DOI:10.19476/j.ysxb.1004.0609.2019.11.18

铅富氧侧吹氧化熔池熔炼相平衡计算模型

刘燕庭1, 2,杨天足1,李明周3

(1. 中南大学 冶金与环境学院,长沙 410083;

2. 长沙有色冶金设计研究院有限公司,长沙 410001;

3. 江西理工大学 材料冶金化学学部,赣州 341000)

摘 要:基于多相平衡原理,采用化学平衡常数法,建立铅富氧侧吹氧化熔池熔炼过程多相平衡模型和仿真系统。在原料组成、氧料比、冷却水量与进出水温差、富氧浓度等典型生产工况条件下,模拟计算平衡产物组成和关键技术指标。计算结果表明:与生产实测值相比,除富铅渣中微量元素外,一次粗铅、富铅渣和烟尘中Pb、Zn、S、Cu、As、Sb、Bi、Cd、Au、Ag质量分数计算值的相对误差均低于10%;渣中铁硅比(RCaO/SiO2)和钙硅比(RCaO/SiO2)、烟尘率、一次铅收率、富铅渣温度等关键技术指标的误差均小于8%。因此,所构建模型和计算系统能较好地反映铅富氧侧吹氧化熔池熔炼过程实际生产情况,具有精准预测该熔炼过程和优化工艺参数的潜力,可有效指导铅富氧侧吹氧化熔池熔炼的生产实践。

关键词:富氧侧吹;铅熔池熔炼;多相平衡;化学平衡常数法

文章编号:1004-0609(2019)-11-2609-11 中图分类号:TF812 文献标志码:A

从矿石或精矿中生产铅几乎都采用火法工艺[1],传统铅冶炼工艺已被多种直接炼铅新工艺取代[2-4],如SKS、QSL、富氧侧吹炼铅工艺、Ausmelt/Isasmelt熔池熔炼法和Kivcet、Outokumpu闪速炼铅法。然而,目前工业应用的几种直接炼铅工艺鼓入空气或富氧的位置不同,含铅物料在炉内的反应条件和控制难度不同,各元素的迁移分配行为和技术经济指标均会有所差异;富氧熔炼带来产能提高和过程强化的同时,也会导致过程工艺条件控制、杂质元素分配调控、渣型优化控制和产品质量保障等难度加大。随着铅原料品位的贫化、杂质元素(Cu、As、Sb、Bi、Cd等)含量升高及其来源的日益复杂,对冶炼工艺参数、技术指标和环保措施产生较大的影响[5]。这些都与工艺过程的热力学反应条件控制紧密相关,需要通过系统热力学分析以探寻优化控制的解决方案。

为解决过程优化控制难题,近年来,直接炼铅工艺的基础理论研究日益引起研究人员的关注。陈卓等[6]、张红亮等[7]采用CFD技术分别对闪速和底吹炼铅过程的多物理场分布行为进行了仿真模拟研究。尹飞等[8]结合铅富氧闪速熔炼的特点和基本原理,对相关渣型进行了研究。谭鹏夫等[9]和陈霖等[5]、汪金良等[10]分别研究建立QSL和Outokumpu直接炼铅工艺的多相平衡热力学模型,并对相应过程进行了热力学分析[11-12],然而,现有QSL和Outokumpu炼铅工艺模型,建模时未全部考虑Cu、As、Sb、Bi、Cd等杂质元素的热力学分配行为,另外,QSL模型计算时所采用的富氧浓度低。迄今为止,在考虑杂质元素的基础上,针对铅富氧侧吹熔池熔炼过程的多相平衡建模和热力学分析的研究鲜见报道。

富氧侧吹熔池熔炼工艺源于前苏联瓦纽科夫法,最初用于铜冶炼,引入铅冶炼领域后,在两台富氧侧吹炉内分别完成硫化铅精矿的氧化和富铅渣的还原过程,形成了一种直接炼铅新工艺[13-14]。该工艺属于高温、多相、多组分复杂体系,常规静态实验无法开展系统热力学分析,亟需构建模型突破实验条件限制。本文基于多相平衡原理,采用化学平衡常数法,建立铅富氧侧吹熔池熔炼过程的多相平衡热力学模型和仿真系统,模拟计算平衡产物组成和关键技术指标,并与工业生产数据进行比较,以期为预测铅富氧侧吹熔池熔炼过程产出、揭示杂质分配行为规律和优化工艺参数提供依据。

1 建模原理与数模系统

1.1 铅富氧侧吹熔池熔炼过程

铅富氧侧吹熔池熔炼的氧化还原两个过程均在图1所示侧吹炉内完成[15]。

铅精矿、熔剂、返尘、硫精矿、铅泥、铅锑矿等物料经配料和制粒后,加入侧吹氧化炉,富氧(约90%O2)从炉体两侧鼓入渣层,强烈搅动炉内高温熔体,含铅物料快速氧化、熔化,在炉内生成部分一次液态粗铅(约96%Pb)和熔融富铅渣(约40%Pb)等,由于相界面积很大,气体给予熔池较高的搅拌动能,炉内传质和传热速度较快,各产物相组成快速趋于热力学平衡[16]。各产物在炉体的炉缸区沉淀分离,一次粗铅从虹吸铅口放出铸锭,富铅渣经溜槽送侧吹还原炉进一步还原熔炼产生二次粗铅、还原渣和还原烟尘等。

图1 富氧侧吹炉结构示意图

Fig. 1 Schematic diagram of oxygen-enriched side-blown furnace

1.2 模型假设

根据铅富氧侧吹氧化熔炼过程反应机理和特点,氧化熔炼过程产物包括一次粗铅、富铅渣、烟气和氧化烟尘。在构建该过程多相平衡模型时,平衡产物相仅包括一次粗铅、富铅渣和烟气三相,而氧化烟尘假定由机械尘和烟气冷却尘两部分组成。各产物化学组成假定如下:

1) 一次粗铅(Ld):Pb、PbS、Zn、Cu2S、FeS、As、Sb、Bi、Cd、Au、Ag、Others;2) 富铅渣(Sl):PbO、PbSO4、PbS、ZnO、Cu2O、Cu2S、FeO、Fe3O4、FeS、CaO、SiO2、As2O3、Sb2O3、Bi2O3、CdO、Au、Ag、Others;3) 烟气(gas):Pb、PbO、PbS、Zn、ZnO、ZnS、As2O3、As2S3、Sb2O3、Sb2S3、CdO、CdS、O2、SO2、S2、CO、CO2、N2、H2O;4) 烟尘(Dt):Pb、PbS、PbSO4、PbO、Zn、ZnS、ZnSO4、ZnO、CuO、FeO、CaO、SiO2、As2O3、As2S3、Sb2O3、Sb2S3、Bi2O3、Bi2S3、CdO、CdS、Au、Ag、Others。

1.3 多相化学平衡常数算法

铅富氧侧吹氧化熔炼过程属于多相多组分反应体系,该过程的模型构建可采用化学平衡常数法构建[17-18]。化学平衡常数法是在恒温恒压条件下,当体系达到平衡态时,根据体系中各元素的总量以及体系中发生的独立化学反应,建立非线性方程组,通过求解非线性方程组计算出体系中各相各组分的量。

对于一个多相多组分的反应体系,存在一组线性独立的分子式向量,称其为独立组分,其余称为从属组分。由化学计量系数矩阵中一组线性无关的行向量所组成的化学平衡反应可构成独立反应方程组。换言之,假设反应体系中含元素种类数为Ne,化学组分数为Nc,则体系中所有组分的数量均可以通过组分间的反应来确定,其中,独立反应数Nb等于Nc-Ne,且Nb个独立反应可用矩阵式(1)表示:

(1)

(1)

式中: 为化学计量系数矩阵;

为化学计量系数矩阵; 为独立组分的分子式矩阵;

为独立组分的分子式矩阵; 为从属组分的分子式矩阵;i、j、k分别为独立组分数、从属组分数、元素种类数。

为从属组分的分子式矩阵;i、j、k分别为独立组分数、从属组分数、元素种类数。

根据矩阵运算规则, 可通过式(2)运算获得。

可通过式(2)运算获得。

(2)

(2)

式中: 为

为 的可计算逆矩阵。

的可计算逆矩阵。

对于铅富氧侧吹氧化熔炼过程,假定0.2%的其他惰性元素(组分)分配进入一次粗铅,99.8%的其他分配进入富铅渣。根据产物假定和相平衡原理,多相平衡产物组成包含17种元素和47种化合物。其中,元素为15个单一元素(Pb、Zn、Cu、Fe、S、As、Sb、Bi、Cd、Au、Ag、O、H、N、C)和2个伪元素(SiO2、CaO);化合物种类数为一次粗铅、富铅渣和烟气中各化合物的种类数之和,则由17个元素构成的17个独立组分,可用表1所示的化学计量系数矩阵表示,而除其他组分外的其它30个从属组分,可用表2所示的化学计量系数矩阵表示。式(1)和式(2)中,i 取值范围1~17,j取值范围1~30,k取值范围1~17。

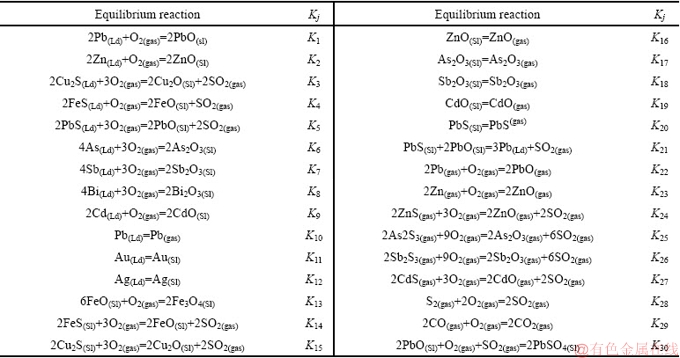

由17个独立组分产生的30个从属组分的30个独立反应(见表3)的平衡常数Kj可用式(3)表示:

表1 侧吹铅熔炼系统17个独立组分的化学计量系数矩阵

Table 1 Stoichiometry matrix for 17 independent species in side blowing lead smelting system

表2 侧吹铅熔炼系统30个从属组分的化学计量系数矩阵

Table 2 Stoichiometry matrix for 30 dependent species in side blowing lead smelting system

表3 独立反应和平衡常数[19]

Table 3 Independent reactions and equilibrium constants[19]

(3)

(3)

式中:R为摩尔气体常数;T为体系平衡温度; 为 i 独立组分的标准吉布斯生成自由能;

为 i 独立组分的标准吉布斯生成自由能; 为 j 从属组分的标准吉布斯生成自由能。

为 j 从属组分的标准吉布斯生成自由能。

当富氧侧吹铅熔炼多相反应体系达到平衡时,17个独立组分与30个从属组分的相互关系如式(4)所示:

(4)

(4)

式中:Xi为i独立组分的摩尔数; 为i独立组分的活度因子;

为i独立组分的活度因子; 为j从属组分的摩尔数;

为j从属组分的摩尔数; 为j从属组分的活度因子;

为j从属组分的活度因子; 为i独立组分所属相的摩尔数;m为产物相;

为i独立组分所属相的摩尔数;m为产物相; 为j从属组分所属相的摩尔数。

为j从属组分所属相的摩尔数。

对于一个封闭体系,根据质量守恒定律,每个元素的质量可由式(5)计算得到。

(5)

(5)

式中: 为k元素的摩尔数。式(4)中m产物相中各组分的总摩尔数Zm可由式(6)计算得到。

为k元素的摩尔数。式(4)中m产物相中各组分的总摩尔数Zm可由式(6)计算得到。

(6)

(6)

式中:i(m)表示只有i独立组分属于m产物相时才求和;j(m)表示只有j从属组分属于m产物相时才求和。

对于一个封闭的火法冶炼体系,假定产物相数为Np,体系温度、压力和各元素数量给定且以达到平衡状态,由式(3)~(5)可知,该多相反应体系共有(Nc+Np)个方程,待求变量数有(Xi+Yj+Zm)个,方程数等于待求变量数,通过求解式(4)~(6)构成的非线性方程组,可得到该系统平衡产物各相中各组分的量。

1.4 求解流程与数模系统

根据侧吹铅熔炼过程的多相反应特点,以及1.3所描述的建模原理,采用化学平衡常数法,构建了侧吹铅熔炼过程的多相平衡数学模型,并采用图2所示的计算流程求解。在采用式(7)所示方程,考虑该冶炼体系中投入物料与产出物料的热平衡关系后,基于MetCal软件开发平台[19-21],研发了如图3所示的数模计算系统。

(7)

(7)

式中:Ai为反应物;Ti为反应物Ai的初始温度;Bj为生成物;Tj为生成物Bj的温度;nA为反应物数量;nB为生成物数量;H为焓值;cp为定压比热容;QLoss为热损失量。

图2 模型计算流程

Fig. 2 Calculation flowchart of model

2 基本数据

2.1 原料成分

铅富氧侧吹熔池熔炼过程的投入原料主要包括混合铅精矿、硫精矿、铅泥、铅锑矿、银精矿、烟灰、石英砂、石灰石、空气、工业氧(氧气体积浓度95%),原料成分如表4所示。

2.2 热力学数据

侧吹铅熔炼过程的平衡产物相组分的吉布斯自由能,根据式(8)计算,各产物组分的标准吉布斯自由能等相关热力学参数由MetCal软件平台查询获 得[19, 21-22],具体见表5。富铅渣和一次粗铅组分活度系数[9-10, 12, 19, 23-24]列于表6,烟气中组分活度系数均 为1。

表6中NPbO、NCu2S、NFeO、NFe3O4、NSiO2为富铅渣中PbO、Cu2S、FeO、Fe3O4、SiO2组分的摩尔分数;pO2为烟气中氧分压。

(8)

(8)

3 模型验证

采用所构建的铅富氧侧吹氧化熔炼过程多相平衡数学模型,以国内某侧吹铅冶炼企业氧化熔炼工段2018年11~12月和2019年1~3月份的平均操作参数作为条件,计算该厂铅富氧侧吹氧化熔炼过程的平衡产物组成。

图3 数模计算系统

Fig. 3 Mathematical model calculation system

表4 侧吹铅熔炼原料成分含量

Table 4 Component content of raw material in side-blowing lead smelting

表5 组分的热力学参数

Table 5 Thermodynamic parameters of components

见续表

上接表5

表6 组分的活度因子

Table 6 Activity coefficient of components

计算条件:原料总投入量55 t/h,其中,混合铅精矿占51.2%,硫精矿占15%、铅泥占1%、铅锑矿占4%、银精矿占1%、烟灰占21%、石英砂占2.8%、石灰石占4%。富氧浓度( ) 90%,氧料比(ROC) 112Nm3/t,冷却水量700 t/h,冷却进水和出水温差为1.5 K,熔炼温度根据热平衡计算获取。经计算,原料的物相组分含量见表7。

) 90%,氧料比(ROC) 112Nm3/t,冷却水量700 t/h,冷却进水和出水温差为1.5 K,熔炼温度根据热平衡计算获取。经计算,原料的物相组分含量见表7。

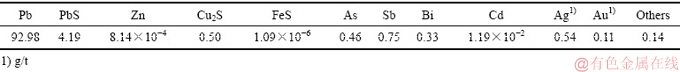

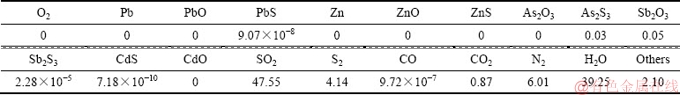

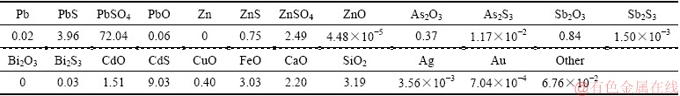

一次粗铅、富铅渣、烟气和烟尘组分的计算结果,分别如表8~11所示。

根据国内该侧吹铅冶炼企业氧化熔炼工段2018年11~12月和2019年1~3月份的生产报表数据,将一次粗铅、富铅渣和烟尘的生产取样分析结果进行平均处理后,与模型计算值进行对比,结果见表12。

由表12数据结果可知,产物中除某些元素生产上未检测外,其他元素计算值与生产平均实测值基本吻合。其中,一次粗铅中Pb、Zn、Cu、S、As、Sb、Bi和Cd元素组成的计算误差分别0.14%、1.80%、0.99%、4.23%、5.13%、3.92%、5.80%和1.00%;富铅渣中Pb、Zn、Cu、Fe、CaO、SiO2、S、As、Sb、Bi和Cd组成计算误差分别为3.68%、3.67%、1.06%、7.09%、5.74%、5.35%、37.58%、38.40%、10.99%、11.28%和4.46%;烟尘中Pb、Zn、S、As、Sb和Cd组成计算误差分别为1.19%、0.38%、1.80%、7.06%、7.19%和6.81%。富铅渣中S、As、Sb和Bi元素模拟计算值和实测值误差较大,是由生产检测时对某些微量元素的检测误差导致。以上结果表明模型基本能反映铅侧吹氧化熔炼过程的多相反应特征,具有精准预测该熔炼生产过程和优化工艺参数的潜力,可作为后续对该过程进行系统热力学分析的有效工具。

表7 原料物相组成

Table 7 Phase composition of raw materials (mass fraction, %)

表8 一次粗铅相(4.68 t)中各组分的计算结果

Table 8 Calculation results of lead bullion (4.68 t) (mass fraction, %)

表9 富铅渣相(28.86 t)中各组分的计算结果

Table 9 Calculation results of lead-rich slag (28.86 t) (mass fraction, %)

表10 烟气相(22.18 t)中各组分的计算结果

Table 10 Calculation results of gas (22.18 t) (mass fraction, %)

表11 烟尘相(8.94 t)中各组分的计算结果

Table 11 Calculation results of dust (8.94 t) (mass fraction, %)

表12 计算结果与生产数据

Table 12 Calculation results and industrial data

经计算,渣中铁硅比(RFeO/SiO2)和钙硅比(RCaO/SiO2)、烟尘率(Rdust)、一次铅收率(YPb)、富铅渣温度(TSlag)等关键技术指标的计算值分别为1.87、0.69、16.25%、21.41%、1018 ℃,与工业生产同期平均实测值(分别为1.90、0.69、15.5%、20.85%、1050℃)相比,误差分别为1.84%、0.41%、4.84%、2.69%、3.05%。表明所构建的多相化学平衡数学模型基本能反映侧吹铅熔炼过程实际生产情况,可作为后续对该过程进行系统热力学分析的有效工具。

4 结论

1) 基于铅富氧侧吹氧化熔炼过程反应机理和特点,采用化学平衡常数法构建了铅富氧侧吹氧化熔炼过程的多相平衡热力学模型,在此基础上研发了多相化学平衡计算系统,为该过程的热力学计算提供了软件工具。

2) 采用所构建模型和计算系统,以国内某企业铅富氧侧吹熔炼典型工况为条件,对模型进行了实例验证,产物组成计算结果与生产实践基本吻合,表明模型基本能反应铅富氧侧吹氧化熔炼过程的多相反应特征,具有精准预测该熔炼生产过程和优化工艺参数的潜力。

3) 经核算对比发现,铅富氧侧吹氧化熔炼过程的关键产出指标计算值与工业生产同期平均实测值误差较小,表明所构建的多相化学平衡数学模型基本能反映铅富氧侧吹氧化熔炼过程的实际生产情况,可作为后续对该过程进行系统热力学分析的有效工具。

REFERENCES

[1] 李允斌. 氧气侧吹炼铅技术的应用[J]. 有色金属(冶炼部分), 2012(11): 13-15.

LI Yun-bin. Application of oxygen side blow lead smelting technology[J]. Nonferrous Metals(Extractive Metallurgy), 2012(11): 13-15.

[2] 王成彦, 陈永强. 中国铅锌冶金技术状况及发展趋势: 铅冶金[J]. 有色金属科学与工程, 2016, 8(6): 1-7.

WANG Cheng-yan, CHEN Yong-qiang. Lead and zinc metallurgy technology situation and development treads of China: lead metallurgy[J]. Nonferrous Metals Science and Engineering, 2016, 8(6): 1-7.

[3] 李卫锋, 张晓国, 郭学益, 张传福. 我国铅冶炼的技术现状及进展[J]. 中国有色冶金, 2010, 39(2): 29-33.

LI Wei-feng, ZHANG Xiao-guo, GUO Xue-yi, ZHANG Chuang-fu. Status and progress of lead smelting technology in China[J]. China Nonferrous Metallurgy, 2010, 39(2): 29-33.

[4] LI W, ZHAN J, FAN Y, WEI C, ZHANG C, HWANG J. Research and industrial application of a process for direct reduction of molten high-lead smelting slag[J]. JOM, 2017, 69(4): 784-789.

[5] 陈 霖, 王振虎, 陈 威, 肖 辉, 刘伟锋, 张杜超, 杨天足. 富氧底吹炼铅氧化熔炼元素分配热力学模拟[J]. 有色金属(冶炼部分), 2018(9): 1-6.

CHEN Lin, WANG Zhen-hu, CHEN Wei, XIAO Hui, LIU Wei-feng, ZHANG Du-chao, YANG Tian-zu. Thermodynamic simulation on elements distribution of lead concentrate oxidative smelting in oxygen-rich bottom-blow smelting process[J]. Nonferrous Metals(Extractive Metallurgy), 2018(9): 1-6.

[6] 陈 卓, 谢德成, 夏中卫, 周 萍, 廖 舟. 悬浮炼铅过程数值仿真[J]. 中南大学学报(自然科学版), 2014, 45(10): 3344-3350.

CHEN Zhuo, XIE De-cheng, XIA Zhong-Wei, ZHOU Ping, LIAO Zhou. Numerical simulation of suspended lead smelting process[J]. Journal of Central South University of Technology(Science and Technology), 2014, 45(10): 3344-3350.

[7] 张红亮, 汤 卓, 陈永明, 叶龙刚. 底吹炼铅炉内流动的数值模拟[J]. 中国有色金属学报, 2017, 27(3): 637-647.

ZHANG Hong-liang, TANG Zhuo, CHEN Yong-ming, YE Long-gang. Numerical simulation of multiphase flow in bottom-blowing furnace for lead smelting[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(3): 637-647.

[8] 尹 飞, 王成彦, 王 忠, 郜 伟, 李 强. 铅富氧闪速熔炼技术基础研究[J]. 有色金属(冶炼部分), 2012(4): 11-14.

YIN Fei, WANG Cheng-yan, WANG Zhong, GAO Wei, LI Qiang. Basic research on lead oxygen-enriched flash smelting technology[J]. Nonferrous Metals(Extractive Metallurgy), 2012(4): 11-14.

[9] 谭鹏夫, 张传福, 张瑞瑛. QSL炼铅过程的计算机模型[J]. 中南工业大学学报(自然科学版), 1996, 27(5): 40-43.

TAN Peng-fu, ZHAGN Chuan-fu, ZHANG Rui-ying. A computer model of QSL lead smelting process[J]. Journal of Central South University of Technology(Natural Science), 1996, 27(5): 40-43.

[10] 汪金良, 张传福, 张文海. 铅闪速熔炼过程的多相平衡模型[J]. 中南大学学报(自然科学版), 2012, 43(2): 429-434.

WANG Jin-liang, ZHANG Chuan-fu, ZHANG Wen-hai. Multi-phase equilibrium model of lead flash smelting process[J]. Journal of Central South University of Technology(Natural Science), 2012, 43(2): 429-434.

[11] 谭鹏夫, 张传福. QSL炼铅过程的热力学分析[J]. 中南工业大学学报(自然科学版), 1996, 27(6): 676-679.

TAN Peng-fu, ZHAGN Chuan-fu. The thermodynamic analysis of QSL lead smelting process[J]. Journal of Central South University of Technology(Natural Science), 1996, 27(6): 676-679.

[12] 汪金良, 张文海, 张传福. 硫化铅矿闪速熔炼过程的热力学分析[J]. 中国有色金属学报, 2011, 21(11): 2952-2957.

WANG Jin-liang, ZHANG Wen-Hai, ZHANG Chuang-fu. Thermodynamic analysis of lead sulfide flash smelting process[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(11): 2952-2957.

[13] 宋光辉, 张乐如. 氧气侧吹直接炼铅新工艺的开发与应用[J]. 有色金属(冶炼部分), 2005(3): 2-5.

SONG Guang-hu, ZHANG Le-ru. Development and application of lead direct smelting with oxygen side-blowing[J]. Nonferrous Metals(Extractive Metallurgy), 2005(3): 2-5.

[14] CHEN L, YANG T, BIN S, LIU W, ZHANG D, BIN W, ZHANG L. An efficient reactor for high-lead slag reduction process: Oxygen-rich side blow furnace[J]. JOM, 2014, 66(9): 1664-1669.

[15] 刘 军, 刘燕庭. 富氧侧吹直接炼铅工艺研究与应用[J]. 中国有色冶金, 2013(1): 34-36.

LIU Jun, LIU Yan-ting. Research and application of oxygen-enriched side-blown direct lead smelting process[J]. China Nonferrous Metallurgy, 2013(1): 34-36.

[16] 刘 军, 刘燕庭, 陈 文. 铜镍矿富氧侧吹熔池熔炼工艺[J]. 甘肃冶金, 2013, 35(1): 4-6.

LIU Jun, LIU Yan-ting, CHEN Wen. The process of oxygen-enriched side-blown bath smelting for copper-nickel mine[J]. Gansu Metallurgy, 2013, 35(1): 4-6.

[17] SHIMPO R, GOTO S, OGAWA O, ASAKURA I. A study on the equilibrium between copper matte and slag[J]. Canadian Metallurgical Quarterly, 1986, 25(2): 113-121.

[18] SHIMPO R, WATANABE Y, GOTO S, OGAWA O. An application of equilibrium calculations to the copper smelting operation[J]. Advances in Sulfide Smelting, 1983, 1: 295-316.

[19] LI M, ZHOU J, TONG C, ZHANG W, CHEN Z, WANG J. Thermodynamic modeling and optimization of the copper flash converting process using the equilibrium constant method[J]. Metallurgical and Materials Transactions B, 2018, 49(4): 1794-1807.

[20] LI M, ZHOU J, TONG C, ZHANG W, LI H. Mathematical model of whole-process calculation for bottom-blowing copper smelting[J]. Metallurgical Research & Technology, 2018, 115(1): 1-15.

[21] 李明周, 周孑民, 张文海, 李贺松, 童长仁. 铜闪速吹炼过程多相平衡热力学分析[J]. 中国有色金属学报, 2017, 27(7): 1493-1503.

LI Ming-zhou, ZHOU Jie-min, ZHANG Wen-hai, LI He-song, TONG Chang-ren. Multiphase equilibrium thermodynamics analysis of copper flash converting process[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(7): 1493-1503.

[22] 李明周, 周孑民, 张文海, 李贺松, 童长仁. 铜闪速吹炼过程杂质元素分配行为的热力学分析[J]. 中国有色金属学报, 2017, 27(9): 1951-1959.

LI Ming-zhou, ZHOU Jie-min, ZHANG Wen-hai, LI He-song, TONG Chang-ren. Thermodynamics analysis of distribution behavior of impurity elements during copper flash converting[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(9): 1951-1959.

[23] SHUVA M A H, RHAMDHANI M A, BROOKS G A, MASOOD S, REUTER M A. Thermodynamics data of valuable elements relevant to e-waste processing through primary and secondary copper production: a review[J]. Journal of Cleaner Production, 2016, 131: 795-809.

[24] 黄金堤, 李 静, 童长仁, 李明周, 徐志峰. 废杂铜精炼过程中动态多元多相平衡热力学模型[J]. 中国有色金属学报, 2015, 25(12): 3513-3522.

HUANG Jin-di, LI Jing, TONG Chang-ren, LI Ming-zhou, XU Zhi-feng. Dynamic multicomponent and multiphase equilibrium thermodynamics model during scrap copper refining process[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(12): 3513-3522.

Phase equilibrium model for lead oxygen-enriched side-blown oxidation bath smelting

LIU Yan-ting1, 2, YANG Tian-zu1, LI Ming-zhou3

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. Changsha Design and Research Institute of Nonferrous Metallurgy, Changsha 410001, China;

3. Faculty of Materials Metallurgy and Chemistry, Jiangxi University of Science and Technology, Ganzhou 341000, China)

Abstract: Based on the principle of multiphase equilibrium, a multiphase equilibrium model and simulation system for lead oxygen-enriched side-blown oxidation bath smelting process were established by using chemical equilibrium constant method. Under typical production conditions, such as raw material composition, oxygen-material ratio, volume of cooling water and temperature of inlet and outlet water, oxygen-enriched concentration, the composition of equilibrium products and key technical indicators were simulated and calculated. The results show that the relative errors of the calculated mass fractions of Pb, Zn, S, Cu, As, Sb, Bi, Cd, Au and Ag in primary lead-rich slag and smoke dust are all less than 10% compared with the measured values in production, and the errors of the key technical indexes, such as RCaO/SiO2, RCaO/SiO2, smoke and dust rate, primary lead recovery rate and temperature of lead-rich slag in slag are less than 8%. Therefore, the model and calculation system can better reflect the actual production situation of lead oxygen-enriched side-blown oxidation bath smelting process, have the potential to accurately predict the smelting process and optimize process parameters, and can effectively guide the production practice of lead oxygen-enriched side-blown oxidation bath smelting.

Key words: oxygen-enriched side-blown; lead bath smelting; multi-phase equilibrium;chemical equilibrium constant method

Foundation item: Project(2011AA061002) supported by the National High Technology Research and Development Program of China; Project(20171BAB206024) supported by the Natural Science Foundation of Jiangxi Province, China

Received date: 2019-05-06; Accepted date: 2019-08-28

Corresponding author: YANG Tian-zu; Tel: +86-13508482570; E-mail: tianzuyang@163.com

(编辑 龙怀中)

基金项目:国家高技术研究发展计划资助项目(2011AA061002);江西省科技厅自然科学基金资助项目(20171BAB206024)

收稿日期:2019-05-06;修订日期:2019-08-28

通信作者:杨天足,教授,博士;电话:13508482570;E-mail:tianzuyang@163.com