文章编号:1004-0609(2013)04-0944-06

等温退火过程中AA3003冷轧铝合金的析出行为

陈 冠1, 2,唐建国1, 2,张新明1, 2,曾丽君1,夏 懿1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:通过电导率测试、硬度试验、偏光显微镜以及透射电镜的观察,研究不同冷轧变形量下AA3003铝合金在等温退火(350~500 ℃)过程中的析出行为及其对合金显微组织的影响。结果表明:随着变形量的增大,最佳析出温度明显地由高温向低温移动,降幅超过100 ℃;冷轧变形促进析出,且随退火温度的升高其促进析出的能力逐渐减弱;尤其在高温段(450、500 ℃)等温退火时,析出峰的移动以及再结晶的影响致使电导率曲线的位置随冷轧变形量的增大而出现上下波动的现象;析出粒子的形核位置也会受到再结晶的影响。

关键词:AA3003铝合金;等温退火;析出;再结晶

中图分类号:TG146.2 文献标志码:A

Precipitation behavior of AA3003 cold-rolled

aluminium alloy during isothermal annealing

CHEN Guan1, 2, TANG Jian-guo1, 2, ZHANG Xin-ming1, 2, ZENG Li-jun1, XIA Yi1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: Under different cold rolling reductions, the precipitation behavior of AA3003 aluminium alloy during isothermal annealing (350~500 ℃) and its effect on the microstructures of the alloy were investigated by electrical conductivity measurements, hardness, polarized light microscopy and transmission electron microscopy. The results show that the most favourable temperature of precipitation moves obviously from high temperature to the low temperature with the reduction increasing, and this drop is more than 100 ℃. The cold rolling deformation accelerates the precipitation and this effect decreases as the annealing temperature increasing. Especially, in the high temperature (450、500 ℃) region of isothermal annealing, the moving precipitation peaks and the effect of recrystallization cause the shift of the conductivity curve to fluctuation as the cold rolling reduction increasing. The nucleation sites of the precipitates are influenced by recrystallization.

Key words: AA3003 aluminium alloy; isothermal annealing; precipitation; recrystallization

基金项目:国家自然科学基金资助项目(50905188)

收稿日期:2012-05-10;修订日期:2012-08-28

通信作者:唐建国,讲师,博士;电话:0731-88830265;E-mail:jgtang@mail.csu.edu.cn

3×××铝合金是以Mn为主要合金元素且热处理不可强化的铝合金。锰在铝基体中的溶解度会随着温度的变化而有较大的改变,加之连续铸轧法冷却速度快(100~1 000 K/s),易形成过饱和固溶体,并会导致铸轧板的再结晶温度明显提高。由于Mn元素扩散系数小及其晶界吸附现象,Al-Mn系合金在铸造过程中产生严重偏析。经冷轧变形处理,合金在随后的中间退火过程中易出现晶粒粗大不均的现象,严重影响板带材的表面质量并使材料的力学性能降低[1-3]。

针对AA3003铸轧铝合金板材在冷轧中间退火过程中出现的晶粒粗大问题,有研究表明[4],在冷轧之前先将铸轧板进行高温均匀化处理,形成尺寸较大的Al6Mn粒子,冷轧后在退火过程中通过这些粒子诱发形核达到细化晶粒的目的。过饱和固溶体在形变后的退火过程中,析出的弥散相对合金的再结晶、织构、晶粒大小及其力学性能都有强烈的影响,并且析出与再结晶会发生相互作用,对此已进行了大量的研 究[5-12]。鉴于工业生产需缩短生产流程和降低能耗的要求,本实验不进行均匀化处理而是直接通过中间退火过程精确调控AA3003过饱和固溶体中弥散相的析出。本文作者研究了4种不同冷轧变形量的AA3003铸轧铝合金在不同等温退火工艺制度下的析出行为及其对微观组织的影响规律,以期达到调控再结晶晶粒尺寸的目的。

1 实验

本实验采用的合金为AA3003铸轧板,合金的化学成分如表1所列。将铸轧板分别冷轧至40%、71%及85%等变形量,并将冷轧后的板材线切割为 1.8 mm×2.0 mm的小方块,然后采用盐浴炉进行等温退火,并分别在350~500 ℃(间隔50 ℃)依次保温1~100 min。

采用7501型号的涡流电导仪对试样进行电导率测试,为保证样品表面与电导仪的良好接触,将样品表面用砂纸磨到1500#,机械抛光后再进行多次测试并取其平均值。试样经电解抛光、阳极覆膜后在XJP-6A型金相显微镜上采用偏光片进行显微组织观察。制样后采用JEM-2100F透射电镜对等温退火后试样的微观组织进行进一步观察。采用Model HV-10B型硬度计测试硬度,载荷为3 kg,加载持续时间为 15 s,每个试样测试8次并取其平均值。

表1 AA3003铝合金的化学成分

Table 1 Chemical composition of AA3003 aluminium alloy (mass fraction, %)

2 结果与分析

2.1 等温退火过程中电导率的变化

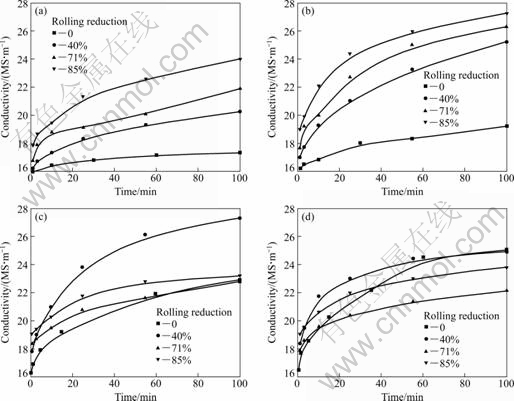

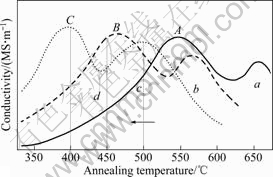

NAGAHAMA和MIKI[13]的研究结果表明,在等温退火过程中,AA3003铝合金电导率的升高主要与合金中第二相粒子的析出和点阵缺陷的消失相关。本实验中冷轧变形(0→85%)所引起的该合金电导率变化小于0.5 MS/m,点阵缺陷消失所引起的电导率变化可以忽略,因此,等温退火过程中电导率的升高主要归因于第二相粒子的析出。图1(a)和(b)显示,在低温段(350、400 ℃)等温退火时,电导率曲线的位置随着变形量的增大而升高,即增大冷轧变形量可以促进粒子的析出。增大冷轧变形量促进粒子的析出主要归于以下几个原因:1) 位错处的畸变结构,溶质原子的偏聚及高储能为析出形核提供了结构、成分及能量起伏,可明显地降低形核功并促进形核。CHEN等[14]研究证实,在3003铝合金的冷轧变形中溶质原子Mn在位错网处的偏聚能够促进形核。CAHN[15]从理论上研究发现,位错处形核比一般条件下的均匀形核快1078倍。2) 位错密度的提高能够增加位错形核点密度。3) 析出过程是原子的扩散过程,原子沿位错等缺陷的扩散激活能约为体扩散的一半,因此位错密度的增加能够提高原子的扩散速率,进而加快析出过程。退火温度升高,回复过程加快,位错等缺陷会有部分消失,变形量对析出的促进作用会随着退火温度的升高有所减弱。如图1(b)~(d)所示,4条电导率曲线随着退火温度的升高,出现曲线束集现象,即随着退火温度的升高,变形量对析出的影响越来越小。

高温段(450、500 ℃)等温退火时,电导率曲线随变形量的增大呈现出较复杂的关系,如图1(c)和(d)所示。在450 ℃等温退火时(图1(c)),随变形量的增大,电导率曲线的位置先升高后降低再升高;在500 ℃等温退火时(图1(d)),电导率曲线也表现出类似的规律,但40%冷轧变形较未变形合金的电导率曲线变化不大,可能是较高的退火温度削弱了变形对析出的促进作用。根据HUMPHERYS和HATHERLY[16]关于合金析出与再结晶交互作用的研究,随着变形量的增大,当再结晶发生在析出开始之前时,析出粒子相当于在部分或全部消除位错等缺陷的再结晶组织上进行,析出形核的位置大量减少,因此,析出过程受到不同程度的推迟且电导率降低,电导率曲线的位置下降。但在本实验中继续增大冷轧变形量,电导率曲线的位置反而又升高。

图1 AA3003铝合金电导率随冷轧变形量的变化

Fig. 1 Variations of electrical conductivity of AA3003 aluminium alloy with cold rolling reductions: (a) 350 ℃; (b) 400 ℃; (c) 450 ℃; (d) 500 ℃

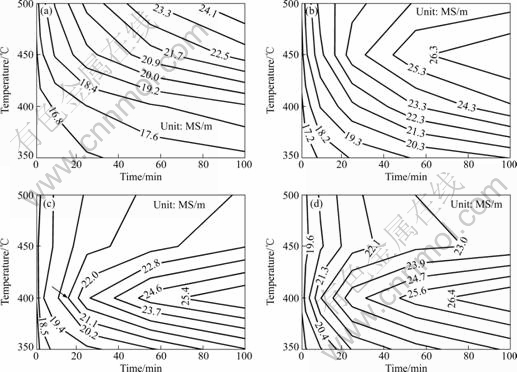

图2所示为不同变形量下电导率曲面的等高线分布图,也就是反映第二相粒子析出的等值线分布图,类似于C曲线(Time—temperature—precipitation)。从图2(a)~(d)可以看出,在等温退火过程中,随着保温时间的延长,电导率逐渐增大。在电导率的等高线分布图中,析出最快处形成的峰称为析出峰(如图2(c)箭头所示),析出峰所对应的温度称为峰值温度;图2(a)~(d)显示,随着变形量的增大,峰值温度明显的由500 ℃→450 ℃→400 ℃左右,即随着冷轧变形量的增大,在随后的等温退火过程中,析出峰的位置明显的由高温向低温移动。

图2 AA3003铝合金电导率曲面的等高线分布

Fig. 2 Contour maps of electrical conductivity space surface of AA3003 aluminium alloys at different cold rolling reductions: (a) 0; (b) 40%; (c) 71%; (d) 85%

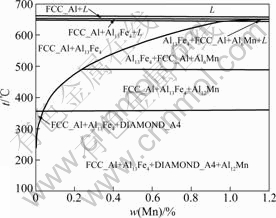

图3所示为Al-xMn-0.43Fe-0.14Si四元合金系平衡相图的垂直截面。由此相图可知,当w(Mn)=1.05%时,该合金在350~490 ℃等温退火时析出Al12Mn,而在490~640 ℃等温退火时析出Al6Mn相。CHEN等[14]研究表明,在高温段(t>500 ℃)退火时,该合金的过饱和固溶体直接析出Al6Mn平衡相;而在低温段退火时,首先析出G1(Al12Mn)亚稳相,然后随着退火时间的延长,G1亚稳相逐渐转变为Al6Mn平衡相。该合金经过85%冷轧变形后,在不同温度下等温退火时,析出曲线(电导率等高线分布曲线)的峰值温度为400 ℃,而在450 ℃等温退火时析出曲线出现拐点(如图2(d)所示),表明在更高的温度(t>500 ℃)退火时还存在另一峰值温度,即存在两个析出反应,这也与相关文献[17]的报道吻合。

图3 Al-xMn-0.43Fe-0.14Si合金系平衡相图垂直截面

Fig. 3 Normal section of calculated equilibrium phase diagram of Al-xMn-0.43Fe-0.14Si alloys

根据图2和3的分析可知,AA3003铝合金在退火温度范围内存在两个析出反应,即两个析出峰,如图4中实线(峰A和峰a)所示。由图4可知,随着变形量的增大,析出峰有向低温移动的明显趋势(图4中箭头所指),如示意图4中两析出峰分别由A→B→C及a→b→c。低温段(350、400 ℃)等温退火时,实验温度(350、400 ℃)始终位于峰值温度的左边,随着析出峰的左移,电导率逐渐上升,因此析出不断增多;而在高温段(450、500 ℃)等温退火时,由于析出曲线的左移,实验温度(450、500 ℃)经过第一个析出峰后最终处于谷d和峰c之间,即随着变形量的增大,在析出峰左移的过程中,电导率出现先增大(过峰C)后降低(过谷d)而后又升高的上下波动现象。

图4 等温退火过程中析出峰随变形量变化的移动示意图

Fig. 4 Sketch of shift of precipitation peaks with reductions during isothermal annealing

2.2 析出与再结晶的交互作用

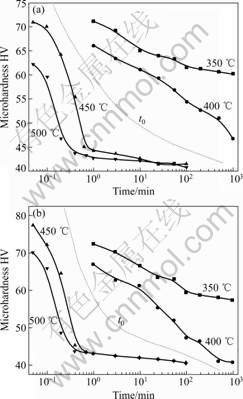

图5所示为不同冷轧量时AA3003铝合金显微硬度随退火时间的变化。由图5可看出,AA4004合金在完全再结晶退火的条件下,维氏硬度为42左右,析出强化对维氏硬度几乎没有作用,因此,可认为硬度曲线的变化只反映再结晶过程。AA3003铝合金铸轧板由于存在严重的Mn偏析,致使合金再结晶温度偏高,再结晶退火困难。除Mn偏析外,析出对再结晶的阻碍也比较严重。例如,71%冷轧变形合金在低温段等温退火100 min后,硬度值仍然较高,即合金未发生再结晶(如图5(a)中350、400 ℃的硬度曲线),继续延长退火时间至1000 min,该样品仍未发生完全再结晶。

图5 不同冷轧量时AA3003铝合金显微硬度随退火时间的变化

Fig. 5 Microhardness as function of annealing time in AA3003 aluminium alloys at cold rolling reductions of 71% (a) and 85% (b)

AA3003铸轧板由于冷却速度快,溶解的Mn元素多,易形成过饱和固溶体。经冷轧变形后,在中间退火过程中该合金会发生析出和再结晶现象。由于析出与再结晶都是热激活过程,而且都有一定的孕育期,因此在不同的条件下析出与再结晶的开始时间会有所不同。

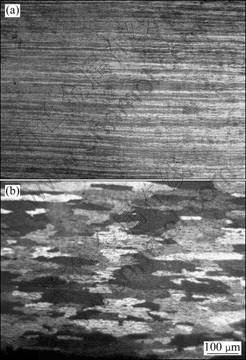

通过图5(a)和(b)的分析发现,图中4条硬度曲线以虚线t0(400 ℃<t0<450 ℃)为界被明显地分隔开来。取图5(b)中虚线t0两侧的400 ℃,25 min和500 ℃, 1 min两个状态为例,前者硬度值仍然较高,微观组织呈纤维状并未发生再结晶(如图6(a)所示)。另外,图

图6 AA3003铝合金板材经不同温度退火后的微观组织

Fig. 6 Microstructures of AA3003 aluminum alloy sheets after annealed at different temperatures: (a) 85%, 400 ℃, 25 min; (b) 85%, 500 ℃, 1 min

1(b)中经85%冷轧合金的电导率曲线显示,等温退火25 min后电导率已明显升高,即析出过程先于再结晶。而后者硬度值达到平衡,冷轧变形组织已发生完全再结晶(如图6(b)所示),图1(d)表明,85%冷轧合金的电导率曲线显示退火1 min时电导率变化并不明显,可认为再结晶过程先于析出过程。

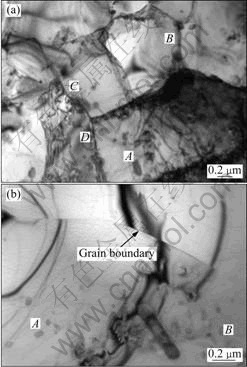

图7所示为该合金在图6两不同退火状态下的TEM像。图7(a)显示,400 ℃退火25 min后,合金中形成了大量的亚晶结构。由于析出先于再结晶开始,未再结晶的畸变组织为析出提供了较多的形核点,析出优先在位错处形核(图7(a)A处),且析出粒子对亚晶界的钉扎严重抑制了随后再结晶的发生(如图7(a)中B、C、D等处)。而经500 ℃退火1 min后,合金中无亚晶结构,只存在少数较平滑的晶界(如图7(b)箭头所示),与金相显微组织(图6(b))一致。由于再结晶先于析出,析出只能在部分或全部消除位错等缺陷的再结晶组织上进行(如图7(b)中A、B等处),析出形核的位置减少,形核的难度加大,因此,再结晶推迟析出过程。

通过图6和7的分析可知,图5中硬度曲线以虚线t0作为分界线将退火温度分为高温段和低温段。高温段(t>t0)等温退火时,再结晶的孕育期较析出过程

图7 AA3003铝合金经不同温度退火后的TEM像

Fig. 7 TEM images of AA3003 aluminum alloy sheets after annealed at different temperatures: (a) 85%, 400 ℃, 25 min; (b) 85%, 500 ℃, 1 min

的短,再结晶先于析出过程开始,位错等缺陷的消失,致使随后析出的形核点大量减少,最终抑制析出过程;低温段(t<t0)等温退火时,析出过程的孕育期较再结晶的短,析出先于再结晶开始,析出粒子在位错等缺陷处大量形核,并阻碍合金回复时位错的移动、亚晶界及再结晶晶界的迁移,析出过程严重阻碍再结晶。

3 结论

1) AA3003铸轧板在不同温度下等温退火时,随着变形量的增大,析出峰出现由高温向低温的明显移动,峰值温度降幅超过100 ℃。

2) AA3003铸轧板在退火温度范围内存在两个析出反应(即析出峰),该析出峰的存在及其随冷轧变形量的移动和基体再结晶的发生,是导致高温段等温退火时电导率曲线的位置随冷轧变形量的增大而出现上下波动的原委。

3) 经过较大冷轧变形量后(如本实验71%、85%),AA3003铸轧板在等温退火时以t0(400 ℃<t0<450 ℃)为界,划分为两区:t>t0时,再结晶先于析出发生并推迟析出;t<t0时,析出先于再结晶发生并严重抑制再结晶,析出粒子多在冷轧变形后的位错等缺陷处形核。

REFERENCES

[1] SUN N. Microstructural evolution in twin roll cast AA3105 during homogenization[J]. Materials Science and Engineering A, 2006, 416(1/2): 232-239.

[2] BIROL Y. Response to annealing treatment of a twin roll cast thin AlFeMnSi strip[J]. Journal of Materials Processing Technology, 2009, 209(1): 506-510.

[3] BIROL Y. Response to annealing treatments of twin-roll cast thin Al-Fe-Si strips[J]. Journal of Alloys and Compounds, 2008, 458(1/2): 265-270.

[4] 刘建文, 涂益友, 张敏达, 张建军, 蒋建清. 均匀化处理对AA3003铝合金铸轧板再结晶组织的影响[J]. 材料热处理学报, 2010, 31(3): 107-111.

LIU Jian-wen, TU Yi-you, ZHANG Min-da, ZHANG Jian-jun , JIANG Jian-qing. Influence of homogenization on recrystallization microstructure of twin roll cast AA3003 aluminium alloy strips[J]. Transactions of Materials and Heat Treatment, 2010, 31(3): 107-111.

[5] HUMPHREYS F J. Nucleation of recrystallization at second phase particles in deformed aluminium[J]. Acta Metallurgica, 1977, 25(11): 1323-1344.

[6] LI Z, DING S X, MORRIS J G. Influence of precipitate structure on recrystallization and formability behavior of continuous strip cast AA3003 aluminum alloy[C]//Light Metals. Warrendale, Pennsylvania: TMS, 1995: 1149-1154.

[7] LIU W C, RADHAKRISHNAN B. Recrystallization behavior of a supersaturated Al-Mn alloy[J]. Materials Letters, 2010, 64(16): 1829-1832.

[8] HUANG H W, OU B L. Evolution of precipitation during different homogenization treatments in a 3003 aluminum alloy[J]. Materials and Design, 2009, 30(7): 2685-2692.

[9] LI Y J, ARNBERG L. Quantitative study on the precipitation behavior of dispersoids in DC-cast AA3003 alloy during heating and homogenization[J]. Acta Materialia, 2003, 51(12): 3415-3428.

[10] 张新明, 吴文祥, 骞 雄, 周卓平. 退火过程中AA3003铝合金的析出行为[J]. 中国有色金属学报, 2005, 15(5): 675-679.

ZHANG Xin-ming, WU Wen-xiang, JIAN Xiong, ZHOU Zhuo-ping. Precipitation behavior of AA3003 aluminium alloy during annealing[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 675-679.

[11] VATNE H E, ENGLER O, NES E. Influence of particles on recrystallization textures and microstructures of aluminium alloy 3103[J]. Materials Science and Technology, 1997, 13(2): 93-102.

[12] KWAG Y, MORRIS J G. Effect of structure on mechanical behavior and stretch formability of constitution ally dynamic 3000 series aluminum alloys[J]. Materials Science and Engineering A, 1986, 77(1/2): 59-74.

[13] NAGAHAMA K, MIKI I. Precipitation during recrystallization in Al-Mn and Al-Cr alloys[J]. Trans Jap Inst Met, 1974, 15(3): 185-192.

[14] CHEN S P, KUIJPERS N C W, VAN DER ZWAAG S. Effect of microsegregation and dislocations on the nucleation kinetics of precipitation in aluminium alloy AA3003[J]. Materials Science and Engineering A, 2003, 341(1/2): 296-306.

[15] CAHN J W. Nucleation on dislocations[J]. Acta Metall, 1957, 5(3): 169-172.

[16] HUMPHREYS F J, HATHERLY M. Recrystallization and related annealing phenomena[M]. Oxford: Elsevier Science Ltd, 1995: 235-237.

[17] MONDOLFO L F. Aluminium alloys: Structure and properties[M]. London: Butterworths, 1976.

(编辑 李艳红)