淬火介质对2519铝合金抗剥落腐蚀性能的影响

李慧中1, 3,李芳芳1, 2,梁霄鹏1,刘 瑛1,张新明1, 3

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 湖南工业大学 材料科学与工程系,湖南 株洲,410000;

3. 有色金属材料科学与工程教育部重点实验室,湖南 长沙,410083)

摘 要:采用显微硬度测试与透射电镜分析,研究淬火介质对2519铝合金抗剥落腐蚀性能的影响。结果表明:采用空气、沸水和室温水(20 ℃)淬火后,各合金在时效过程中都表现出3个阶段时效特性:欠时效、峰值时效及过时效。合金经空气淬火并峰值时效后,晶界析出相呈不连续分布,且无沉淀析出带的平均宽度为100 nm;合金经室温水淬并峰值时效后,晶界析出相呈链状连续分布,无沉淀析出带平均宽度为60 nm;经室温水(20 ℃)淬火并峰值时效后合金抗剥落腐蚀性能最好,经100 ℃水淬火并峰值时效后的合金次之,经空气淬火并峰值时效后的合金抗剥落腐蚀性能最差。

关键词:2519铝合金;淬火介质;显微组织;剥落腐蚀

中图分类号:TG292 文献标识码:A 文章编号:1672-7207(2009)02-0389-06

Effect of quenching agent on exfoliation corrosion resistance of 2519 aluminum alloy

LI Hui-zhong1, 3, LI Fang-fang1, 2, LIANG Xiao-peng1, LIU Ying1, ZHANG Xin-ming1, 3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Department of Materials Science and Engineering, Hunan Industry University, Zhuzhou 410000, China;

3. The Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education,

Changsha 410083, China)

Abstract: The effect of quenching agent on exfoliation corrosion resistance of 2519 alloy was investigated by means of hardness tests and transmission electron microscopy (TEM). The results show that the three aged stages are observed in 2519 aluminum alloys after quenching in air, in the room temperature water and in boiling water. There are pre-ageing, peak-ageing and over-ageing. The precipitation of equilibrium is discontinuous on grain boundary and the average width of precipitation free zones (PFZ) is about 100 nm in air. The grain boundary precipitates have chain continuous distribution and average width of PFZ is about 60 nm for quenched alloys in the room temperature. Quenching in air has the worst resistance to exfoliation corrosion after peak ageing, while a better resistance against exfoliation corrosion can be expected by quenching in boiling water and the best anticorrosion performance is obtained by quenching in the room temperature water after peak ageing.

Key words: 2519 aluminum alloy; quenching agent; microstructure; exfoliation corrosion

2519铝合金属于高Cu/Mg比Al-Cu-Mg系热处理可强化铝合金,主要用于飞机蒙皮、火箭、舰船等的结构材料和两栖装甲突击车等的装甲材料[1-3]。该合金具有良好的力学性能、抗弹性能、焊接性能及良好的抗腐蚀性能。人们对淬火介质及淬火速率对铝合金的组织和性能的影响进行了研究,得出:经室温水淬和沸水淬火,可使7055铝合金的晶界析出相由空气淬火时的不连续分布转变为链状的连续分布,且可使无沉淀析出带变窄[4];1420铝锂合金在油中淬火可得到比空气和水淬更好的综合力学性能[5];淬火速率提高可减小7055铝合金的晶界无沉淀析出带的宽度,提高合金的抗晶间腐蚀能力[6]。目前,人们对2519铝合金腐蚀性能的研究主要集中在形变热处理和时效过程对合金的抗晶间腐蚀及抗应力腐蚀敏感性的影响[7-12],对2519铝合金的剥落腐蚀行为也进行了研究。时效前的预变形对2519铝合金的抗剥蚀行为有重要的影响,当时效前预变形量为5%~15%时,2519铝合金抗剥蚀性能较差[13]。但目前还未见淬火介质对该合金抗剥落腐蚀行为的影响报道,为此,本文作者通过改变2519铝合金固溶后的淬火介质来研究合金的抗剥落腐蚀性能,以便为2519铝合金适宜淬火介质的选择提供理论依据。

1 实 验

实验材料采用厚度为2 mm的2519铝合金热轧板材,实际成分为(质量分数,%):Cu 5.8,Mn 0.3,Mg 0.2,Zr 0.22,Ti 0.06,Fe 0.15和Si 0.05,余量为Al。在530 ℃保温2 h,分别于室温水(20 ℃)、沸水和空气中淬火以获得快、中、慢的淬火速率,转移时间不高于15 s。合金淬火后经10%冷轧变形,于180 ℃进行人工时效。将峰值时效的样品分别标记为APQ(Air peak quench),RPQ(Room water peak quench),BPQ (Boiling water peak quench)。

剥蚀按ASTM 34—79[14]标准进行。取平行试样3块,面积约50 mm×15 mm,保留原始面为实验面,非实验面用松香与石蜡熔融混合物密封。溶液体系为NaCl 234 g/L+KNO3 50 g/L+HNO3 6.3 mL/L,面容比为50 cm2/L,实验温度为(25±1) ℃,分别于腐蚀后6,12,24,48,72和96 h间断观察,拍摄样品腐蚀后表面宏观形貌,并根据标准[14]判定其剥蚀程度,并评定腐蚀等级。设定:N为无明显点蚀;P为点蚀;其中“+”和“-”代表腐蚀的严重程度,“+”表示更严重;“-”表示没有达到某种程度;EA→EB→EC→ED代表剥落腐蚀程度逐渐加重。透射电镜分析在TecnaiG220型电镜下进行,其样品先用机械方法将厚度减薄到0.1 mm,在MIT-Ⅱ型双喷电解仪上用30% HNO3+70% CH3OH(体积分数)溶液双喷减薄,双喷温度为-25 ℃,电压为10~20 V,电流为80~100 mA。

2 实验结果

2.1 合金时效硬化行为

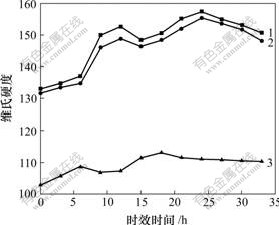

经不同介质淬火的合金于180 ℃等温时效的时效特征曲线如图1所示。由图1可见,各合金在时效过程中都表现出明显的双阶段时效硬化行为,即各合金都分别经历了欠时效、第1阶段峰值时效、第2阶段峰时效以及过时效的过程。随着时效时间的增加其硬度逐渐增大,当达到第2阶段峰值时效时硬度达到最大值,其中,空气淬火峰值硬度(HV)为113.2;沸水和室温水(20 ℃)淬火的峰值硬度分别为155.5和157.5。继续增加时效时间,合金进入过时效状态,硬度开始下降。同时,空气淬火时合金到达峰值时效所需时间最短,为18 h。沸水和室温水淬火达到峰值时效的时间为24 h,说明随着冷却速度的降低,合金到达峰值的时间提前。

1—RPQ;2—BPQ;3—APQ

图1 合金180 ℃等温时效硬化曲线

Fig.1 Isothermal age-hardening curves at 180 ℃

2.2 合金剥落腐蚀行为

将样品浸入实验溶液后,分别选取时效时间为6,12,24,48,72和96 h作为节点,并对实验面进行拍照,分别如图2~4所示。可见,空气淬火样品剥蚀实验约6 h以后就开始有零星分散的微小蚀点及空洞出现,并伴随有明显的鼓泡现象(图2);而经室温水淬火(图3)与沸水淬火(图4)的样品,12 h以后开始有零星分散的微小蚀点及空洞出现,伴随有鼓泡开裂现象。随着浸泡时间的增加,腐蚀不断深入,蚀点数量增多,孔径有所增大,这些试样的剥落腐蚀过程都经历了点蚀→(鼓泡,开裂)→分层→表层金属剥落的发展过程。经过空气淬火的样品(图2)先发生点蚀、鼓泡,而后沿样品表层向下快速腐蚀,至96 h腐蚀剥落层深入样品内部,并产生大量的剥落腐蚀产物;而经过室温水淬火(图3)与沸水淬火(图4)的样品剥蚀速度较慢,但同样也经历了点蚀、鼓泡,而后沿样品表层向下快速腐蚀,至96 h腐蚀剥落层深入样品内部,并产生大量的剥落腐蚀产物。总体来说,空气淬火样品比室温水淬火与沸水淬火的样品抗剥蚀敏感性要差,产生的剥蚀产物明显比室温水淬火与沸水淬火的样品多。室温水淬火样品与沸水淬火样品剥蚀倾向相当。但在结束时进行剥蚀测试发现,室温水淬火样品的剥蚀深度低于沸水淬火样品的剥蚀深度。

浸泡时间/h: (a) 6; (b) 12; (c) 48; (d) 96

图2 APQ腐蚀形貌

Fig.2 Corrosion morphologies of APQ

浸泡时间/h: (a) 6; (b) 12; (c) 48; (d) 96

图3 RPQ腐蚀形貌

Fig.3 Corrosion morphologies of RPQ

浸泡时间/h: (a) 6; (b) 12; (c) 48; (d) 96

图4 BPQ腐蚀形貌

Fig.4 Corrosion morphologies of BPQ

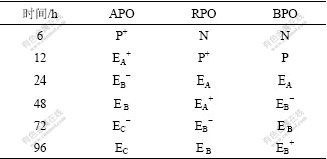

根据剥蚀等级标准结合腐蚀形貌与腐蚀产物,对不同浸泡时间的腐蚀样品进行等级评定,结果如表1所示。由表1可知,经空气淬火峰值时效处理后的样品约在12 h时就出现了剥蚀,随着时间的推移,腐蚀深度加大,到96 h时剥蚀等级为EC;经室温水淬峰值时效处理后的样品,约在24 h时就出现了剥蚀,到96 h时剥蚀等级变化为EB;经沸水淬峰值时效处理后的样品,约在24 h时出现剥蚀,到96 h时剥蚀等级变化为EB+。

表1 浸泡不同时间后合金的腐蚀等级评定

Table 1 Ratings of exfoliation corrosion after immersion into EXCO for different time

2.3 合金透射电镜观察

经过不同介质淬火并进行峰值时效处理以后样品的TEM形貌如图5所示。可见,经空气淬火峰值时效的试样(图5(a)),晶界上析出相粒子尺寸粗大,呈不连续分布,无沉淀析出带(PFZ)比较宽,约为100 nm,而经室温水淬并峰值时效的试样(图5(b)),晶界上的析出相比较细小、均匀,呈连续链状分布,PFZ的宽度约为60 nm。

3 实验结果分析

3.1 淬火介质对晶界析出相及PFZ宽度的影响

合金在淬火过程中,溶质原子会在晶界上发生非平衡偏聚,形成许多纳米级的富溶质层,而使晶界附近形成贫溶质区[15]。快速淬火如室温水淬时,温度降低很快,第二相没有足够时间形核析出,导致晶界析出第二相尺寸较小,随着淬火速率减小,如空气淬火,淬火过程中溶质原子有较多时间扩散到晶界析出θ(或θ′)相,进行时效处理时,由于空气淬火后晶界上已经有θ(或θ′)相析出,这些相吸收周围的溶质原子快速长大,沿晶界析出粗大的第二相(图5(a)),与此同时,也抑制了晶界上新的第二相的形核。

(a) APQ; (b) RPQ

图5 不同介质淬火的合金峰值时效的TEM像

Fig.5 TEM images of peak aged with different quenching agents

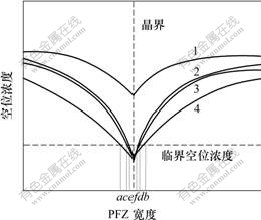

合金淬火后不同区域的过饱和空位浓度不同。由于合金在冷却过程中空位向晶界扩散而造成晶界附近空位浓度降低;远离晶界的地方无空位扩散,浓度高,这样,就形成一定的浓度差。当合金时效时,低于临界空位浓度的区域不能析出G.P.区而形成PFZ带,其宽度取决于空位浓度[16],当淬火速率慢时,经过时效处理,在晶界上容易析出较粗大的平衡相,在第二相形成的同时,也导致晶界附近溶质原子浓度和空位浓度降低。当淬火速率越小时,更多的空位扩散并消失在晶界,晶界无沉淀析出带就越宽。结合文献[4]中的研究结果,建立了2519铝合金晶界无沉淀带析出带宽度与淬火速度的关系模型,如图6所示。当淬火速率慢如空气淬火时,PFZ宽度为ab;当淬火速率快如沸水淬火时,PFZ宽度为cd;居于中间淬火速率如室温水淬火时,PFZ宽度为ef。可见,淬火速率越快,PFZ宽度越窄。

1—溶质原子的浓度分布; 2—室温水淬的空位浓度分布;

3—沸水淬的空位浓度分布; 4—空气淬的空位浓度分布

图6 晶界无沉淀析出带宽度与淬火速率的关系

Fig.6 Relationship between quenching rate and width of PFZ

3.2 晶界析出相及PFZ宽度对铝合金剥落腐蚀性能的影响

一般认为,剥蚀的发生需要2个条件[16-17]:拉长的晶粒和晶界电偶腐蚀(沉淀相/溶质贫化区)造成的腐蚀通道。此外,对铝合金剥蚀产生重要影响的因素是腐蚀产物所产生的外推力。外推力与晶粒形状有关,晶粒被拉长得越大,产生的外推力越大。剥蚀遵循应力腐蚀机理,即腐蚀产物楔入力在裂纹尖端产生拉应力集中,使腐蚀以SCC机理扩展。只要腐蚀尖端的拉应力存在,剥蚀就会一直发展下去。

在2519铝合金中,无沉淀带(PFZ)中的Cu含量(一般不超过2%)比基体的低,θ相沿晶界析出,其电极电位为-0.53 V,贫Cu区的电极电位为-0.75,基体的的电位为-0.69 V[7]。由于贫Cu(PFZ)区、晶界析出相和基体之间的电位差形成了腐蚀电池,而晶界析出相和无沉淀带(PFZ)往往形成阳极而优先溶解,从而形成沿晶界的阳极通道,不断产生不溶性产物(AlCl3或者Al(OH)3)。这些不溶物逐渐在晶界堆积,对周围组织产生压应力,当压应力超过晶粒的压应力屈服点时,就形成了剥蚀。在时效状态下,样品APQ由于淬火速率很小,晶界析出相θ(或θ′)较多,其附近Cu含量较低,无沉淀析出带较宽,使晶界附近成为阳极,而θ(或θ′)相和晶粒本身成为阴极,在腐蚀介质作用下,析出相周围的无沉淀带很快被消耗而形成腐蚀产物,当腐蚀产物对上层的晶粒产生应变很快达到晶粒断裂应变,导致晶粒断裂,直至剥落,从而导致严重剥蚀,剥蚀等级为EC。而样品RPQ由于抗剥落腐蚀能力较强,晶界析出物较少,无沉淀析出带较窄,形成的腐蚀电池较弱。

4 结 论

a. 采用空气、沸水和室温水(20 ℃)淬火后的各合金在时效过程中都表现出欠时效、第1阶段峰时效、第2阶段峰时效及过时效时效特征。空气淬火合金达到峰值时效时间最短,为18 h,峰值硬度最低,为113.2。

b. 合金经室温水淬火并时效后,晶界上的析出相呈链状连续分布,无沉淀析出带较窄,平均宽度为 60 nm;而经空气淬火时效后,晶界上析出相粒子粗 大,呈不连续分布,无沉淀析出带较宽,平均宽度为100 nm。

c. 2519铝合金经室温水(20 ℃)淬火时效后,合 金抗剥落腐蚀性能最强,合金剥落等级为EB;经100 ℃水淬火时效后的合金次之,剥落等级EB+,而经空气淬火时效后,抗剥落腐蚀能力最弱,剥落等级为EC。

参考文献:

[1] James J F, Lawrence S K, Joseph R P. Aluminum alloy 2519 in military vehicles[J]. Advanced Materials and Processes, 2002, 160(9): 43-46.

[2] Devincent S M, Devletian J H, Gedeon S A. Weld properties of the newly developed 2519-T87 aluminum armor alloy[J]. Welding Journal, 1988, 67(7): 33-43.

[3] Sonnino C B, Ford T, Vanark V. Potentionetric and potentiostatic determination of corrosion rate of welded 2519 aluminum alloy[J]. ASTM Special Technical Publication, 1991(1134): 132-140.

[4] 刘胜胆, 张新明, 游海江, 等. 淬火介质对7055铝合金晶界析出行为的影响[J]. 特种铸造及有色合金, 2006, 26(11): 696-698.

LIU Sheng-dan, ZHANG Xin-ming, YOU Hai-jiang, et al. Effect of quenching agent on grain boundary precipitation behaviors of 7055 aluminum alloy[J]. Special Casting and Nonferrous Alloys, 2006, 26(11): 696-698.

[5] 张 涛, 吉泽升. 淬火介质对1420铝锂合金组织及性能的影响[J]. 哈尔滨理工大学学报, 2002, 7(1): 47-49.

ZHANG Tao, JI Ze-sheng. Effect of quenched rate to the microstructure and tensile properties of 1420 Al-Li alloy[J]. Journal Harbin University Science and Technology, 2002, 7(1): 47-49.

[6] 张新明, 刘胜胆, 刘 瑛, 等. 淬火速率和锆含量对7055型铝合金晶间腐蚀的影响[J]. 中南大学学报: 自然科学版, 2007, 38(2): 181-185.

ZHANG Xin-ming, LIU Sheng-dan, LIU Ying, et al. Influence of quench rate and zirconium content on intergranular corrosion of 7055 type aluminum alloy[J]. Journal of Central South University: Science and Technology, 2007, 38(2): 181-185.

[7] 李慧中, 张新明, 陈明安, 等. 热处理制度对2519铝合金晶间腐蚀性能的影响[J]. 材料热处理学报, 2005, 26(1): 20-23.

LI Hui-zhong, ZHANG Xin-ming, CHEN Ming-an, et al. Effect of heat treatment on intergranular corrosion of 2519 aluminum alloy[J]. Transactions of Materials and Heat Treatment, 2005, 26(1): 20-23.

[8] Hamilton B C, Saxena A. Transient crack growth behavior in aluminum alloys C415-T8 and 2519-T87[J]. Engineering Fracture Mechanics, 1999, 62(1): 1-22.

[9] Kramer L S, Blair T P, Blough S D, et al. Stress-corrosion cracking susceptibility of various product forms of aluminum alloy 2519[J]. Journal of Materials Engineering and Performance, 2002, 11(6): 645-650.

[10] Dymek S, Dollar M. TEM investigation of age-hardenable A1 2519 alloy subjected to stress corrosion cracking tests[J]. Materials Chemistry and Physics, 2003, 81(2/3): 286-288.

[11] 李慧中, 张新明, 陈明安, 等. 时效过程对2519铝合金抗晶间腐蚀性能的影响[J]. 金属热处理, 2005, 30(5): 58-60.

LI Hui-zhong, ZHANG Xin-ming, CHEN Ming-an, et al. Effect of aging process on the intergranular corrosion of 2519 aluminum alloy[J]. Heat Treatment of Metals, 2005, 30(5): 58-60.

[12] LI Hui-zhong, ZHANG Xin-ming, CHEN Ming-an, et al. Effect of pre-deformation on the stress corrosion cracking susceptibility of aluminum alloy 2519[J]. Rare Metals, 2007, 26(4): 385-390.

[13] 刘 瑛, 张新明, 周古昕, 等. 预变形量对2519 铝合金抗剥落腐蚀性能的影响[J]. 材料热处理学报, 2006, 27(6): 61-65.

LIU Ying, ZHANG Xin-ming, ZHOU Gu-xin, et al. Effect of predeformation amount on exfoliation corrosion resistance of 2519 aluminum alloy[J]. Transactions of Materials and Heat Treatment, 2006, 27(6): 61-65.

[14] ASTM G34—79. Exfoliation corrosion susceptibility in 2××× and 7××× series aluminum alloys (EXCO test)[S].

[15] Hirosawa S, Oguri Y, Sato T. Formation mechanism of precipitate free zones in age-hardenable Al alloys[J]. Materials Forum, 2004, 28(6): 666-671.

[16] Kelly D J, Robinson M J. Influence of heat treatment and grain shape on exfoliation corrosion of Al-Li alloy 8090[J]. Corrosion, 1993, 49(10): 787-795.

[17] Robinson M J. The role of wedging stresses in the exfoliation corrosion of high strength aluminum alloys[J]. Corrosion Science, 1981, 23(8): 887-899.

收稿日期:2008-04-01;修回日期:2008-06-18

基金项目: 国家重点基础研究发展规划项目(2005CB623706);中国博士后基金资助项目(20070420828);中南大学博士后基金资助项目(2007-08)

通信作者:李慧中(1968-),男,湖南常宁人,副教授,博士,从事高强铝合金研究;电话:0731-8830377;E-mail: lhz606@mail.csu.edu.cn