火灾模拟实验智能测控系统

赵望达1, 2, 徐志胜1, 吴 敏2, 段方英1

(1.中南大学 土木建筑学院, 湖南 长沙, 410075;

2.中南大学 信息科学与工程学院, 湖南 长沙, 410083)

摘要: 按国际标准ISO834升温特性, 针对火灾模拟实验炉开发了一套火灾模拟实验过程智能测控系统。 该系统包含带智能通信的多路温度采集、 带主元分析神经网络炉温数据融合、 炉温智能PID控制等多种智能信息处理技术。 智能通信同时拥有RS-485串行和EPP并行接口, 保证了所采集的多路温度数据的实时性; 采用带主元分析和RBF神经网络的炉温数据融合模型使炉温估计精度比采用常规的最小二乘方法所得的拟合精度明显提高; 采用智能PID控制则使炉膛的实际升温曲线符合ISO834国际标准升温要求。

关键词: 火灾模拟实验; 智能通信; 主元分析; 神经网络; 智能PID控制

中图分类号:TP273 文献标识码:A 文章编号: 1672-7207(2005)06-1054-05

Intelligent test and control system for fire simulated experiment

ZHAO Wang-da1, 2, XU Zhi-sheng1, WU Min2, DUAN Fang-ying1

(1. School of Civil and Architectural Engineering, Central South University, Changsha 410075, China;

2. School of Information Science and Engineering, Central South University, Changsha 410083, China)

Abstract: An intelligent test and control system for fire simulated experiment process is developed based on temperature rising speciality of fire simulated experiment furnace according to international standard ISO834. This system combines multi-technique of intelligent information process such as multi-loops temperature collection with intelligent communication, furnace temperature data fusion with principle component analysis neural network and furnace temperature intelligent PID control. With RS-485 serial and EPP parallel interface simultaneously, intelligent communication can ensure the real time characteristics of collected multi-loops temperature data. Furnace temperature data fusion model with principle component analysis and RBF neural network makes the estimate precision of furnace temperature 2 times higher than that of general least square.The intelligent PID control makes the practical furnace temperature curve well meet with standard ISO834.

Key words: fire simulated experiment; intelligent communication; principle component analysis; neural network; intelligent PID control

目前, 建筑火灾日益增多, 使得人们对建筑构件在火灾作用下的性能变化以及由此产生的危害愈加关注。 为了对火灾后建筑构件综合性能进行诊断并加固维修, 首先必须对其在火灾后的损伤特性进行研究。 中南大学建筑火灾实验室建造的液化气火灾模拟实验炉就是用于对墙、 楼板、 屋顶、 梁、 柱等建筑构件进行实验测试。 实验的主要内容是对炉内温度、 炉内压力、 构件背火面温度、 构件内部温度等参数进行实时监测, 并控制燃烧液化气流量以保证升温符合国际标准ISO834[1]。 实验中如何对多路热电偶信号进行数据融合进而在线估计炉温[2], 并按照国际标准ISO834升温曲线对实验炉的温度进行控制[3], 是整个实验的关键。 为此, 针对自行设计建造的火灾实验炉, 开发了一套融合智能通信、 数据融合和智能控制等集成智能信息处理技术的建筑构件火灾实验过程智能测控系统。

1 基于智能通信的温度采集

1.1 温度传感器选型

在火灾实验中, 用液化气对火灾模拟实验炉进行加温, 使其达到国际标准ISO834要求的温度。 具体要求是炉内温度最高达1300 ℃, 试件内部温度最高至900 ℃, 试件背火面温度为400~500 ℃, 故分别选用S型和K型热电偶及热电阻3种测温传感器, 共测试54点温度参数。

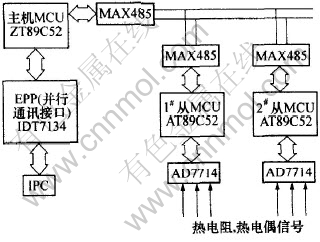

1.2 温度采集系统硬件组成

该温度检测系统硬件主要由AT89C52、 程序存储器28C64、 AD芯片AD7714、 数据存储器6264、 全双工串行通信芯片MAX488、 双口RAM-IDT7134、 锁存器74LS373、 可编程看门狗监控EEPROM-X25043等以及一些外围电路组成[4], 如图1所示。

图 1 54路温度采集系统硬件框图

Fig. 1 Hardware frame of 54 loops temperature collection system

1.3 数据通信技术

1.3.1 串行通信

该系统中串行通信主要是针对主单片机和每台温度采集单片机之间的通信, 采用RS-485标准。 RS-485是利用平衡发送和差分接收方式来实现通信, 在发送端TXD将串行口的TTL电平信号转换成差分信号A和B两路输出, 经传输后在接收端将差分信号还原成TTL电平信号。 RS-485实现了多点互连, 最多可达32台驱动器和32台接收器, 便于多器件的连接。 该系统共有54个温度点, 每台单片机采集3个点, 共18台子单片机。 采用全双工方式的MAX-488作为通信芯片。

1.3.2 并行通信

在检测系统中, PC机与主单片机间采用并行通信方式互传数据, 通信协议采用增强EPP协议。 采用双口RAM芯片IDT7134来实现PC机和单片机的信息共享和数据传输, 如图2所示。

图 2 EPP通信接口

Fig. 2 EPP communication interface

2 基于数据融合的炉温软测量模型

2.1 软测量模型

在本实验系统中, 虽然有12路热电偶信号测量不同部位的炉温, 但国际标准ISO834升温曲线对应的炉温是一个虚拟的“炉温”, 不能由12路热电偶测量值中任意一个来代表, 而必须根据12路传感器信号用合适的软测量模型[5, 6]来进行数据融合和参数估计。 经过研究和比较, 采用主元分析(PCA)[7]和RBF神经网络相结合的软测量数据融合模型。

2.2 主元分析及结果

设过程输入数据矩阵X∈Rm×n已经按列零均值化或标准化, 其中m为测量数据长度, n为输入变量个数。 定义X的协方差矩阵为

Cov(X)=XTX/(m-1)。(1)

对该矩阵进行正交分解, 得

Cov(X)=Pn·D·PTn。(2)

式中: D=diag(λ1, λ2, …, λn), 是协方差矩阵的n个按照降序排列(λ1≥λ2≥…≥λn)构成的对角矩阵; Pn=[p1, p2, …, pn], 是特征值对应的特征矩阵; 前k个主元所概括的原测量变量的信息量可由前k个主元的方差贡献率∑λk/∑λn来表示; ∑λk为前k个主元的方差和; ∑λn为所有变量的方差和。 若前k个主元的方差贡献率大于某一预先设定值C[8](通常选取C>85%), 则可求得主元个数k并定义如下主元模型:

T=XP。(3)

而原来的测量矩阵可以重构为:

X=XZ+XC。(4)

式中: XZ=TPTk, 为主测量矩阵; XC为X的残差或辅助测量矩阵; T为主元矩阵; Pk为负荷矩阵。 这样, 以前k个特征向量构成的PCA子空间就能够提取X的绝大部分信息, 因而实现了Rn→Rk的线性变换, 达到了特征提取和降低变量维数的目的。

以立式炉为例, 其12路热电偶信号分布在上、 下、 左、 右各个位置, 而需要去进行PID运算的仅1路温度, 因此, 采用主元分析(PCA)和RBF神经网络构成12路输入、 1路输出的数据融合系统。 PCA方法的基本思想是按照方差降序来排列所有输入变量, 在允许误差范围内, 对输入变量的方差贡献较小的主元进行删除来降维[8]。 在本系统的炉温估计中, 选择前3个主元, 其累计方差达82.6%, 选择前5个主元, 累计方差达93.8%, 按PCA方法, 一般累计方差不小于85%, 再考虑该系统中RBF神经网络的计算量, 最后选取5个主元作为RBF网络的输入。

2.3 RBF神经网络

RBF神经网络是一种性能良好的前向网络, 它具有最佳逼近性能, 在结构上具有输出—权值线性关系, 训练方法快速易行, 不存在局部最优问题。 该网络的学习算法有很多种, 在此, 将带遗忘因子的梯度下降法应用于RBF神经网络的参数调整[9-12]。

2.4 软测量结果分析

共采集12路温度输入数据150组, 经主元分析在前100组中确定5个主元输入数据进行RBF神经网络训练, 后50组的5路温度输入数据作为RBF网络的测试样本。 采用均方根计算其训练精度和测试精度, 分别为0.028%和0.035%; 而用最小二乘法对12路温度输入前100组数据进行拟合, 其均方根精度为0.085%。 采用PCA-RBF神经网络测试精度比采用最小二乘拟合方法所得的精度高, 且能很好地满足智能PID控制对测量温度的要求。

3 炉温智能PID控制器

3.1 控制原理

炉温智能PID控制器实际上就是一种参数在线Fuzzy自整定的PID控制器, 如图3所示, 它是在PID控制算法的基础上求误差E和误差变化率EC, 利用Fuzzy规则进行推理, 查询Fuzzy矩阵表进行参数修正。 Fuzzy规则采用IF AND THEN 产生式语句形式来表述, 并作为知识存入微处理机。 参数的Fuzzy自校正思想是依据被控对象的响应在采样时刻的偏差E和偏差变化率EC来确定KP, KI和KD这3个参数修正的方向和大小[13-15]。

图 3 Fuzzy自校正PID控制器

Fig. 3 PID controller with Fuzzy self-tuning

运用Fuzzy规则推理进行PID参数自校正的Fuzzy算法步骤为:

a. 将E, EC和KP, KI, KDFuzzy化, 确定各Fuzzy子集的隶属度;

b. 用PID参数Fuzzy调整模型来表达参数校正过程;

c. 应用Fuzzy合成推理计算出KP, KI和KD的Fuzzy校正矩阵表。

对系统响应的误差E和误差变化率EC将其变化范围(或映射范围)定义为Fuzzy集上的论域: E={-5, -4, -3, -2, -1, 0, 1, 2, 3, 4, 5}, EC={-5, -4, -3, -2, -1, 0, 1, 2, 3, 4, 5}。 设E和EC的Fuzzy子集为: E={NB, NM, NS, O, PS, PM, PB}, EC={NB, NM, NS, O, PS, PM, PB}, E, EC, KP, KI和KD均服从正态分布, 得出各个Fuzzy子集的隶属度, 再根据隶属度的赋值表和各参数Fuzzy调整模型, 由Fuzzy合成推理设计出PID参数调整的Fuzzy矩阵表, 查出修正参数, 按下列3个公式计算:

KP=KP′+ΔKP;(5)

KI=KI′+ΔKI;(6)

KD=KD′+ΔKD。(7)

其中: 参数KP′, KI′和KD′由临界比例法整定(初值)。 在线运行过程中, 计算机对Fuzzy逻辑规则结果处理、 查表和运算, 计算出ΔKP,ΔKI和ΔKD来完成对PID参数的最佳调整[16-21]。

3.2 控制效果分析

采用Fuzzy自整定的PID控制器模拟火灾炉的控制方法, 使模拟火灾炉的升温曲线几乎没有超调量, 很快进入稳定状态, 并且使炉温曲线符合ISO834要求。 而采用传统的PID控制器模拟火灾炉, 炉温的升温曲线超调量比较大, 相应地, 进入稳定状态的时间比较长。 图4所示是它们在实际控制中的对比图。 可以看出, 采用Fuzzy自整定的PID控制优于纯PID控制。

图 4 2种控制结果比较

Fig. 4 Comparison of two kinds of control methods

4 结 论

a. 火灾实验过程的检测和控制系统集成了智能通信、 数据融合和智能控制等智能信息处理和控制技术, 提供了一种新颖的实验室测控手段。

b. 温度检测系统同时利用RS-485串口和EPP并口通信实现了54路温度的在线检测, 并在工控机上显示实验过程的各种温度曲线, 保证了所采集的多路温度数据的实时性。

c. 采用主元分析与RBF神经网络相结合的软测量模型进行炉温数据融合, 温度估计精度高。

d. 控制系统采用Fuzzy自整定的PID控制, 比单纯PID控制具有更稳定、 可靠的控制效果, 提高了炉温的控制精度, 降低了火灾实验液化气的消耗量, 使炉膛的实际温度符合ISO834升温要求。

参考文献:

[1]GB9978—88, 建筑构件耐火试验方法[S].

GB9978—88, Architecture component fire endurance experiment methods[S].

[2]赵望达, 黎燕. 基于多传感器数据融合方法的火灾模拟实验炉温度采集系统[J]. 电子质量, 2002(2): 32-33.

ZHAO Wang-da, LI Yan. A fire simulated experiment furnace temperature collection system based on multi-sensors data fusion[J]. Electronics Quality, 2002(2): 32-33.

[3]Gan F C, Zhao W D, Xu Z S, et al. Temperature fuzzy control system of building structure fire experiment furnace[A]. Huang P, Wang Y J, Li S C, et al. Progress in Safety Science and Technology. Vol.Ⅲ, Part B[C]. Beijing: Science Press, 2002, 10: 1251-1255.

[4]赵望达, 黎燕, 彭势清, 等. 基于RS-485串口和EPP并口的火灾实验温度采集系统[J]. 电子质量, 2003(8): 23-24.

ZHAO Wang-da, LI Yan, PENG Shi-qing, et al. A fire experiment temperature collection system based on RS-485 serial and EPP parallel interface[J]. Electronic Quality, 2003(8): 23-24.

[5]刘瑞兰, 苏宏业, 楮健. 基于改进模糊神经网络的软测量建模方法[J]. 信息与控制, 2003, 32(4): 367-370.

LIU Rui-lan, SU Hong-ye, CHU Jian. A soft sensor modeling algorithm based on modified fuzzy neural network[J]. Information and Control, 2003, 32(4): 367-370.

[6]孙自强, 顾幸生, 叶方军, 等. 连续催化重整再生器氧含量的软测量[J]. 自动化仪表, 2003, 24(12): 17-19.

SUN Zi-qiang, GU Xing-sheng, YE Fang-jun, et al. Soft measurement of oxygen content of continuous catalytic reforming regenerator[J]. Process Automation Instrumentation, 2003, 24(12): 17-19.

[7]XU Lei. Theories of unsupervised learning, PCA and its nonlinear extensions[A]. Proc IEEE ICNN. Part 2[C]. Oilando, 1994. 1254-1257.

[8]Karhuren J, et al. Generalization of PCA, optimization problems and NN[J]. Neural Networks, 1995, 8(4): 549-562.

[9]Bianchini M. Learning without local minim in radial basis function networks[J]. IEEE Trans on Neural Networks, 1995, 6(3): 749-755.

[10]YAO Xin. Evolving artificial neural networks[J]. Proceedings of the IEEE, 1999, 87(9): 1432-1447.

[11]Catelsni M, Fort A. Fault diagnosis of electronic analog circuit using a radial basis function network classifier [J]. Measurement, 2002, 28: 147-148.

[12]张广军, 武晓利. 基于RBF神经网络的红外二氧化碳传感器数学模型[J]. 仪器仪表学报, 2004, 25(1): 72-75.

ZHANG Guang-jun, WU Xiao-li. Mathematic model of IR carbon dioxide sensor based on RBF neural networks[J]. Chinese Journal of Scientific Instrument, 2004, 25(1): 72-75.

[13]赵望达, 鲁五一, 徐志胜, 等. PID控制器及其智能化方法探讨[J]. 化工自动化及仪表, 1999, 26(6): 45-48.

ZHAO Wang-da, LU Wu-yi, XU Zhi-sheng, et al. Study on PID controller and its intelligent methods[J]. Chemical Industry Automation and Instruments, 1999, 26(6): 45-48.

[14]顾勤龙, 姚明海, 张芮. 基于变尺度馄饨优化方法的PID控制器设计[J]. 控制工程, 2003, 10(2): 149-152.

GU Qin-long, YAO Ming-hai, ZHANG Rui. Design of PID controller based on mutativescale chaos optimization algorithm[J]. Control Engineering of China, 2003, 10(2): 149-152.

[15]Zhuang M, Atherton D P. Automatic tuning of optimum PID controller[J]. IEE Proceedings, Part D: Control Theory and Applications, 1993, 140(3): 216-224.

[16]Bi Q, Cai W J, Wang Q C, et al. Advanced controller auto-tunning and its application in HVAC system[J]. Control Engineering Practice, 2000, 8(6): 633-644.

[17]Astrom K J, Hagglund T. Automatic Tuning of PID Controllers[M]. North Carolina: Instrument Society of America, 1988.

[18]Astrom K J, Hagglund T. PID Controllers: Theory, Design, and Tuning. 2nd Edition[M]. North Carolina: Instrument Society of America, 1995.

[19]Astrom K J, Hagglund T, Hang C C, et al. Automatic tuning and adaptation for PID controllers——A survey[J]. Control Eng Practice, 1993, 1(4): 699-714.

[20]许良琼, 陆新江, 李群明. 模糊PID控制器在电磁悬浮平台中的应用[J]. 中南大学学报(自然科学版), 2005, 36(4): 631-636.

XU Liang-qiong, LU Xin-jiang, LI Qun-ming. Application of fuzzy-PID control to electromagnctic suspension platform[J]. Journal of Central South University(Science and Technology), 2005, 36(4): 631-636.

[21]潘祥亮, 罗利文. 模糊PID控制在工业锅炉控制系统中的应用[J]. 工业炉, 2004, 26(3): 38-40.

PAN Xiang-liang, LUO Li-wen. Application of the Fuzzy-PID control in industrial boiler control system[J]. Industrial Furnace, 2004, 26(3): 38-40.

收稿日期:2005-01-20

基金项目: 国家“十五”科技攻关项目(2002BA806B03); 湖南省科技厅计划项目(02SSY3027)

作者简介:赵望达(1965-), 男, 湖南双峰人, 博士研究生, 教授, 从事智能仪器、 智能控制和土木工程测控等研究

论文联系人: 赵望达, 男, 教授; 电话: 0731-2656625(O), 13974814968(手机); E-mail: wdzhao@mail.csu.edu.cn; zwd6509@sina.com