文章编号:1004-0609(2012)09-2642-06

高钙镁型钛渣物相重构法制取人造金红石

董海刚1, 2,郭宇峰1,姜 涛1,陈家林2,范兴祥2

(1. 中南大学 资源加工与生物工程学院,长沙 410083;

2. 贵研铂业股份有限公司 稀贵金属综合利用新技术国家重点实验室,昆明 650106)

摘 要:开展了高钙镁型钛渣通过添加Na2CO3焙烧进行矿相重构制取人造金红石的研究。采用XRD、SEM等技术对焙烧产物微观结构、物相组成和浸出产物物相组成进行表征。结果表明,在Na2CO3与钛渣质量比为3:7、焙烧温度为900 ℃、焙烧时间为2 h的条件下,所得焙烧产物经酸浸、煅烧后,获得TiO2品位为92.23%、回收率为92%、CaO+MgO含量(质量分数)为0.78%的人造金红石。该制备过程的机理主要在于高钙镁型钛渣添加Na2CO3焙烧可使其中的主要杂质转变为易选择性溶出的铁酸钠、Na-Fe-Ti-O系和Na-Mg-Ti-O系新矿相;通过酸浸,焙烧产物中大部分杂质被选择性溶出,钛组分转变成金红石型和锐钛型TiO2,实现了高品位人造金红石的制取。

关键词:钛渣;物相重构;人造金红石

中图分类号:TF111. 3 文献标志码:A

Production of synthetic rutile from high Ca and

Mg type titanium slag by mineral phase reconstruction process

DONG Hai-gang1, 2, GUO Yu-feng1, JIANG Tao1, CHEN Jia-lin2, FAN Xing-xiang2

(1. School of Resources Processing and Bioengineering, Central South University, Changsha 410083, China;

2. State Key Laboratory of Advanced Technologies for Comprehensive Utilization of Platinum Metals,

Sino-platinum Metals Co., Ltd., Kunming 650106, China)

Abstract: Study on the production of synthetic rutile from high Ca and Mg type titanium slag by adding Na2CO3 roasting for mineral phase reconstruction was carried out. The microstructure and mineral phase composition of the roasted product and leached product were characterized by XRD and SEM. The results show that a synthetic rutile with TiO2 grade of 92.23%, recovery of about 92% and CaO+MgO content (mass fration) of 0.78% is obtained by leaching and calcining the roasted product under the conditions of mass ratio of Na2CO3 to titanium slag of 3:7, roasting temperature of 900 ℃ and roasting time of 2 h. The mechanism of the preparation process is that after the titanium slag adding Na2CO3 being roasted, the impurities associated with titanium slag convert to easily selective soluble sodium titanate, sodium ferrite, Na-Fe-Ti-O and Na-Mg-Ti-O system minerals phase by roasting with Na2CO3. The roasted product is subjected to acid leaching, the impurities are selectively leached out, the titanium component converts into rutile and anatase type TiO2, which realizes the production of high grade synthetic rutile.

Key words: titanium slag; mineral phase reconstruction; synthetic rutile

基金项目:国家杰出青年科学家基金资助项目(50725416)

收稿日期:2011-08-30;修订日期:2011-12-02

通信作者:董海刚,助理研究员,博士;电话:0871-8329545; E-mail: donghaigang0404@126.com

四川攀西地区是我国钛资源储量最大的地区,探明储量达8.7亿 t(以TiO2计),占全国钛资源的90.54%。该资源通过分选获得的钛铁矿精矿,经过电炉熔炼后,获得TiO2品位为72%~85%、CaO+MgO含量高达8%~10%的钛渣。该渣仅适合用作硫酸法钛白生产原料,不宜于用于氯化钛白生产或海绵钛制取,严重制约我国钛工业产业的发展。因此,如何将攀钢电炉钛渣升级,去除钛渣中Ca和Mg等杂质,提高钛渣TiO2的品位,制取优质人造金红石,是实现我国攀西地区钛资源大规模高效利用的紧迫课题[1]。目前,对于高钙镁钛渣制取人造金红石的主要方法有:氧化-还原焙烧-浸出[2-4]、氧化-氯化焙烧-浸出[5]、酸碱联合浸出[6-7]、硫酸化焙烧-浸出[8-10]、选择性析出-分选-浸出法[11-12]等,但这些技术均存在流程长、焙烧温度高、能耗高、设备要求高及难以大型化等问题;国外对于这方面的研究技术高度保密,有研究提出了苏打灰焙烧-酸浸法处理钛渣制取人造金红石[13-16],其原料钛渣中CaO和MgO的总含量仅在2.5%左右,对于以CaO和MgO含量高的钛渣制取人造金红石的相关研究较少。国内也有研究提出采用碱焙烧-酸浸的方法,但都因原料性质不同而结果各异,并且没有对其过程机理进行深入研究[]17-18]。董海刚[19]和郭宇峰 等[20]曾采用活化焙烧-酸浸工艺处理攀枝花钛铁矿还原-磨选所得的富钛料[19-20]制取人造金红石,取得了一定的效果。本文作者以攀枝花钛铁矿经电炉熔炼获得的高钙镁型钛渣为研究对象,采用添加Na2CO3焙烧进行矿相重构后进行酸浸的技术路线制取人造金红石,并对其过程机理通过X射线衍射(XRD)及扫描电镜(SEM)分析技术进行讨论。

1 实验

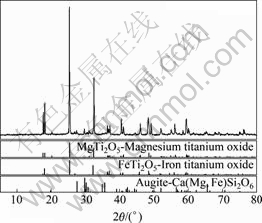

实验所用的原料为攀钢(集团)钛业公司电炉熔炼法所得钛渣,其主要化学成分见表1,XRD谱见图1。

表1 钛渣的主要化学成分

Table 1 Main chemical compositions of titanium slag (mass fraction, %)

由表1和图1可见,攀钢电炉钛渣TiO2品位低,仅为72.42%,主要杂质成分为Fe、SiO2、Al2O3、CaO、MgO等,其中对氯化法钛白生产及海绵钛制取危害较大的CaO和MgO总量高达9.57%。XRD分析表明,攀钢电炉钛渣中含钛的主要矿物是MgTi2O5、FeTi2O5(Me3O5)及硅酸盐类矿物。

图1 钛渣的XRD谱

Fig. 1 XRD pattern of titanium slag

具体实验方法如下:将电炉钛渣用球磨机细磨至粒径小于0.045 mm,按一定的质量比配加一定量的碳酸钠,充分混合后,装入坩埚,置于设定温度的卧式管炉内,恒温焙烧至指定的时间,取出,自然冷却后,取焙烧样进行XRD和SEM分析;余样进行酸浸、煅烧,冷却后,称量,取样分析煅烧产品的化学成分,计算TiO2回收率。

根据前期研究结果[21],确定两段酸浸条件如下:第一段浸出硫酸浓度15%(质量分数),浸出时间1.5 h,第二段浸出硫酸浓度25%(质量分数),浸出时间2 h,酸浸温度均为沸腾温度,液固比均为10:1(质量比),搅拌速度均为500 r/min;酸浸后,煅烧温度为900 ℃,时间为30 min。

2 结果与分析

2.1 Na2CO3/钛渣质量比的影响

研究了Na2CO3/钛渣质量比对TiO2品位及回收率的影响,结果见图2。实验时,焙烧温度为900 ℃,焙烧时间为2 h。

由图2可以看出,随着Na2CO3/钛渣质量比的提高,人造金红石TiO2品位逐渐升高,回收率变化不明显。Na2CO3/钛渣质量比为3:7时,人造金红石TiO2品位为92.21%,回收率为91.95%;继续提高Na2CO3/钛渣质量比为2:3时,人造金红石TiO2品位提高幅度不大,回收率变化不明显。这表明,Na2CO3/钛渣质量比需达到3:7以上,才能较好实现高钙镁型钛渣主要杂质向易选择性溶出矿相的转变。

图2 Na2CO3/钛渣质量比对TiO2品位及回收率的影响

Fig. 2 Effect of mass ratio of Na2CO3 to titanium slag on TiO2 grade and recovery rate

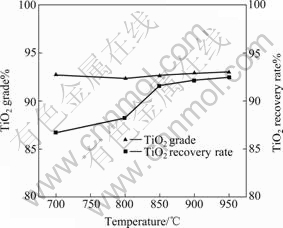

2.2 焙烧温度的影响

在矿相重构过程中,焙烧温度是影响钛渣与Na2CO3焙烧反应的重要因素。为确定适宜的焙烧温度,在Na2CO3/钛渣质量比为3:7,焙烧时间为2h的条件下,研究了不同焙烧温度对TiO2品位及回收率的影响,其结果见图3。

图3 焙烧温度对TiO2品位及回收率的影响

Fig. 3 Effect of roasting temperature on TiO2 grade and recovery rate

由图3可以看出,提高焙烧温度有利于高钙镁型钛渣主要杂质向易选择性溶出矿相的转变,从而提高酸浸除杂效果。随着焙烧温度的升高,人造金红石TiO2品位逐渐提高,回收率变化不明显。在Na2CO3/钛渣质量比为3:7的条件下,当焙烧温度提高到900 ℃时,人造金红石的TiO2品位为92.21%,回收率为91.95%。对于大多数固相反应而言,扩散过程是控制反应速率的关键。钛渣添加Na2CO3焙烧,两种固体只能在它们接触的界面上起反应,随着焙烧温度的提高,固相物质内能增大,晶格质点振动增强,离子迁移速度提高,体系趋于不稳定,加速了焙烧反应过程。实验过程中发现,当焙烧温度提高到950 ℃时,出现焙烧产物烧结现象。

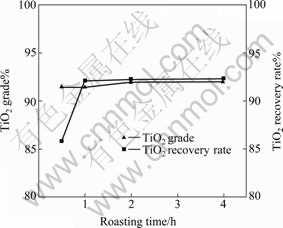

2.3 焙烧时间的影响

在焙烧温度一定的条件下,焙烧时间决定着固相反应进行程度,即矿相转变程度。实验研究了焙烧时间对TiO2品位及回收率的影响。实验时,Na2CO3/钛渣质量比为3:7,焙烧温度为900 ℃,其结果见图4。

图4 4焙烧时间对TiO2品位及回收率的影响

Fig. 4 Effect of roasting time on TiO2 grade and recovery rate

由图4可以看出,随着焙烧时间的延长,人造金红石TiO2品位及回收率均有一定的提高,但回收率的提高幅度不大。当焙烧时间为2 h时,人造金红石TiO2品位为92.21%,焙烧时间延长至4 h,人造金红石TiO2品位及回收率变化不明显。这是由于当焙烧时间较短时,钛渣与Na2CO3的反应不完全,随着焙烧时间的延长,固体物之间有足够的时间充分扩撒,反应进行比较彻底。从实验结果来看,钛渣与Na2CO3的反应在2 h内基本完成。

3 过程机理研究

3.1 焙烧产物物相变化

为了研究焙烧产物的变化,对钛渣中添加Na2CO3在不同条件下焙烧所得产物进行XRD分析。焙烧条件如下:温度900 ℃,时间2 h。其结果见表2。

由表2可以看出,不添加Na2CO3时,焙烧产物主要物相为Fe2TiO5、TiO2(金红石型)、硅酸盐类矿物和MgTi2O5。这主要是由于通过氧化焙烧,钛渣中Fe(II)转变成Fe(III),也就是亚铁板钛矿FeTi2O5被氧化形成了铁板钛矿Fe2TiO5及少量TiO2(金红石型)。当Na2CO3/钛渣质量比为3:7时,焙烧产物主要结晶物相有非化学计量的Na0.79Fe0.8Ti1.2O4和Na0.9Mg0.45Ti1.55O4以及NaFeTiO4;当Na2CO3/钛渣质量比提高到4:6时,焙烧产物主要物相有Na8Ti5O14、Na2TiO3、Na20Mg2 Ti20O52、Na0.75Fe0.75Ti0.25O2及NaFeO2等,同时硅酸盐类矿物和MgTi2O5相消失。这说明钛渣添加Na2CO3焙烧后,发生固相反应,其中的主要杂质生成一系列的可溶性新矿相,通过浸出,焙烧产物中的杂质不同程度地被溶出,含钛组分未被溶出,从而获得优质人造金红石,与前面实验结果相吻合。

表2 焙烧产物物相组成

Table 2 Mineral phase of roasted products

3.2 焙烧产物结构形态变化

焙烧产物物相分析结果表明,钛渣添加Na2CO3进行焙烧发生了一系列的化学反应,经历了原有物相的消失和新物相的形成过程,这一过程必然会对原有矿物的结构形态产生影响。为查明这一影响,对钛渣和焙烧产物进行SEM分析,结果见图5。焙烧条件如下:Na2CO3/钛渣质量比为3:7,焙烧温度为900 ℃,焙烧时间为2 h。

由图5可以看出,焙烧产物形态与钛渣形态相比发生了显著变化,添加Na2CO3焙烧后,焙烧产物形成了针状、絮团状多孔化合物,比表面积显著增大,这种结构形态的改变有利于加快焙烧产物酸浸反应速率,提高酸浸除杂效果,前面实验结果也进一步得到证实。

图5 钛渣和焙烧产物的SEM像

Fig. 5 SEM images of titanium slag (a) and roasted product (b)

3.3 焙烧产物酸浸行为

前面结果表明,在适宜的条件下,可以获得TiO2品位大于92%的优质人造金红石。为了证实焙烧产物的酸浸效果,对焙烧产物酸浸前后的物相组成进行了分析,结果见图6。

由图6可以看出,焙烧产物酸浸后,其物相明显发生变化。焙烧产物酸浸前,主要物相为Na0.9Mg0.45- Ti1.55O4和Na0.79Fe0.8Ti1.2O4及部分NaFeTiO4。酸浸后,浸出渣的主要物相为金红石型和锐钛型TiO2;另外,在2θ为28°~30°处,出现了少量的Na0.35Fe0.69Ti3.34O8化合物。这说明含焙烧产物与硫酸发生反应,其中Na、Fe和Mg等杂质元素被溶出,以及其它固溶于其中或存在于非晶态物质中的杂质组分被溶出,而含钛物相形成TiO2。据此推测,焙烧产物与硫酸发生的反应可表示如下:

Na0.79Mg0.45Ti1.55O4+H2SO4→

Na2SO4+MgSO4+TiO2+H2O (1)

NaFeTiO4+H2SO4→Na2SO4+Fe(SO4)3+

Na0.35Fe0.69Ti3.34O8+TiO2+H2O (2)

Na0.79Fe0.8Ti1.2O4+ H2SO4→Na2SO4+Fe2(SO4)3+

Na0.35Fe0.69Ti3.34O8+TiO2+H2O (3)

图6 焙烧产物酸浸前后的XRD谱

Fig. 6 XRD patterns of roasted product before and after acid leaching: (a) Before leaching; (b) After leaching

4 结论

1) Na2CO3/钛渣的质量比是高钙镁型钛渣添加Na2CO3焙烧进行矿相重构制取人造金红石的主要影响因素,其适宜的质量比为3:7。在焙烧温度为900 ℃、焙烧时间为2 h条件下所得焙烧产物经酸浸、煅烧后,获得TiO2品位为92.23%、回收率92%左右、CaO+MgO含量为0.78%的优质人造金红石。

2) 高钙镁型钛渣添加Na2CO3焙烧后,生成了钛酸钠、铁酸钠、Na-Fe-Ti-O和Na-Mg-Ti-O系等物相,使其中的主要杂质转变为易选择性溶出新矿相,并且焙烧产物呈针状、絮团多孔状,比表面积显著增加,加快焙烧产物酸浸反应速率,提高了酸浸除杂效果。

REFERENCES

[1] 莫 畏, 邓国珠, 罗方承. 钛冶金[M]. 2版. 北京: 冶金工业出版社, 1998: 118-198.

MO Wei, DENG Guo-zhu, LUO Fang-cheng. Titanium metallurgy [M]. 2nd ed. Beijing: Metallurgical Industry Press, 1998: 118-198.

[2] van Dyk J P. Beneficiation of titania slag by oxidation and reduction treatment: US6803024 [P]. 2004-10-31.

[3] Borowiec K, Grau A E, Gueguin M, Turgeon J F. Method to upgrade titania slag and resulting product: US5830420 [P]. 1997-05-29.

[4] 孙朝辉, 杨保祥, 张 帆, 杨小琴. 一种提高钛渣TiO2品位的方法: 中国, 200310110821.2 [P]. 2004-10-27.

SUN Chao-hui, YANG Bao-xiang, ZHANG Fan, YANG Xiao-qin. A method of upgrading TiO2 grade of titanium slag: CN200310110821.2 [P]. 2004-10-27.

[5] Gueguin M. Method of preparing a synthetic rutile from a titaniferous slag containing magnesium value: US5063032 [P]. 1991-11-05.

[6] 雷 霆, 米家蓉, 张玉林, 马 翔, 杨艳华, 周 林. 一种用电炉钛渣制取富钛料的方法: 中国, 200510048754 [P]. 2006-06-28.

LEI Ting, MI Jia-rong, ZHANG Yu-lin, MA Xiang, YANG Yan-hua. A method of producing Ti-rich material from electric furnace titanium slag: CN200510048754 [P]. 2006-06-28.

[7] 杨艳华. 电炉钛渣制备富钛料实验研究[D]. 昆明: 昆明理工大学, 2006: 25-30.

YANG Yan-hua. Experimental study on the production Ti-rich material from electric furnace titanium slag [D]. Kunming: Kunming University of Science and Technology, 2006: 25-30.

[8] ELGER G W, HOLMES R A. Purifying titanium-bearing slag by promoted sulfation: US4362557 [P]. 1982-10-07.

[9] Borowiec, K. Sulphidization of solid titania slag [J]. Scandinavian Journal of Metallurgy, 1991, 20(3): 198-204.

[10] ELGER G W, STADLER R A, SANKER P E. Process for purifying a titanium-bearing material and upgrading ilmenite to synthetic rutile with sulfur trioxide: US4120694 [P]. 1978-10-17.

[11] 张 力, 李光强, 隋智通. 高钛渣氧化过程的动力学[J]. 中国有色金属学报, 2002, 12(5): 1069-1073.

ZHANG Li, LI Guang-qiang, SUI Zhi-tong. Oxidation kinetics of titaniferous slag [J]. The Chinese Journal of Nonferrous Metals, 2002, 12(5): 1069-1073.

[12] 杨成洁. 改性高钛渣中金红石相的分离研究[D]. 沈阳: 东北大学, 2008: 21-67.

YANG Cheng-jie. Separation of rutile phase in the modified titania Slag [D]. Shenyang: Northeastern University, 2008: 21- 67.

[13] Lasheen T A. Soda ash roasting of titania slag product from Rosetta ilmenite [J]. Hydrometallurgy, 2008, 93(3/4): 124-128.

[14] GOMES J M, O’KEEFE D A. Preparation of TiO2 and artificial rutile from sodium titanate: US3976761 [P]. 1976-08-24.

[15] LAHIRI A, JHA A. Kinetics and reaction mechanism of soda ash roasting of ilmenite ore for the extraction of titanium dioxide [J]. Metallurgical and Materials Transactions B, 2007: 939-948.

[16] SAHU K K, ALEX T C, MISHRA, D, AGRAWAL, A. An overview on the production of pigment grade titania from titania-rich slag [J]. Waste Management Research, 2006, 24(1): 74-79.

[17] 蒋训雄, 帅兴国, 范艳青, 黄 斌, 蒋 伟, 蒲年文, 汪胜东, 翁庆强, 冯林永, 刘 巍. 一种钛渣生产人造金红石的方法. 中国, 101812595A [P]. 2010-08-25.

JIANG Xun-xiong, SHUAI Xing-guo, FAN Yan-qing, HUANG Bin, JIANG Wei, PU Wen-nian, WANG Sheng-dong, WENG Qing-qiang, FENG Li-yong, LIU Wei. A method on product of synthetic rutile from titanium slag: CN101812595A [P]. 2010-08-25.

[18] 薛天艳, 齐 涛, 王丽娜, 初景龙, 曲景奎, 刘长厚. 钠碱熔盐法处理高钛渣制备TiO2的基础研究[J]. 中国稀土学报, 2008, 26(专辑): 123-127.

XUE Tian-yan, QI Tao, WANG Li-na, CHU Jing-long, QU Jing-kui, LIU Chang-hou. Preparation of the titanium dioxide from titanium slag using molten sodium alkali [J]. Journal of the Chinese Rare Earth Society, 2008, 26(Special Issue): 123-127.

[19] 董海刚. 高钙镁电炉钛渣制备优质人造金红石的研究[D]. 长沙: 中南大学, 2010: 46-88.

DONG Hai-gang. Study on Production of High-quality Synthetic Rutile from Electric Furnace Titanium Slag with High Content of Calcium and Magnesium [D]. Changsha: Central South University, 2010: 46-88.

[20] 郭宇峰, 肖春梅, 姜 涛, 邱冠周, 黄柱成, 董海刚. 活化焙烧-酸浸法富集中低品位富钛料[J]. 中国有色金属学报, 2005, 15(9): 1146-1150.

GUO Yu-feng, XIAO Chun-mei, JIANG Tao, QIU Guan-zhou, HUANG Zhu-cheng, DONG Hai-gang. Enrichment of moderate and low grade titania feedstock by activated roasting-acidic leaching [J]. The Chinese Journal of Nonferrous Metals, 2005, 15(9): 1146-1150.

(编辑 何学锋)