Microstructure and tensile property of SLM 316L stainless steel manufactured with fine and coarse powder mixtures

来源期刊:中南大学学报(英文版)2020年第2期

论文作者:刘世锋 杨鑫 任垚嘉 王庆娟 时明军

文章页码:334 - 343

Key words:selective laser melting; powder mixture; microstructure; solidification; mechanical properties

Abstract: Selective laser melting (SLM) technology is the prevailing method of manufacturing components with complex geometries. However, the cost of the additive manufacturing (AM) fine powder is relatively high, which significantly limits the development of the SLM. In this study, the 316L fine powder and coarse powder with a mass ratio of 80:20, 70:30 and 60:40 were mixed using a ball milling and the samples with a relative density greater than 97% were prepared by SLM. The results show that the intricate temperature gradients and surface tension gradients in SLM will produce Marangoni flow, forming a typical molten pool morphology, cellular and strip subgrain structures. And as the proportion of coarse powder increases, the scanning track morphology changes from smooth to undulating; the morphology of the molten pool and subgrain structure are weakened. Meanwhile, the unmelted particles appear on the surface of the SLM sample. On the premise of an introducing appropriate amount of large particle size powder (20%), the SLM samples still have good mechanical properties (662 MPa, 47%).

Cite this article as: YANG Xin, REN Yao-jia, LIU Shi-feng, WANG Qing-juan, SHI Ming-jun. Microstructure and tensile property of SLM 316L stainless steel manufactured with fine and coarse powder mixtures [J]. Journal of Central South University, 2020, 27(2): 334-343. DOI: https://doi.org/10.1007/s11771-020-4299-9.

J. Cent. South Univ. (2020) 27: 334-343

DOI: https://doi.org/10.1007/s11771-020-4299-9

YANG Xin(杨鑫)1, REN Yao-jia(任垚嘉)2, LIU Shi-feng(刘世锋)2,WANG Qing-juan(王庆娟)2, SHI Ming-jun(时明军)2

1. College of Materials Science and Engineering, Xi’an University of Technology, Xi’an 710048, China;

2. School of Metallurgical and Engineering, Xi’an University of Architecture and Technology,Xi’an 710055, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Abstract: Selective laser melting (SLM) technology is the prevailing method of manufacturing components with complex geometries. However, the cost of the additive manufacturing (AM) fine powder is relatively high, which significantly limits the development of the SLM. In this study, the 316L fine powder and coarse powder with a mass ratio of 80:20, 70:30 and 60:40 were mixed using a ball milling and the samples with a relative density greater than 97% were prepared by SLM. The results show that the intricate temperature gradients and surface tension gradients in SLM will produce Marangoni flow, forming a typical molten pool morphology, cellular and strip subgrain structures. And as the proportion of coarse powder increases, the scanning track morphology changes from smooth to undulating; the morphology of the molten pool and subgrain structure are weakened. Meanwhile, the unmelted particles appear on the surface of the SLM sample. On the premise of an introducing appropriate amount of large particle size powder (20%), the SLM samples still have good mechanical properties (662 MPa, 47%).

Key words: selective laser melting; powder mixture; microstructure; solidification; mechanical properties

Cite this article as: YANG Xin, REN Yao-jia, LIU Shi-feng, WANG Qing-juan, SHI Ming-jun. Microstructure and tensile property of SLM 316L stainless steel manufactured with fine and coarse powder mixtures [J]. Journal of Central South University, 2020, 27(2): 334-343. DOI: https://doi.org/10.1007/s11771-020-4299-9.

1 Introduction

Selective laser melting (SLM) is an additive manufacturing (AM) technology that uses CAD software to create a model of the part to be machined and uses a laser beam as an energy source to melt the metal powder layer by layer [1]. It can manufacture functionally graded materials with complex geometries, high precision and high density, and is considered to be a near net shape processing technology that is different from traditional technology [2, 3]. 316L stainless steel is a chromium-nickel austenitic stainless steel with low carbon (<0.03%). Due to its addition of molybdenum, it has better corrosion resistance while possessing excellent mechanical properties [4, 5]. It is widely used in petrochemical, electric power, nuclear industry and other fields [6-8]. Its powder is one of the raw materials of SLM, which has the characteristics of simple manufacturing process and good sphericity [9, 10].

The cost affordability of additively manufactured metal products has been a concern for their wider acceptance. Under the existing AM powder preparation technology, the cost of the fine powder is relatively high, and the price is about 10 times that of the conventional powder. Therefore, from the perspective of saving raw materials and reducing production costs, the low-cost AM technology is a difficult problem for researchers to overcome for a long time. In recent years, researchers have made some efforts and achievements. TANG et al [11] studied the effect of powder reuse times on the characteristics of Ti-6Al-4V powder in the AM process; they achieved up to 21 powder reuse times, and the properties of the formed samples meet ASTM mechanical performance requirements. ATTAR et al [12] studied the effect of powder particle shape induced by milling time on the density and compression properties of SLM-processed Ti-TiB composite samples. It was found that prolonged milling results in a higher shape irregularity of the powder mixture, and the SLM sample has a lower relative density and compression properties. GU et al [13] studied the effect of powder particle size distribution on the properties of SLM-formed Ti6-Al-4V alloy. The results show that in the same particle size range, the sample prepared from the metal powder with bimodal distribution as the raw material has higher density and exhibits higher mechanical properties.

This paper is aimed at better understanding the effect of powder mixture of two different particle size powders on the microstructure and tensile properties of SLM processed 316L stainless steel, and the SLM samples meeting the national standard requirements were successfully prepared.

2 Experimental

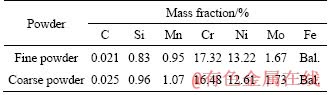

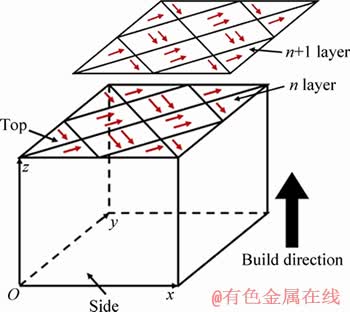

Two kinds of gas atomized 316L stainless steel powders of fine powder (D50=29.69 μm) and coarse powder (D50=82.78 μm) were used as raw materials for this experiment with the chemical compositions listed in Table 1. The fine powder and the coarse powder were mixed by a ball mill at a mass ratio of 80:20, 70:30 and 60:40 for 1 h to obtain powder mixtures, which were denoted by 80:20, 70:30 and 60:40, respectively. Subsequently, the SLM samples were produced in a Mlab cusing R (Concept Laser) with a laser power of 100 W, a scan speed of 600 mm/s, a hatch spacing of 80 μm, a powder layer thickness of 25 μm, and the whole process takes place under N2(>99.9%) protection. Samples were produced using a 45° checkerboard scanning strategy and the scanning direction was rotated by 90° after each layer, as shown in Figure 1. The SLM samples prepared from the mass ratio of 80:20, 70:30 and 60:40 powder mixtures were referred to as sample 80:20, 70:30 and 60:40, respectively. In addition, the coarse powder was recorded as 0:100, the fine powder was recorded as 100:0 and the sample prepared from the fine powder was referred to as sample 100:0.

Table 1 Chemical composition of 316L stainless steel powders

Figure 1 Checkerboard scanning strategy and scanning directions illustration during SLM process

The morphologies of all the SLM samples were revealed by the etching solution of Glyceregia (15 mL HCl+10 mL glycerol+5 mL HNO3) for about 20 s. Powder flowability and packing density were measured by Hall flow tests and volumetric measurement, respectively. Microstructure and fracture diagrams were analyzed using a Hitachi S4800 scanning electron microscope (SEM) with energy dispersive spectrometer (EDS). Phase composition of the powders and the samples were examined by X-ray diffraction (XRD) using a D8 Advance A25 X. The particle size distribution was determined by laser particle size analyzer (LPSA) using a Mastersizer 2000. Density of samples was measured via Archimedes principle. According to GB/T 228.1-2010, the room temperature tensile tests were carried out in a MTS C45 universal testing machine at a strain rate of 10-3 s-1.

3 Results and discussion

3.1 Examination of powder

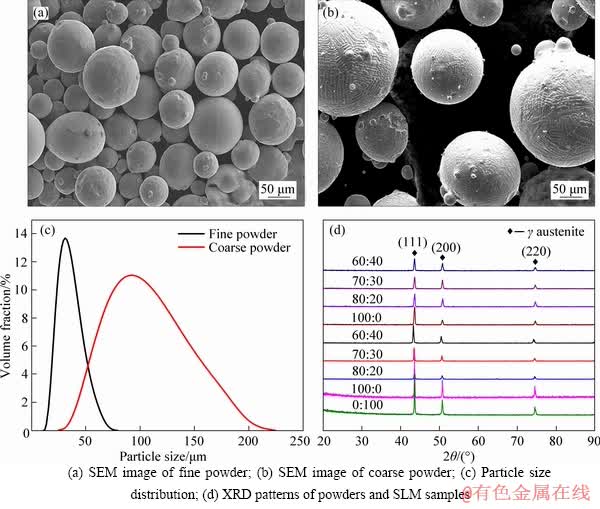

Figures 2(a) and (b) show SEM image of fine and coarse powder. SEM examination of two kinds of gas atomized 316L stainless steel powders showed that most of particles were spherical or spheroidal and contained satellite particles. The fine powder has a better surface finish than the coarse powder, and the dendritic solidification structure is noticeable from the coarse powder surface. The mean particle sizes of fine and coarse powders are 29.69 μm and 82.78 μm, respectively. Figure 2(c) shows the particle size distribution of two powders and both are in a positively skewed distribution. Figure 2(d) depicts the XRD pattern of two gas atomized powders, powder mixtures and SLM samples. The results indicate that strong diffraction peaks corresponding to γ-Fe crystal planes (111), (200) and (220) in the powders and SLM samples are clearly identified. The intensity of each diffraction peak of the powder mixture is lower than the intensity of each diffraction peak of the gas atomized powder. This is because during the ball milling process, the interactions between the powder, the grinding balls, and the ball-milling tank cause plastic deformation and fracture of the powder, the internal stress of the powder increases and lattice distortion and dislocations occur, resulting in a decrease in the diffraction peak height. When the coarse powder mixing ratio is increased to more than 30%, the corresponding diffraction peak of the mixed powder has a significant shift to the left. It is shown that the diffraction angle becomes small, the corresponding interplanar spacing increases, γ-Fe undergoes lattice distortion, and the lattice constant a becomes large. The diffraction peaks of the as-deposited samples were not offset, indicating that the internal stress of the powder was released during remelting and solidification. Meanwhile, according to XRD patterns, there is no evidence that martensite phases generated during the present SLM process. Although the cooling rate is very high during the SLM process, only single austenite phases were obtained due to the existence of austenite stabilizing elements Ni and Cr with high contents [14].

Figure 2 SEM images of 316L:

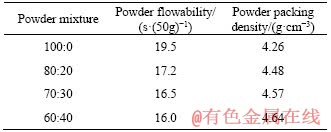

Powder flowability and powder packing density of the powder mixtures are shown in Table 2. As the mixing ratio of the coarse powder increases, the powder flowability decreases, and the powder can’t be smoothly coated across the built area and generate inhomogeneous regions, which subsequently increases its packing density. Existing simulation studies for SLM have shown that higher powder packing density disrupts melt pool stability, which causes pore defects during the rapid cooling process and arises balling effects at porous sites that can result in defective parts [15, 16]. Therefore, the density of the sample formed by SLM is gradually decreased as the mixing ratio of the coarse powder increases. The relative densities of the SLM samples 100:0, 80:20, 70:30 and 60:40 are 98.42%, 98.07%, 97.54% and 97.17%, respectively.

Table 2 Properties of 316L stainless steel powder mixtures

3.2 Microstructural characterization

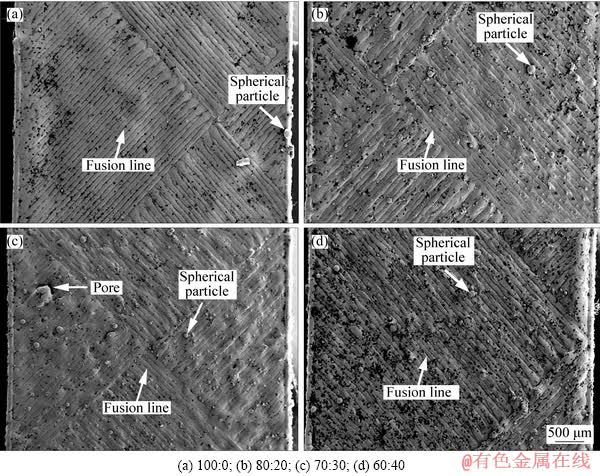

In a typical SLM process, molten material is deposited on a substrate of its own type, forming a strong metallurgical bond and dynamic diffusion of the liquid based on homogenous wetting conditions. The morphology of the same material after solidification is determined only by the temperature after solidification of the sample. Therefore, the introduction of the coarse powder will cause the regions to be incompletely melted, producing different temperature fields and affecting the final surface morphology [17]. Figures 3(a), (b), (c) and (d) show top-view SEM images of 100:0, 80:20, 70:30 and 60:40 SLM samples, respectively. It can be seen from Figure 3(a) that the laser scanning track of the top surface of the 100:0 SLM sample is evenly flat and has no obvious spheroidization phenomenon, and only the spherical particles due to the outer contour scanning are present at the edge of the sample. When 20% of the coarse powder is mixed in, the top scanning track of the 80:20 SLM sample fluctuates, and spherical particles are present inside and outside the laser scanning track, and the size of the spherical particles is different. The 70:30 SLM sample is similar to 80:20 except that the scanning track further produces undulations, and since the coarse powder particles require more energy to melt, the surface produces poorly fused pore defects that span across multiple laser beam scanning regions. The 60:40 SLM sample also has a large number of spherical particles, but the corresponding spheroidization caused by interfacial tension is not the main factor at this time. Due to the introduction of a large amount of coarse powder particles, the laser energy is insufficient to melt sufficiently to cause large curvature and undulation of the scanning track.

Figure 3 Microstructures of SLM 316L SS samples:

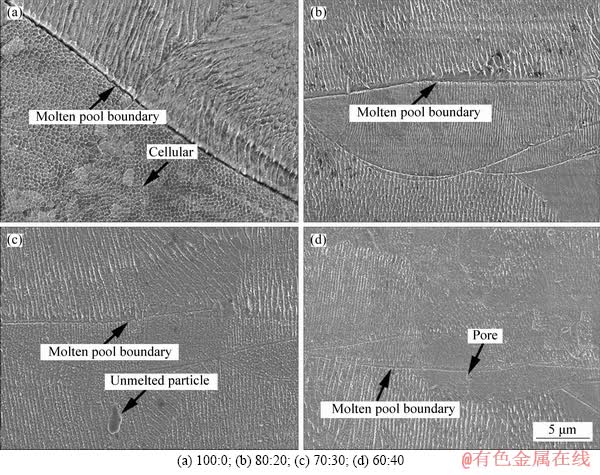

Figures 4(a), (b), (c) and (d) show side-view SEM microstructure images of 100:0, 80:20, 70:30 and 60:40 SLM samples, respectively. It can be seen from Figure 4(a) that the boundary of the molten pool of the 100:0 SLM sample is obvious, and there is a complex subgrain structure in the local area of the micro-melting pool, and the subgrain structure does not cross the boundary of the molten pool. The cellular structure size is about 1 μm, and it has not only hexagonal but also square and pentagonal structures. This is due to the fluctuation of the Ma of the melt convection, and the hexagonal structure is further in instability and evolves into a pentagonal according to the geometric topology, thereby forming a square structure [18]. The width of the strip structure is 300-500 nm and the length is 15-20 μm. The internal structure of grains consists of strip structure with parallel melt flow direction, separated from each other by low angle. In addition to the above two structures, the phenomenon of transition of the cell structure to the strip structure can be observed. The geometric topological transition of the hexagonal structure to the strip structure occurs on a short spatial scale (300 nm). Due to the high solidification rate, the transition is not completed, the elongated cellular structure with orientation is formed, and the orientation is related to the melt flow of the molten pool. Complex subgrain structures were formed by the local convection and Bénard instabilities in front of the solid/liquid (S/L) interface affected by intricate temperature gradients and surface tension gradients [19]. Different melt convection modes caused by temperature gradients and surface tension gradients can be described by Marangoni number, Ma=| σ/

σ/ T|△Tdη-1χ-1, where |

T|△Tdη-1χ-1, where | σ/

σ/ T| is the temperature dependence of surface tension, △T is the vertical temperature difference of the molten pool, d is the thickness of the liquid layer, η is the dynamic viscosity, and χ is the thermal diffusivity [20]. In order to better explore the effect of Ma on different melt convection modes, Ma is usually divided into vertical Maver and horizontal Mahor. Due to the strong temperature gradient present in the SLM process, both Maver and Mahor exceed the critical Mac. When the vertical Maver is dominant, the melt is driven by surface tension to form Bénard convection, resulting in cellular structure; when the horizontal Mahor is dominant, the melt is driven by surface tension to form longtitudinal roll, resulting in strip structure; when the molten pool is under an inclined temperature gradient (which is influenced by Maver and Mahor), the two convection modes can transform to each other and form cellular-strip region [19-22]. Similar images of cellular substructure are shown in Refs. [23, 24].

T| is the temperature dependence of surface tension, △T is the vertical temperature difference of the molten pool, d is the thickness of the liquid layer, η is the dynamic viscosity, and χ is the thermal diffusivity [20]. In order to better explore the effect of Ma on different melt convection modes, Ma is usually divided into vertical Maver and horizontal Mahor. Due to the strong temperature gradient present in the SLM process, both Maver and Mahor exceed the critical Mac. When the vertical Maver is dominant, the melt is driven by surface tension to form Bénard convection, resulting in cellular structure; when the horizontal Mahor is dominant, the melt is driven by surface tension to form longtitudinal roll, resulting in strip structure; when the molten pool is under an inclined temperature gradient (which is influenced by Maver and Mahor), the two convection modes can transform to each other and form cellular-strip region [19-22]. Similar images of cellular substructure are shown in Refs. [23, 24].

Figure 4 Typical microstructure of SLM samples:

The molten pool of the SLM sample prepared by the fine powder has a mean width of more than 100 μm and a mean depth of more than 50 μm. The same research results are also found in the report of CASATI et al [25]. With the increase of the coarse powder mixing ratio, the cellular structure, the cellular-strip regions and the boundary of the molten pool are weakened, while the width and depth of the molten pool are reduced. 20% mass coarse powder mixed makes the size of the molten pool of the SLM sample greatly reduced. The width of the molten pool is only 10 μm, and the depth is only 30 μm, as shown in Figure 4(b). The cellular structure is weakened and transits to the strip structure, and there are large amounts of white spherical particles around the strip structure boundary. This is due to the fact that under the same process parameters, the laser energy density cannot fully melt the coarse powder introduced. Under the condition of low relative energy density, a slender micro-molten pool morphology will be produced, which will generate turbulence under Rayleigh- Taylor instability, resulting in the decrease of surface tension gradient and the formation of spherical particles. As the proportion of coarse powder mixing increases further, the transition from cellular to strip structure disappears, and only strip structure exists, as shown in Figure 4(c). In addition, there are unmelted special shaped particles on the surface. As is shown in Figure 4(d), the molten pool boundary of sample 60:40 is almost indistinguishable and large amounts of spherical particles exist in the subgrain structure. The feature of subgrain structure cannot be clearly identified. Except for the strip structure, there is no subgrain structure morphology in the local area. This is due to the increase of the average particle size of the powder, which results in the need for more energy for laser beam to melt metal powder, and the melting pool depth of the laser beam will decrease if the laser energy remains unchanged; the average energy of melting powder mixture is lower than that of melting fine powder, the temperature gradient along the building direction will be reduced, so that the melt flow will be stationary without convection, resulting in the weakening of the morphological feature of the sugrain structure.

3.3 Mechanical properties

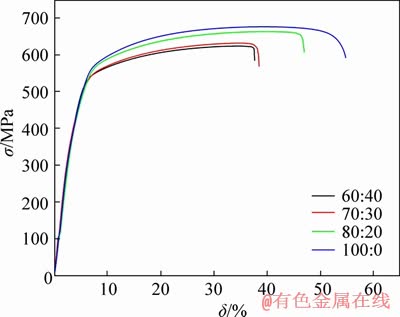

Figure 5 reports the room temperature tensile curve of the SLM samples to highlight the effect of the powder mixture on the tensile behavior of the sample. The ultimate tensile strength (UTS) and elongation of sample 100:0 were 676 MPa and 54 %, respectively, which are much higher than the properties of the conventional wrought sample (555 MPa, 30%) [26]. This is due to the subgrain structure created by the unique temperature gradient and high cooling rate of the SLM process. A large amount of subgrain boundaries make the slip of dislocations more difficult and make the strength and toughness improve significantly. The mixing of the coarse powder causes a decrease in the strength and ductility of the sample, and the ultimate tensile strength and elongation of the sample 80:20 (662 MPa, 47%) are lower than those of the sample 100:0. This is related to the morphology of the micro-molten pool. In the same area, the total length of the molten pool boundary is smaller when the size of the molten pool is large. The molten pool boundary is the heat-affected boundary of laser (energy distribution is Gauss distribution) in the scanning process. The boundary is not a grain boundary, and it does not hinder the sliding of dislocations in the tensile process. On the contrary, as the joint of interlayer boundaries is not tight, it reduces the mechanical properties of the SLM sample. When the coarse powder mixing ratio is increased to 30%, the fine cellular structure disappeares, the boundary of the molten pool is weakened and unmelted particle defects occur. The ultimate tensile strength of sample 70:30 was dropped from 662 MPa to 632 MPa and elongation was dropped from 47% to 38%. It indicates that the subgrain structure plays an important role in the mechanical properties of the SLM samples, and the generation of unmelted particles can damage the plasticity and strength. Sample 60:40 has similar tensile properties to sample 70:30, and its ultimate tensile strength and elongation are about 623 MPa and 37%, respectively. The tensile properties of the 10% coarse powder mixed sample were almost the same as those of the sample 100:0, and thus were not depicted. When the mass ratio of fine powder to coarse powder is 50:50, the flowability of the mixed powder is too poor to be processed by SLM.

Figure 5 Stress-strain curves of SLM samples with different powder mixtures

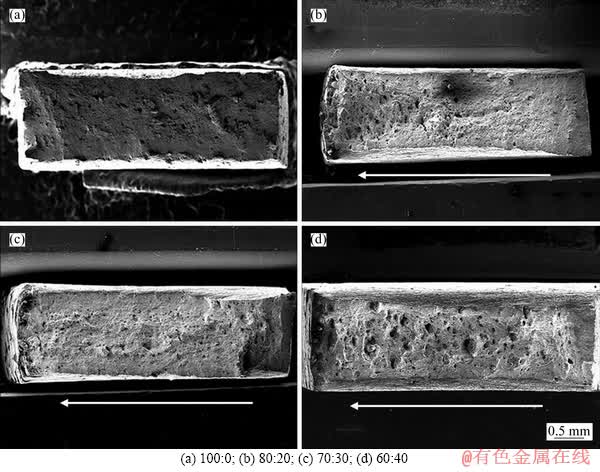

Figures 6(a), (b), (c) and (d) show the macro fracture morphology of SLM sample 100:0, 80:20, 70:30 and 60:40, respectively. The fractures have cup and cone features and both have significant necking down phenomenon. They gradually change from flat to jagged. Due to the introduction of coarse powder particles, the energy density is insufficient to fully melt the powder and fill the pores, and the pore defects on the fracture surface are significantly increased, which is consistent with the change in density of the sample. As the amount of coarse powder mixed further increases, the section size increases slightly, and the area occupied by the shear lip area increases significantly. In addition, the white arrows in Figures 6(b), (c) and (d) are the building direction (BD). It can be seen that the number of pore defects increases along the building direction, and there is a phenomenon of defect enrichment at the top of the sample, which proves that SLM technology has significant size effect. In the initial forming stage, the SLM samples have better forming quality and fewer pore defects, but the surface defects formed on the upper layer will seriously affect the quality of the powder laying on the next layer, and the accumulation of defects will occur during the second forming process. The self-healing phenomenon of hole defects in SLM process has also been proved by ZHOU et al [27], that is, local hole defects heal in the subsequent forming process to form closed pore defects, which will not expand indefinitely, as shown in Figure 6(a). The self-healing mechanism has obviously become a secondary factor after the introduction of large particle size powders, which can only play a synergistic role in alleviating the pore defects and inhibiting the further increase of pore defects.

Figure 6 Macroscopic fracture morphology of SLM samples:

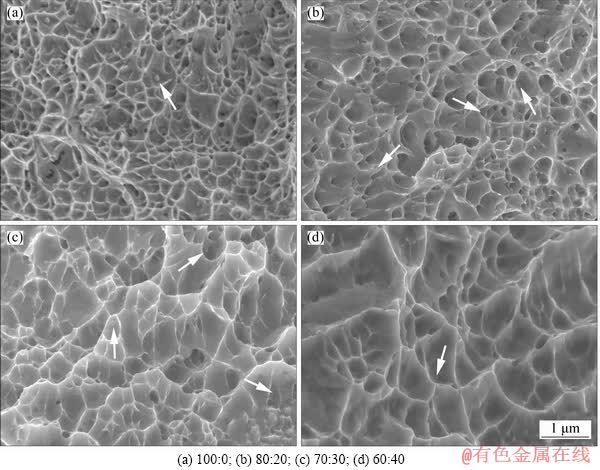

Figures 7(a), (b), (c) and (d) show the micro fracture morphology of the SLM sample 100:0, 80:20, 70:30 and 60:40 with fine dimples and they both have a typical feature of ductile fracture. It is found that the dimples size increases slightly with the increase of coarse powder ratio. A lot of nano-spherical second phase particles are observed inside the dimples as indicated by the arrows [28]. The nano-spherical particles are formed by the reaction of the active element (like Si) with oxygen, which has been confirmed by ZHONG et al [24]. This phenomenon of randomly distributing spherical nano-inclusions can significantly improve the strength and hardness of the alloy without affecting the plasticity, and is a new method for preparing oxide dispersion strengthened (ODS) steel [29]. However, the increase in pore defects and the presence of unmelted particles have a greater impact on the tensile properties of the sample, reducing the mechanical properties of the sample 70:30. It is worth noting that the micro fracture morphology of sample 60:40 is different from the fracture morphology of sample 70:30. The dimples are larger and deeper due to the further increase of the coarse powder mixing ratio, and the number of nano-spherical particles in the dimple is reduced, resulting in the tensile properties of the sample 60:40 slightly lower than that of the sample 70:30.

4 Conclusions

In this study, the fine powder and the coarse powder with a weight ratio of 80:20, 70:30 and 60:40 were mixed, and all the samples with a relative density greater than 97% were prepared by SLM. Through this powder mixture method, the SLM samples meet the national standard requirements while significantly reducing costs. The main results can be concluded as follows.

1) The XRD analysis showed that the main phases of fine, coarse powder and SLM samples prepared by powder mixture were FCC-γ phase, which shows that the powder mixture has no effect on phase composition. The intensity of each diffraction peak of the powder mixture is lower than that of the gas atomized powder, and the corresponding diffraction peak shifts to the left, resulting in lattice distortion. As the proportion of coarse powder increased, the flowability of the powder mixture decreased and the powder packing density increased.

2) It is found that the subgrain morphology in the micro-melting pool of SLM is caused by different Marangoni flow convection modes. The formation of subgrain structure is affected by both the Maver and Mahor. When Maver dominates, the microstructure has cellular structure, and when Mahor dominates, it results in strip structure. When the difference between the Maver and Mahor is small, it is the cell-strip region.

Figure 7 Microscopic fracture morphology of SLM samples:

3) With the increase of mixing proportion of coarse powder, the top-view of scanning track morphology changes from uniform and smooth, no obvious spheroidization to curvature and undulation; the size of the micro-molten pool morphology on the side-view decreases and the subgrain structure weakens gradually. There is even no subgrain structure morphology in the local area and the phenomenon of unmelted particles occurs.

4) Tensile tests at room temperature show that the tensile properties (676 MPa, 54 %) of the 100:0 SLM samples prepared by SLM technology are higher than those of conventional forged samples (555 MPa, 30%). The 70:30 and 60:40 SLM samples showed a significant decrease in mechanical properties (623 MPa, 37%) due to the introduction of excess coarse powder. The 80:20 SLM sample still has good mechanical properties (662 MPa, 47%) under the premise of introducing appropriate large-size powder particles.

References

[1] Jafari D, Wits W W. The utilization of selective laser melting technology on heat transfer devices for thermal energy conversion applications: A review [J]. Renewable and Sustainable Energy Reviews, 2018, 91: 420-442. DOI: 10.1016/j.rser.2018.03.109.

[2] BOBBIO L D, OTIS R A, BORGONIA J P, DILLON R P, BEESE A M. Additive manufacturing of a functionally graded material from Ti-6Al-4V to Invar: Experimental characterization and thermodynamic calculations [J]. Acta Materialia, 2017, 127: 133-142. DOI: 10.1016/j.actamat. 2016.12.070.

[3] LI Ling, POST B, KUNC V, ELLIOTT A M, PARANTHAMAN M P. Additive manufacturing of near-net- shape bonded magnets: Prospects and challenges [J]. Scripta Materialia, 2017, 135: 100-104. DOI: 10.1016/j.scriptamat. 2016.12. 035.

[4] WU Cong-feng, WANG Xin-he, ZHANG Hai-long, WANG Xi-tao. Effect of alloy elements on the mechanical properties and pitting corrosion resistance of 316LN austenitic stainless steel [J]. Chinese Journal of Engineering, 2015, 37(9): 1157-1164. DOI: 10.13374/j.issn2095-9389.2015.09.008.

[5] TRELEWICZ J R, HALADA G P, DONALDSON O K, MANOGHARAN G. Microstructure and corrosion resistance of laser additively manufactured 316L stainless steel [J]. JOM, 2016, 68(3): 850-859. DOI: 10.1007/s11837- 016-1822-4.

[6] DARGAHI M, HOSSEINIDOUST Z, TUFENKJI N, OMANOVIC S. Investigating electrochemical removal of bacterial biofilms from stainless steel substrates [J]. Colloids Surf B: Biointerfaces, 2014, 117: 152-157. DOI: 10.1016/j.colsurfb.2014.02.021.

[7] GUO Shu, HAN En-hou, WANG Hai-tao, ZHANG Zhi-ming, WANG Jian-qiu. Life prediction for stress corrosion behavior of 316L stainless steel elbow of nuclear power plant [J]. Acta Metallurgica Sinica, 2017, 53(4): 455-464. DOI: 10.11900/ 0412.1961.2016.00462.

[8] Lodhi M J K, Deen K M, Haider W. Corrosion behavior of additively manufactured 316L stainless steel in acidic media [J]. Materialia, 2018, 2: 111-121. DOI: 10.1016/j.mtla.2018.06.015.

[9] YU Sheng-sheng, Zhang Pei-cong, QIU Ke-hui, ZHANG Wen-tao, LI Jun-feng, YAO Shuai, ZHOU Ding-yang, YAO Ni-na, LI Jin-chi. Preparation and characterization of 316L spherical powder for different uses by supersonic laminar flow atomization [J]. Ferroelectrics, 2018, 530(1): 25-31. DOI: 10.1080/00150193.2018.1454071.

[10] Quinn P, O’Halloran S, Lawlor J, Raghavendra R. The effect of metal EOS 316L stainless steel additive manufacturing powder recycling on part characteristics and powder reusability [J]. Advances in Materials and Processing Technologies, 2019, 5(2): 1-12. DOI: 10.1080/2374068X.2019.1594602.

[11] TANG H P, QIAN M, LIU N, ZHANG X Z, YANG G Y, WANG J. Effect of powder reuse times on additive manufacturing of Ti-6Al-4V by selective electron beam melting [J]. JOM, 2015, 67(3): 555-563. DOI: 10.1007/s11837-015-1300-4.

[12] Attar H, Prashanth K G, Zhang L C, Calin M., Okulov I V, Scudino S, Yang C, Eckert J. Effect of powder particle shape on the properties of in situ Ti-TiB composite materials produced by selective laser melting [J]. Journal of Materials Science & Technology, 2015, 31(10): 1001-1005. DOI: 10.1007/s11837-015-1300-4.

[13] Gu H, Gong H, Dilip J, Pal D, Hicks A, Doak H, Stucker B. Effects of powder variation on the microstructure and tensile strength of Ti6Al4V parts fabricated by selective laser melting [C]// Proceedings of the 25th Annual International Solid Freeform Fabrication Symposium. Austin, TX, USA, 2014: 4-6. https:// www.researchgate.net/publication/280114583_Effects_of_Powder_Variation_on_the_Microstructure_and_Tensile_Strength_of_Ti6Al4V_Parts_Fabricated_by_Selective_Laser_Melting.

[14] Wang D, Song C, Yang Y, Bai Y. Investigation of crystal growth mechanism during selective laser melting and mechanical property characterization of 316L stainless steel parts [J]. Materials & Design, 2016, 100: 291-299. DOI: 10.1016/j.matdes.2016.03.111.

[15] Rausch A, Küng V, Pobel C, MARKL M, KoRNER C. Predictive simulation of process windows for powder bed fusion additive manufacturing: Influence of the powder bulk density [J]. Materials, 2017, 10(10): 1117. DOI: 10.3390/ma10101117.

[16] Korner C, Attar E, Heinl P. Mesoscopic simulation of selective beam melting processes [J]. Journal of Materials Processing Technology, 2011, 211(6): 978-987. DOI: 10.1016/j.jmatprotec.2010.12.016.

[17] Schiaffino S, Sonin A A. Motion and arrest of a molten contact line on a cold surface: An experimental study [J]. Physics of Fluids, 1997, 9(8): 2217-2226. DOI: 10.1063/1.869344.

[18] Schatz M. F, VanHook S J, McCormick W, Swift J, Swinney H L. Time-independent square patterns in surface-tension-driven Bénard convection [J]. Physics of Fluids, 1999, 11(9): 2577-2582. DOI: 10.1063/1.870120.

[19] Mizev A I, Schwabe D. Convective instabilities in liquid layers with free upper surface under the action of an inclined temperature gradient [J]. Physics of Fluids, 2009, 21(11): 112102. DOI: 10.1063/1.3251755.

[20] Ueno I, Kurosawa T, Kawamura H. Thermocapillary convection in thin liquid layer with temperature gradient inclined to free surface [J]. Heat Transfer, 2002, 2: 129-134. https://www.researchgate.net/ publication/237224463_Thermocapillary_Convection_in_Thin_Liquid_Layer_with_Temperature_Gradient_Inclined_to_Free_Surface.

[21] Shklyaev O E, Nepomnyashchy A A. Thermocapillary flows under an inclined temperature gradient [J]. Journal of Fluid Mechanics, 2004, 504: 99-132. DOI: 10.1017/S0022112003007687.

[22] DIETRICH S. Convective instabilities in complex systems with partly free surface [J]. Journal of Physics: Conference Series, 2007, 64: 012001. DOI: 10.1088/1742- 6596/64/1/012001.

[23] Suryawanshi J, Prashanth K g, Ramamurty U. Mechanical behavior of selective laser melted 316L stainless steel [J]. Materials Science and Engineering A, 2017, 696: 113-121. DOI: 10.1016/j.msea.2017.04.058.

[24] Zhong Y, Liu L, Wikman S, Cui D, Shen Z. Intergranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting [J]. Journal of Nuclear Materials, 2016, 470: 170-178. DOI: 10.1016/j.jnucmat.2015.12.034.

[25] Casati R., Lemke J, Vedani M. Microstructure and fracture behavior of 316L austenitic stainless steel produced by selective laser melting [J]. Journal of Materials Science & Technology, 2016, 32(8): 738-744. DOI: 10.1016/j.jmst. 2016.06.016.

[26] Mower T M, Long M J. Mechanical behavior of additive manufactured, powder-bed laser-fused materials [J]. Materials Science and Engineering A, 2016, 651: 198-213. DOI: 10.1016/j.msea.2015.10.068.

[27] ZHOU X, WANG D, LIU X, ZHANG D, QU S, JING M, London G, SHEN Z, WEI L. 3D-imaging of selective laser melting defects in a Co–Cr–Mo alloy by synchrotron radiation micro-CT [J]. Acta Materialia, 2015, 98(2): 1-16. DOI: 10.1016/j.actamat.2015.07.014.

[28] Saeidi K, Kvetková L, Lofaj F, Shen Z. Austenitic stainless steel strengthened by the in situ formation of oxide nanoinclusions [J]. RSC Advances, 2015, 5(27): 20747-20750. DOI: 10.1039/c4ra16721j.

[29] Boegelein T, Dryepondt S N, Pandey A, Dawson K, Tatlock G J. Mechanical response and deformation mechanisms of ferritic oxide dispersion strengthened steel structures produced by selective laser melting [J]. Acta Materialia, 2015, 87: 201-215. DOI: 10.1016/j.actamat.2014.12.047.

(Edited by YANG Hua)

中文导读

混合粉末制备沉积态316L不锈钢的组织和性能

摘要: 激光选区熔化(SLM)技术是近年来制备具有复杂几何结构零件的常用方法。然而,增材制造(AM)用微细粉的成本相对较高,严重限制了SLM技术的进一步发展。本研究通过球磨法将316L细粉与粗粉按80:20、70:30、60:40的质量比混合1 h得到混合粉末,以混合粉末为原料通过SLM技术成功制备了相对密度大于97%的样品。结果表明,SLM中复杂的温度梯度和表面张力梯度会产生毛细流动,形成典型的熔池形貌和胞状、条状亚晶结构。随着粗粉比例的增加,扫描轨道形貌由均匀、平整,无明显球化向弯曲及起伏过渡,熔池形貌和亚晶组织特征减弱,沉积态试样表面出现未熔化的颗粒。在引入适量大颗粒粉末(20%)的前提下,沉积态试样仍具有良好的力学性能(662 MPa,47%)。

关键词:激光选区熔化;混合粉末;显微组织;凝固;力学性能

Foundation item: Projects(51671152, 51304153, 51504191, 51874225) supported by the National Natural Science Foundation of China; Project(14JK512) supported by the Natural Science Foundation of Shaanxi Educational Committee, China; Project(18JC019) supported by Shaanxi Provincial Department of Education Industrialization Project, China; Project(14JK1512) supported by Shaanxi Provincial Department of Education Natural Science Special Project, China

Received date: 2019-06-04; Accepted date: 2019-07-09

Corresponding author: LIU Shi-feng, PhD, Professor; Tel: +86-29-82202933; E-mail: liushifeng66@126.com; ORCID: 0000-0003- 4369-5730