DOI: 10.11817/j.issn.1672-7207.2021.02.005

蠕变时效对2219铝合金搅拌摩擦焊接头力学性能与微观组织的影响

焦君1,李国鹏2,湛利华2,杨有良2,胡正根3,刘观日3

(1. 中国运载火箭技术研究院,北京,100076;

2. 中南大学 机电工程学院,湖南 长沙,410083;

3. 北京宇航系统工程研究所,北京,100076)

摘要:为了研究蠕变应力作用下的时效热处理对2219铝合金搅拌摩擦焊接头力学性能与微观组织的影响,对蠕变时效与人工时效2种不同热处理工艺板材的搅拌摩擦焊接进行对比实验。研究结果表明:相比于人工时效板材的搅拌摩擦焊(AA+FSW)接头,蠕变时效板材搅拌摩擦焊(CA+FSW)接头的显微硬度、抗拉强度和伸长率均更高;CA+FSW板材和AA+FSW板材在焊缝横截面区的显微硬度呈“W”形分布,且低谷均位于热机影响区;与母材相比,CA+FSW板材和AA+FSW板材接头处的抗拉强度和伸长率都有所降低,其中,CA+FSW板材焊缝抗拉强度平均值为317.8 MPa,为母材的71.9%;AA+FSW板材后焊缝抗拉强度293.8 MPa,为母材的69.1%。板材在焊接过程中基体内的析出相发生了回溶现象,其中CA+FSW板材仍然残留少部分强化相θ′,而AA+FSW板材的析出相则基本全部回溶,因此,焊接后,应力时效板材的显微硬度和抗拉强度更高。

关键词:2219铝合金;蠕变时效;人工时效;搅拌摩擦焊;力学性能;微观组织

中图分类号:TG456.9 文献标志码:A

OSID:

文章编号:1672-7207(2021)02-0368-08

Effect of creep ageing on mechanical properties and microstructure of 2219 aluminum alloy friction stir welding joint

JIAO Jun1, LI Guopeng2, ZHAN Lihua2, YANG Youliang2, HU Zhenggen3, Liu Guanri3

(1. China Academy of Launch Vehicle Technology, Beijing 100076, China;

2. College of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China;

3. Beijing Institute of Astronautical Systems Engineering, Beijing 100076, China)

Abstract: In order to find out the effect of aging heat treatment under creep stress on the mechanical properties and microstructure of 2219 aluminum alloy friction stir welding(FSW) joints, a comparative experimental study on friction stir welding of two different heat treatment processes, creep aging and artificial aging was carried out.The results show that the microhardness, tensile strength and elongation of creep aging sheet friction stir welding joint are higher than those of the friction stir weldingof artificial aging sheet (AA+FSW). The hardness of the two kinds of heat-treated plates in the weld seam area is roughly W-shaped distribution, and the minimum hardness locates in the thermo-mechanically affected zone. The tensile strength and elongation of the welded joint are lower than those of the base material. The average tensile strength of CA+FSW is 317.8 MPa (71.9% of the base material), which is higher than 293.8 MPa in AA+FSW(69.1% of the base material). Microstructure analysis shows that the precipitation phase of the substrats during the welding process has been re-dissolved. Among the CA+FSW plates, a small part of the precipitated phase θ′ remains, but the precipitated phases of the AA+FSW plates are almost completely re-dissolved, which is the reason why the microhardness and tensile strength of the stress aging plate are higher after welding.

Key words: 2219 aluminum alloy; creep aging; artificial aging; friction stir welding; mechanical properties; microstructure

蠕变时效成形是为了制备高性能高精度大型薄壁构件而发展起来的一种新型成形工艺[1],其原理是利用材料的蠕变和时效强化特性,使构件在同一个制造环境中同时实现成形与成性。相对于传统成形技术,蠕变时效成形具有成形精度高、可重复性好、成本低等优点,已在国外航空航天运载器例如B-1B超音速战略轰炸机上机翼壁板、空客A380的上机翼蒙皮及土星五号火箭贮箱壁板[2-4]中广泛应用。目前,我国也将蠕变时效成形技术运用于新一代运载火箭贮箱瓜瓣与壁板的制造中[5]。运载火箭贮箱一般由整体成形的大型板材作为基本单元拼焊而成,以往贮箱焊接多采用熔焊方法,这种焊接方法存在焊缝缺陷多、焊接变形大、生产周期长等问题[6]。1991年,英国焊接研究所发明的搅拌摩擦焊技术(FSW)成功克服了上述缺陷,使焊接性能大幅提高[7]。以2219铝合金为例,与TIG焊缝相比,搅拌摩擦焊焊缝的平均抗拉强度提高17%,断后伸长率提高87.5%,缺陷发生率降低90%左右。目前,搅拌摩擦焊已在Delta II和IV贮箱(2219-T87)、猎鹰9号贮箱(2198铝锂合金)、太空发射系统贮箱(2219-T87)等火箭贮箱中得到了广泛应用[6, 8]。

通常,焊接后的热处理可以消除残余应力,使晶粒形状更加均匀,是一种能够有效提高焊缝性能的手段[9-10]。但在实际工程中,拼焊成形后的火箭贮箱直径较大(一般为3.35 m),难以进行整体固溶处理,因此,一般通过调整板材初始坯料状态的方法改善焊缝区域性能。AYDIN等[11]研究了2024-O态、2024-T4态和2024-T6态焊缝的性能,发现随坯料基体材料析出强化的增强,接头的拉伸性能不断提高,2024-T6态(190 ℃/10 h)焊缝抗拉强度最高,达到496 MPa;对于断裂位置,2024-T4态和2024-T6态断裂发生在热影响区,2024-O态断裂发生在焊接基材上。VENKATESWARLU等[12]研究了2219-T62和2219-T87 2种不同初始状态板材的搅拌摩擦焊接性能,发现不同坯料热处理工艺会对焊接接头微观结构和性能产生很大影响,虽然2219-T87板材的粗化更为严重,但抗拉强度明显比2219-T62板材的高:2219-T62板材的焊缝抗拉强度为母材的39.1%,2219-T87板材的焊缝抗拉强度为母材的59.87%。

已有研究表明,与人工时效(AA)相比,可时效热处理强化铝合金蠕变(应力)时效(CA)性能与微观结构有较大差异,在时效过程中,因蠕变成形施加在材料上的应力可以促进强化相析出,减少达到峰值时效所需要的时间,提高峰值时效强度[13-15],从而对焊缝区组织性能产生显著的影响。目前,对蠕变(应力)时效后的板材进行搅拌摩擦焊的研究较少。在此,本文作者对比研究2219-T35铝合金蠕变时效后搅拌摩擦焊(CA+FSW)与人工时效后搅拌摩擦焊(AA+FSW)焊缝区域的显微硬度、力学性能和组织形貌,探究应力时效后板材搅拌摩擦焊的可行性,为大型薄壁构件蠕变时效成形+搅拌摩擦焊接技术的实际工程应用提供理论依据与指导。

1 实验材料与方法

实验材料为2219-T35铝合金,材料成分见表1。蠕变时效成形板材(贮箱箱底瓜瓣)坯料大端宽度×小端宽度×长度×厚度为940 mm×420 mm×1 300 mm×5 mm,人工时效板材坯料长×宽×厚为700 mm×140 mm×5 mm。

表1 2219铝合金的主要化学成分(质量分数)

Table 1 Main chemical compositions of 2219 aluminum alloy(mass fraction) %

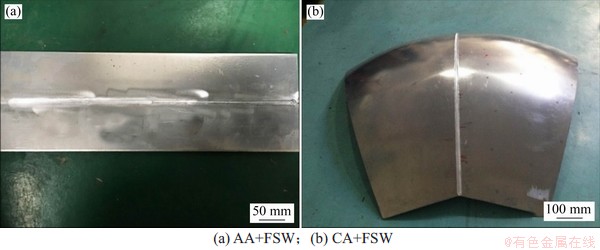

采用应力作用下贮箱瓜瓣的时效成形试验获取蠕变时效成形板材。首先,将梯形铝合金板材放置于瓜瓣成形模具上,包覆真空袋,通过抽真空的方式进行气压加载,使板材紧贴于模具表面,然后,将板材放入热压罐中,罐内施加气压载荷到0.8 MPa,升温到165 ℃,保温8 h。同时,另取2块长方形板材放入热压罐中同步进行人工时效。将蠕变时效与人工时效后的板材使用砂纸打磨待焊区,并清除碎屑,保证2个板材待焊区可紧密相接,放到专用卡具上卡紧。使用五轴搅拌摩擦焊床进行焊接,焊后构件如图1所示。

图1 2种不同热处理工艺的搅拌摩擦焊接照片

Fig. 1 FSW of two different heat treatment processes

在焊接位置用线切割机截下长×宽×厚为30 mm×20 mm×5 mm的长条板材,分别对打磨抛光后的焊接区域的截断面与上表面进行显微硬度试验,自焊缝中心向两侧取点,取点间隔为1 mm。在2种不同初始热处理板材的接头上各取9个标准拉伸试样进行常温力学性能测试,常温拉伸实验在CMT-5504型电子万能试验机上按国家标准《金属室温拉伸试验方法》进行,拉伸速率为2 mm/min。对断后试样用扫描电子显微镜观察断口形貌。在母材区域和焊缝区域分别取样,制得直径为3 mm、厚度为0.08 mm圆片作为透射样品,将此圆片通过双喷电解仪进行双喷电解腐蚀至穿孔,双喷溶液中HNO3和CH3OH的体积比为3:7。双喷减薄过程中,设备内部温度保持在-25~-35 ℃之间,电压设定为15 V。利用JEM-2100F透射电镜对焊缝区微观组织进行观察,工作加速电压为200 kV。

2 结果与讨论

2.1 显微硬度

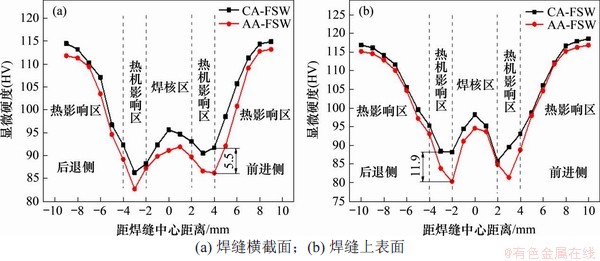

图2所示为CA+FSW和AA+FSW板材接头的横截面和上表面显微硬度分布。从图2(a)可以看出:人工时效与蠕变时效母材硬度基本相当,在113~117 (HV)之间,焊接区域的硬度低于母材;焊缝横截面的显微硬度呈现出典型的“W”型分布:从焊接中心到热机影响区显微硬度逐渐降低直至最低点,然后向热影响区增加,直到与母材硬度相同;CA+FSW的焊接接头显微硬度比AA+FSW焊接接头的显微硬度略高。从图2(b)可见:上表面硬度分布与焊缝截面的硬度分布类似,但整体硬度更高。

整体上,2219-T35铝合金焊缝硬度最低值位于热机影响区,其中,AA+FSW接头的最低硬度(HV)为82.0;CA+FSW接头的最低硬度(HV)为86.3。搅拌摩擦焊接头焊接部位的强度降低是因为这些区域受到搅拌针内部摩擦产生热量和轴肩与焊缝表面摩擦生热的共同影响,过高热输入改变了微观结构[16-17]。

无论在焊缝区域的上表面还是横截剖面,CA+FSW板材的硬度整体略高于AA+FSW板材的硬度:横截面硬度(HV)最大差值为5.5,位于焊缝前进侧的热机影响区;焊缝上表面硬度(HV)最大差值为11.9,位于在后退侧的热机影响区。综上可知,蠕变时效后板材焊接性能整体上比人工时效的略高,硬度产生差别的原因主要与应力对析出相的影响有关。

2.2 拉伸性能

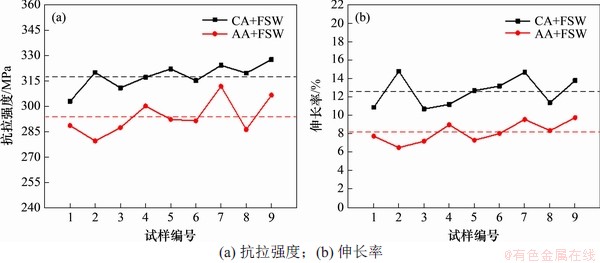

焊接试验前,取2种不同时效工艺处理的母材进行常温力学性能测试。其中,蠕变时效后,瓜瓣母材抗拉强度平均值为441.9 MPa,伸长率为17.2%;人工时效后,母材抗拉强度平均值为425.2 MPa,伸长率为16.5%。对焊缝区所取试样进行拉伸力学性能测试,所有试样的断裂均发生在焊核区与后退侧。测试结果如图3所示。由图3(a)可以看出:蠕变时效板材焊接接头力学性能较好,抗拉强度和伸长率平均值分别为317.8 MPa和12.6%,为母材的71.9%和73.3%;人工时效板材焊接接头抗拉强度和伸长率平均值为293.8 MPa和8.2%,分别为母材的69.1%和49.7%。

图2 焊缝区域显微硬度对比

Fig. 2 Comparison of microhardness distribution of welded joints

图3 CA+FSW与AA+FSW板材焊接区域性能

Fig. 3 Mechanical properties of CA+FSW and AA+FSW joints

2组热处理工艺板材的焊接接头抗拉强度与伸长率均比各自的母材的低,尤其是AA+FSW接头的伸长率仅8.2%。对比力学性能可知,CA+FSW板材焊后强度和伸长率均比AA+FSW的高,分别高8%和35%。拉伸力学性能测试结果说明蠕变(应力)时效可提高2219-T35铝合金后续搅拌摩擦焊焊缝的力学性能。

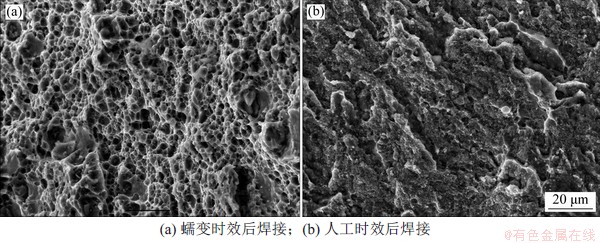

2.3 断口形貌

虽然搅拌摩擦焊可以得到性能优异的焊缝,但受摩擦热等因素的影响,接头处的性能在一定程度上低于母材的性能。图4所示为蠕变时效与人工时效坯料经搅拌摩擦焊后的焊缝区域SEM断口形貌。由图4可以看出:二者断口形貌差别较大(如图4(a)所示),CA+FSW的拉伸断裂断口韧窝十分细密,尺寸较小,仅为几微米,分布均匀,左下角有小部分韧窝发生连结,形成局部沿晶,为明显的韧性断裂特征;而AA+FSW的拉伸断裂断口韧窝数量较少,断口可以观察到较多的第二相粒子,大部分为沿晶断裂与穿晶断裂,体现了脆性与韧性混合断裂特性(如图4(b)所示)。断口扫描图解释了蠕变时效板材的焊缝断裂韧性要高于人工时效板材的原因。

图4 2219铝合金拉伸断口扫描照片

Fig. 4 Fracture morphology of 2219 aluminum alloy

2.4 微观组织

2219铝合金属于可热处理强化合金,不同的热处理工艺对材料的强度造成较大影响。蠕变时效引入了应力的作用,在析出相的种类和密度方面有明显差别。与人工时效相比,在相同的时效温度与时间下,蠕变时效会产生更多的位错,析出相数目增加,析出相也会由 转换为

转换为 与

与 共存,从而材料性能提高[14]。

共存,从而材料性能提高[14]。

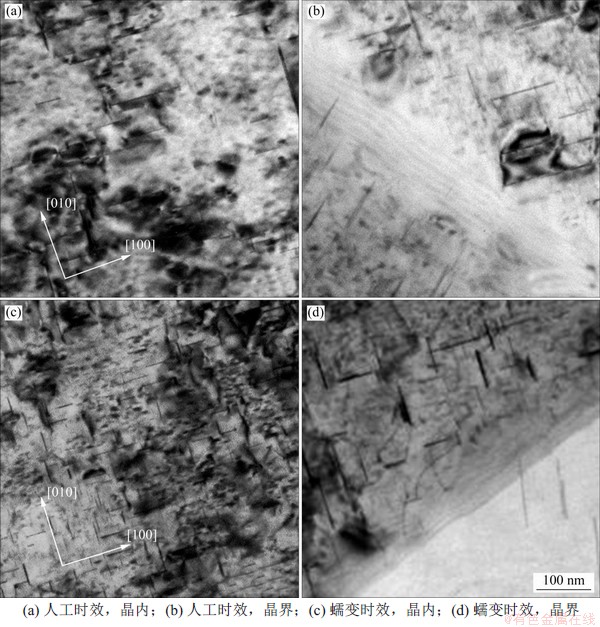

图5所示为人工时效板材和蠕变时效板材母材的TEM微观组织。从图5(a)可以看到,人工时效处理后的母材有大量弥散细小的GP区与可剪切的 相(Al2Cu),析出相沿[001]方向析出,长度为30~120 nm,这些细小的GP区与

相(Al2Cu),析出相沿[001]方向析出,长度为30~120 nm,这些细小的GP区与 相在晶格缺陷和位错的位置产生,随着时效时间的延长,还将继续生长粗化变为

相在晶格缺陷和位错的位置产生,随着时效时间的延长,还将继续生长粗化变为 相。从图5(c)和图5(d)可以看到:有大量相互垂直的析出相存在,与文献对比可知,这些析出相为

相。从图5(c)和图5(d)可以看到:有大量相互垂直的析出相存在,与文献对比可知,这些析出相为 相与

相与 相[14],析出相长度在90~120 nm之间,厚度为10~15 nm。与人工时效母材相比,析出相的整体密度增大,

相[14],析出相长度在90~120 nm之间,厚度为10~15 nm。与人工时效母材相比,析出相的整体密度增大, 相占比明显增加;

相占比明显增加; 相比

相比 相更难以被剪切,可以为材料提供更为有效的强化,从而使蠕变时效后板材母材性能更高。

相更难以被剪切,可以为材料提供更为有效的强化,从而使蠕变时效后板材母材性能更高。

图5 人工时效和蠕变时效母材TEM微观组织照片

Fig. 5 TEM images of base metal after artificial aging and creep aging

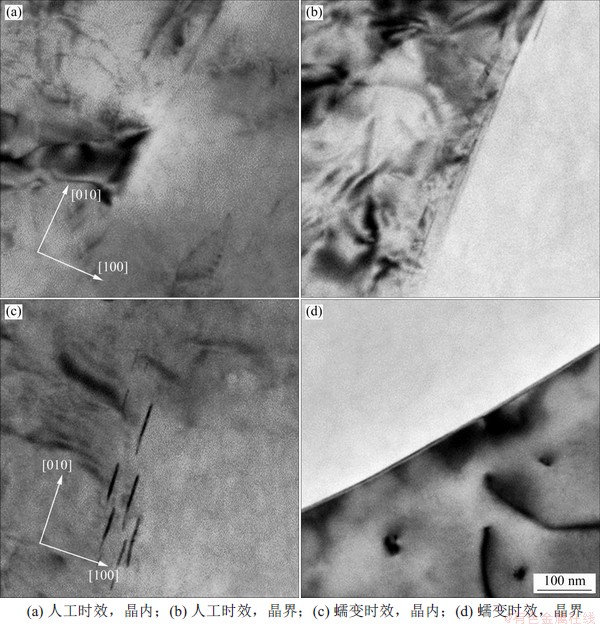

图6所示为AA+FSW与CA+FSW焊缝区的TEM微观组织。从图6(a)可以看到:AA+SWF的焊缝区域析出相基本上在搅拌摩擦高热作用下回溶,因此,强度相对母材大幅下降。从图6(c)可以看到CA+SWF的焊缝区零星分布的 相,长度为200 nm左右,这些

相,长度为200 nm左右,这些 相分布较为集中,不能有效地通过阻碍晶格畸变提高材料的强度,相较于母材区域,

相分布较为集中,不能有效地通过阻碍晶格畸变提高材料的强度,相较于母材区域, 相已经发生了较为明显的粗化,另外,从图6(d)可以看到,晶界附近有一定的位错结构。经对比分析可知,蠕变时效板材焊接后强度相对母材也出现明显下降,但由于基体内仍存在少量析出相和位错,强度比人工时效板材焊后的略高。

相已经发生了较为明显的粗化,另外,从图6(d)可以看到,晶界附近有一定的位错结构。经对比分析可知,蠕变时效板材焊接后强度相对母材也出现明显下降,但由于基体内仍存在少量析出相和位错,强度比人工时效板材焊后的略高。

图6 人工时效和蠕变时效板材焊接接头TEM微观组织照片

Fig. 6 TEM images of welded joints after artificial aging and creep aging

综合上述分析可知,无论是以人工时效还是蠕变时效板材作为初始坯料,与母材相比,焊缝区的析出相都明显的减少。这是因为在搅拌摩擦焊焊接过程中,搅拌针和轴肩等位置与板材摩擦产生的高温使大量析出相产生溶解,仅存的析出相也会在高温下快速粗化,减弱析出强化效果。这是导致焊接区域强度降低的主要原因。晶粒尺寸在搅拌焊接中也会产生很大的变化,对强度也会产生一定的影响。对比人工时效与蠕变时效后板材的焊缝区域,蠕变时效后再进行焊接的焊缝区仍存有一定量的析出相,而人工时效板材的焊缝微观组织中析出相基本完全回溶,这在一定程度上解释了CA+FSW板材性能强于AA+FSW板材性能的原因。

3 结论

1) 蠕变时效与人工时效板材在焊缝区的性能均有所降低,其中,AA+FSW板材焊缝抗拉强度平均值为293.8 MPa,伸长率为8.2%;CA+FSW板材焊缝抗拉强度平均值为317.8 MPa,伸长率为12.6%,可见,蠕变时效板材的焊接接头强度和伸长率略高。

2) 蠕变时效与人工时效板材的焊缝区域硬度曲线都呈“W”形分布,可以明显观测到焊缝区域硬度下降,两者的硬度最低值均出现在热机影响区。在截面与表层,CA+FSW板材焊缝最低硬度(HV)比AA+FSW焊缝的最低硬度(HV)分别高5.5和11.9。

3) 蠕变时效与人工时效板材焊缝区域的析出相均发生回溶,AA+FSW板材焊缝区析出相基本完全回溶,CA+FSW板材焊缝区仍有少量残余 相和位错结构。

相和位错结构。

参考文献:

[1] 湛利华, 杨有良. 大型构件蠕变时效成形技术研究[J]. 航空制造技术, 2016, 59(13): 16-23.

ZHAN Lihua, YANG Youliang. Research on creep age forming technology for large integrated component[J]. Aeronautical Manufacturing Technology, 2016, 59(13): 16-23.

[2] 曾元松, 黄遐, 黄硕. 蠕变时效成形技术研究现状与发展趋势[J]. 塑性工程学报, 2008, 15(3): 1-8.

ZENG Yuansong, HUANG Xia, HUANG Shuo. The research situation and the developing tendency of creep age forming technology[J]. Journal of Plasticity Engineering, 2008, 15(3): 1-8.

[3] ZHAN Lihua, LIN Jianguo, DEAN T A, et al. Experimental studies and constitutive modelling of the hardening of aluminium alloy 7055 under creep age forming conditions[J]. International Journal of Mechanical Sciences, 2011, 53(8): 595-605.

[4] HAMBRICK D M. Age forming technology expanded in an autoclave[J]. Society of Automotive Engineer, 1986, 4(6): 649-664.

[5] 孙找, 湛利华, 刘健, 等. 2219铝合金蠕变时效成形过程中的断裂行为[J]. 塑性工程学报, 2018, 25(5): 284-290.

SUN Zhao, ZHAN Lihua, LIU Jian, et al. Fracture behavior in creep aging forming process of aluminum alloy 2219[J]. Journal of Plasticity Engineering, 2018, 25(5): 284-290.

[6] 宋建岭, 李超. 搅拌摩擦焊在运载火箭贮箱制造中的应用与发展[J]. 焊接, 2018(5): 21-27, 66.

SONG Jianling, LI Chao. Application of FSW technology to tank manufacturing of launch vehicle and its development[J]. Welding & Joining, 2018(5): 21-27, 66.

[7] LAKSHMINARAYANAN A K, MALARVIZHI S, BALASUBRAMANIAN V. Developing friction stir welding window for AA2219 aluminiumalloy[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(11): 2339-2347.

[8] THOMAS W M, NICHOLAS E D. Friction stir welding for the transportation industries[J]. Materials & Design, 1997, 18(4/5/6): 269-273.

[9] 李小霞, 黄亮, 李建军, 等. 搅拌摩擦焊和热处理复合工艺对2219铝合金组织性能的影响[J]. 中国机械工程, 2017, 28(23): 2880-2888.

LI Xiaoxia, HUANG Liang, LI Jianjun, et al. Effects of compound technology of FSW and heat treatment on microstructures and properties of 2219 aluminum alloys[J]. China Mechanical Engineering, 2017, 28(23): 2880-2888.

[10] 贺地求, 杨传平, 林俊渊. 2219铝合金搅拌摩擦焊和固溶处理的工序顺序研究[J]. 热加工工艺, 2018, 47(5): 1-4.

HE Diqiu, YANG Chuanping, LIN Junyuan. Study on procedure sequence of friction stir welding and solution treatment of 2219 aluminum alloy[J]. Hot Working Technology, 2018, 47(5): 1-4.

[11] AYDIN H, BAYRAM A, UGUZ A, et al. Tensile properties of friction stir welded joints of 2024 aluminum alloys in different heat-treated-state[J]. Materials & Design, 2009, 30(6): 2211-2221.

[12] VENKATESWARLU D, CHEEPU M, KRANTHI KUMAR B, et al. Analysing the friction stir welded joints of AA2219 Al-Cu alloy in different heat-treated-state[J]. IOP Conference Series: Materials Science and Engineering, 2018, 330: 012074.

[13] 王萌, 湛利华, 李文科, 等. 2219铝合金蠕变时效研究及宏微观本构建模[J]. 热加工工艺, 2017, 46(6): 221-225.

WANG Meng, ZHAN Lihua, LI Wenke, et al. Creep aging research and macro and micro constitutive modelling of 2219 aluminum alloy[J]. Hot Working Technology, 2017, 46(6): 221-225.

[14] MA Ziyao, ZHAN Lihua, LIU Chunhui, et al. Stress-level-dependency and bimodal precipitation behaviors during creep ageing of Al-Cu alloy: Experiments and modeling[J]. International Journal of Plasticity, 2018, 110: 183-201.

[15] 晋坤, 邓运来, 周亮, 等. 6156铝合金的人工时效与蠕变时效研究[J]. 航空材料学报, 2011, 31(5): 18-22.

JIN Kun, DENG Yunlai, ZHOU Liang, et al. Investigation on artificial aging and creep aging of 6156 aluminum alloy[J]. Journal of Aeronautical Materials, 2011, 31(5): 18-22.

[16] LIU H J, FUJII H, MAEDA M, et al. Tensile properties and fracture locations of friction-stir-welded joints of 2017-T351 aluminum alloy[J]. Journal of Materials Processing Technology, 2003, 142(3): 692-696.

[17] 吕赞, 王琳, 岳玉梅, 等. 搅拌头压入速度和停留时间对2024铝合金搅拌摩擦焊接温度场的影响[J]. 热加工工艺, 2013, 42(1): 171-173.

LU Zan, WANG Lin, YUE Yumei, et al. Effect of penetration speed and reserving time of rotational tool on temperature field of friction stir welded 2024 aluminum alloy[J]. Hot Working Technology, 2013, 42(1): 171-173.

(编辑 赵俊)

收稿日期: 2020 -03 -18; 修回日期: 2020 -05 -29

基金项目(Foundation item):国家重点研发计划项目(2017YFB0306300);中南大学创新驱动计划项目(2015CX002);湖南省科技计划项目(2016RS2015) (Project(2017YFB0306300) supported by the National key R&D Program of China; Project(2015CX002) supported by the Innovation-driven Plan in Central South University; Project(2016RS2015) supported by the Science and Technology Plan in Hunan Province)

通信作者:湛利华,教授,从事轻质高强材料构件形性一体化制造研究;E-mail:yjs-cast@csu.edu.cn

引用格式:焦君, 李国鹏, 湛利华, 等. 蠕变时效对2219铝合金搅拌摩擦焊接头力学性能与微观组织的影响[J]. 中南大学学报(自然科学版), 2021, 52(2): 368-375.

Citation:JIAO Jun, LI Guopeng, ZHAN Lihua, et al. Effect of creep ageing on mechanical properties and microstructure of 2219 aluminum alloy friction stir welding joint[J]. Journal of Central South University(Science and Technology), 2021, 52(2): 368-375.