文章编号:1004-0609(2012)10-2882-08

镁还原工序中高温机械化装出料无轴螺旋机构的设计

任 玲,夏德宏,叶 岩

(北京科技大学 机械工程学院,北京 100083)

摘 要:针对目前金属镁热还原工序中人工装出料的现状,提出采用无轴螺旋体作为罐内执行机构的机械装出料方式。通过理论设计计算确定螺旋体的结构、尺寸和运动参数,采用ANSYS有限元分析螺旋体的整体弯曲和扭转性能,以保证机构设计参数合理并具有良好的机械性能。研究表明:通过对叶片截面温度场的分析发现,叶片在工作时间内的温升在材料的允许范围内,验证所选叶片材质的合理性;通过对螺旋体的应力分析,发现自由端叶片和螺旋内径处为薄弱环节,提出螺旋体自由端的缩径结构和外窄内宽的梯形叶片截面。采用本机构进行机械化装出料,可将装出料时间由2 h缩短为15 min,大大缩短热还原工序的时间,具有实际推广和应用价值。

关键词:镁热还原;高温装出料;机械化;无轴螺旋

中图分类号:TF822 文献标志码:A

Development of screw structure without shaft for

high-temperature mechanized charging and

discharging in magnesium reduction process

REN Ling, XIA De-hong, YE Yan

(School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: In traditional thermal reduction process of magnesium, charging and discharging were carried out in manual operation. Based on this, the screw structure without shaft was proposed as the actuator inside the reduction jar. The corresponding structure sizes and motion parameters were determined by theoretical calculation. The bending and torsion stress were analyzed by the finite element analysis of ANSYS software, which can guarantee feasible parameters designed and good mechanical property of the structure. By analyzing the temperature distribution of blade section, the temperature changes of blade during the working time are in the range of material allowed, which proves that the blade material is available. The blades at free end and at inner periphery are weak by the stress analysis. Therefore, a diameter shrinkage structure at free end and blade with trapezoid cross section are presented. The results show that, by applying the screw structure without shaft, the time for charging and discharging is shortened from traditional 2 h to 15 min, which shows the designed structure with practical value is worth popularizing.

Key words: thermal reduction of magnesium; high-temperature charging and discharging; mechanization; screw structure without shaft

基金项目:中央高校基本科研业务费专项资金资助项目(FRF-AS-10-005B)

收稿日期:2011-09-23;修订日期:2012-04-05

通信作者:任 玲,讲师,博士;电话:010-62332730;传真:010-62332741;E-mail: renl@me.ustb.edu.cn

我国原镁产量现居世界第一位,占世界总产量的80%以上[1]。目前,我国99%以上镁厂采用硅热法生产金属镁[2-3]。热还原工序是硅热法炼镁的核心工序,但其工作周期过长一直是金属镁冶炼行业难以解决的问题。热还原工序需要在真空热还原罐中完成,包括真空热还原和装出料两个环节。由于还原罐内高温、罐体氧化变形的影响,目前还原罐的装出料环节通常采用人工方式。其工作流程一般是将配备好的球团料由人工使用推料铲送入还原罐内,在高温下还原成金属镁,剩余矿渣由人工使用扒渣铲清除后再装料,进入下一工作周期。因此,如果能以机械代替人工进行装出料,不仅可大幅缩短还原工序时间,还可改善炼镁过程的生产环境,降低工人劳动负荷,提高生产自动化水平。

目前还原罐大多为横置且输送物料温度很高,因此在使用期间会发生局部剥落、不可逆的塌陷和弯曲变形。曾有学者提出刮板式除渣装置[4],但是受结构的限制,适应还原罐变形有限,且不利于装出料的高温工作环境[5-6]。对于还原罐这种狭长且一端封闭的结构,螺旋输送是较理想的机械输送方式,其结构如图1所示。这种方式具有结构简单、操作简便、效率高等优点,特别是通过在螺旋轴内通冷却水的方式基本解决了高温工作的问题[7],但是不能适应还原罐的变形要求。对于铲式除渣装置[8],虽然机构的铲头较灵活,可以适应还原罐变形,但是整个扒渣装料过程不连续,效率低。

图1 有轴螺旋体结构

Fig. 1 Screw structure with shaft

尽管人们对机械装出料方式做了各种尝试,但迄今依然没有找到一种既能适应高温工作条件,又能适应还原罐变形的方式。针对上述问题,本文作者提出一种无轴螺旋结构为罐内执行机构(见图2)。这种结构拥有螺旋输送的所有优点,同时由于中心无轴,无轴螺旋整体具有较大柔性,可适应还原罐的变形要求,使得装出料的机械化成为可能。进一步通过理论设计计算和仿真模拟等方法,得到装出料机的主要结构尺寸和工艺参数。

图2 无轴螺旋体结构

Fig. 2 Screw structure without shaft

1 装出料执行机构的设计

1.1 设计条件及工作流程

还原罐的规格选为总长3.5 m,高温部分外径(Do) 0.339 m,内径(Di)0.273 m,长2.86 m;低温部分外径(Do)0.3 m,内径(Di)0.29 m,长0.65 m。热还原过程炉温1 200 ℃左右。开炉后随着装出料的进行,炉温会有所下降。由于镁渣在低于675 ℃时会粉末化,造成扒渣困难,因此装出料温度不应太低,一般为900~ 1 200 ℃。

假设单罐产量30 kg,根据物料平衡计算得还原反应球团料191 kg,镁渣160 kg,平均装出料量2.1 t/h。装出料机的工作流程为无轴螺旋体旋进扒渣,到罐底后继续旋转至扒渣完全;之后反转进行装料,待物料到达还原罐底,逐渐旋出罐外。设计要求15 min内完成整个装出料过程,且螺旋装出料时间小于10 min。

1.2 主要结构尺寸及运动参数的确定

为了满足单罐装出料时间的要求,需要螺旋体有一定的装出料量。螺旋体的装出料量Q(t/h)可表示 为[9-10]

(1)

(1)

式中:D为螺旋直径,m;S为螺距,m;n为螺旋转速,r/min; 为螺旋体移动速度,m/s;f为物料输送填充系数;γv为物料堆积密度,t/m3;c为倾斜输送系数,还原罐横置时取为1。物料(球团料、镁渣)的输送填充系数和堆积密度如表1所列。

为螺旋体移动速度,m/s;f为物料输送填充系数;γv为物料堆积密度,t/m3;c为倾斜输送系数,还原罐横置时取为1。物料(球团料、镁渣)的输送填充系数和堆积密度如表1所列。

从式(1)中可以看出,螺旋输送量与螺旋外径、螺距、螺旋转速和螺旋体移动速度等参数有关,因而需要进一步确定各参数的具体数值。

表1 球团料与镁渣的特性参数

Table 1 Characteristic parameters of pellet and slag

1.2.1 螺旋直径与螺距

螺旋直径受还原罐内径的限制。考虑还原罐变形的影响,螺旋直径选取标准直径D=0.2 m。螺距S=D/(47AK2.5),其中K、A为物料特性系数,如表1所列。球团料和残渣特性系数不同,计算出的螺距也不同。但是由于螺距正比于螺旋输送量,为了保证螺旋输送量,螺距取大值S=160 mm。

1.2.2 运动参数

螺旋体的运动参数包括螺旋转速和旋进旋出时的移动速度。由于输送物料的不同,这两个参数应分别计算。对于出料过程,设螺旋体前进速度为 ,则单位时间的进渣量Qc为

,则单位时间的进渣量Qc为

(2)

(2)

式中:j为镁还原渣在罐内的填充系数,取为0.7。此时的出渣量Qd为

(3)

(3)

为保证螺旋体前进过程中镁渣不发生堆积,并且螺旋体的输送能力可充分发挥,令进渣量等于出渣量,得到如下螺旋前进速度、输送填充系数和螺旋转速之间的关系式

(4)

(4)

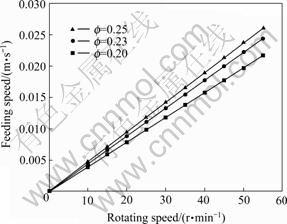

针对本机构的高温工作环境,应尽量减少螺旋叶片在高温炉渣中的时间,因此设计中要降低物料输送填充系数。物料输送填充系数分别为0.2、0.23和0.25时螺旋旋进速度与转速的关系如图3所示。从图3中可知,转速一定,要降低物料输送填充系数则必然要降低附加轴向速度 ,因此又会延长出料时间,所以应综合考虑。

,因此又会延长出料时间,所以应综合考虑。

图3 不同输送填充系数下螺旋旋进速度与螺旋转速的 关系

Fig. 3 Relationship between feeding speed and rotating speed under various filling coefficients for conveying

综合考虑出渣和装料时间分配,设计出渣时间3.5 min以内为宜,因此,螺旋体前进速度应大于0.166 m/s,根据图3满足这一条件的最低转速为40 r/min。取螺旋体前进速度0.017 m/s,可得到平均输送填充系数0.24,则螺旋旋进时间206 s,出渣量2.8 t/h。整个出料时间应在螺旋体旋进时间的基础上加上镁渣输送一个还原罐长的时间。无附加轴向速度时,物料输送速度0.107 m/s,输送一个还原罐总长时间33 s。则总出料时间239 s,总出料量3.4 t/h。实际生产中,还原罐使用前期变形程度较小,可取大于40 r/min的转速,保持前进速度不变从而减小填充系数,减少叶片在镁渣中的接触传热时间;还原罐使用后期变形程度加深,可降低转速,以应对随时可能发生的紧急状况。

对于装料过程,与出料过程相似,球团料在还原罐中的填充系数j=1(即装满),令填充量等于装料量,得

(5)

(5)

根据时间分配,装料过程用时6 min以内,其中包括输送一个罐长的时间。球团料较镁还原渣更易破损,因此,螺旋转速不能太高。装料过程中球团料填充系数最大可达0.3,满足设计装料时间的最低转速30 r/min。轴向退出速度应比设计值略大,取轴向退出速度0.012 m/s,则旋出时间292 s,装料量2.3 t/h。无轴向附加速度时的物料输送速度0.08 m/s,输送一个总罐长时间38 s,即从开始装料到螺旋体开始退出间隔38 s。总装料时间330 s,总装料量2.7 t/h。

表2 螺旋体主要结构尺寸及运动参数

Table 2 Dimensions and motion parameters of screw structure

综上所述,螺旋体的主要结构尺寸及运动参数如表2所列。装出料总时间为569 s,平均装出料量为2.8 t/h,满足设计要求。

1.2.3 螺旋内径、传动轴长和叶片厚度

除螺旋直径和螺距,螺旋体的结构尺寸还包括螺旋内径d、传动轴长L和叶片厚度δ。这3个参数对螺旋体整体弯曲和扭转性能会有较大影响,因而进一步采用ANSYS有限元软件进行静应力分析,确定这3个参数的合理设计值。螺旋体总长取为4 m,螺旋体材质选用310 s耐热钢,则弹性模量200 GPa,泊松比0.3,密度7 980 kg/m3。在ANSYS中,螺旋叶片选用弹性壳单元shell63,传动轴选用三维实体单元solid45,有限元模型如图4所示。网格大小设为0.01 m,经验证可满足精度要求。弯曲分析中,在自由端施加0.1 m的挠度变形;扭转分析中,传动轴端施加实际工作扭矩64 N×m。

图4 无轴螺旋体的有限元模型

Fig. 4 Finite element model for screw structure without shaft

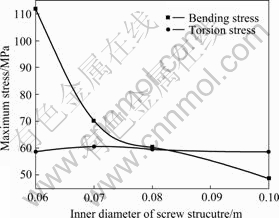

对于不同内径下,螺旋体受弯矩和扭矩时最大应力的变化如图5所示。图中传动轴长L=0.4 m,叶片厚度δ=0.01 m,螺旋内径分别取为0.06、0.07、0.08和0.1 m。由图5中可知,随着螺旋内径的增大,无轴螺旋体的最大弯曲应力减小,而最大扭转应力变化不大,即螺旋体弯曲刚度显著下降,扭转刚度变化不明显。说明螺旋内径越大,整体弯曲扭转性能越好。但是随着螺旋内径的增大,螺旋叶片的有效输送面积减小,从而影响装出料量和输送效率。螺旋内径与物料输送填充系数的关系曲线如图6所示,说明输送填充系数越大,则要求螺旋内径越小。对于本机构,要求物料填充系数至少要大于0.25,因此螺旋内径选取为0.08 m,内外径比为0.4。

对于不同的传动轴长,最大应力的变化规律如图7所示。图中螺旋内径d =0.08 m,叶片厚度δ=0.01 m,传动轴长分别取为0.4、0.55、0.7和1.05 m。由图7可以看出,随着传动轴长的增加,最大弯曲应力显著增大,而最大扭转应力变化较小。

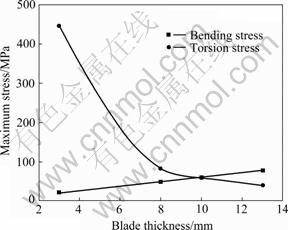

对于传动轴长L=0.4 m,螺旋内径d=0.08 m,叶片厚度分别取为0.003、0.008、0.01和0.013 m,最大应力随叶片厚度的变化如图8所示。由图8可知,随着叶片厚度的增加,最大弯曲应力增大,最大扭转应力减小。

图5 最大应力随螺旋内径的变化(L=0.4 m,δ=0.01 m)

Fig. 5 Dependence of maximum stress on inner diameter of screw structure (L=0.4 m, δ=0.01 m)

图6 螺旋内径与输送填充系数的关系(L=0.4 m,δ=0.01 m)

Fig. 6 Dependence of inner diameter on filling coefficient for conveying (L=0.4 m, δ=0.01 m)

图7 最大应力随传动轴长的变化(d=0.08 m,δ=0.01 m)

Fig. 7 Dependence of maximum stress on shaft length (d =0.08 m, δ=0.01 m)

图8 最大应力随叶片厚度的变化规律(L=0.4 m,d=0.08 m)

Fig. 8 Dependence of maximum stress on blade thickness (L=0.4 m, d=0.08 m)

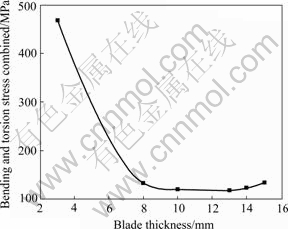

综上所述,螺旋体应当在保持一定扭转刚度的情况下,弯曲刚度尽可能小。然而在螺旋内径确定的情况下,螺旋体的扭转刚度和弯曲刚度受传动轴长与叶片厚度的综合影响。对比分析图7和图8,发现叶片厚度对应力的影响比传动轴长更明显。而传动轴长应尽量取较小的值,考虑到传动轴与螺旋叶片的连接稳定性,传动轴长取为L=0.55 m。进一步以弯曲扭转应力之和为评价指标,得到其随叶片厚度的变化,如图9所示。在叶片厚度为0.013 m时,弯曲扭转应力之和取最小值,因此,叶片厚度取为0.013 m。

图9 弯曲扭转应力之和随叶片厚度的变化(L=0.5 m,d=0.08 m)

Fig. 9 Dependence of bending and torsion stress combined on blade thickness(L=0.5 m, d=0.08 m)

2 螺旋体的模拟仿真与结构优化

2.1 叶片截面温度场分析

无轴螺旋体的结构不便于做水冷循环,因此有必要分析叶片在工作时间内的温升。假设叶片各向同性,并忽略叶片变形所产生的变形热、叶片无内热源,认为叶片与炉料、空气之间的换热系数是常数,且计算时间步足够小,以保证每一个区域内的热流在该时间步长内均视为常数。

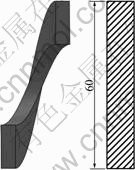

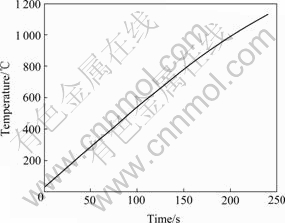

叶片各截面沿长度方向的热载荷相同,且长度远大于其高度和宽度,故将问题简化为二维瞬态传热问题[11]。沿径向切割螺旋体得到螺旋叶片截面,如图10所示。自由端的螺旋叶片在扒渣过程中一直与镁渣接触,为接触换热;中部螺旋叶片为接触换热与辐射换热交替;传动轴端主要为罐口的辐射换热。此外,叶片温升最大出现在扒渣结束时,因此对加热240 s的自由端叶片截面温度场进行分析。热分析采用ANSYS软件中三维具有面内导热能力的单元shell57。

图10 螺旋叶片截面

Fig. 10 Blade section of screw structure (mm)

由于自由端叶片始终与镁渣接触,简化为变热流边界条件,即

(6)

(6)

式中:TR为镁渣温度,K;hd为接触热传导系数,与界面的表面状况和接触压力的大小有关,W/(m2·K)[12-14]。叶片起始各节点的温度设为室温25 ℃。

将叶片厚度初步定为0.01 m,则叶片截面边界点的温升曲线如图11所示。从图11中可以看出,叶片截面加热240 s后,温度从25 ℃升至1 100 ℃左右。由于该热分析是假设自由端叶片始终与镁渣接触,而叶片沿轴向各截面根据接触时间不同最高温度也有所不同,因此,也可将图11看成是沿轴向不同位置叶片截面的最高温度曲线。根据螺旋体转速和移动速度,可求得各位置叶片与镁渣的接触时间,进而通过图11可得到扒渣结束时各位置叶片的最高温度。从图11中可以看出,螺旋体大部分叶片的最高温度在850 ℃以下,只有自由端部叶片温度较高。本文作者所选定的310 s耐热钢最高工作温度可达1 150 ℃,因此可满足工作要求。

进一步分析叶片厚度对叶片截面温升的影响。不同叶片厚度下,加热240 s后叶片截面的温度分布如图12所示。由图12可看出,由于叶片较薄,因此内

图11 叶片截面边界的升温曲线

Fig. 11 Temperature increasing curve at boundary of blade section

图12 叶片截面温度分布

Fig. 12 Temperature distributions of blade section: (a) δ= 0.01 m; (b) δ=0.015 m

外温差较小。增加叶片厚度,会降低叶片中心点温度,但厚度增加会引起弯曲刚度的增加。若将叶片厚度由0.01 m增加为0.015 m,可使叶片中心点的温度降低10 ℃,但整体机构弯曲应力将增加20 MPa。因此叶片厚度值的选择应以螺旋体静应力的分析结果为主要依据,取为0.013 m,而机构的高温工作问题可以通过提高材料的性质来解决。

2.2 螺旋体应力分析

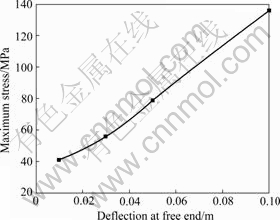

还原罐变形前期,螺旋体工作时只受扭矩,当还原罐出现轴向弯曲变形后,螺旋体将受到弯曲和扭转应力的共同影响。螺旋体最大弯曲挠度分别为0.01、0.03、0.05、0.1 m时螺旋体的最大应力如图13所示。由图13可看出,310 s耐热钢在1 000 ℃时的屈服强度约为110 MPa。螺旋体工作时的最大应力值在110 MPa内的最大允许挠度为0.08 m,若自由端挠度高于此值时则会发生屈服变形。经分析发现螺旋体的最大应力多出现在内径处,如图14所示为一局部叶片的应力分布。从图14中可以看出,内径处应力较外径明显增大,因此实际生产中应加强内径处的结构强度。

图13 螺旋体最大应力随自由端挠度的变化

Fig. 13 Dependence of maximum stress on deflection at free end

图14 局部叶片的应力分布

Fig. 14 Stress distribution of local blade (Pa)

2.3 螺旋体结构优化

通过上述分析,可以验证本文作者所设计的结构和所选材料基本满足还原罐内装出料的使用要求,但自由端叶片和螺旋内径处为薄弱环节。基于此,本文作者提出了相应的改进方法。针对自由端叶片,可将自由端螺旋体做成缩径结构,如图15(a)所示,由此可保证自由端在拥有一定输送能力的基础上加强高温结构强度。针对螺旋内径处应力较大、外径处应力较小的问题,可将螺旋叶片截面做成外窄内宽的梯形,如图15(b)所示,由此可以在保证叶片总质量不变的情况下,加强螺旋内径处的结构强度。

图15 改进后的螺旋叶片

Fig. 15 Improved blade of screw structure: (a) Diameter shrinkage at free end of blade; (b) Blade with trapezoid cross section

3 结论

1) 提出采用无轴螺旋体作为镁还原罐内高温装出料的执行机构,确定了螺旋体的叶片材质、螺旋外径、螺距、螺旋体转速、螺旋体轴向进出速度、装出料时间及装出料量等参数的数值。为保证机构具有良好的机械性能,通过ANSYS有限元分析螺旋体的整体弯曲和扭转性能,确定了螺旋内径、传动轴长和叶片厚度的合理尺寸值。

2) 通过对叶片截面温度场的分析,发现叶片在工作时间内的温升在材料的允许范围内,验证所选叶片材质的合理性。通过对螺旋体的应力分析,发现自由端叶片和螺旋内径处为薄弱环节,提出螺旋体采用自由端缩径结构和外窄内宽梯形叶片截面的改进方案。

3) 采用本机构进行机械化装出料,可将2 h的装出料时间缩短为15 min,大大缩短了热还原工序的时间,因此具有很强的推广应用价值,且经济效益显著。

4) 还原罐在使用前期变形较小,建议采用带有内置水冷循环的传统有轴螺旋体作为罐内执行机构;当还原罐变形增大到一定程度后,建议更换为无轴螺旋机构,以充分发挥其整体柔性的优点,且可增加螺旋叶片的使用寿命。

5) 针对扒渣后螺旋叶片可能粘有镁渣的情况,建议配备两套无轴螺旋机构分别进行扒渣和装料,同时还可减少螺旋叶片因冷热交替而产生的热疲劳,延长叶片的使用寿命。

REFERENCES

[1] 孟树昆, 吴秀铭, 韩 薇, 董春明. 发展中的中国镁业[J]. 中国有色金属, 2006(8): 19-21.

MENG Shu-kun, WU Xiu-ming, HAN Wei, DONG Chun-min. Developing magnesium industry in China[J]. China Nonferrous Metals, 2006(8): 19-21.

[2] 夏德宏, 郭 梁, 张 刚, 余 涛, 黄银善, 江运喜. 硅热炼镁还原炉的用能分析与节能措施探讨[J]. 冶金能源, 2005, 24(3): 32-35.

XIA De-hong, GUO Liang, ZHANG Gang, YU Tao, HUANG Yin-shan, JIANG Yun-xi. The thermal analysis on magnesium reducing furnace using Si-based reducing and some energy saving measures[J]. Energy for Metallurgical Industry, 2005, 24(3): 32-35.

[3] RAMAKRISHNAN S, KOLUN P. Global warming impact of the magnesium produced in China using the Pidgeon process[J]. Resources, Conservation and Recycling, 2004, 42(1): 49-64.

[4] 晏 燕. 扒渣装置: 中国, CN2864542[P]. 2007-01-31.

YAN Yan. Slagging-off machine: China, CN2864542[P]. 2007-01-31.

[5] 刘金平, 杨雪春, 谢水生, 李华清, 徐 河. 皮江法炼镁技术的缺陷及改进途径[J]. 冶金能源, 2005, 24(5): 21-23.

LIU Jin-ping, YANG Xue-chun, XIE Shui-sheng, LI Hua-qing, XU He. The deficiency and improvement methods of Pidgeon process Mg-smelting[J]. Energy for Metallurgical Industry, 2005, 24(5): 21-23.

[6] 于旭光, 邱竹贤. 镁工业生产及应用的现状和展望[J]. 材料与冶金学报, 2003, 2(3): 189-192.

YU Xu-guang, QIU Zhu-xian. Present situation and prospect of magnesium production and applications[J]. Journal of Materials and Metallurgy, 2003, 2(3): 189-192.

[7] 周富生. 金属镁冶炼炉的机械除渣装置: 中国, CN2795778[P]. 2006-07-12.

ZHOU Fu-sheng. Mechanical slagging-off machine for magnesium furnace: China, CN2795778[P]. 2006-07-12.

[8] 乔焰锋. 金属镁生产用机: 中国, CN201224755[P]. 2009-04-22.

QIAO Yan-feng. Machine for magnesium production: China, CN201224755[P]. 2009-04-22.

[9] 胡勇克, 戴莉莉, 皮亚南. 螺旋输送器的原理与设计[J]. 南昌大学学报: 工科版, 2000, 22(4): 29-33, 91.

HU Yong-ke, DAI Li-li, PI Ya-nan. Theories and calculation of the auger-type conveyer[J]. Journal of Nanchang University: Engineering & Technology, 2000, 22(4): 29-33, 91.

[10] 孙 洁, 尹忠俊, 陈 兵. 开式螺旋输送原理分析与参数设计[J]. 起重运输机械, 2010(5): 11-16.

SUN Jie, YIN Zhong-jun, CHEN Bing. An analysis of the principle of open-type spiral conveyance and related parameter design[J]. Hoisting and Conveying Machinery, 2010(5): 11-16.

[11] 尹忠俊, 陈 兵, 孙 洁, 张连万. 螺旋式输送机叶片温度场的有限元仿真分析[J]. 矿山机械, 2010, 38(13): 70-73.

YIN Zhong-jun, CHEN Bing, SUN Jie, ZHANG Lian-wan. FEA of temperature field of blade of screw conveyor[J]. Mining & Processing Equipment, 2010, 38(13): 70-73.

[12] 包仲南, 陈先霖, 张清东. 带钢热连轧机工作辊瞬态温度场的有限元仿真[J]. 北京科技大学学报, 1999, 21(1): 60-63.

BAO Zhong-nan, CHEN Xian-lin, ZHANG Qing-dong. Imitation of instantaneous temperature field of work roll in hot strip mill by finite element method[J]. Journal of University of Science and Technology Beijing, 1999, 21(1): 60-63.

[13] 牛 铁, 刘建生. 45钢静态接触时热传导系数的实验研究[J]. 机械工程与自动化,2010(2): 114-115, 118.

NIU Tie, LIU Jian-sheng. Testing thermal conductivity of 45 steel under static contact[J]. Mechanical Engineering & Automation, 2010(2): 114-115, 118.

[14] BURTE P R, YONG-TEAK I M, ALTAN T, SEMIATIN S L. Measurement and analysis of heat transfer and friction during hot forging[J]. Journal of Engineering for Industry, 1990, 112(4): 332-339.

(编辑 李艳红)