DOI: 10.11817/j.ysxb.1004.0609.2020-39676

废催化剂微波-超声波强化处理工艺中稀有金属的行为

马致远1, 2, 3,刘 勇1, 2, 3,吕建芳1, 2, 3,吕先谨1, 2, 3,周吉奎1, 2, 3,刘牡丹1, 2, 3

(1. 广东省科学院资源综合利用研究所,广州 510650;

2. 稀有金属分离与综合利用国家重点实验室,广州 510650;

3. 广东省矿产资源开发和综合利用重点实验室,广州 510650)

摘 要:针对国内某石化企业废石化催化剂处理过程中出现的产品纯度低、污染大等问题,提出了一种微波-超声波强化处理废催化剂的工艺采用物质流方法对工艺中稀有金属钒、钼元素的行为进行研究。结果表明:采用微波-超声波强化处理工艺,可制备高纯V2O5产品(纯度>99.9%)和普通V2O5产品(纯度>99%),钒的直收率为91.32%,未有效回收的钒主要分散在浸出渣、净化沉淀渣、萃钒余液和二段反萃液沉淀母液中,共占原料钒的7.58%。同时,可以制备合格的钼酸铵产品,钼的直收率为91.68%,未有效回收的钼主要分散在浸出渣、净化沉淀渣、负载钒有机相、萃钼余液和沉钼母液中,共占原料钼的7.99%。本工艺的特色主要体现在微波强化浸出和超声波强化反萃工序。微波强化浸出工艺中,钒和钼的浸出效率得到明显提高,这与反应的温度体系、矿物宏/微观结构变化以及高价钒含量的提高有密切关系。超声波反萃工艺可明显缩短反萃时间,超声波技术可降低晶体的团聚程度,有效消除氯化铵反萃过程中团聚晶体堵塞管道的现象。

关键词:废催化剂;微波;超声波;钒;钼

文章编号:1004-0609(2021)-02-0479-11 中图分类号:TG146.1 文献标志码:A

引文格式:马致远, 刘 勇, 吕建芳, 等. 废催化剂微波-超声波强化处理工艺中稀有金属的行为[J]. 中国有色金属学报, 2021, 31(2): 479-489. DOI: 10.11817/j.ysxb.1004.0609.2020-39676

MA Zhi-yuan, LIU Yong, LYU Jian-fang, et al. Behaviors of rare metals in process of microwave-ultrasonic enhanced treatment of spent catalyst[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(2): 479-489. DOI: 10.11817/j.ysxb.1004.0609.2020-39676

在现代石油和化学产业中,90%以上的化学反应需通过催化过程实现,如石油的催化裂化、烷基化、加氢脱硫等过程[1]。大多数石化催化剂是以氧化铝为载体,以钒、钼、镍、钴等氧化物为活性组分烧结而成[2]。石化催化剂经过长时间的使用,逐渐受到原油中碳、硫等杂质的污染而失去活性。由于含有大量对环境有害的成分,废石化催化剂已被归类为有害固体废弃物,需无害化处理[3]。从另一角度看,报废的石化催化剂中含有大量贵重的稀有金属资源,其含量远高于矿产资源中相应金属的品位,对其循环利用有着巨大的经济、社会和环境效益[4]。废石化催化剂中钒和钼的回收价值最大。五氧化二钒(V2O5)是世界上最紧缺的资源之一,特别是高纯V2O5是制备液流电池用高纯电解液的优质原料,同时,高纯V2O5还是制备钒铝合金的优质原料,是航空航天领域的重要基础材料,在新能源、新材料领域发挥着重要作用[5-7]。钼的主要产品钼酸铵在冶金工业中主要是生产高纯钼粉、钨钼合金、钼丝等的原料,其次是在化工行业中用于制作高分子化合物催化剂的原料,在化工和金属合金材料领域发挥着重要作用[8]。传统回收废催化剂中钒和钼的工艺可分为火法工艺、湿法工艺和火法-湿法联合工艺,其中比较成熟的工艺为火法-湿法联合工艺,主要采用焙烧-浸出-净化-沉淀的方法进行钒和钼的回收,工艺具有回收率高的优点,但同时存在产品纯度低、环境污染大等问题,难以实现高纯V2O5产品的生产,因此,研发废催化剂的高效处理工艺具有重要意义[9]。近年来,微波、超声波等外场技术已在矿物加工、浸出、溶剂萃取等领域应用并取得了较好的发展。微波技术由于独特的加热原理,具有加热效率高、绿色环保等优点[10-14];超声波技术在反应过程中具有机械效应、热效应和空化效应,对于改善冶金多相反应具有显著作用[15]。

本文提出了一种废催化剂微波-超声波强化处理工艺,可从废催化剂制备高纯V2O5产品(纯度>99.9%)、普通V2O5产品(纯度>99%)和钼酸铵产品。采用物资流方法[16-18],对微波-超声波强化处理过程中稀有金属钒、钼元素的行为和主要机理问题进行研究,以期对于废催化剂高效绿色处理工艺的研发具有一定的指导作用。

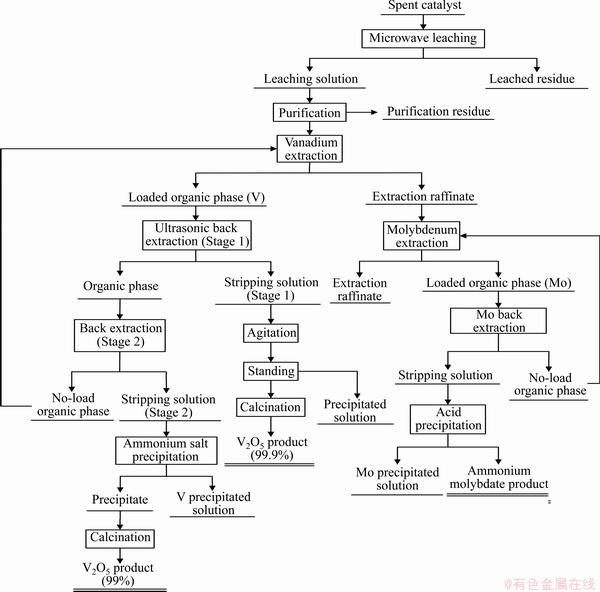

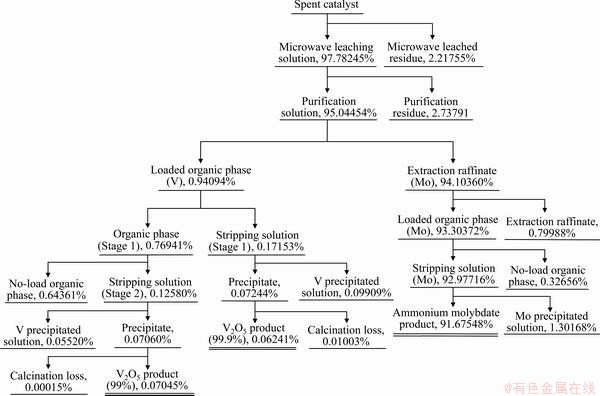

1 实验

本研究以国内某石化企业提供的已经过脱油处理的废石化催化剂为原料,实验室规模下,对一种废催化剂微波-超声波强化处理工艺的主要工序如微波浸出、钒萃取反萃、沉钒煅烧、钼萃取反萃、加酸沉钼等进行模拟实验研究,对各工序所得固液产物进行元素含量分析,得出主要稀有金属钒和钼的分布走向图,为废催化剂处理工艺的改进提供指导。本文采用的试剂均为分析纯,工艺流程如图1所示。

图1 工艺流程图

Fig. 1 Process flow diagram

1.1 实验材料

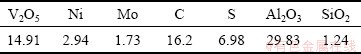

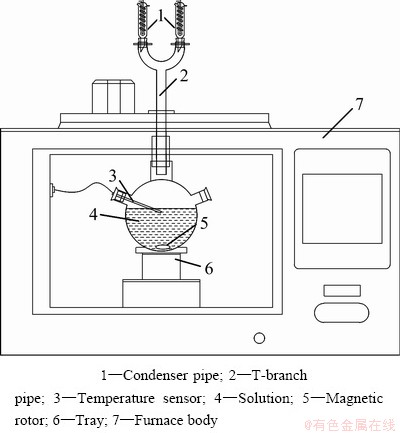

实验采用的废催化剂[19],含有铝、钒、镍、钼、碳、硫等元素,其主要成分见表1。废催化剂主要含有的稀有金属为钒和钼,重金属为镍,轻金属为铝,还含有碳、硫、硅等非金属物质。对原料进行了扫描电镜分析,如图2所示,废催化剂中钒主要以V-O物相、V-Fe-Al-Si-S-O物相、Fe-V-Al-S-O物相、Al-V-S物相和Al-V-S-O物相的形式存在;铝主要以Al2O3和铝钒氧化物的形式存在;碳和硫主要以C-S物相和单质硫存在。可以看出,废催化剂物质组成十分复杂,相互混杂,包裹现象严重,增加了提取有价金属的难度。

表1 废催化剂的主要化学组分

Table 1 Main elements and composition of spent catalyst (mass fraction, %)

1.2 微波浸出工序

图2 废催化剂SEM形貌

Fig. 2 SEM morphologies of spent catalyst

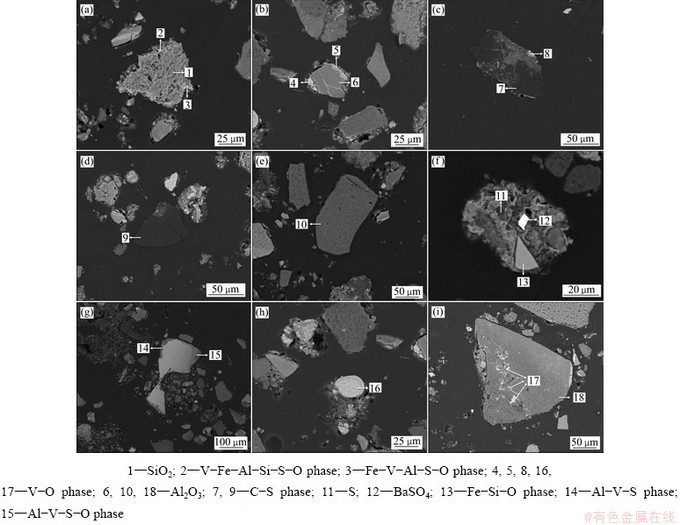

微波浸出工序采用的实验设备型号为XH-200A (北京祥鹄科技发展有限公司,2450 MHz,1000 W),实验装置如图3所示。微波浸出条件可参考文献[19],往微波设备专用三口球形烧瓶分别加入50 g废催化剂和浓度为87.51 g/L的NaOH溶液,控制微波功率为648 W,固液比为0.20 g/mL,在目标温度90 ℃条件下搅拌反应13.5 min。浸出完成后,进行真空过滤,由于微波浸出设备炉腔尺寸的局限性,一次处理的量最多只能50 g废催化剂。为了后续工序原料充足,所以总共进行20次重复实验,共加入1000 g废催化剂,浸出渣采用纯水洗涤,将溶液定容至6.0 L,烘干后的浸出渣质量为574.31 g。结合相应元素的检测结果,根据式(1)计算出在微波浸出工序中稀有金属元素(钒和钼)在产物中的质量分配比,下同。

(1)

(1)

式中:R为分配比;m为质量;i代表s(固体)或l(液体)。

图3 微波浸出实验装置图

Fig. 3 Schematic diagram of microwave leaching experimental installation

1.3 钒萃取工序

浸出液中含有较多的杂质,影响萃取分离效果,需先进行净化除杂。采用调节pH值的方法进行溶液的净化除杂,pH值控制在8.5,沉淀完成后,进行真空过滤,沉淀渣采用纯水洗涤,将溶液定容至6.0 L,烘干后的沉淀渣质量为40.5 g。

固液分离后的含钒溶液采用N263+仲辛醇+煤油体系萃取,工艺条件为初始pH 8.5、萃取剂浓度30%、仲辛醇浓度5%、时间3 min、相比(O/A) 1/1,进行三级逆流萃取,获得负载有机相6.0 L,萃余液6.0 L。

1.4 钒反萃工序

为了制备高纯V2O5的同时兼顾钒的反萃率,设计两段反萃工艺。一阶段反萃主要目的是获得纯度99.9%以上V2O5产品。为了降低产品杂质含量,采用氯化铵作为反萃剂,但传统氯化铵反萃过程中容易出现结晶团聚现象,从而堵塞管道,而超声波技术能够克服此困难。由于超声波独特的机械效应、热效应和空化效应,不仅可以解决堵塞问题,而且能够提高反萃效率。超声波反萃工序采用的实验设备型号为XH-2008DE (北京祥鹄科技发展有限公司,25 kHz,1500 W),实验装置如图4所示。一段反萃条件为超声波频率为25 kHz,超声波功率为500 W,氯化铵浓度2.0 mol/L、相比(O/A) 5/2、时间1 min。二阶段釆用NaOH和NaCl作为反萃剂进行反萃实验,反萃条件为NaOH浓度1.0 mol/L、NaCl浓度2.0 mol/L、相比(O/A) 3/2、时间3 min。经过一级NH4Cl反萃+三级NaOH、NaCl逆流反萃工艺处理后,获得一段反萃液2.4 L,二段反萃液4.0 L。

图4 超声波反萃实验装置图

Fig. 4 Schematic diagram of ultrasonic extraction experimental installation

1.5 沉钒煅烧工序

由于一段反萃工艺采用的反萃剂为氯化铵溶液,超声波处理后溶液浑浊,但不堵塞管道。为了使反萃液中钒沉淀更加完全,常温搅拌5 min后,静置30 min,进行真空过滤,采用马弗炉对沉淀物进行煅烧,煅烧温度550 ℃,时间2 h,获得含量大于99.9%的高纯V2O5产品86.15 g,沉淀母液定容2.4 L。

由于二段反萃液为碱性,所以采用弱碱性铵盐沉淀法进行沉钒实验。在初始pH 8.5,加铵系数(实际/理论) 2.5的条件下搅拌1 h后,进行真空过滤,采用马弗炉对沉淀物进行煅烧,煅烧温度550 ℃,时间2 h,获得含量大于99%的普通V2O5产品50.54 g,沉淀母液定容4.0 L。

1.6 钼萃取反萃工序

采用N235-煤油体系对萃钒工艺萃余液进行萃取实验,萃取条件为初始pH 2.0、萃取剂浓度20%、仲辛醇浓度10%、相比(O/A) 1/6、时间3 min,获得负载有机相1.0 L,萃余液6.0 L。

采用氨水作为反萃剂进行反萃实验,反萃条件为相比(O/A) 5/1、氨水浓度10%(体积分数)、时间5 min,获得反萃液0.2L。

1.7 沉钼工序

将钼反萃溶液倒入烧杯中,遵循先快后慢的原则往溶液中加入浓盐酸,调节pH为2,在温度45 ℃条件下搅拌30 min;溶液出现大量的结晶,搅拌结束后,自然降温,然后过滤;采用pH=2的盐酸溶液洗涤得到的晶体,然后放至烘箱里面烘干,获得钼酸铵产品26.13 g,沉淀母液定容0.2 L。

2 稀有金属元素的物质流分析

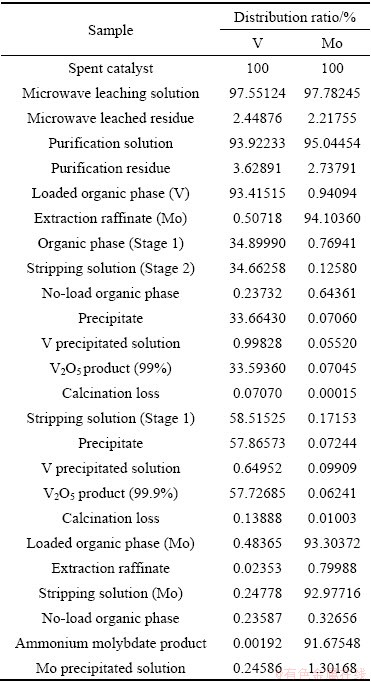

根据废催化剂处理过程中各个工序的元素分配情况,可计算出各工序产物中稀有金属钒、钼的质量与废催化剂中相应元素的质量之比,结果如表2所示。

2.1 稀有金属钒的走向

根据表2结果可以绘制稀有金属元素钒和钼的走向分布图。图5所示为钒的走向分布图。由图5可以看到,采用微波-超声波强化处理工艺,可以制备两种V2O5产品:高纯V2O5产品(>99.9%)和普通V2O5产品(>99%),直收率分别为57.73%和33.59%,钒的总直收率为91.32%。工艺的优势主要体现在微波强化浸出和超声波强化反萃工序,未有效回收的钒主要分散在浸出渣、净化沉淀渣、萃钒余液和二段反萃液沉淀母液中,共占原料钒的7.58%。

表2 废催化剂处理过程中产物的稀有金属元素分配表

Table 2 Rare metal element distribution ratios in treatment process for spent catalyst

微波强化浸出工序:参考文献[2, 19],在相同反应时间(13.5 min)条件下,微波强化浸出的浸出效果优于传统浸出的;微波强化浸出时,钒浸出率为97.55%,明显高于传统浸出时的66.23%,将传统浸出时间延长到30 min,NaOH浓度提高到100 g/L,钒浸出率为75.68%,仍然明显低于微波强化浸出的,这与反应体系固液温度差和矿物宏/微观结构变化有密切关系。

由于钒的价态对浸出的影响较大,对原料和微波照射后的废催化剂中不同价态钒的含量百分数进行了测量,如表3所示。微波照射条件:微波功率648 W,时间5 min,可以看出原料中三价、四价和五价的钒含量占总钒含量的分别为2.85%、26.93%和70.22%,低价态的钒含量仍接近30%,处理难度较大,必须使低价钒转变为可溶性的高价态钒才能有效实现钒的充分溶出;而经过微波处理后的废催化剂,三价和四价的钒含量共占7.77%,低价钒的含量明显降低,高价钒的含量的提高能够促进浸出反应的进行。

图5 废催化剂处理工艺中钒的分布

Fig. 5 Distribution of vanadium in treatment process for spent catalyst

表3 微波处理前后废催化剂中不同价态钒的分布

Table 3 Distribution of vanadium with different valences in spent catalysts before and after microwave treatment

废催化剂经过碱性浸出,钒、钼和少部分铝被浸出提取,过滤后的不溶物为富含镍和铝的原料,可采用酸浸工艺进行回收,由于非本研究主要工序,此处不详细讲述。

钒萃取工序:首先采用调节pH值的方法进行溶液的净化除杂,由于共沉淀的原因,原料中3.63%的钒进入沉淀渣中。沉淀渣中含有钒、铝、钼等有价金属,可进一步回收。萃取工序钒的萃取率为99.46%,萃取效果良好。

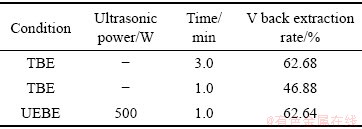

钒反萃工序:反萃工序分为两段,第一段工序采用超声波反萃,与传统的萃取反萃技术相比较,超声波萃取反萃技术具有效率高、速度快的优点。表4所示为传统反萃与超声波强化反萃的对比结果。在其他工艺条件相同的情况下,超声波反萃效果优于传统反萃的,在反萃时间为1 min时,传统反萃工艺中钒的反萃率为46.88%,超声波强化反萃率为62.64%;将传统反萃时间延长至3 min,可达到与超声波反萃1 min的效果。此外,超声波技术对于特定的反应体系有独特的优势,例如在反萃过程中容易形成结晶团聚的情况,加入超声波可降低晶体的团聚程度,有效解决团聚晶体堵塞管道的问题。这与JORDENS等[20]学者的研究一致,可通过调节超声波的条件降低团聚程度,而不影响单晶的形态。第二段反萃工艺中,钒的反萃率可达到99.32%,效果良好。

表4 传统反萃与超声波强化反萃的对比实验

Table 4 Comparison between traditional back extraction (TBE) and ultrasonic enhanced back extraction (UEBE) of spent petrochemical catalyst

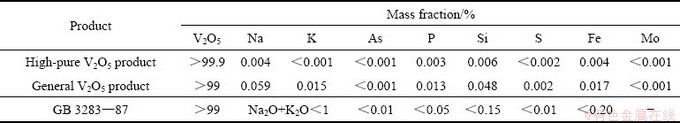

沉钒煅烧工序:一段反萃采用超声波反萃,加入氯化铵为反萃剂,可直接制备出纯度较高的偏钒酸盐,焙烧后产出高纯V2O5产品。高纯V2O5产品主要化学分析如表5所示。铵盐沉淀法是一种主要的回收钒的方法,可分为弱碱性铵盐沉淀法、弱酸性铵盐沉淀法和酸性铵盐沉淀法等。由于本实验中二段反萃液为碱性,所以采用弱碱性铵盐沉淀法进行沉钒实验。弱碱性铵盐沉淀法是基于弱碱性偏钒酸盐溶液与铵盐作用生成偏钒酸铵的反应。铵盐的选择主要考虑到尽量不引入新的杂质或者引入的杂质易处理,常采用的铵盐有硫酸铵和氯化铵。由于反萃采用氢氧化钠和氯化钠为反萃剂,为了不引入其他阴离子,采用氯化铵作为沉钒剂。在弱碱性钒溶液中,钒是以偏钒酸盐(NaVO3)形式存在,主要按照反应式(2)进行:

NaVO3+NH4Cl=NH4VO3+NaCl (2)

对沉淀物进行焙烧,可获得普通V2O5产品,主要化学分析如表5所示。如表5所示,与国标GB 3283—87对比[21],所获得的高纯和普通V2O5产品中V2O5的含量分别高于99.9%和99%,并且杂质的含量也符合行业标准。根据两种产品中钒的含量计算,产品富集了催化剂中91.32%的钒,具有良好效果。

钼萃取反萃工序:进入到钼萃取反萃工序的钒占原料的0.51%。

沉钼工序:进入到沉钼工序的钒占原料的0.25%,大部分存在于沉钼母液中,但总体损失率不高。

2.2 稀有金属钼的走向

图6所示为钼的走向分布图。由图6可以看 到,采用微波-超声波强化处理工艺,可以制备合格的钼酸铵产品,钼的总直收率为91.68%,未有效回收的钼主要分散在浸出渣、净化沉淀渣、负载钒有机相、萃钼余液和沉钼母液中,共占原料钼的7.99%。

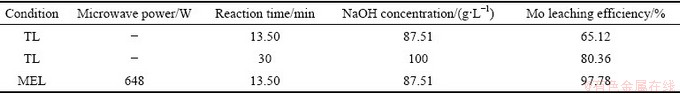

微波强化浸出工序:与钒浸出效果一致,微波强化浸出钼的效果优于传统浸出,如表6所示。在相同时间条件下,微波强化浸出时,钼浸出率为97.78%,明显优于传统浸出(65.12%);适当延长时间和增加溶剂浓度,钼浸出率仍然低于微波强化浸出时的浸出率。浸出渣分布了一部分钼,约为2.22%,为了进一步提高钼的回收率,需加强对浸出渣中钼的综合回收工作。

钒萃取工序:溶液的净化除杂过程中,由于共沉淀的原因,原料中2.74%的钼进入沉淀渣中,沉淀渣可进一步回收。由于共萃的原因,萃取工序中钼的萃取率为0.99%,负载钒有机相中分布了0.94%的钼,总体钒/钼分离系数为18420,钒/钼分离效果良好。

钒反萃工序:第一段反萃工序中,反萃液中分布了0.17%的钼。第二段反萃工艺中,反萃液中分布了0.13%的钼,整体分布率低。

钼萃取反萃工序:进入到钼萃取反萃工序的钼占原料的94.10%。钼的萃取率和反萃率分别为99.15%和99.65%,萃取反萃效果良好,0.80%和0.33%的钼分别分布于萃余液和空载有机相中。

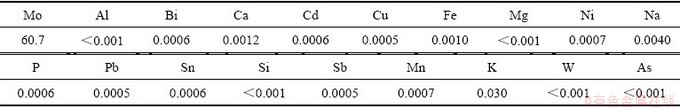

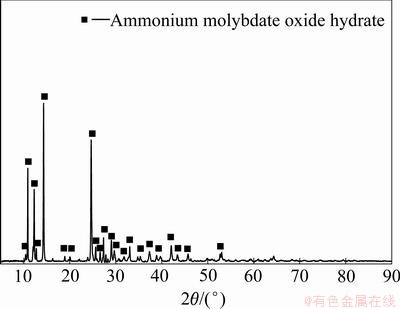

沉钼工序:进入到沉钼工序的钼占原料的92.98%,经过沉钼工艺处理后,钼酸铵产品中富集了91.68%的钼,但仍然有1.30%的钼分布在沉钼母液中。将制备的钼酸铵产品进行了化学分析,如表7所示,其中钼含量为60.7%,由此可推算所制备的钼酸铵产品中四钼酸铵((NH4)2Mo4O13)的纯度为99.26%。四钼酸铵产品颜色纯白,流动性较好,产品质量良好,符合国家标准GB/T 3460—2007-MSA-3《钼酸铵》标准[22]。图7所示为产品的XRD谱。由图7可以看出,图谱中无其他杂质峰,表明产品杂质含量低。

表5 五氧化二钒产品化学分析

Table 5 Chemical analysis of vanadium pentoxide products

图6 废催化剂处理工艺中钼的分布

Fig. 6 Distribution of molybdenum in treatment process for spent catalyst

表6 废催化剂传统浸出与微波辅助浸出的对比实验

Table 6 Comparison between traditional(TL) and microwave enhanced leaching(MEL) of spent petrochemical catalyst

表7 钼酸铵产品化学分析

Table 7 Chemical analysis of ammonium molybdate product (mass fraction, %)

图7 钼酸铵产品的XRD谱

Fig. 7 XRD patterns of ammonium molybdate product

3 结论

1) 采用微波-超声波强化处理工艺,可以制备两种V2O5产品:高纯V2O5产品(纯度>99.9%)和普通V2O5产品(纯度>99%),直收率分别为57.73%和33.59%,V的总直收率为91.32%。未有效回收的钒主要分散在浸出渣、净化沉淀渣、萃钒余液和二段反萃液沉淀母液中,共占原料钒的7.58%。

2) 采用本研究方案,可以制备合格的钼酸铵产品,钼的总直收率为91.68%,未有效回收的钼主要分散在浸出渣、净化沉淀渣、负载钒有机相、萃钼余液和沉钼母液中,共占原料钼的7.99%。

3) 本工艺的优势主要体现在微波强化浸出和超声波强化反萃工序。微波强化浸出可明显提高浸出效率,这与反应体系固液温度差、矿物宏/微观结构变化以及原料中高价钒含量的提高有密切关系。超声波反萃效果优于传统反萃的,反萃时间明显缩短,并且超声波技术对于本研究的反萃体系有独特的优势,可降低晶体的团聚程度,有效解决氯化铵反萃过程中管道堵塞问题。

REFERENCES

[1] 刘 健, 邱兆富, 杨 骥, 等. 我国石油化工废催化剂的综合利用[J]. 中国资源综合利用, 2015, 33(6): 38-42.

LIU Jian, QIU Zhao-fu, YANG Ji, et al. The comprehensive utilization of spent petrochemical catalysts in China[J]. China Resources Comprehensive Utilization, 2015, 33(6): 38-42.

[2] MA Z Y, LIU Y, ZHOU J K, et al. Recovery of vanadium and molybdenum from spent petrochemical catalyst by microwave-assisted leaching[J]. International Journal of Minerals Metallurgy and Materials, 2019, 26(1): 35-42.

[3] BANDA R, NGUYEN T H, SOHN S H, et al. Recovery of valuable metals and regeneration of acid from the leaching solution of spent HDS catalysts by solvent extraction[J]. Hydrometallurgy, 2013, 133: 161-167.

[4] AKCIL A, VEGLIO F, FERELLA F, et al. A review of metal recovery from spent petroleum catalysts and ash[J]. Waste Management, 2015, 45: 420-433.

[5] KOLOGRIEVA U A, VOLKOV A I, KIRICHENKO A S, et al. Development of a production scheme for utilizing vanadium pentoxide hydrometallurgical production waste[J]. Metallurgist, 2019, 63(3/4): 813-818.

[6] 李晏廷, 魏 昶, 李存兄, 等. 在压力场下从石煤中提取五氧化二钒的工艺[J]. 中南大学学报:自然科学版, 2010, 41(4): 1268-1275.

LI Yan-ting, WEI Chang, LI Cun-xiong, et al. Technics for vanadium pentoxide extraction fromblack shale in pressure field[J]. Journal of Central South University (Science and Technology), 2010, 41(4): 1268-1275.

[7] 张小云, 覃文庆, 田学达, 等. 石煤微波空白焙烧-酸浸提钒工艺[J]. 中国有色金属学报, 2011, 21(4): 908-912.

ZHANG Xiao-yun, QIN Wen-qing, TIAN Xue-da, et al. Microwave roasting-acidic leaching technique for extraction of vanadium from stone coal[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(4): 908-912.

[8] 李 飞, 陈星宇, 何利华, 等. 氢氧化钠分解不溶性钼酸盐的浸出热力学[J]. 中国有色金属学报, 2014, 24(11): 229-235.

LI Fei, CHEN Xing-yu, HE Li-hua, et al. Leaching thermodynamics of decomposing sparingly soluble molybdate by sodium hydroxide[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(11): 229-235.

[9] BARIK S P, PARK K H, PARHI P K, et al. Extraction of metal values from waste spent petroleum catalyst using acidic solutions[J]. Separation & Purification Technology, 2012, 101: 85-90.

[10] MA Z Y, YANG H Y, HUANG S T, et al. Ultra fast microwave-assisted leaching for the recovery of copper and tellurium from copper anode slime[J]. International Journal of Minerals Metallurgy and Materials, 2015, 22(6): 582-588.

[11] ZHANG X L, SUN C B, XING Y, et al. Thermal decomposition behavior of pyrite in a microwave field and feasibility of gold leaching with generated elemental sulfur from the decomposition of gold-bearing sulfides[J]. Hydrometallurgy, 2018, 180: 210-220.

[12] HE A X, CHEN G, CHEN J, et al. A novel method of synthesis and investigation on transformation of synthetic rutile powders from Panzhihua sulphate titanium slag using microwave heating[J]. Powder Technology, 2018, 323(1): 115-119.

[13] TIAN L, XU Z F, CHEN L J, et al. Effect of microwave heating on the pressure leaching of vanadium from converter slag[J]. Hydrometallurgy, 2019, 184: 45-54.

[14] JEROEN S, THOMAS A A. Combined microwave assisted roasting and leaching to recover platinum group metals from spent automotive catalysts[J]. Minerals Engineering, 2020, 146(1): 1-7.

[15] BEHERA S S, PANDA S K, MANDAL D, et al. Ultrasound and microwave assisted leaching of neodymium from waste magnet using organic solvent[J]. Hydrometallurgy, 2019, 185: 61-70.

[16] YAN L Y, WANG A J, CHEN Q S, et al. Dynamic material flow analysis of zinc resources in China[J]. Resources, Conservation and Recycling, 2013, 75: 23-31

[17] WANG P, JIANG Z Y, GENG X Y, et al. Dynamic material flow analysis of steel resources in China based on circular economy theory[J]. Advanced Materials Research, 2013, 813: 64-71.

[18] HAO H, LIU Z W, ZHAO F Q, et al. Material flow analysis of lithium in China[J]. Resources Policy, 2017, 51: 100-106.

[19] 马致远, 刘 勇, 周吉奎, 等. 响应曲面法优化废催化剂中微波浸出钒的工艺[J]. 中国有色金属学报, 2019, 29(6): 1308-1315.

MA Zhi-yuan, LIU Yong, ZHOU Ji-kui, et al. Optimization of microwave assisted leaching of vanadium from spent catalyst based on response surface methodology[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(6): 1308-1315.

[20] JORDENS J, GIELEN B, XIOURAS C, et al. Sonocrystallization: Observations, theories and guidelines[J]. Chemical Engineering and Processing, 2019. 139: 130-154.

[21] GB 3283—87. 五氧化二钒[S].

GB 3283—87. Vanadium pentoxide[S]

[22] GB/T 3460—2007. 钼酸铵[S].

GB/T 3460—2007. Ammonium molybdate[S].

Behaviors of rare metals in process of microwave-ultrasonic enhanced treatment of spent catalyst

MA Zhi-yuan1, 2, 3, LIU Yong1, 2, 3, LYU Jian-fang1, 2, 3, LYU Xian-jin1, 2, 3, ZHOU Ji-kui1, 2, 3, LIU Mu-dan1, 2, 3

(1. Institute of Resources Comprehensive Utilization, Guangdong Academy of Sciences, Guangzhou 510650, China;

2. State Key Laboratory of Separation and Comprehensive Utilization of Rare Metals, Guangzhou 510650, China;

3. Guangdong Provincial Key Laboratory of Development and Comprehensive Utilization of Mineral Resources, Guangzhou 510650, China)

Abstract: Aiming at the problems of low product purity and high pollution in the treatment process of spent petrochemical catalyst for a petrochemical enterprise in China, a microwave-ultrasonic enhanced process for spent catalyst treatment was proposed, and the behaviors of vanadium and molybdenum in the process were studied by material flow method. The results show that high purity V2O5 product (purity>99.9%) and common V2O5 product (purity>99%) can be prepared by microwave-ultrasonic enhanced treatment process. The direct yield of vanadium is 91.32%. The ineffective recovery of vanadium is mainly dispersed in the leached residue, purified precipitation residue, vanadium extraction raffinate and second stage back-extraction solution precipitated solution, which account for 7.58% of vanadium in the raw material. At the same time, qualified ammonium molybdate product can be prepared. The direct yield of molybdenum is 91.68%. The ineffective recovery of molybdenum is mainly dispersed in the leached residue, purified precipitation residue, loaded vanadium organic phase, molybdenum extraction raffinate and molybdenum precipitated solution, which account for 7.99% of molybdenum in the raw material. The characteristics of this process are mainly reflected in microwave enhanced leaching and ultrasonic enhanced back-extraction process. In the microwave enhanced leaching process, the leaching efficiencies of vanadium and molybdenum are obviously improved, which is attributed to the temperature system of the reaction, the macro/microstructure change of the mineral and the increase of the high valence state vanadium content. Ultrasonic back-extraction technology can obviously shorten the back-extraction time. Moreover, ultrasound can reduce the agglomeration degree of crystals and effectively eliminate the phenomenon of the agglomeration crystals blocking the pipes in the ammonium chloride back-extraction process.

Key words: spent catalyst; microwave; ultrasonic; vanadium; molybdenum

Foundation item: Projects(2016GDASRC-0201, 2017GDASCX-0841, 2016GDASPT-0104, 2017GDASCX-0109) supported by the Project of Science and Technology Development of GDAS, China; Project(21607138) supported by the National Natural Science Foundation of China

Received date: 2020-01-19; Accepted date: 2020-07-20

Corresponding author: LYU Jian-fang; Tel: +86-20-61086451; E-mail: 576105498@qq.com

(编辑 龙怀中)

基金项目:广东省科学院发展专项资金项目(2016GDASRC-0201,2017GDASCX-0841,2016GDASPT-0104,2017GDASCX-0109);国家自然科学基金资助项目(21607138)

收稿日期:2020-01-19;修订日期:2020-07-20

通信作者:吕建芳,工程师,博士;电话:020-61086451;E-mail:576105498@qq.com