,在碳纤维束中的单根碳纤维周围,可以观察到环状ZrC相的存在。此种环状ZrC相的存在说明在此熔渗温度下,Zr的熔渗能力优于Si的,因而ZrC能存在于碳纤维束内部更深入的区域。熔渗过程是一个溶解-析出过程[26],C原子通过扩散进入熔体之中和熔体反应同时析出陶瓷相。根据热力学计算,在2000 ℃的条件下,液相Zr和SiC可能反升反应:

Zr(l)+SiC(s)=ZrC(s)+Si(l) (3)

式(1)的吉布斯自由能小于0,由此可以推断,当C原子进入熔体之后,ZrC的析出能力明显强于SiC的析出能力,即使SiC生成,也有可能通过反应(1)生成ZrC。因此,在图4中可以观察到ZrC在碳纤维束内部区域也有分布。

此外,从图4(a)中样品Z1中还可以发现,MoSi2和SiMoZrC固溶体的存在,而在图4(b)的样品Z4中仅有SiMoZrC固溶相存在,与XRD结果一致。并且在碳纤维附近区域的SiMoZrC固溶体呈散点状分布,而SiC相附近的SiMoZrC固溶体则呈现连续分布。

采用TEM对碳纤维附近区域的SiMoZrC进行观察(见图5)可以发现,在碳纤维附近的SiMoZrC固溶体呈散点状分布,与SEM观察结果相一致。散点状分布的SiMoZrC固溶体很可能是在熔渗过程中溶解-析出反应过程中析出,并随着SiC相的生成而被推移至界面处。并且SiMoZrC元素面扫描能谱显示固溶体中Zr元素的分布更加靠近固溶体的边缘区域,证明Zr和C之间结合能力更好。

2.3 熔渗机理分析

针对本实验所涉及的Si-Mo-Zr体系,结合微观结构以上分析,可以推断熔渗反应过程如下:

首先在1400 ℃时,Si熔化发生反应:

Si+C=SiC (4)

2Si+Zr=ZrSi2 (5)

2Si+Mo=MoSi2 (6)

其中,式(5)为Si渗入到基体内部与基体C发生反应,样品Z10和M3内部少量SiC即是在这一阶段生成的。

其次在约1650 ℃时,ZrSi2熔化发生反应:

ZrSi2+3C=ZrC+2SiC (7)

反应(7)为Zr和Si元素共同渗入的过程,样品Z10和M3靠近样品表面的ZrC和SiC共存区域即是在这一阶段生成。

图4 熔渗样品碳纤维束附近区域SEM像

Fig. 4 SEM images for regions around carbon fiber bundles of infiltrated sample

图5 碳纤维附近区域SiMoZrC固溶体的TEM像与元素面扫描能谱分析结果

Fig. 5 TEM image and element mapping distribution of SiMoZrC solid solutions around carbon fiber

接下来在1850 ℃时Zr熔化,此时熔体中应当含有Zr和Si元素。若此时熔体成分处于体系的高熔点区域,则会生成高熔点相,熔渗过程无法继续进行,若熔体成分处于体系的低熔点区域,则熔渗继续进行,发生式(1)和以下反应:

Zr+C=ZrC (8)

此时,式(8)的发生是优于反应(1)的,样品Z1和Z4中的环状ZrC区域即是在此阶段生成的。

最后在2000 ℃达到反应温度,此时整个熔体的组成应为Si、Mo和Zr元素。若熔体组成处于体系的高熔点区域,则Mo和反应生成的MoSi2无法溶解在Si和Zr中,熔渗反应无法继续进行。若熔体组成处于整个体系处于低熔点区域,则Mo、MoSi2可以溶解在Si和Zr中,共同进行熔渗反应。当熔体进入基体的孔隙之后,熔渗反应为溶解-扩散机制,反应的进行主要靠C的扩散来完成,C扩散进熔体后熔体成分为Si、Zr、Mo、C;此后各种陶瓷相会陆续析出,最终陶瓷相的分布由其和C之间的润湿性决定。随着陶瓷相的析出,样品便形成了所观察到的微观形貌。

综上所述,此种含有不同熔点的多组元粉末反应熔渗过程遵循以下规律:

1) 低熔点元素(如Si和Zr等)会在达到反应温度之前熔化变为液态,单独渗入基体内部。

2) 高熔点元素要依靠低熔点元素将其熔化来完成熔渗过程,因此,此类熔渗反应经常会观察到固溶相的存在。若高熔点元素不能熔入低熔点元素之中,则熔渗反应无法继续进行。

3) 在共同反应阶段,各熔渗元素与C的反应能力以及生成物与C的润湿性能都会影响复合材料中陶瓷相的分布。

2.4 烧蚀性能与烧蚀行为分析

图6(a)所示为采用不同成分熔渗料所得Si-Mo-Zr反应熔渗C/C复合材料经不时间烧蚀后的质量烧蚀率。可以看到,当烧蚀时间为300 s时,得益于表面致密陶瓷层的存在,所有样品的质量烧蚀率都不高。而当烧蚀时间增加到600 s时,随着表面陶瓷层的逐渐破坏,以及孔洞、裂纹等缺陷结构的形成和扩展,样品的质量烧蚀率明显升高,尤其是熔渗效果较差且内部陶瓷相含量很低的样品Z10和M3的,其质量烧蚀率的升高十分显著。其中最为明显的样品为M3,其600 s的质量烧蚀率相比300 s时的升高了53倍。图6(b)所示为采用不同成分熔渗料所得Si-Mo-Zr反应熔渗C/C复合材料经不同时间烧蚀后的线烧蚀率。可以看到,其线烧蚀率和质量烧蚀率呈现基本一致的变化规律。所有样品的线烧蚀率随烧蚀时间延长而增加,并且Z10和M3的烧蚀率增加较为显著,而Z1和Z4烧蚀率的增加相对较小。其中烧蚀率增加最为显著的M3烧蚀率增加了5.5倍。样品Z1和Z4虽然在600s时质量烧蚀率和线烧蚀率也明显提升,但其质量烧蚀率并没有像Z10和M3一样随着烧蚀时间的增加产生了数量级的差异。

图6 不同成分熔渗料所得Si-Mo-Zr反应熔渗C/C复合材料烧蚀后的质量烧蚀率和线烧蚀率

Fig. 6 Mass ablaion rate(a) and linear ablation rate(b) of ablated C/C composites infiltrated by Si-Mo-Zr mixed powder with different chemical compositions

可以推断,Z1和Z4的抗烧蚀能力主要得益于其内部陶瓷相在表面陶瓷相受到一定破坏之后还可以在一定程度上起到保护C/C复合材料的作用。抗烧蚀性能最好的样品Z4其300 s的质量烧蚀率和线烧蚀率分别为0.03 mg/s和2 μm/s,600 s的质量烧蚀率和线烧蚀率分别为0.25 mg/s和4 μm/s。由于样品在600 s已遭受毁灭性破坏,因此主要考查其烧蚀300 s后样品的表面状态。

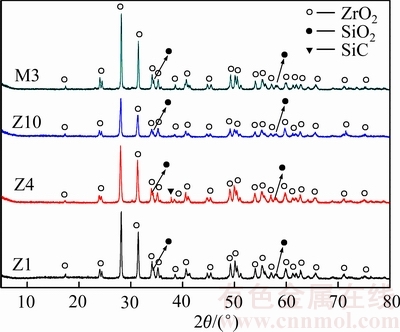

图7所示为样品烧蚀300 s之后的表面XRD谱。从图7可以看出,样品烧蚀过后表面主要相为ZrO2,此外还有少量SiO2相存在,这种二元的氧化层结构是具有较好的抗烧蚀能力,这一点在其质量和线烧蚀率上都有所体现。值得注意的是,在样品Z4的XRD谱上还可以观察到微弱的SiC相特征峰,表明其表面氧化程度较低,表明样品Z4具有较强的抗烧蚀能力,与质量和线烧蚀率的分析结果相一致。

图7 不同成分熔渗料所得Si-Mo-Zr反应熔渗C/C复合材料烧蚀后的XRD谱

Fig. 7 XRD patterns of ablated C/C composites infiltrated by Si-Mo-Zr mixed powder with different chemical compositions

图8所示为样品烧蚀300 s之后的表面SEM像。从图8可以看出,样品Z1和Z4表面有一层较为致密且连续的ZrO2层,而样品Z10和M3表面的ZrO2 基本是以单独颗粒的状态存在。这主要是由于Z10和M3的熔渗效果较差,内部陶瓷相含量较低,因此在烧蚀过程中,很难形成连续的ZrO2层,较易被高速气流剥蚀。并且没有ZrO2保护的SiO2也很难抵抗高速气流的剥蚀,将持续被剥蚀。而SiO2被不断剥蚀又导致未被剥蚀的ZrO2颗粒进一步高于烧蚀面,更易被高速气流所带来的剪应力所剥蚀,SiO2的剥蚀和ZrO2 的剥蚀互相影响,形成恶性循环,导致烧蚀过程中生成的氧化产物很难形成一定的保护作用,从而最终导致毁灭性破坏。而内部陶瓷相含量较高的Z1和Z4在表面受到一定破坏之后,其内部陶瓷相被氧化之后仍可继续形成较为连续的氧化物层,因而抗烧蚀能力优于样品Z1和Z4的。

图8 不同成分熔渗料所得Si-Mo-Zr反应熔渗C/C复合材料烧蚀后的SEM像

Fig. 8 SEM images of ablated C/C composites infiltrated by Si-Mo-Zr mixed powder with different chemical compositions

3 结论

1) 2000 ℃时,采用Si-Mo-Zr混合粉末反应熔渗C/C复合材料,最终所得样品密度随Zr含量增加先增加后减小,孔隙率随Zr含量增加先减小后增加;密度随Mo含量增加而较小,孔隙率随Mo含量增加而增大。

2) 当混合粉末成分配比为n(Si):n(Mo):n(Zr)= 10:1:4时,样品熔渗效果最佳,密度和孔隙率分别为2.66 g/cm3和8.1%。

3) 熔渗效果较差的样品Z10和M3仅在靠近样品表面区域有SiC和ZrC共存的陶瓷相存在,内部仅有少量SiC;熔渗较好的样品Z1和Z4可以在样品内部观察到SiMoZrC固溶相和环状ZrC相。

4) 低熔点元素(如Si和Zr)可以在温度达到反应温度之前渗入基体内部,而高熔点元素(如Mo)需要依靠熔入低熔点元素之中,随低熔点元素一同完成熔渗过程。

5) 在熔体进入C/C基体之后,反应过程为溶解-扩散反应,各熔渗元素与C的反应能力以及生成物与C的润湿性能都会影响复合材料中陶瓷相的分布。

6) 熔渗效果较差的样品由于内部陶瓷相含量很低,表面难以形成连续的氧化层,在烧蚀时间较长时,烧蚀性能较差;熔渗效果较好的样品得益于内部较高的陶瓷相含量,可以在表面形成连续氧化层,抗烧蚀能力明显提升,其中抗烧蚀性能最好的样品Z4其300 s的质量烧蚀率和线烧蚀率分别为0.03 mg/s和2 μm/s,600 s的质量烧蚀率和线烧蚀率分别为0.25 mg/s和4 μm/s。

REFERENCES

[1] WINDHORS T, BLOUNT G. Carbon-carbon composites: A summary of recent developments and applications[J]. Materials & Design, 1997, 18(1): 11-15.

[2] GUO W M, XIAO H N. Mechanisms and modeling of oxidation of carbon felt/carbon composites[J]. Carbon, 2007, 45(5): 1058-1065.

[3] 姚栋嘉, 李贺军, 张守阳, 李克智, 王永杰. C/C复合材料SiC涂层强冲蚀环境的烧蚀性能研究[J]. 中国材料进展, 2015, 34(7): 610-614.

YAO Dong-jia, LI He-jun, ZHANG Shou-yang, LI Ke-zhi, WANG Yong-jie. Anti-ablation property of SiC coating on C/C composites at high speed[J]. Materials China, 2015, 34(7): 610-614.

[4] JIANG G P, YANG J F, XU Y D, GAO J Q, ZHANG J Z, ZHANG L T, CHENG L F, LOU J J. Effect of graphitization on microstructure and tribological properties of C/SiC composites prepared by reactive melt infiltration[J]. Composites Science and Technology, 2008, 68(12): 2468-2473.

[5] LIU L, LI H J, FENG W, SHI X H, WU H, ZHU J L. Effect of surface ablation products on the ablation resistance of C/C-SiC composites under oxyacetylene torch[J]. Corrosion Science, 2013, 67: 60-66.

[6] WANG Y L, XIONG X, LI G D,LIU H F, CHEN Z K, SUN W, ZHAO X J. Ablation behavior of HfC protective coatings for carbon/carbon composites in an oxyacetylene combustion flame[J]. Corrosion Science, 2012, 65: 549-555.

[7] 张 鹏. 合金反应熔渗法制备C/C-SiC-HfC复合材料[J]. 材料科学与工程学报, 2015, 33(2): 173-177.

ZHANG Peng. C/C-SiC-HfC composite prepared by alloyed reactive melt infiltration[J]. Journal of Materials Science and Engineering, 2015, 33(2): 173-177.

[8] SUN W, XIONG X, HUANG B Y, LI G D, ZHANG H B, CHEN Z K, ZHENG X L. ZrC ablation protective coating for carbon/carbon composites[J]. Carbon, 2009, 47(14): 3368-3371.

[9] ZOU L H, WALI N, YANG J M, BANSAL N P. Microstructural development of a Cf/ZrC composite manufactured by reactive melt infiltration[J]. Journal of the European Ceramic Society, 2010, 30(6): 1527-1535.

[10] 孙 威, 郝振华, 熊 翔, 李小斌, 李江鸿. 化学气相沉积ZrC涂层的缺陷形成机制及控制[J]. 中国有色金属学报, 2013, 23(6): 1611-1617.

SUN Wei, HAO Zhen-hua, XIONG Xiang, LI Xiao-bin, LI Jiang-hong. Formation mechanism and control of defects for ZrC ceramic coatings by chemical vapor deposition[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1611-1617.

[11] 张仲灵, 易茂中, 周文艳, 吴 皇, 庞伟林, 葛毅成, 冉丽萍. 粉末熔渗制备C/C-ZrC-Cu复合材料的组织结构[J]. 粉末冶金材料科学与工程, 2016, 21(2): 311-316.

ZHANG Zhong-ling, YI Mao-zhong, ZHOU Wen-yan, WU Huang, PANG Wei-lin, GE Yi-cheng, RAN Li-ping. Microstructure of C/C-ZrC-Cu composite fabricated by reactive melt infiltration[J]. Material Science and Engineering of Powder Metallurgy, 2016, 21(2): 311-316.

[12] 郝振华, 孙 威, 熊 翔, 但奇善, 李江鸿. 常压化学气相沉积ZrO2涂层的显微结构与微观力学性能[J]. 中国有色金属学报, 2013, 23(7): 1937-1943.

HAO Zhen-hua, SUN Wei, XIONG Xiang, DAN Qi-shan, LI Jiang-hong. Microstructure and micro-mechanical properites of zironia coating by atomspheric pressure chemical vapor deposition[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1937-1943.

[13] WANG D N, ZENG Y, XIONG X, LI G D, CHEN Z K, SUN W, WANG Y L. Ablation behavior of ZrB2-SiC protective coating for carbon/carbon composites[J]. Ceramics International, 2015, 41(6): 7677-7686.

[14] FENG T, LI H J, HU M H, LIN H J, LI L. Oxidation and ablation resistance of the ZrB2-CrSi2-Si/SiC coating for C/C composites at high temperature[J]. Journal of Alloys and Compounds, 2016, 662: 302-307.

[15] LI L, LI H J, LI Y Y, YIN X M, SHEN Q L, FU Q G. A SiC-ZrB2-ZrC coating toughened by electrophoretically- deposited SiC nanowires to protect C/C composites against thermal shock and oxidation[J]. Applied Surface Science, 2015, 349: 465-471.

[16] HUANG J F, WANG B, LI H J, LIU M, GAO L Y, YAO C H. A MoSi2/SiC oxidation protective coating for carbon/carbon composites[J]. Corrosion Science, 2011, 53(2): 834-839.

[17] FU Q G, LI H J, WANG Y J, LI K Z, SHI X H. B2O3 modified SiC-MoSi2 oxidation resistant coating for carbon/carbon composites by a two-step pack cementation[J]. Corrosion Science, 2009, 51(10): 2450-2454.

[18] FU Q G, ZOU X, CHU Y H, LI H J, ZOU J Z, GU C G. A multilayer MoSi2-SiC-B coating to protect SiC-coated carbon/carbon composites against oxidation[J]. Vacuum, 2012, 86(12): 1960-1963.

[19] ESFEHANIAN M, GUENSTER J, HEINRICH J G, HORVATH J, KOCH D, GRATHWOHL G. High-temperature mechanical behavior of carbon-silicide-carbide composites developed by alloyed melt infiltration[J]. Journal of the European Ceramic Society, 2008, 28(6): 1267-1274.

[20] JAYASEELAN D D, Rafael G D S, BROWN P, LEE W E. Reactive infiltration processing (RIP) of ultra high temperature ceramics (UHTC) into porous C/C composite tubes[J]. Journal of the European Ceramic Society, 2011, 31(3): 361-368.

[21] 李 军, 杨 鑫, 刘红卫, 黄启忠, 苏哲安. 耐烧蚀超高温陶瓷改性C/C复合材料的研究进展[J]. 中国有色金属学报, 2015, 25(7): 1731-1743.

LI Jun, YANG Xin, LIU Hong-wei, HUANG Qi-zhong, SU Ze-an. Research process of ultra high temperature ceramics modified carbon/carbon composite for ablation resistance[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(7): 1731-1743.

[22] LIU C X, SU Z A, HUANG Q Z, CHEN J X, YANG X, CAO L X, YIN T, ZHONG P. Ablation behavior of ZrC-SiC coated C/C-ZrC-SiC composites prepared by precursor infiltration pyrolysis combined with reactive melt infiltration[J]. Journal of Alloys and Compounds, 2014, 597: 236-242.

[23] FU Q G, ZHUANG L, REN Q W, FENG L, LI H J, GUO Y A. Carbon nanotube-toughened interlocking buffer layer to improve the adhesion strength and thermal shock resistance of SiC coating for C/C-ZrC-SiC composites[J]. Journal of Materiomics, 2015, 1(3): 245-252.

[24] HAO Z H, SUN W, XIONG X, CHEN Z K, WANG Y L. Effects of Ti/Al addition on the microstructures and ablation properties of Cf/C-MoSi2-SiC composites[J]. Journal of the European Ceramic Society, 2016, 36(3): 457-464.

[25] HAO Z H, SUN W, XIONG X, CHEN Z K, WANG Y L, CHANG Y B, XU Y L. Microstructure and ablation properties of a gradient Cf/C-XSi2-SiC (X=Mo,Ti) composite fabricated by reactive melt infiltration[J]. Journal of the European Ceramic Society, 2016, 36(15): 3775-3782.

[26] NESS J N, PAGE T F. Microstructural evolution in reaction- bonded silicon carbide[J]. Journal of Materials Science, 1986, 21(4): 1377-1397.

Microstructure and ablation properties of Si-Mo-Zr modified C/C composites by reactive melt infiltration

HAO An-lin1, HAO Zhen-hua2, 3, SUN Wei2, XIONG Xiang2, CHEN Zhao-ke2, WANG Ya-lei2

(1. School of Mechanical Engineering, Anyang Institute of Technology, Anyang 455000, China;

2. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

3. Henan Province Industrial Technology Research Institute of Resources and Materials, Zhengzhou University, Zhengzhou 450000, China)

Abstract: In order to improve the ablation resistance of C/C composites, C/C composites were modified by Si-Mo-Zr mixed powder with different chemical compositions by reactive melt infiltration. X-ray diffractometry(XRD), scanning electronic microscopy(SEM) and transmission electron microscopy(TEM) were used to analyze the phase composition and microstructure of the modified C/C composites. The results show that infiltrated composite have the best infiltration effect when the chemical composition of the mixed powder is n(Si):n(Mo):n(Zr)=10:1:4, whose density and porosity are 2.66 g/cm3 and 8.1%, respectively. The regions with ZrC and SiC ceramics can be only observed around the surface of the samples with worse infiltration effect while only SiC can be observed inside of them. However, for the samples with better infiltration effect, SiMoZrC solid solutions and ringlike ZrC can be observed inside the samples. The ablation properties of the samples with worse infiltration effect decrease when the ablation time increases from 300 s to 600 s due to their limited ceramics phases inside.

Key words: C/C composites; ceramic matrix composites; SiC; reactive melt infiltration; ablation property

Foundation item: Project(51405522) supported by the National Natural Science Foundation of China; Project (PM-CSU-2015-03) supported by the Self-fund of State Key Laboratory for Powder Metallurgy, Central South University, China

Received date: 2016-11-29; Accepted date: 2017-05-23

Corresponding author: HAO Zhen-hua; Tel: +86-13787198338; E-mail: haozhenhua@csu.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51405522);中南大学粉末冶金国家重点实验室自主课题资助项目(PM-CSU-2015-03)

收稿日期:2016-11-29;修订日期:2017-05-23

通信作者:郝振华,博士; 电话:13787198338; E-mail: haozhenhua@csu.edu.cn