采用气雾化Zn-22%Al粉末挤压制造微型螺旋齿轮

来源期刊:中国有色金属学报(英文版)2012年第6期

论文作者:LEE Kyung-Hun LEE Jung-Min PARK Joon-Hong KIM Byung-Min

文章页码:1313 - 1321

关键词:螺旋齿轮;粉末挤压;气雾化Zn-22%Al粉;超塑性

Key words:helical gear; powder extrusion; gas atomized Zn-22%Al powder; superplasticity

摘 要:基于Zn-22%Al共析合金的超塑性,采用粉末挤压工艺制造微型螺旋齿轮,以减小成形压力和获得细小的显微组织。该螺旋齿轮的规格为:模数0.3,齿数1.2,螺旋角15°。将粉末压制坯通过烧结和固溶热处理进行致密化。致密化的坯料由层状和细晶状组织组成。在温度250 ℃,应变速率2.36×10-3和1.18×10-1s-1的条件下对坯料进行挤压,并对挤压成形的螺旋齿轮的力学性能进行测试。

Abstract: Powder extrusion, which is based on the superplastic behavior of Zn-22%Al eutectoid alloy, was proposed to reduce the forming load and promises to provide fine microstructures in the manufacture of miniature helical gears. The specifications of the helical gears were as follows: module, 0.3; number of teeth, 12; and helix angle, 15°. Compacted powders were consolidated by sintering and solution heat treatment. The consolidated billets consisted of lamellar and fine-grained microstructures. Extrusion experiments were carried out under the following conditions: temperature, 250 ℃; strain rates, 2.36×10-3 s-1 and 1.18×10-1 s-1. The mechanical properties of the extruded helical gears were investigated by measurement of the Vickers hardness and extrusion load, and by scanning electron microscopy.

![]()

Trans. Nonferrous Met. Soc. China 22(2012) 1313-1321

LEE Kyung-Hun1, LEE Jung-Min2, PARK Joon-Hong3, KIM Byung-Min4

1. Precision Manufacturing Systems Division, Pusan National University,

30 Jangjeon-Dong, Kumjeong-Gu, Busan 609-735, Korea;

2. Dongnam Regional Division, Korea Institute of Industrial Technology,

1274 Jisa-dong, Gangseo-gu, Busan 618-230, Korea;

3. Department of Mechanical Engineering, DONG-A University,

840 Hadan 2-dong, Saha-gu, Busan 604-714, Korea;

4. Engineering Research Center for Net Shape and Die Manufacturing, Pusan National University,

30 Jangjeon-Dong, Kumjeong-Gu, Busan 609-735, Korea

Received 5 July 2011; accepted 16 April 2012

Abstract: Powder extrusion, which is based on the superplastic behavior of Zn-22%Al eutectoid alloy, was proposed to reduce the forming load and promises to provide fine microstructures in the manufacture of miniature helical gears. The specifications of the helical gears were as follows: module, 0.3; number of teeth, 12; and helix angle, 15°. Compacted powders were consolidated by sintering and solution heat treatment. The consolidated billets consisted of lamellar and fine-grained microstructures. Extrusion experiments were carried out under the following conditions: temperature, 250 °C; strain rates, 2.36×10-3 s-1 and 1.18×10-1 s-1. The mechanical properties of the extruded helical gears were investigated by measurement of the Vickers hardness and extrusion load, and by scanning electron microscopy.

Key words: helical gear; powder extrusion; gas atomized Zn-22%Al powder; superplasticity

1 Introduction

Recently, several researchers have shown interest in the development of high-precision processing and miniaturization techniques for the fabrication of lightweight gears. YI [1] demonstrated some key issues regarding the current development of microfactory/ miniature manufacturing systems and discussed how these developments could influence the determination of technology- and equipment-development strategies for microforming. ALBERS and MARZ [2] introduced restrictions to production engineering and investigated their influence on the product development process for primary-shaped micro components from metallic and ceramic materials.

Miniature spur gears made of polymers, ceramics, and powders are core components of power transmission devices. Miniature gears are generally produced by machining processes. However, forming processes offer certain distinct advantages over conventional machining methods, such as low material loss and time costs, and increased gear-tooth strength. The feasibility of using forming processes for the fabrication of miniature gears has been extensively studied because of the abovementioned merits. SHAN et al [3] developed hybrid forging processes for a micro-double gear using microforming technology. A fabrication method using micro powder injection molding for micro gears with a diameter and height of 1 mm was proposed by TAY et al [4]. Micro components from a Zn-22%Al alloy were fabricated by different microforming methods, combining the superplastic behavior of metal with hot forming technologies, such as the micro-forward extrusion by KIM et al [5], hot embossing technology by YEH et al [6], and micro-backward extrusion by SAOTOME and IWAZAKI [7]. In particular, YEH and CHANG [8] confirmed that the fine-grained eutectoid Zn-22%Al alloy, which exhibits superplastic behavior, has excellent forgeability.

When using helical gears, vibrations and noise can be reduced and the contact ratio can be improved. However, conventional processes used for the manufacture of miniature helical gears, such as forging and extrusion, have disadvantages that include high forming loads and short tool lives because the cross-section of the die used is complex and asymmetric, as suggested by SAMANTA [9], CHOI et al [10], and JUNG et al [11]. There are some reports on manufacturing processes for miniature helical gears from metal powders. K?NIG and R?BER [12] described for the first time the principle of tooth geometries for tooling and processing parameters, with which powder forged helical gears can be manufactured. JAMES [13] indicated new shaping methods, such as cold forging, powder forging, rotary forming, and pseudo-HIP processing, for powder metallurgy components like aircraft parts and double helical gears. Meanwhile, MAHN and COHRT [14] introduced warm compaction with advanced tooling, with higher densities and improved density distributions attained in this way.

In this study, an extrusion method was developed using Zn-22%Al eutectoid alloy powder for the fabrication of miniature helical gears, with the aim of reducing the load in gear forming. The initial powder billets consolidated by sintering and solution heat treatment consisted of lamellar and fine-grained microstructures. The extrusion die used in the extrusion experiments was machined by precision electric discharge machining (EDM), employing an electrode. The specifications of the fabricated helical gears are as follows: module, 0.3; number of teeth, 12; and helix angle, 15°. Powder extrusion experiments on the consolidated billets were performed under the forming condition that induces superplasticity in the Zn-22%Al powder. Finally, the influence of the initial microstructure and strain rates during deformation on the extrusion behavior of the miniature helical gears was estimated by measurements of an extrusion load and Vickers hardness, as well as by scanning electron microscopy (SEM) observations.

2 Experimental

2.1 Materials

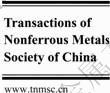

In this study, the eutectoid Zn-22%Al alloy powder, obtained by gas atomization, was used as the material for powder extrusion. SEM images of the gas atomized powder are shown in Fig. 1. These powders are comprised of particles with spherical morphologies (Figs. 1(a) and (b)), so they have better powder formability properties, such as filling, flow, and compressibility, compared with those comprised of flaky and granular particles. Since the powder contains particles of various sizes below 40 μm (Fig. 1(a)), a bridging effect can be achieved, and since smaller particles are added to fill the voids between the larger particles, the relative density of the green compact increases. As shown in Figs. 1(c) and (d), the microstructure of the atomized powder particles shows a fine two-phase structure: the bright phase is Zn, and the dark phase is Al, showing a structure of Zn-22%Al eutectoid alloy that has been summarized by XUN and MOHAMED [15]. Compared with other materials, the Zn-22%Al alloy can be formed under low forming load and temperature conditions. In addition, since grain boundary sliding is the main deformation mechanism, products can be obtained with good quality roughness and microformability, in accordance with the observations of KIM et al [5].

Fig. 1 SEM images of gas-atomized Zn-22%Al alloy powder: (a) Particle size distribution; (b) Surface equiaxed solidification morphology; (c) Two-phase microstructure in a powder particle; (d) Enlarged area in Fig. 1(c)

2.2 Compaction

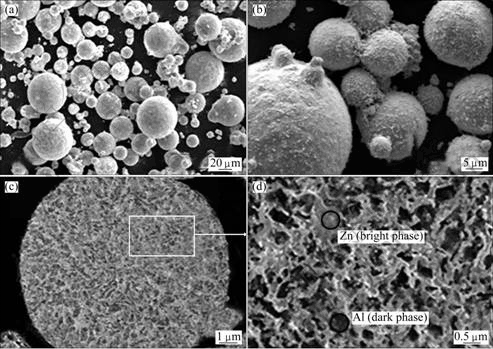

Figure 2 shows the compaction equipment employed and the appearance of the initial billets used for the powder extrusion experiment. The Zn-22%Al alloy powders were compacted into a conical shape (d4.9 mm×14 mm) under 30 kN, giving a relative density to the compacted billets of about 0.85, as in the previous studies by KIM et al [16] and HWANG et al [17]. The initial billets have the same shape as the interior of the extrusion container.

2.3 Consolidation

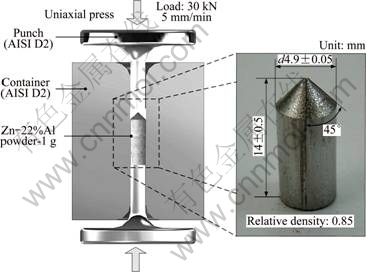

Because the microstructure of the billet material affects its superplastic deformation, grain refinement was carried out using heat treatment or plastic deformation methods. According to XUN and MOHAMED [15], Zn-22%Al eutectoid alloy with lamellar structures would have no effect on superplastic deformation. In this study, compacted powder billets were consolidated by solution heat treatment or sintering, as shown in Fig. 3. As suggested by YEH and CHANG [8] for fine grained structures, the compacted powder billets were homogenized at 375 °C for 22 h and then solution treated at 340 °C for 90 min, before being quenched by liquid nitrogen and then stabilized at 250 °C for 30 min (Fig. 3(a)). The compacted powder billets were sintered at 350 °C for 2 h and cooled in a furnace (Fig. 3(b)), in the same way as in the previous studies by KIM et al [16] and HWANG et al [17], to compare the two types of consolidation methods. Figure 4 shows the micro- structures of the powder billets consolidated by solution heat treatment and sintering. As shown in Fig. 4(a), the microstructure of the billet is very fine-grained, with a microhardness of about HV67.1 (Load: 0.98 N), with a mixture of equiaxed zinc-rich (dark areas) and aluminum- rich phase structure obtained after solution heat treatment. The microstructure of the sintered billet shows a typical lamellar eutectoid structure, and the distance between the respective phases is 2-4 μm (Fig. 4(b)).

Fig. 2 Powder compaction equipment and compacted billet for extrusion

Fig. 3 Powder consolidation processes for fine-grained structure: (a) Solution heat treatment; (b) Sintering

Fig. 4 Microstructures of consolidated billet: (a) Fine-grained equiaxed structure obtained by solution heat treatment; (b) Lamellar structure obtained by sintering

2.4 Extrusion equipment

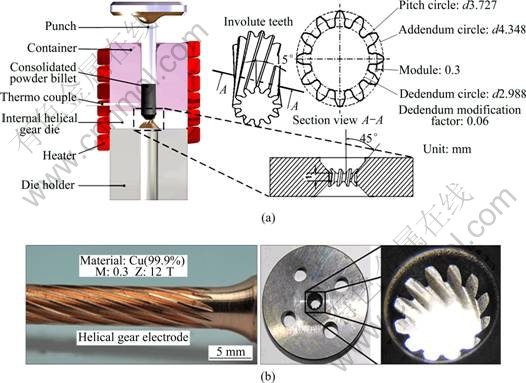

It is challenging to design and manufacture dies for miniature helical gear extrusion because of their geometrical complexity. The accuracy of a helical gear depends upon the manufacture of the die, which involves precision machining of the electrode and EDM. Since the cross-section of a miniature helical gear die is complex, asymmetric, and extremely small, a precision EDM process should be employed when the die is machined. In this study, the electrodes were machined with a standard module and a shaving hob cutter. By controlling the dedendum modification factor of 0.04 mm and then using its electrode, the die was machined by a precision EDM process, as suggested by KWON et al [18]. The geometries of the extrusion die equipment, copper electrode, and machined die are shown in Fig. 5. The determined specifications of the helical gears are as follows: module, 0.3; number of teeth, 12; pitch diameter, 3.727 mm; helix angle, 15°; and reduction ratio, about 50%. AISI H13 was used for the extrusion die. The half die angle was 45° and the bearing length was 1 mm.

2.5 Extrusion conditions

In this study, extrusion experiments using consolidated billets were performed to evaluate the effect of powder grain refinement and strain rate on the extrusion behavior of miniature helical gears in a hot powder extrusion process.

Fig. 5 Powder extrusion experiment for miniature helical gears: (a) Schematic of experiment equipment; (b) Electrode and machined die

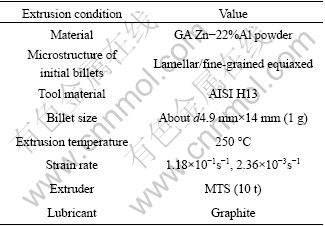

Table 1 presents the conditions of the extrusion experiments carried out in this work. The extrusion temperature was 250 °C, which is a hot working temperature for superplastic deformation behavior. The extrusion velocities were 5 and 0.1 mm/min under strain rates (![]() ) of 1.18×10-1 s-1 and 2.36×10-3 s-1, respectively. The microstructure of the initial powder billets was found in the previous studies to be an important parameter that influences the extrusion load. To determine the optimal microstructure, Zn-22%Al powder billets were extruded with both fine-grained equiaxed- and lamellar-microstructures. During extrusion, a graphite lubricant (Klüber Press DC5-01KR) was spread on the extrusion die and billet to prevent adhesion between the powdered billet and the die. Extrusion experiments were carried out at universal testing machine (MTS, 10 t), and the temperature was controlled by a T-type thermocouple.

) of 1.18×10-1 s-1 and 2.36×10-3 s-1, respectively. The microstructure of the initial powder billets was found in the previous studies to be an important parameter that influences the extrusion load. To determine the optimal microstructure, Zn-22%Al powder billets were extruded with both fine-grained equiaxed- and lamellar-microstructures. During extrusion, a graphite lubricant (Klüber Press DC5-01KR) was spread on the extrusion die and billet to prevent adhesion between the powdered billet and the die. Extrusion experiments were carried out at universal testing machine (MTS, 10 t), and the temperature was controlled by a T-type thermocouple.

Table 1 Conditions of extrusion experiments

3 Results and discussion

The surfaces of the helical gears extruded under compressive strain rates of 1.18×10-1 s-1 and 2.36×10-3 s-1, are shown in Fig. 6. The surfaces of the gear teeth were fine, and no surface defects were observed under any of the conditions used. Furthermore, there were no surface flaws when the forming conditions of the strain rate of 1.18×10-1 s-1 and lamellar-structured billet were used, thus these conditions did not cause superplastic behavior.

3.1 Microstructures

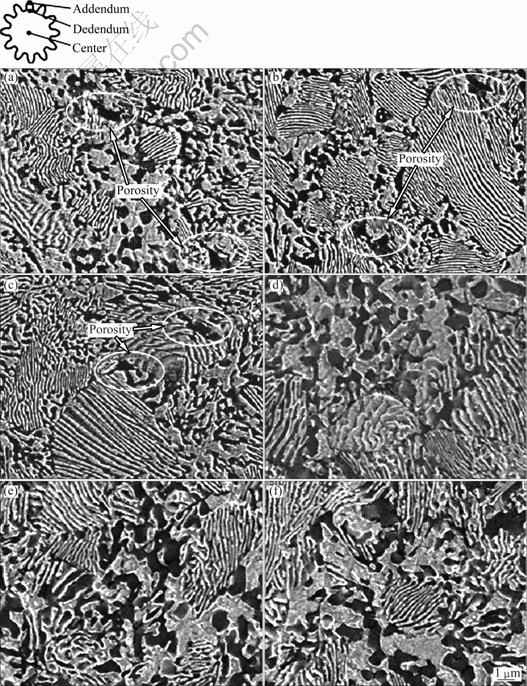

The microstructure of eutectoid Zn-22%Al alloy was found to be highly sensitive to the extrusion behavior. Figure 7 shows, by SEM (Hitachi), the microstructures of helical gears extruded using a sintered billet with lamellar structures under different strain rates, with the respective sections of the addendum, dedendum, and center. There was a tendency for the microstructure of the helical gears to be coarser than that of the initial consolidated billets. In the helical gear sections, the microstructure at the addendum of gears was finer than that at the center under a strain rate of 1.18×10-1 s-1 due to the high deformation energy at the tooth face. The microstructure of the initial billets remained mostly intact. The dislocation motion was the main deformation mechanism observed for lamellar Zn-22%Al eutectoid alloy, where a critical dislocation density was reached at the highest levels of specific compressive strain, promoting a dynamic recovery (and/or recrystallization) effect at elevated temperatures. This caused some of the lamellar microstructures to partially disappear, and newly fine-grained and equiaxed structures were then observed at a compressive strain rate of 2.36×10-3 s-1.

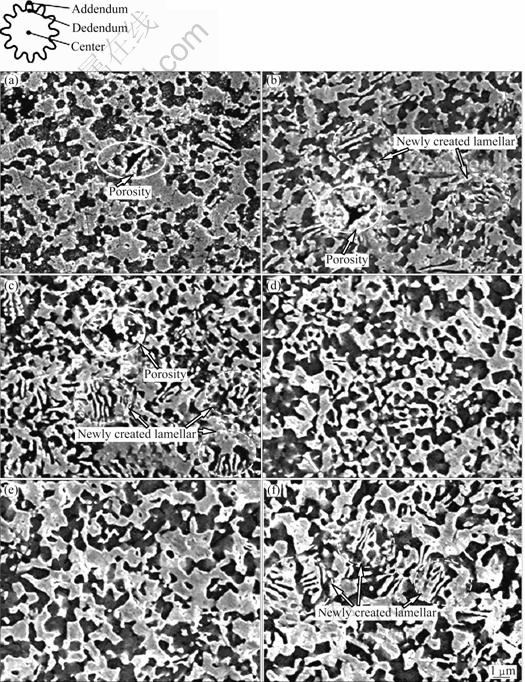

SEM images of Zn-22%Al eutectoid alloy with a fine-grained microstructure are shown in Fig. 8. The fine-grained equiaxed structure was maintained during the extrusion process and no microcracks were observed in the material at the strain rate of 2.36×10-3 s-1. These results may be attributed to the diffusion creep and grain boundary sliding mechanism which played important roles during the powder extrusion process for the fine-grained Zn-22%Al eutectoid alloy to form helical gears under compression stresses.

In addition, greater porosities exhibited when the higher strain rate, 1.18×10-1 s-1, was used. Due to a higher strain rate, the particles were restricted and plastically deformed at a short punch stroke. Thus, the period of particle rearrangement decreased and porosity in the helical gear occurred, in agreement with the findings of LEE et al [19].

Fig. 6 Surface appearance of helical gears extruded under various extrusion conditions: (a) Sintering, 1.18×10-1 s-1; (b) Solution heat treatment, 1.18×10-1 s-1; (c) Sintering, 2.36×10-3 s-1; (d) Solution heat treatment, 2.36×10-3 s-1

Fig. 7 SEM micrographs of helical gears extruded using sintered billets: (a) At addendum with ![]() =1.18×10-1 s-1; (b) At dedendum with

=1.18×10-1 s-1; (b) At dedendum with ![]() =1.18×10-1 s-1; (c) At center with

=1.18×10-1 s-1; (c) At center with ![]() =1.18×10-1 s-1; (d) At addendum with

=1.18×10-1 s-1; (d) At addendum with ![]() =2.36×10-3 s-1; (e) At dedendum with

=2.36×10-3 s-1; (e) At dedendum with ![]() =2.36×10-3 s-1; (f) At center with

=2.36×10-3 s-1; (f) At center with ![]() =2.36×10-3 s-1

=2.36×10-3 s-1

3.2 Extrusion behavior

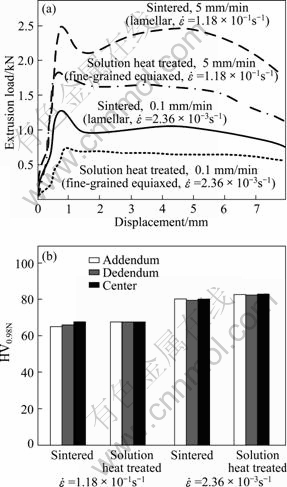

Figure 9(a) shows a graph of displacement versus forming loads. The lowest forming load was measured at the strain rate of 2.36×10-3 s-1 with fine-grained equiaxed structure billets (max. 0.74 kN), resulting from their superplastic behavior. On the other hand, the highest load was measured at the strain rate of 1.18×10-1 s-1 with lamellar-structured billets (max. 2.5 kN). A higher extrusion velocity provided a higher compressive strain rate and so the flow stresses of the specimens increased. Consequently, a higher deformation energy is required to fill the fine teeth of the helical gear during extrusion compared with forming under a slow extrusion velocity.

Fig. 8 SEM micrographs of helical gears extruded using solution heat treated billets: (a) At addendum with ![]() =1.18×10-1 s-1; (b) At dedendum with

=1.18×10-1 s-1; (b) At dedendum with ![]() =1.18×10-1 s-1; (c) At center with

=1.18×10-1 s-1; (c) At center with ![]() =1.18×10-1 s-1; (d) At addendum with

=1.18×10-1 s-1; (d) At addendum with ![]() =2.36×10-3 s-1; (e) At dedendum with

=2.36×10-3 s-1; (e) At dedendum with ![]() =2.36×10-3 s-1; (f) At center with

=2.36×10-3 s-1; (f) At center with ![]() =2.36×10-3 s-1

=2.36×10-3 s-1

Figure 9(b) shows the micro-Vickers hardness (Load: 0.98 N) at the addendum, dedendum, and center of the helical gear. The highest hardness was measured on the helical gear extruded at 2.36×10-3 s-1 with the fine-grained equiaxed structure billets (about HV80), and the distribution of hardness was uniform over all of the measured points. In contrast, the helical gear extruded at 1.18×10-1 s-1 with lamellar structure billets had the lowest hardness (about HV68). At increased strain rates, dislocations move faster than solute atoms that can diffuse, therefore the dislocations are relatively solute-free and the drag is minimized. These lead to a lower Vickers hardness.

Fig. 9 Extrusion load (a) and Vickers hardness (b) of helical gears extruded under various extrusion conditions

4 Conclusions

An extrusion process based on the use of Zn-22%Al eutectoid alloy powder was developed for the fabrication of miniature helical gears, with the aim of reducing the forming load and improving the fine mechanical properties.

1) Compacted powder billets with fine-grained equiaxed structures were produced after consolidation by solution heat treatment.

2) The lowest load and highest hardness were observed at an extrusion velocity of 0.1 mm/min for a fine-grained billet. This is a result of employing conditions that induce superplastic behavior at 250 °C with a compressive strain rate of 2.36×10-3 s-1.

References

[1] YI Q. Micro-forming and miniature manufacturing systems— Development needs and perspectives [J]. Journal of Materials Processing Technology, 2006, 177: 8-18.

[2] ALBERS A, MARZ J. Restrictions of production engineering on micro-specific product development [J]. Microsystem Technologies, 2004, 10: 205-210.

[3] SHAN D, XU J, WANG C, CUO B. Hybrid forging processes of micro-doouble gear using micro-forming technology [J]. International Journal of Advanced Manufacturing Technology, 2009, 44: 238-243.

[4] TAY B Y, LOH N H, TOR S B, NG F L, FU G, LU X H. Characterisation of micro gears produced by micro powder injection moulding [J]. Powder Technology, 2009, 188: 179-182.

[5] KIM J Y, JOO S M, KIM H K. Superplastic microextrusion for microgear [J]. Transactions of the Korean Society of Machine Tool Engineers, 2008, 17(4): 1-7.

[6] YEH M S, LIN H Y, LIN H T, CHANG C B. Superplastic micro-forming with a fine grained Zn-22Al eutectoid alloy using hot embossing technology [J]. Journal of Materials Processing Technology, 2006, 180: 17-22.

[7] SAOTOME Y, IWAZAKI H. Superplastic backward microextrusion of microparts for micro-electro-mechanical systems [J]. Journal of Materials Processing Technology, 2001, 119: 307-311.

[8] YEH M S, CHANG C B. Microstructure effects on the forgeability of Zn-22Al eutectoid alloy [J]. Journal of Materials Engineering and Performance, 2002, 11: 71-74.

[9] SAMANTA S K. Helical gear: A noble method of manufacturing it [C]//Proc 4th North American Metalworking Research Conf. Battele’s Columbus Labs, Society of Manufacturing Engineers, 1976: 199-205.

[10] CHOI J C, CHO H Y, KWON H H. A new extrusion process for helical gears: Experimental study [J]. Journal of Materials Processing Technology, 1994, 44: 35-53.

[11] JUNG S Y, PARK J H, KIM C H, CHANG Y J, KIM C. A study on the extrusion using two-step processes for manufacturing helical gear [J]. Journal of the Korean Society for Precision Engineering, 2007, 24: 34-40.

[12] K?NIG W, R?BER G. Powder forging of helical gears for car manual gear boxes—Concept and properties [J]. Metal Powder Report, 1990, 45(4): 269-273.

[13] JAMES B W. New shaping methods for powder metallurgy components [J]. Materials & Design, 1987, 8(4): 187-197.

[14] MAHN A, COHRT H. Production and properties of high strength high density helical gears [J]. Metal Powder Report, 1999, 54(6): 47.

[15] XUN Y, MOHAMED F A. Microstructure and deformation in the spray deposited Zn-22A%Al alloy [J]. Materials Science and Engineering A, 2006, 432: 261-268.

[16] KIM J W, LEE S J, LEE J M, KIM B M. Extrusion of spur gear using high energy ball milled Al-78Zn powder [J]. Transactions of the Korean Society of Mechanical Engineering A, 2009, 33: 440-446.

[17] HWANG D W, LEE K H, KIM B M. Manufacturing powder extrusion die and experiment for fabrication of miniature helical-gears [J]. Transactions of Materials Processing, 2010, 19: 283-289.

[18] KWON J J, JOUN B Y, JOUN M S. Precision electric discharge machining of a cold forging die for helical gear manufacturing [C]//YANG D Y. Proc Kor Soc for Precision Eng Conf. Korean Society for Precision Engineering, 2005: 170-173.

[19] LEE K H, LEE J M, KIM B M. Densification simulation of compacted Al powders using multi-particle finite element method [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: s98-s75.

LEE Kyung-Hun1, LEE Jung-Min2, PARK Joon-Hong3, KIM Byung-Min4

1. Precision Manufacturing Systems Division, Pusan National University,

30 Jangjeon-Dong, Kumjeong-Gu, Busan 609-735, Korea;

2. Dongnam Regional Division, Korea Institute of Industrial Technology,

1274 Jisa-dong, Gangseo-gu, Busan 618-230, Korea;

3. Department of Mechanical Engineering, DONG-A University,

840 Hadan 2-dong, Saha-gu, Busan 604-714, Korea;

4. Engineering Research Center for Net Shape and Die Manufacturing, Pusan National University,

30 Jangjeon-Dong, Kumjeong-Gu, Busan 609-735, Korea

摘 要:基于Zn-22%Al共析合金的超塑性,采用粉末挤压工艺制造微型螺旋齿轮,以减小成形压力和获得细小的显微组织。该螺旋齿轮的规格为:模数0.3,齿数1.2,螺旋角15°。将粉末压制坯通过烧结和固溶热处理进行致密化。致密化的坯料由层状和细晶状组织组成。在温度250 °C,应变速率2.36×10-3和1.18×10-1s-1的条件下对坯料进行挤压,并对挤压成形的螺旋齿轮的力学性能进行测试。

关键词:螺旋齿轮;粉末挤压;气雾化Zn-22%Al粉;超塑性

(Edited by YUAN Sai-qian)

Foundation item: Project (2010-0008-277) supported by the NCRC (National Core Research Center) Program through the National Research Foundation of Korea, funded by the Ministry of Education, Science, and Technology; Project (NRF-2009-K20601000004-09E0100-00410) supported by PNU-IFAM JRC

Corresponding author: KIM Byung-Min; Tel: +81-51-5103074; E-mail: bmkim@pusan.ac.kr

DOI: 10.1016/S1003-6326(11)61320-4