J. Cent. South Univ. (2012) 19: 1724-1727

DOI: 10.1007/s11771-012-1199-7

Mathematical models and expert system for grate-kiln process of iron ore oxide pellet production. Part II: Rotary kiln process control

FAN Xiao-hui(范晓慧), WANG Yi(王祎), CHEN Xu-ling(陈许玲)

School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2012

Abstract: Rotary kiln process for iron ore oxide pellet production is hard to detect and control. Construction of one-dimensional model of temperature field in rotary kiln was described. And the results lay a solid foundation for online control. Establishment of kiln process control expert system was presented, with maximum temperature of pellet and gas temperature at the feed end as control cores, and interval estimate as control strategy. Software was developed and put into application in a pellet plant. The results show that control guidance of this system is accurate and effective. After production application for nearly one year, the compressive strength and first grade rate of pellet are increased by 86 N and 2.54%, respectively, while FeO content is 0.05% lowered. This system can reveal detailed information of real time kiln process, and provide a powerful tool for online control of pellet production.

Key words: mathematical model; expert system; one-dimensional temperature field; rotary kiln; iron ore oxide pellet

1 Introduction

Rotary kiln is a widely used equipment for iron ore oxide pellet induration. Preheated pellets are fed into rotary kiln for roasting. While tumbling in circumferential direction, pellets also slide forward along axial direction, exchanging heat with countercurrent gas and kiln wall. Fuel is injected into rotary kiln by burner and provides heat for the whole grate-kiln system. Recycle gas, i.e. secondary air, enters rotary kiln from the lower end as heat supplement. The reactions inside pellet, such as decomposition, oxidation, de- sulphurization, crystallization, recrystallization and crystal growth proceed in the high temperature environment inside rotary kiln. Pellet strength is further improved by pellet shrinkage, mineral composition homogenization and structural densification.

Rotary kiln is a typical complex, large-scale, continuous process. The key of rotary kiln process control is keeping the thermal regulation stable. However, fluctuations are inevitable due to material conditions, equipment working conditions, etc. Therefore, it is necessary to take real time detection and adjustment on kiln process.

Rotary kiln is relatively closed. As a result, the detections during kiln process are limited to routine tests such as gas temperatures at ends, rotate speed, and gas pressure. Moreover, the detecting equipments are affected by environment, and short in service life. With the growing demands for kiln process detection and progress in sensor research, new detecting techniques, such as microwave radiometry [1], infrared temperature measurement [2], optical fiber sensor [3], image analysis [4], model simulation [5-7], and artificial intelligence [8-10], are gradually developed.

Mathematical model of temperature field in rotary kiln can take full advantage of the detection information under the existing condition, and obtain wealth of crucial information that can not be easily detected. Plenty of models have been established based on different assumptions and analytical methods, including one-dimensional axial model [11], cross-section model [12], quasi-three-dimensional model [5], flame zone model [13], and kiln wall heat transfer model [14], etc. However, these researches are mostly process simulations. Applications of kiln model in iron ore pellet production are rarely reported.

With the rich data acquired by both field detection and model calculation, expert system can take expertise of domain experts as basis, and give suggestions of expert level [15], subsequently, realize on-line control guidance of kiln process for iron ore oxide pellet production.

Therefore, this work focuses on mathematical model and expert system for kiln process.

2 Mathematical model of temperature field in rotary kiln

One-dimensional model of temperature field in rotary kiln for iron ore oxide pellet production was developed to provide basis for real time production status estimation.

Considering a radial slice of length dz at any position along the kiln axis, the following assumptions are made for simplification:

1) the process is at steady state;

2) a perfectly mixed burden is exerted;

3) gas temperature is uniform in each unit;

4) heat released by fuel combustion is transferred by gas;

5) the outside temperature of rotary kiln is constant;

6) heat conduction is negligible in the axial and radial direction of kiln, except for heat conduction between kiln lining and arcuate surface of pellet bed, as well as heat conduction between outer shell and ambient environment;

7) inlet and outlet end are adiabatic.

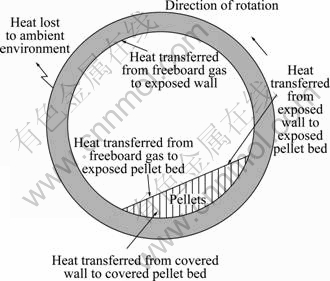

Inside the rotary kiln, heat is released by fuel combustion and chemical reactions of pellets, transferred among pellets, gas flow and kiln wall by conduction, convection and radiation. Heat transfer paths in the cross section are shown in Fig. 1.

Fig. 1 Heat transfer paths in radial cross section

Figure 1 shows that, for pellets, they are heated by gas flow and both covered and exposed part of kiln wall, moreover, heat is released by physical and chemical reactions in pellets. And the total amount of the heat is carried by advection of pellets. For gas flow, the heat incoming is from fuel combustion, and the outgoing is heat transferred to exposed kiln wall and the top surface of pellet bed. The difference between these two equals heat carried by advection of gas flow. There is no heat accumulation in kiln wall at steady state, therefore, for kiln wall, heat lost from outer shell to ambient environment equals the difference between heat transferred from gas flow to the exposed part and heat transferred from kiln wall to pellet bed. Therefore, energy balance equations for pellet, gas flow and kiln wall are as follows:

(1)

(1)

(2)

(2)

(3)

(3)

where h is the coefficient of heat transfer, J/(m2·K), and

,

,  ,

,

,

,  ,

,  ; M is

; M is

mass flow rate, kg/s; c is specific heat, J/(kg·K); A is heat transfer area, m2; T is temperature, K; z is position along axial direction of kiln, m; Qreaction is reaction heat, J/m. Subscript “p” represents for pellet, while “cp” and “ep” stand for pellets that covers the kiln wall and top surface of pellet bed; subscript “w” represents for kiln wall, while “cw” and “ew” stand for kiln wall covered by pellets and exposed kiln wall; subscript “g” represents for gas; “sh” represents for kiln outer shell; and “a” represents for ambient environment. Superscript “CD”, “CV” and “R” represent for conduction, convection and radiation, respectively.

3 Expert system for kiln process control

Real time information of thermal status in kiln is provided by the model above as well as field detection. Among these data, maximum temperature of pellet and gas temperature at the feed end can reflect total heat and heat distribution. Therefore, they were chosen as core parameters for kiln process control.

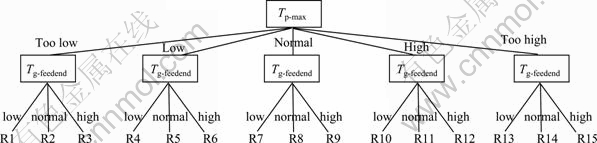

In order to minimize interferences of detection and calculation errors, and avoid frequent adjustment, interval control strategy was adopted. Parameters were divided into several intervals according to specific standards under corresponding production plans. According to the requirements of kiln process control, gas temperature at the feed end is divided into three grades, i.e. “low”, “normal” and “high”, while maximum temperature of pellet has two more grades “too low” and “too high”. These standards are stored in Access tables with the structure shown in Table 1, and each table represents a production plan range.

Table 1 Structure of interval partition tables

Fifteen possible statuses in kiln process are shown in Fig. 2, where Tp-max and Tg-feedend are maximum temperature of pellet and gas temperature at the feed end, respectively. Corresponding adjustment measures were established and numbered as R1-R15.

These adjustment measures have the following features:

1) Rotate speed of kiln is adjusted if and only if maximum temperature of pellet is in the intervals of “too high” or “too low”, so that abnormal status can be solved quickly and efficiently, and the output of pellet will not be affected.

2) These adjustments are procedural. Optimal measures are selected to adjust the current status back to normal. After the formation of a new status, corresponding new measures are suggested. And the “judge-adjust” process is repeated until normal status is finally achieved. Instead of blind pursuing less adjustment steps, the primary objective of procedural adjustment is to ensure that every step is in the correct direction and the status is changing towards normal.

3) Adjustment range of coal injection rate is determined by sequence number of rules, so that semiquantitative control guidance is realized. The smaller the rule number is, the larger the difference is between current value of heat in kiln and its suitable value, and the larger the adjustment range should be.

Therefore, fifteen rules were made based on expertise, represented using production rule, in the form of: “if condition 1 and condition 2, then conclusion”. Forward reasoning was chosen for inference rules.

4 Software development and application

Software of kiln process control expert system was developed by Visual C++ programming. Data reading, model calculation, and expert system inference are run in background. Real time status of kiln process is presented at the user-friendly software interface. Temperature field in rotary kiln is displayed by curve, which reveals the roasting process inside kiln visually. With the excellent interactive function, users can check the detailed data information of temperature and position by resting the mouse on these curves. Production status is diagnosed every minute and the result is provided to users in text form.

This system was put into use in a pellet plant in China. Production data at 2010-07-01 9:29:13 are given in Table 2. Mathematical model of grate process provided the data that inlet temperature of pellet into rotary kiln was 906 ℃ and mass flow rate into rotary kiln was 63.75 kg/s.

Pellet temperature and gas temperature in rotary kiln changing along axial direction were calculated with the model above. The results are shown in Fig. 3. Pellet temperature curve shows a parabolic shape. The maximum value is 1 207 ℃ at the point 15 m away from the lower end, and reduces to 1 021 ℃ till the lower end. Gas temperature reaches the maximum value of 1 216 ℃ at the point 19 m away from the lower end, and reduces to 1 066 ℃ flowing out of kiln to provide heat for preheating section.

In response, the abnormal message was displayed as “Maximum temperature of pellet is low and gas temperature at the feed end is normal”. The suggestion of adjustment measures given by expert system was “Increase coal injection rate”.

Operators at production site took the same measures as that suggested by the expert system. Coal injection rate was increased from 1.12 kg/s to 1.24 kg/s. Till 9:31:42, the production status was back to normal that maximum temperature of pellet was 1 223 ℃, and gas temperature at the feed end was 1 066 ℃.

Fig. 2 Decision tree

Fig. 3 Temperature field in rotary kiln

Table 2 Data collected from production

This system was put into production for nearly one year. Pellet quality was improved. The compressive strength and first grade rate were increased by 86 N and 2.54%, respectively, while FeO content was 0.05% lowered.

5 Conclusions

1) One-dimensional model of temperature field in rotary kiln was proposed, by which pellet temperature and gas temperature of each computing unit along axial direction could be obtained.

2) Expert system of kiln process control is established to improve control accuracy. Maximum temperature of pellet and gas temperature at the feed end are considered as control cores. They are both divided into several intervals according to specific parameter standards under corresponding production plans, and interval control strategy is adopted. Fifteen rules were represented using production rule based on expertise.

3) Software of kiln process control expert system is developed by Visual C++ programming. Functions such as real time calculation and display of temperature field, as well as adjustment suggestion are realized.

4) This system is validated with production data from a pellet plant in China. The control guidance is proved to be accurate and effective. After production application for nearly one year, compressive strength and first grade rate of pellet are increased by 86 N and 2.54%, respectively, while FeO content is 0.05% lowered. Pellet quality is improved.

References

[1] STEPHAN K D, WANG Ling-yun, RYZA E. Microwave radiometry for cement kiln temperature measurements [J]. Journal of Microwave Power and Electromagnetic Energy, 2007, 40(3): 140-144.

[2] DU Qi-liang, MO Hong-qiang, MAO Zong-yuan, LIN Jun. Infrared temperature measurement and analysis in a barium sulphide rotary kiln [J]. Chinese Journal of Scientific Instrument, 2007, 28(8): 1492-1496. (in Chinese)

[3] XIAO Chun, CHEN Jing, YUAN You-xin, HUANG Bi-hui, LI Jia. Research on kiln body health monitoring of ceramic roller kiln with oxygen-enriched and pure oxygen combustion [C]// 2008 Pacific-Asia Workshop on Computational Intelligence and Industrial Application. Wuhan, 2008: 607-611.

[4] HOGAN H. Accent on applications: Digital imaging enables researchers to take a kiln’s temperature without getting burned [J]. Photonics Spectra, 2006, 40(8): 34.

[5] BOATENG A A. Rotary kilns [M]. Oxford: Butterworth-Heinemann, 2008: 205-238.

[6] MASTORAKOS E, MASSIAS A, TSAKIROGLOU C D, GOUSSIS D A, BURGANOS V N, PAYATAKES A C. CFD predictions for cement kilns including flame modelling, heat transfer and clinker chemistry [J]. Applied Mathematical Modelling, 1999, 23(1): 55-76.

[7] LIU Jiao-yu, CHEN Kun, DENG Yi. Simulation of the atmosphere-temperature decoupling system on grey predicting PID control of the gas-burning roller ceramic kilns in SIMULINK [C]// Proceedings of the 9th International Conference on Electronic Measurement & Instruments, Beijing, 2009: 3742-3746.

[8] MOHANTY D, CHANDRA A, CHAKRABORTI N. Genetic algorithms based multi-objective optimization of an iron making rotary kiln [J]. Computational Materials Science, 2009, 45(1): 181-188.

[9] ZHANG Hong-liang, ZOU Zhong, LI Jie, CHEN Xiang-tao. Flame image recognition of alumina rotary kiln by artificial neural network and support vector machine methods [J]. Journal of Central South University of Technology, 2008, 15(1): 39-43.

[10] GUO Feng, LIU Bin, HAO Xiao-chen, GAO Peng. Research on the fuzzy predictive control for calcining temperature of the rotary cement kiln [C]// 10th International Conference on Signal Processing Proceedings. Beijing, 2010: 2568-2571.

[11] MA Ai-chun, ZHOU Jie-min, SUN Zhi-qiang, LI Wang-xing. A one-dimensional thermal model for the alumina clinker kiln [J]. Energy for Metallurgical Industry, 2004, 23(1): 23-26. (in Chinese)

[12] BARR P V, BRIMACOMBE J K, WATKINSON A P. A heat-transfer model for the rotary kiln: Part II. Development of the cross-section model [J]. Metallurgical Transactions B, 1989, 20(3): 403-419.

[13] GOROG J P, ADAMS T N, BRIMACOMBE J K. Heat transfer from flames in a rotary kiln [J]. Metallurgical Transactions B, 1983, 14(3): 411-424.

[14] GOROG J P, ADAMS T N, BRIMACOMBE J K. Regenerative heat transfer in rotary kilns [J]. Metallurgical Transactions B, 1982, 13(2): 153-163.

[15] PETRICA VIZUREANU. Expert systems[M]. Vukovar: Intech, 2010: 47-64.

(Edited by HE Yun-bin)

Foundation item: Project(NCET-05-0630) supported by Program for New Century Excellent Talents in University of China

Received date: 2011-05-24; Accepted date: 2011-11-09

Corresponding author: WANG Yi, PhD candidate; Tel: +86-731-88877952; E-mail: wangyicsu@yahoo.com.cn