DOI:10.19476/j.ysxb.1004.0609.2018.06.11

铜轧制油中磷酸酯的吸附特性与润滑性能

严旭东,孙建林,熊桑

(北京科技大学 材料科学与工程学院,北京 100083)

摘 要:采用密度泛函理论(DFT)计算轧制油中二烷基二硫代磷酸酯(DDE)分子的反应活性,建立DDE-铜表面稳定吸附构型;利用四球摩擦磨损试验机和四辊轧机分别考察DDE对轧制油摩擦学性能和润滑性能的影响;并通过X射线光电子能谱(XPS)对磨损实验后铜表面产物进行分析。结果表明:DDE是一种具有优异极压性能及良好抗磨减摩性能的铜轧制油添加剂,在基础油中添加0.05%(质量分数)DDE使得轧制油油膜强度pB达到588 N,比基础油的提高66.57%,同时摩擦因数与磨斑直径明显降低。其吸附本质是在DDE与铜表面摩擦过程中发生化学反应形成S、O与Cu的化合物,计算的吸附能达到225.80 kJ/mol,表明分子在Cu表面产生稳定的化学吸附。含0.05% DDE的轧制油在实际轧制过程中的最小可轧厚度为22 μm。

关键词:铜;轧制油;吸附特性;润滑性能;吸附能

文章编号:1004-0609(2018)-06-1168-08 中图分类号:TG335.12 文献标志码:A

磷酸酯常应用于涡轮油[1]、金属加工液、润滑脂[2]和航空润滑油[3]等领域。在边界润滑条件下,由于其分子中的P、O元素能与金属表面生成有机磷的保护膜[4],起到减小摩擦副表面擦伤的作用,并可显著提高润滑油的油膜承载能力pB值。磷酸酯[5]经分解后,与铁表面发生反应,生成的磷化物与附近的铁生成流动性更好的共溶合金,随着摩擦运动流向金属表面的凹陷处,形成一层平滑的极压膜,起到了类似抛光的效果。然而磷酸酯与金属间保护膜的抗磨作用有限,尤其是在更苛刻的摩擦条件下,保护膜会发生脱落,甚至发生水解[6]。通过使用改性磷酸酯,引入其他元素改善添加剂原有的极压抗磨性能成为当前研究的 热点。

近年来学者们大多采用实验研究阐述改性磷酸酯的抗磨减摩性能,任朋飞等[7]合成了一种含氮磷酸酯并考察了其在基础油中的摩擦学性能,实验结果证明了这种改性磷酸酯具有良好的抗磨极压性能。熊桑等[8]通过四球摩擦磨损实验证实了磷酸酯与含氮硼酸酯复配后具有更优异的摩擦学性能。由于轧制润滑油膜处于纳米级别,仅从宏观实验角度很难揭示机理,借助分子动力学方法[9-10]可以从原子的尺度更直观、有效地解释这些化学物理过程。ONODERA等[9]通过分子动力学模拟的方法研究了二烷基二硫代磷酸锌与Fe(001)相互作用模型,证实了其由于在铁表面形成吸附膜起到的抗磨减摩机理。对于该同一添加剂,JIANG[10]利用量子化学方法计算其中两个P—S键长,结果说明两键键长相等且呈对称分布,并且键长、键角的变化是分子与金属表面形成氧化物的根本原因。采取理论分析与宏观实验相结合的方式对添加剂进行研究[11],为解决微观润滑问题提供了新思路。

二烷基二硫代磷酸酯(DDE,C10H23O4PS2)作为铜轧制油中一种新型的改性磷酸酯添加剂,同时包含S、P、O元素,其分子的润滑性能以及对摩擦副的极压抗磨作用机理尚未研究。本文作者基于分子动力学理 论,选取二烷基二硫代磷酸酯为研究对象,计算添加剂分子的量子化学参数,从原子角度构建添加剂与金属的吸附构型以及分析其作用效果,并结合四球摩擦磨损实验、万能磨损实验、铜板冷轧实验以及X射线光电子能谱(XPS)的分析结果进行验证。

1 计算与实验部分

1.1 量子化学计算

采用密度泛函理论(DFT)[12-13],运用Material Studio软件包中的DMol3模块[14-15],在GGA/PW91基组水平上对二烷基二硫代磷酸酯(DDE)进行几何优化,计算得到添加剂分子在等值面为0.03a.u.的前线轨道分布,以此分析DDE分子的全局活性。另外通过对添加剂分子Fukui指数的计算,分析DDE的亲核或亲电反应性以及确定分子的局部活性位点。

1.2 分子动力学模拟

轧制过程中添加剂分子与铜的相互作用通过分子动力学(MD)方法来模拟,选择Material Studios中的Discover模块,运用Smart Minimize进行优化,经优化后Cu的晶格参数为0.3614 nm,与其他研究人员所做的计算和实验值0.361 nm结果一致[16],这说明使用该模型计算是合理的。选择Cu(110)面作为吸附面,共分三层,第一、二层为金属原子,第三层包含1个添加剂分子,选取的体系大小为1.807 nm×1.277 nm× 2.128 nm;由于实际的体系中主要成分为D130基础油,其模拟密度取为0.824 g/mL。为提高计算效率,模拟过程中冻结金属表面体系中的所有原子,而第三层添加剂分子与金属表面自由相互作用。动力学模拟选取compass力场,用NVT正则系综,取室温298 K为参考温度,添加剂分子在Cu表面的吸附能由式(1)给出[17]:

(1)

(1)

式中: 是孤立的添加剂分子的能量;

是孤立的添加剂分子的能量; 是未吸附添加剂分子时金属表面的能量;

是未吸附添加剂分子时金属表面的能量; 表示添加剂分子和金属表面的体系总能量;

表示添加剂分子和金属表面的体系总能量; 即为吸附能,单位为kJ/mol。

即为吸附能,单位为kJ/mol。

1.3 实验材料

选取Exxsol D130作为基础油,二烷基二硫代磷酸酯(DDE)为添加剂制备5种不同轧制油进行四球磨损实验,基础油和添加剂的理化性能如表1所列。添加剂的含量(质量分数)分别为0,0.05%,0.10%,0.15%和0.20%;选择d 50 mm的45#钢盘与d 60 mm的T2紫铜环(纯度为99.9%)试样作为铜-钢摩擦副材料进行万能磨损实验;最后使用T2铜板(规格200 mm×50 mm×0.5 mm)进行冷轧实验验证DDE对铜的实际轧制润滑效果。

1.4 四球摩擦学性能测试

四球磨损实验按照GB/T 12583—1998标准在转速(1760±40) r/min、室温25 ℃、时间10 s条件下测试不同轧制油的最大无卡咬负荷(pB值),试验所用钢球均为 GCr15标准钢球。另外按照四球法以载荷(392±5) N,转速(1200±5) r/min,室温25 ℃,时间30 min条件测得其摩擦因数μ与磨斑直径WSD。磨斑形貌通过XJZ-6AZEISS光学显微镜进行观察。

1.5 铜-钢摩擦副磨损实验

使用MM-W1A立式万能型摩擦磨损试验机,以基础油、基础油+0.05%DDE作为润滑剂,分别在不同转速条件下(100,200,300,400及500 r/min)进行铜-钢摩擦副的磨损实验,自动采集摩擦因数,测试条件如下:盘-环磨损形式,接触压力为0.3 MPa,室温25 ℃,每一个转速条件测试时间为15 min。通过XPS对万能摩擦磨损实验后铜环表面产物进行分析,各元素的结合能通过NIST XPS 数据库获取。

1.6 铜板四辊冷轧实验

采用d 95 mm×200 mm×200 mm四辊冷轧实验轧机在室温下按4个道次,压下率分别为30%、30%、20%、20%的相同实验条件对不同轧制油润滑状态下铜板进行冷轧实验,压靠后继续轧制5个道次。实验后结果用于最小可轧厚度的测量以及铜板表面的观察。

2 结果与讨论

2.1 添加剂分子全局活性分析

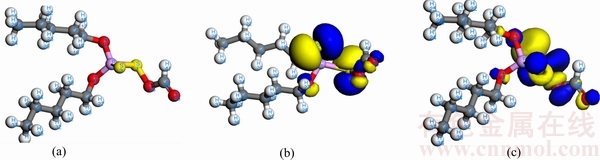

前线轨道理论[18]认为反应物间的相互作用仅发生在分子的前线轨道之间,因此为分析添加剂在金属表面的吸附行为,必须考虑分子的最高占有轨道(HOMO)和最低未占轨道能(LUMO),EHOMO表示分子给电子的能力,ELUMO是分子接受电子的能力。图1(b)和(c)所示分别为DDE分子在等值面为0.03 a.u.的HOMO与LUMO轨道上的分布,通过与图1(a)的原始分子结构对比可以发现:DDE分子的活性主要集中在S、O、P等极性原子上,烷基链上基本不存在活性位点。其HOMO分布中S(3)、O(4)、S(1)、O(38)、O(40)等原子呈现明显的π键,易给出电子;而LUMO分布中S(3)、S(2)、O(38)、O(40) 等原子呈π键,O(5)、P(2)等原子呈σ键,易得到电子。不难发现,DDE分子中存在多个S、O原子同时具备较强的得失电子能力,这使得DDE分子具有多个活性位点,容易与金属表面吸附并发生化学反应。

表1 基础油和添加剂的理化性能

Table 1 Physicochemical property of base oil and additives

图1 二烷基二硫代磷酸酯的结构图

Fig. 1 Structure of molecular with optimized configurationfor DDE(a), HOMO isosurface with value of 0.03 a.u. for DDE(b), LUMO isosurface with value of 0.03 a.u. for DDE(c)

2.2 添加剂分子局部活性分析

为确定添加剂分子可能的吸附位点,需分析其局部活性,对Fukui指数进行计算。该指数不仅可测定分子的反应活性位点和强弱,同时还可以确定活性位点的亲核或亲电特性。Fukui函数 的计算公式如下[15]:

的计算公式如下[15]:

(2)

(2)

定义为电子密度

定义为电子密度 对电子数N的1阶偏导。利用有限差分法近似方法,Fukui函数

对电子数N的1阶偏导。利用有限差分法近似方法,Fukui函数 可表示为

可表示为

(3)

(3)

(4)

(4)

式中: 、

、 、

、 分别代表分子为阳离子、中性、阴离子时,分子中原子k所带的电量;

分别代表分子为阳离子、中性、阴离子时,分子中原子k所带的电量; 为亲电子进攻指数,表示分子给电子的能力;

为亲电子进攻指数,表示分子给电子的能力; 为亲核进攻指数,表示分子得电子的能力;

为亲核进攻指数,表示分子得电子的能力; /

/ 数值越大,得/给电子能力越强。

数值越大,得/给电子能力越强。

部分典型原子的计算参数值列于表2,对于DDE分子有 >

> ,说明分子具有亲电特性,更易得到电子参加亲核反应,则利于与正价的金属离子相结合。Fukui指数的数值表明DDE分子活性集中在的S(1)、S(3)、O(40)等多个原子,使得添加剂分子能在金属表面吸附稳定,并保证吸附膜具备一定的承载能力。其中S(1)同时具备最高的

,说明分子具有亲电特性,更易得到电子参加亲核反应,则利于与正价的金属离子相结合。Fukui指数的数值表明DDE分子活性集中在的S(1)、S(3)、O(40)等多个原子,使得添加剂分子能在金属表面吸附稳定,并保证吸附膜具备一定的承载能力。其中S(1)同时具备最高的 指数及

指数及 指数,说明它既容易与金属的d轨道结合接受电子形成反馈键,又容易得到电子形成配位键,是分子的亲电以及亲核反应中心。这样的活性特点使得S(1)极易在金属表面发生断键或形成新键,产生稳定的化学吸附。由于DDE的活性集中在S、O、P等极性原子基团上,可以在金属表面形成多个吸附位点,根据吸附机理,有效的添加剂是至少一极性官能团稳定地吸附于金属表面,非极性的分子如碳链,烷基被“牵引”以平行或倾斜的方式分布,形成致密的润滑膜,起到抗磨减摩以及极压的作用。

指数,说明它既容易与金属的d轨道结合接受电子形成反馈键,又容易得到电子形成配位键,是分子的亲电以及亲核反应中心。这样的活性特点使得S(1)极易在金属表面发生断键或形成新键,产生稳定的化学吸附。由于DDE的活性集中在S、O、P等极性原子基团上,可以在金属表面形成多个吸附位点,根据吸附机理,有效的添加剂是至少一极性官能团稳定地吸附于金属表面,非极性的分子如碳链,烷基被“牵引”以平行或倾斜的方式分布,形成致密的润滑膜,起到抗磨减摩以及极压的作用。

表2 添加剂分子中原子局部活性参数

Table 2 Calculated local reactivity descriptors of studied molecules

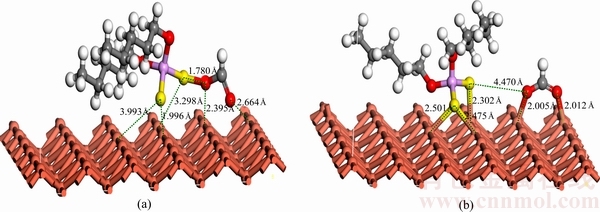

2.3 分子动力学计算分析

添加剂分子在铜表面吸附的初始构型和优化后的最终构型如图2(a)和(b)所示。计算过程中发现:无论添加剂分子的初始构型是垂直、倾斜或平行于Cu表面,分子最终都是平行吸附于金属表面。其中根据键长的变化[18-19],在DDE-Cu体系中,O—S键键长由原来的0.178 nm变为0.447 nm,即发生了断键,而Cu—S键,Cu—O键长缩短,并形成新键,这说明在Cu与DDE分子相互作用过程中,分子更倾向于以S(1)、S(3)、O(38)、O(40)等极性原子吸附于Cu表面并形成Cu与S,O的化合物。这样的吸附特性有利于增强DDE分子在Cu表面的抗磨减摩性能;同时可以看出DDE与Cu表面作用时保持了原添加剂分子的相对完整性,吸附更为稳定,这样使得吸附膜不易破裂,有利于对润滑油膜强度的提高。

图2 DDE在Cu(110)表面的吸附构型

Fig. 2 Adsorption models on Cu (110) crystal plane with initial configuration(a) and optimized configuration(b)

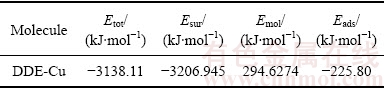

为了进一步解释添加剂分子与金属表面的相互作用,对体系中添加剂分子的单分子吸附能进行了定量计算,吸附能反映分子与金属表面的结合强度。分析表3数据可知:DDE分子与铜表面的吸附能为负值,依据热力学原理,引起溶液中某种粒子在界面层中吸附的基本原因是由于吸附过程伴随着体系自由能的降低,负值表示吸附过程为放热过程,意味着它可吸附于金属表面 [20],有助于润滑膜的形成。在模拟中发现DDE-Cu体系的吸附属于化学吸附[21-22](Eads>40 kJ/mol),说明有新化合物的产生,与上述量子化学计算的分析结果一致。这一结果进一步阐释了在铜-钢摩擦过程中添加剂分子易粘着于铜表面或发生化学反应,形成一层稳定润滑薄膜。

表3 添加剂分子与Cu(110)面的吸附能

Table 3 Average values of adsorption energies (Eads) on Cu surface for molecule

2.4 含添加剂轧制油摩擦学性能分析

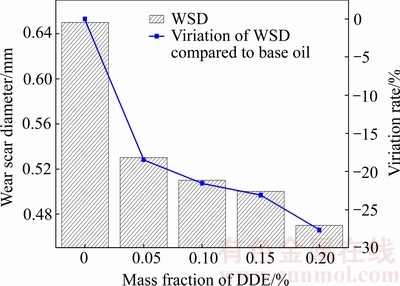

对比5组油样的四球摩擦磨损实验结果,如图3所示,只添加的0.05%DDE能使pB值达到588 N,比基础油的提高66.57%,之后pB随DDE含量增加而缓慢增加;其摩擦因数维持在0.072~0.079之间,相较于基础油有明显减少;图4所示为磨斑直径变化及同比基础油的变化曲线。添加0.05%DDE实验后磨斑直径为0.47 mm,同基础油相比降低18.9%,其磨斑直径随DDE含量增加呈现出先急剧降低之后变化平缓的趋势。这说明DDE的添加能显著改善润滑油极压抗磨性能,而不同添加量的DDE对于润滑油摩擦学性能的改变量相对较小。

图3 油膜强度和摩擦因数随DDE含量变化曲线

Fig. 3 Changing curves of pB and friction coefficient with DDE content

图4 磨斑直径变化及同比基础油的变化率随含量的变化曲线

Fig. 4 Changing curves of WSD and variation rate with DDE content

四球摩擦磨损实验后的磨斑形貌如图5所示。在磨斑表面观察中发现,只含有基础油的磨斑表面光亮,但磨痕较重,且磨斑较大;DDE的加入使得磨斑有明显的减小,磨痕细化。而随着添加剂浓度的增加,磨斑表面质量逐渐下降。其中添加0.05%DDE在提高润滑油极压抗磨性能的同时也具有相对光洁的表面。四球实验结果证实了DDE对于轧制油极压性能和抗磨减摩性能的作用。但是通过摩擦化学反应也会在金属表面生成新的化合物产生腐蚀磨损,在实际应用中,在保证铜轧制油400 N以上的油膜强度的同时,考虑到成本和环保问题,将DDE的添加量控制在0.05%以内为合适的选择。

图5 不同润滑条件下四球长磨实验磨斑形貌

Fig. 5 Morphologies of wear scar in four-ball wear test with condition with base oil(a), base oil+0.05%DDE(b) and base oill+0.2%DDE(c)

基础油与添加0.05%DDE轧制油在不同转速条件下的铜-钢摩擦副磨损试验如图6所示,在整个试验过程中,DDE的添加有效地降低了摩擦因数,改善了摩擦副之间的摩擦状况,在基础油润滑条件下,摩擦因数随转速增加变化较大,曲线波动明显,摩擦状态以边界润滑为主;而添加DDE后,摩擦因数在开始的100 r/min有明显降低,摩擦因数低于0.1,此时摩擦副间的润滑状态已由边界润滑向薄膜润滑转变,整个过程中摩擦因数曲线波动和随转速的变化均较小,进一步说明了DDE在金属表面吸附成膜且增强了油膜的稳定性;同时可以看出添加剂的使用会改变润滑油膜原有的边界润滑状态,这样的结果会导致摩擦副表面质量的下降,因此,控制添加剂的使用量尤为重要。

图6 不同转速条件下轧制油摩擦因数随磨损时间变化

Fig. 6 Friction coefficient vs time of rolling oil under different rotating speed

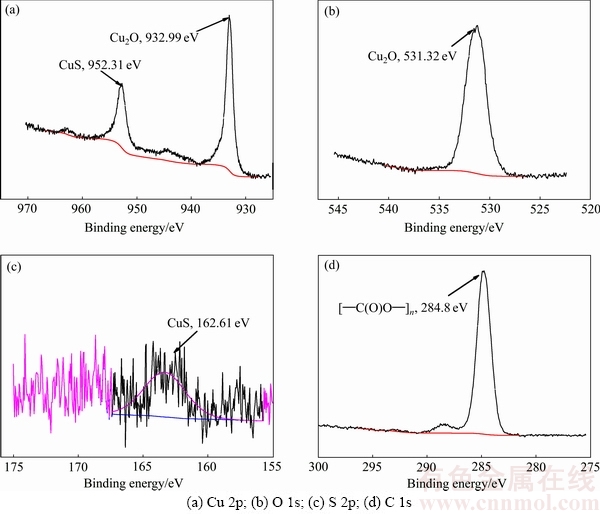

2.5 XPS结果分析

为进一步探究DDE的润滑机理,对磨损实验后铜摩擦副表面产物进行XPS分析,图7所示为DDE润滑条件下铜摩擦副表面XPS谱,首先,在Cu 2p的谱图中,结合能的峰位分别出现在952.31和932.99 eV,两峰值的强度有明显的差异,分别代表Cu的2p1/2轨道和2p3/2轨道,推测为两种不同化合物;根据O1s谱图中的峰值结合能为531.32 eV,与标准物Cu2O的两种元素结合能十分吻合,这说明在DDE与Cu的摩擦过程中形成了Cu2O的化合物。其次,S 2p谱图中结合能的峰值出现在162.61 eV,与之前Cu 2p1/2轨道中的结合能数值952.31 eV相对应,说明摩擦过程中生成了化合物CuS。在C 1s的谱图中只出现一个明显峰值,代表酯基的存在,这说明C元素并未与Cu生成新的化合物。XPS谱图的结果证实了在DDE与Cu吸附过程中生成了O、S极性基团与Cu的化合物,这种化学吸附使得DDE在Cu表面吸附牢固,一方面保证了油膜的承载能力;同时由于金属硫化物的生成,易剪切与滑移,其抗磨减摩效果也明显提高。

图7 铜摩擦副表面的XPS谱(0.05%DDE, 300 N)

Fig. 7 XPS spectra of copper after wear test

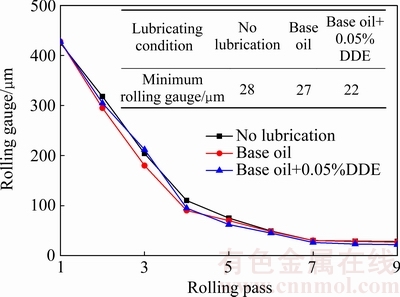

2.6 铜板冷轧及轧后表面分析

图8所示为实际轧制中不同润滑条件下铜板轧制厚度随轧制道次的变化曲线,结合铜板最小可轧厚度结果可以看出,基础油+0.05%DDE组铜板的最小可轧厚度达到22 μm,这说明DDE的添加增强了轧制效率。对轧后铜板的显微表面进行观察,如图9(a)所示在无润滑条件下的轧件表面有较深的沟槽,局部有撕裂状,粘着磨损显著;表面的深色凹坑、孔洞、麻点较多,这属于典型的磨粒磨损。而在边界润滑条件下的轧件表面形貌如图9(b)、(c)所示,其表面粘着磨损大大减少,轧制纹理也更加均匀,因为润滑在降低摩擦因数的同时,能够及时的将接触表面的磨屑和热量带走,防止磨粒在表面的聚集和长大,在控制添加剂的用量的情况下,轧件保持了与基础油润滑时相近的表面形貌。

图8 不同润滑条件下铜板轧制厚度随轧制道次的变化

Fig. 8 Evolution of rolling gauge under different lubricating conditions

图9 不同润滑条件下铜板轧制后表面形貌

Fig. 9 Morphologies of copper foil after rolling test lubricated

3 结论

1) 通过密度泛函理论计算得出二烷基二硫代磷酸酯(DDE)的活性集中在S、P、O等原子上,在铜表面形成多个吸附位点,这种分布有利于分子同时形成配位键和反馈键,使添加剂分子在金属表面形成稳定的吸附,是添加剂分子起到减摩抗磨作用的理论依据。

2) DDE分子在与铜表面相互作用时,S—O键发生断裂,O、S元素分别在Cu金属表面吸附形成Cu—S和Cu—O新键。DDE的吸附能达到225.80 kJ/mol,为化学吸附,使分子能与铜表面吸附牢固,这种稳定的吸附特性使得DDE具有优异的极压性能,同时新生成的铜的硫化物使得吸附膜具有较低的剪切强度,有利于其抗磨性能的提高,与XPS实验结果一致。

3) DDE的添加使得轧制油pB提高为588 N及以上,μ降低至0.072~0.079并显著减小了磨斑直径;但是DDE的添加使得铜-钢摩擦副由边界润滑状态转变为薄膜润滑状态,铜表面质量下降。控制DDE的添加量为0.05%, 能获得厚度为22 μm的铜箔,同时也能保持相对较好的表面质量,符合铜箔产品要求。

REFERENCES

[1] FORBES E S, BATTERSBY J. Application of adsorption/ reaction mechanism to load-carrying results[J]. ASLE Trans, 1974, 17(4): 268-270.

[2] DE N G, KIBBY J, MAZUREK W. Determination of ortho-cresyl phosphate isomers of tricresyl phosphate used in aircraft turbine engine oils by gas chromatography and mass spectrometry[J]. Journal of Chromatography A, 2008, 1200(2): 211-216.

[3] 杨 超, 邵腾飞, 魏朝良, 程 亮, 逢翠翠. 不同结构含磷极压剂润滑行为研究[J]. 摩擦学学报, 2016, 36(4): 458-464.

YANG Chao, SHAO Teng-fei, WEI Chao-liang, CHENG Liang, FENG Cui-cui. Lubricating mechanism of different structure phosphates as extreme-pressure additive[J]. Tribology, 2016, 36(4): 458-464.

[4] WINDER C, BALOUET J C. The toxicity of commercial jet oils[J]. Environmental Research, 2002, 89(2): 146-164.

[5] BEECK O, GIVENS J W, WILLIAMS E C. On the mechanism of boundary lubrication. Ⅱ. Wear prevention by addition agents[C]// Proceedings of the Royal Society of London A: Mathematical, Physical and Engineering Sciences. The Royal Society, 1940, 177(968): 103-118.

[6] FORBES E S, REID A J D. Liquid phase adsorption/reaction studies of organo-sulfur compounds and their load-carrying mechanism[J]. Tribology Transactions, 1973, 16(1): 50-60.

[7] 任朋飞, 李为民, 段伟娜. 新型含氮磷酸酯添加剂的合成及摩擦学性能研究[J]. 润滑与密封, 2011, 36(12): 41-44.

REN Peng-fei, LI Wei-min, DUAN Weina. The synthesis of new nitrogen-containing phosphate additives and its tribological behavior[J]. Lubrication Engineering, 2011, 36(12): 41-44.

[8] 熊 桑, 孙建林. 新型氮磷添加剂对铜箔轧制摩擦学性能与磨损行为的影响[J]. 中国有色金属学报, 2014, 24(9): 2352-2359.

XIONG Sang, SUN Jian-lin. Effect of oil additive containing nitrogen and phosphorus on tribology performance and wear behavior of copper foil during rolling[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(9): 2352-2359.

[9] ONODERA T, MORITA Y, SUZAKI A, SHNOUN R, KOYAMA M, TSUBOI H, HATAKEYAMA N, ENDOU A, TAKABA H, KUBO M, CARPIOC A D, MINFRAY C, MATIN J, MIYAMOTO A. A theoretical investigation on the abrasive wear prevention mechanism of ZDDP and ZP tribofilms[J]. Applied Surface Science, 2008, 254(23): 7976-7979.

[10] JIANG Shao-yi, DASGUPTA S, BLANCO M. Structures, vibrations, and force fields of dithiophosphate wear inhibitors from ab initio quantum chemistry[J]. Journal of Physical Chemistry, 1996, 100(39): 15760-15769.

[11] 熊 桑, 孙建林, 徐 阳, 严旭东. 基于分子动力学理论制备含氮磷硼酸酯添加剂及其摩擦学性能[J]. 中国有色金属学报, 2015, 25(6): 1721-1729.

XIONG Sang, SUN Jian-lin, XU Yang, YAN Xu-dong. Preparation of nitrogen- and phosphorus-containing boric acid ester additive based on molecular dynamics theory and its tribology properties[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(6): 1721-1729.

[12] KHALED K F, FADL-ALLAH S A, HAMMOUTI B. Some benzotriazole derivatives as corrosion inhibitors for copper in acidic medium: Experimental and quantum chemical molecular dynamics approach[J]. Materials Chemistry & Physics, 2009, 117(1): 148-155.

[13] ROY P D, QUIROZ-JIMENEZ J D, PEREZ-CRUZ L L. Late quaternary paleohydrological conditions in the drylands of northern Mexico: A summer precipitation proxy record of thelast80calkaBP[J]. Quaternary Science Reviews, 2013, 78(454): 342-354.

[14] SHINDE R N, SOBHIA M E. Binding and discerning interactions of PTP1B allosteric inhibitors: Novel insights from molecular dynamics simulations[J]. Journal of Molecular Graphics & Modelling, 2013, 45(5): 98-110.

[15] PANDARINATHAN V, LEPKOVA K, BAILEY S I, BECKER T, GUBNER R. Adsorption of corrosion inhibitor 1-dodecylpyridinium chloride on carbon steel studied by in situ AFM and electrochemical methods[J]. Industrial & Engineering Chemistry Research, 2014, 53(14): 5858-5865.

[16] 熊 桑, 刘娜娜, 夏 垒. 压延电子铜箔轧制与润滑性能研究[J]. 矿冶, 2013, 22(S1): 79-82.

XIONG Sang, LIU Na-na, XIA Lei. Research on rolling and lubricating performance of calendaring electronic copper foil[J]. Mining and Metallurgy, 2013, 22(S1): 79-82.

[17] KORNHERR A, HANSAL S, HANSAL W E G, KRONBERGER H, NAUER G E. Molecular dynamics simulations of the adsorption of industrial relevant silane molecules at a zinc oxide surface[J]. Journal of Chemical Physics, 2003, 119(18): 9719-9728.

[18] ARIMAT T, KIKUCHI K, KASUYA M. Optical excitations in CuO sub 2, sheets and their strong dependence on Cu-O coordination and bond length[J]. Physical Review B Condensed Matter, 1991, 44(2): 917-920.

[19] KNOP O, BOYD R J, CHOI S C. ChemInform abstract: S-S bond lengths, or can a bond length Be estimated from a single parameter?[J]. Journal of the American Chemical Society, 1989, 20(3): 7299-7301.

[20] 范荣玉, 郑细鸣. 铅(Ⅱ)离子印迹复合膜对重金属离子的吸附热力学与吸附动力学[J]. 化工学报, 2013, 64(5): 1651-1659.

FAN Rong-yu, ZHENG Xi-ming. Thermodynamics and dynamics for adsorption of heavy metal ions on Pb(Ⅱ) ion-imprinted composite membrane. CIESC Journal, 2013, 64(5): 1651-1659.

[21] BASERI J R, PALANISAMY P N, SIVAKUMAR P. Application of polyaniline nano composite for the adsorption of acid dye from aqueous solutions[J]. E-Journal of Chemistry, 2012, 9(3): 1266-1275.

[22] KANDIL A E H T, SAAD E A, AZIZ A A A, ABOELHASAN A E. Study on adsorption behavior and separation efficiency of naturally occurring clay for some elements by batch experiments[J]. European Journal of Chemistry, 2012, 3(1): 99-105.

Adsorption characterization and lubrication properties of phosphate ester in copper rolling oil

YAN Xu-dong, SUN Jian-lin, XIONG Sang

(School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: The activity of dialkyldithiophosphate ester (DDE) was calculated based on DFT theory, and the stable adsorption configuration of molecule-copper surface was built. The effects of DDE on the tribological performances and lubrication properties were investigated using a four-ball wear tester and a 4-high rolling mill, respectively. And the compositions of surface attachments were analyzed with XPS. The results show that DDE exhibits excellent extreme pressure and anti-wear properties as additives. With 0.05% (mass fraction) DDE into base oil, the maximum non-seizure load (pB) reaches 588 N, increases by 66.57% compared with that of base oil. The calculated adsorption energy of DDE-Cu is 225.80 kJ/mol. It is indicating stable chemical adsorption generated by O, S element on Cu surface during the wear process. The friction coefficient and wear scar are obviously reduced, and the minimum rolling gauge decreases to 22 μm.

Key words: copper; rolling oil; adsorption characterization; lubrication property; adsorption energy

Foundation item: Project(51474025) supported by the National Natural Science Foundation of China

Received date: 2017-01-20; Accepted date: 2018-01-10

Corresponding author: SUN Jian-lin; Tel: +86-10-62333768; E-mail: sjl@ustb.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51474025)

收稿日期:2017-01-20;修订日期:2018-01-10

通信作者:孙建林,教授,博士;电话:010-62333768;E-mail: sjl@ustb.edu.cn