活化烧结工艺制备Ni-Cr/BN自润滑复合材料

余 琨,阳 震,王日初,谭映国

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘 要:以羰基Ni粉、Cr2O3和C粉为原料,添加六方BN(h-BN)作为固体润滑剂,采用粉末冶金活化烧结工艺制备Ni-Cr基自润滑材料(Ni-Cr/BN)。研究烧结温度、升温速度和保温时间对材料性能的影响,利用X射线衍射仪、金相显微镜、摩擦试验机和硬度计分析和测定材料的物相组成、显微组织、材料的摩擦磨损性能和硬度。研究结果表明:Ni-Cr/BN复合材料是以Ni-Cr合金作为基体,以Ni与Ni3B的低熔点共晶组织(熔点1 097 ℃)作为粘结相;于1 100 ℃保温1 h可以制备孔隙度高达48%的Ni-Cr/BN材料,其布氏硬度为18,抗拉强度为24.8 MPa,磨损率为74.4 μg/min,平均摩擦因数为0.266。

关键词:活化烧结;Ni-Cr/BN;复合材料;固体润滑

中图分类号:TG146.1+5 文献标识码:A 文章编号:1672-7207(2008)03-0538-05

Preparation of Ni-Cr/BN self-lubricating composites by

active sintering process

YU Kun, YANG Zhen, WANG Ri-chu, TAN Ying-guo

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Ni-Cr/BN composite was produced in the active sintering process using nickel carbonyl, Cr2O3 and C powders as original materials, and hexagonal BN(h-BN) powder as solid lubricant. The influences of sintering temperature, heating-up speed and holding time on the properties of Ni-Cr/BN were studied. The composition and microstructure of Ni-Cr/BN were analyzed by X-ray diffraction(XRD) and optical microscope(OM). The frictional behavior and hardness were measured by ring-block friction testing machine and Brinell hardness tester. The results show that Ni-Cr alloy is the matrix and low-melting eutectic compound of Ni and Ni3B is the bonding phase in the composite. The porosity reaches 48% and hardness is 18 when the composite is fabricated at 1 100 ℃ for 1 h. Its tensile strength is 24.8 MPa, wear rate reaches 74.4 μg/min, and the average friction coefficient is 0.266.

Key words: active sintering; Ni-Cr/BN; composites; solid lubrication

在现代机械制造工程中,为发展热动力机械等先进设备,需要研制出能够在高温下使用的自润滑复合材料

[1]。这类材料要既能在较高温度和无润滑状况下工作,又具有高温抗氧化性和稳定的物理机械性能

[2]。镍基高温合金具有工作温度高(<1 100 ℃),组织稳定,有害相少,抗氧化和抗热腐蚀能力强等优点,可以代替某些难熔金属制作高温自润滑材料

[3-4]。镍表面容易被氧化形成具有较好可塑性和附着性的NiO层,这有益于降低材料的磨损,而且NiO本身还是一种高温固体润滑剂

[5]。固体润滑剂h-BN呈白色,具有类似石墨的结构,固有“白石墨”之称

[6]。它熔点高(升华温度为3 000 ℃

[7]),且在较高温度( 900~1 200 ℃)下才会发生氧化

[8]。h-BN具有良好的可磨耗性能和润滑性能,近年来被广泛用作航空航天发动机的高温可磨耗封严材料

[9],是高温自润滑材料的优良添加剂。目前,人们对镍基自润滑复合材料进行了大量研究,并研制出应用于工业生产的产品,但对h-BN作为固体润滑剂的材料研究较少。Ni-Cr /BN固相烧结时,h-BN阻碍Ni-Cr合金粉末的烧结过程,当BN含量达到15%时,材料不能烧结

[10]。本文作者采用活化烧结的方法,制备BN含量为11%~15%的Ni-Cr/BN复合材料,并对Ni-Cr/BN复合密封材料的烧结工艺进行研究,以获得低硬度、高孔隙度的高温可磨耗密封材料的途径。

1 实 验

实验用Ni粉、C粉和BN的平均粒度分别为3.0,5.8和10.0 μm,六方BN中的氧体积分数低于0.5%,氧化铬粉(Cr2O3)为分析纯。首先,将Cr2O3,C和BN按一定比例均匀混合,在真空炉内合成Cr/BN复合粉体,再与Ni粉按一定比例混合制备出Ni-Cr/BN混合料。然后,将混合料在室温、压力为240~300 MPa时单向压制成相对密度为58%~60%(理论密度为6.50 g/cm3,根据混合定律计算获得)的坯料。最后,在以H2为保护气氛的管式电阻炉中分别采用不同的升温速度、烧结温度和保温时间进行烧结。

采用Rigaku D-MAX2000型X射线衍射仪对材料进行物相分析;使用POLYVER-MET光学金相显微镜对材料的显微组织进行观察与分析;以GCr40钢作为配副,载荷为60 N,转速为400 r/min,在无润滑条件下,于M-2000型环-块滑动摩擦试验机上进行摩擦试验;用HW187?5型布洛维三用硬度计测量材料的布氏硬度;压头是直径为5 mm的钢球,实验力为612.9 N,保持时间为60 s。

2 实验结果与分析

2.1 粉体合成及复合材料烧结前后材料物相分析

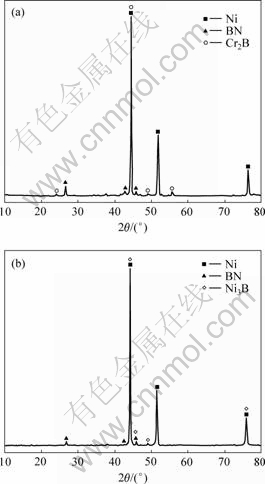

Cr/BN复合粉体合成前后的XRD图谱见图1。图1(a)中存在Cr2O3,BN和C 3种物相的特征峰;图1(b)中存在Cr2B和BN这2种物相的特征峰。在真空条件下,Cr2O3,BN和C反应合成的Cr/BN复合粉体,主要成分为Cr2B和BN,Cr2B中的Cr是Ni-Cr合金中Cr的惟一来源,剩余的BN将保证复合材料中BN的含量为11%~15%。

(a) 合成前;(b) 合成后

图1 Cr/BN复合粉体合成前后的XRD图谱

Fig.1 XRD patterns of Cr/BN composite powder before and after synthesizing

图2所示为Ni-Cr/BN烧结前后的XRD图谱。比较图2(a)和图2(b)可知,烧结前的Cr2B在烧结时与Ni反应生成Ni3B,同时置换出Cr。Cr又固溶于Ni中,形成固溶体,从而导致图2(b)中Ni的特征峰出现左偏。

(a) 烧结前;(b) 烧结后

图2 材料烧结前后的XRD图谱

Fig.2 XRD patterns of Ni-Cr/BN before and after sintering

2.2 烧结后材料(烧结体)的组织分析

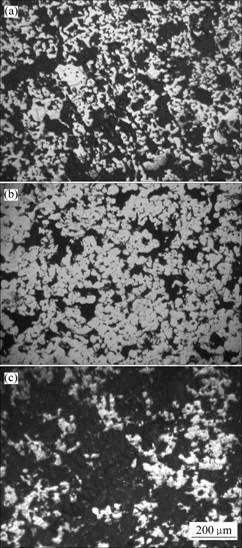

图3(a),(b)和(c)所示分别为于1 050,1 100和 1 150 ℃保温1 h后材料的显微组织照片。图3(a)中金属颗粒间形成烧结颈,彼此连接;图3(b)中出现了大量团块状组织(由液相包裹固体颗粒凝结而成),孔隙相对较少;图3(c)中几乎全为孔隙,只有少量团状组织。这是因为强化烧结主要包括活化烧结、瞬时液相烧结和液相烧结3种方式[11]。这3种烧结方式的快速扩散通道都是通过第二相(固相或液相)在粉末颗粒界面上的析出实现的[12]。活化烧结Ni-Cr/BN的动力学介于固相烧结与液相烧结之间,类似液相烧结的溶解和析出过程。液相形成之前进行固相烧结,形成之后进行活化烧结。通过比较图3(a)和图3(b)可以发现,液相的形成温度超过1 050 ℃,这与Ni-B相图所示结果相符[13]。活化烧结的液相量不超过10%,所以,烧结体内存在大量不被液相填充的孔隙。

温度/℃:(a) 1 050;(b) 1 100;(c) 1 150

白色部分是基体,黑色部分是孔隙

图3 Ni-Cr/BN在不同温度下保温1 h后的显微组织

Fig.3 Microscopic structures of Ni-Cr/BN at different sintering temperatures for 1 h

2.3 烧结后材料(烧结体)的性能分析

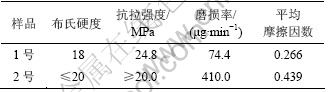

于1 100 ℃保温1 h后的材料(1号)与国外同类材料(2号)的性能对比结果见表1。可以看出,材料的性能接近,部分甚至超过国外同类材料性能。烧结体的硬度和摩擦性能与其密度密切相关。在一般情况下,烧结体的密度越高,其硬度和强度就越高;随着烧结体密度的变化,烧结体的摩擦性能也会发生相应的变化。作为高温可磨耗封严材料,Ni-Cr/BN的硬度越小,对配副材料的磨损就越小;但随着硬度的降低,材料的强度也不断下降。所以,为了使烧结体能够获得合适的硬度、强度和摩擦性能,就必须对影响烧结体密度的因素进行分析和研究。

表1 烧结后Ni-Cr/BN的性能

Table 1 Properties of Ni-Cr/BN after sintering

2.4 影响烧结体密度的因素分析

影响烧结体密度的因素较多,如粉末的物理性能、坯料的冷压密度,烧结气氛、烧结温度等。烧结试样密度主要与坯料密度有关,烧结温度的升高使孔隙缩小和球化,但孔隙形状的改变不能明显提高烧结体的密度[14];同时,由于Ni-Cr/BN坯料的密度很低,烧结初期体积的膨胀以及BN对烧结颈形成和长大的阻碍作用[15],都不利于材料的烧结和致密化。但是,活化烧结通过提供快速扩散通道(液相)的方式来降低烧结温度,缩短烧结时间,从而提高烧结材料的密度[16]。

2.4.1 烧结温度对材料相对密度的影响

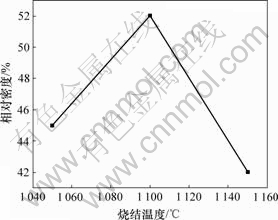

由Ni-B相图[12]可知,Ni和Ni3B的共晶转变温度为1 093 ℃,即在1 093 ℃附近坯料中开始出现液相。图4所示为材料分别在1 050,1 100和1 150 ℃保温1 h后相对密度的变化情况。可见,材料在1 100 ℃的相对密度比1 050 ℃的高。这是因为,随着温度的升高,出现的液相增多,粘附在固体颗粒间隙的液相也就越多。凝固后的液相像胶水一样将固体颗粒粘结成块,使材料强度和硬度都有所提高,密度增加。因此,在烧结温度超过低熔相的熔点后,材料的密度出现了较大幅度的增加。活化烧结不同于液相烧结,烧结时由含量较少的低熔相形成的液相难以填充孔隙,所以,不能像液相烧结那样通过液相填充孔隙来提高材料的密度。进一步提高烧结温度不能提高材料的密度,反而提高了液相的流动性,使液相从材料的表面渗出,导致材料成为废品。

图4 烧结温度对Ni-Cr/BN相对密度的影响

Fig.4 Influence of sintering temperature on relative density of Ni-Cr/BN

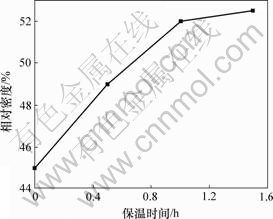

2.4.2 保温时间对材料相对密度的影响

图5所示为以12 ℃/min升温速度升至1 100 ℃并于不同保温时间下各材料的相对密度的变化情况。可以看出,保温30 min后,烧结体的相对密度从45%上升到49%;再延长30 min,上升至52%;继续延长时间,相对密度变化不大。温度一定时,保温时间愈长,烧结体性能也愈高。在温度达到1 100 ℃的初期,坯料中虽有液相出现,但由于时间较短,此时的液相量并未达到1 100 ℃所能出现液相的最大值。经过一段时间后,液相的量不再增加。由于液相是坯料基体中原子扩散的快速扩散通道,此时原子扩散速度达到最大值。在随后的一段时间内,烧结体的相对密度有较大幅度的提高。此后,进一步延长烧结时间,烧结体的相对密度不再提高。

图5 保温时间对Ni-Cr/BN相对密度的影响

Fig.5 Influence of holding time on relative density of Ni-Cr/BN

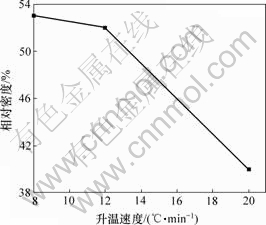

2.4.3 升温速度对材料相对密度的影响

图6所示为以不同升温速度升温至1 100 ℃并保温1 h后各材料相对密度的变化情况。可见,在升温速度为8~12 ℃/min时,对烧结体相对密度影响不大;而为12~20 ℃/min时,烧结体相对密度呈下降趋势。由于材料中BN颗粒不与金属颗粒发生烧结,因而烧结时起阻碍作用。在烧结初期,由于畸变能释放会使体积发生膨胀,若升温过快,则接触的金属颗粒来不及烧结,往往会导致烧结体沿变形量大的轴向产生裂纹,从而大大降低烧结体的密度和粒径。当升温速度达到或大于20 ℃/min时,烧结体易产生微裂纹,甚至开裂;若升温速度过慢,则又会变相地延长保温时间,造成能源浪费。

图6 升温速度对Ni-Cr/BN相对密度的影响

Fig.6 Influence of heating-up speed on relative density of Ni-Cr/BN

3 结 论

a. 活化烧结工艺在1 100 ℃保温1 h制备Ni-Cr/BN,其孔隙度可达48%,布氏硬度仅为18,抗拉强度为24.8 MPa;低载荷低转速时的磨损率为 74.4 μg/min,平均摩擦因数为0.266,完全满足自润滑材料的使用要求。

b. Ni-Cr/BN以Ni与Ni3B的低熔点共晶作为粘结相。当温度升至1 093 ℃左右时,坯料中开始出现液相;在烧结过程中,液相可作为原子的快速扩散通道,有利于原子的扩散,从而降低材料的烧结温度,缩短烧结时间;液相可填充部分孔隙,提高材料的密度。

c. 活化烧结的烧结温度必须超过共晶的熔点,以1 100 ℃为宜;烧结温度过低,无液相出现;烧结温度过高,液相溢出造成复合材料成分不均。保温时间不超过1 h,时间过短,扩散不充分,密度变化不大;时间过长,不能进一步提高复合材料密度。升温速度以10~14 ℃/min为宜。

参考文献:

[1] Matsunaga M. 固体润滑手册[M]. 范 煜, 译. 北京: 机械工业出版社, 1986.

Matsunaga M. Manual of solid lubrication[M]. FAN Yu, transl. Beijing: China Machine Press, 1986.

[2] 刘如铁, 李溪滨. 镍基高温自润滑材料[J].粉末冶金材料与工程, 1997, 2(1): 32-38.

LIU Ru-tie, LI Xi-bin. Nickel-base high temperature self-lubricate material[J]. Powder Metallurgy Material and Engineering, 1997, 2(1): 32-38.

[3] FU Xing-wang. Effects of solid lubricant MoS2 on the tribological behavior of hot pressed Ni/MoS2 self-lubricating composites at elevated temperature[J]. Tribology Trans, 1996, 39(2): 392-397.

[4] 李溪滨, 王丹丹, 刘如铁, 等. 固溶处理对镍铬钼合金力学性能的影响及断口分析[J]. 中南大学学报: 自然科学版, 2004, 35(3): 353-357.

LI Xi-bin, WANG Dan-dan, LIU Ru-tie, et al. Influence of solid-solution treatment on mechanical properties of Ni-Cr-Mo alloy and analysis of its fracture[J]. Journal of Central South University: Science and Technology, 2004, 35(3): 353-357.

[5] 刘如铁, 李溪滨, 熊党生, 等. 一种镍基高温自润滑材料摩擦学特性的研究[J]. 中南工业大学学报: 自然科学版, 2002, 31(3): 260-263.

LIU Ru-tie, LI Xi-bin, XIONG Dan-sheng, et al. Study on the tribological characteristics of a high-temperature self-lubricating nickel-base material[J]. Journal of Central South University of Technology: Natural Science, 2002, 31(3): 260-263.

[6] 胡婉莹. 连续合成六方氮化硼的新工艺[J]. 先进技术陶瓷, 2002(2): 35-36.

HU Wan-ying. Study on a new process for synthesis of hexagonal boron nitride[J]. Advanced Ceramics, 2002(2): 35-36.

[7] 郭志猛, 宋月清. 超硬材料与工具[M]. 北京: 冶金工业出版社, 1996.

GUO Zhi-meng, SONG Yue-qing. Superhard material and tool[M]. Beijing: Metallurgical Industry Press, 1996.

[8] 郭圣波, 王为民. 高性能C/BN层状复合材料的研究进展[J]. 陶瓷学报, 2005, 26(4): 285-289.

GUO Sheng-bo, WANG Wei-ming. Research progress of C/BN laminated composites with high properties[J]. Journal of Ceramics, 2005, 26(4): 285-289.

[9] LI Fan, ZHANG Deng-jun, LI Bao-hou, et al. A new chemical plating system for hexagonal boron nitride particles[J]. The Chinese Journal of Process Engineering, 2002(10): 425-430.

[10] 魏圣明, 王日初, 李庆勇, 等. BN对镍基可磨耗密封材料烧结性能的影响[J]. 稀有金属材料与工程, 2006, 35(1): 127-130.

WEI Sheng-ming, WANG Ri-chu, LI Qin-yong, et al. Effect of BN on sintering properties of Ni-based abradant seal alloy[J]. Rare Metal Material and Engineering, 2006, 35(1): 127-130.

[11] 刘 咏, 韦伟峰, 黄伯云, 等. 粉末冶金强化烧结的定性与定量分析理论综述[J]. 材料导报, 2003, 17(3): 1-4.

LIU Yong, WEI Wei-feng, HUANG Bo-yun, et al. Qualitative and quantitative theory of enhanced sintering in powder metallurgy[J]. Materials Review, 2003, 17(3): 1-4.

[12] Munir Z A, German R M. A generalized model for the prediction of periodic trends in the activation of sintering of refractory[J]. High Temperature Science, 1977(9): 275-283.

[13] Portnoi1 KI, Romashovl V M, Chubarov1 V M, et al. Phase diagram of the system nickel-boron[J]. Powder Metallurgy and Metal Ceramics, 1967, 6(2): 99-103.

[14] Mordike B L, Kaczmar J, Kielbinski M, et al. Effect of tungsten content on the properties and structure of cold extended Cu-W composite materials[J]. Powder Metallurgy International, 1991, 23(2): 91-95.

[15] German R M, Munir Z A. Activated sintering of refractory metals by transition metal additions[J]. Reviews in Powder Metallurgy and Physical Ceramic, 1982, 2(1): 9-43.

[16] DUAN Long-chen, LIU Xiao-yang, MAO Bao-song, et al. Research on diamond enhanced tungsten carbide composite button bits[J]. Journal of Materials Processing Technology, 2002, 129(1/3): 395-398.

收稿日期:2007-09-25;修回日期:2007-11-22

基金项目:国家民口配套科研项目(MKPT-03-182)

通信作者:余 琨(1974-),男,湖南长沙人,副教授,从事有色金属材料的研究;电话:0731-8876264;E-mail: kunyugroup@163.com