文章编号:1004-0609(2015)-05-1168-08

深冷时效循环处理铝基原位复合材料的显微组织和力学性能

李桂荣1, 2,崔玉华1,王宏明1,赵玉涛1

(1. 江苏大学 材料科学与工程学院,镇江 212013;

2. 上海交通大学 金属基复合材料国家重点实验室,上海 200240)

摘 要:采用熔体直接反应法,以工业7055铝合金为基体,利用K2TiF6和K2ZrF6多组元制备Al3(Ti0.5Zr0.5)原位颗粒强化铝基复合材料,再将复合材料经过挤压、固溶时效处理后进行深冷时效循环处理。采用正交实验设计法研究降温速度、处理时间和循环次数对复合材料显微组织和力学性能的影响。采用差示热分析仪对复合材料进行低温热分析,采用SEM和TEM对材料显微组织进行观察。结果表明:材料从液氮温度77 K升温至165 K左右时出现了明显的放热峰,此温度处出现了相变。热计算结果表明该温度下大量析出了S相(Al2CuMg)。深冷处理后复合材料内部细小析出相数量增多,主要组分是η(MgZn2)相和η′(MgZn2′)相;随着降温速度、处理时间和循环次数增加,性质不稳定且硬度高的η′相数量减少,性质稳定硬度较低的η相数量增加。与未冷处理试样相比,深冷时效循环处理后试样的平均抗拉强度提高14.7%,冲击韧性提高10.9%,伸长率提高50%,断裂机制为韧窝型断裂机制。当试样具有高强度、高韧性时,对应的最优冷处理参数为:降温速度v为1 ℃/min、保温时间t为24 h、循环次数N为1或2。当试样的伸长率最高时,对应的参数为:v为10 ℃/min、t为36 h、N为1。复合材料强化机制为析出相强化、位错强化和细晶强化等。

关键词:铝基原位复合材料;深冷时效循环处理;显微组织;力学性能

中图分类号:TG146 文献标志码:A

Microstructure and mechanical properties of in-situ aluminum matrix composites treated by cryogenic aging circular treatment

LI Gui-rong1, 2, CUI Yu-hua1, WANG Hong-ming1, ZHAO Yu-tao1

(1. School of Materials Science and Engineering, Jiangsu University, Zhenjiang 212013, China;

2. The State Key Laboratory of Metal Matrix Composites, Shanghai Jiao Tong University, Shanghai 200240, China)

Abstract: The in-situ Al3(Ti0.5Zr0.5) composite was synthesized using K2TiF6 and K2ZrF6 components in 7055 aluminum alloy by melt direct reaction method. Cryogenic aging circular treatment (CACT) was performed after extrusion deformation and solution-aging heat treatment. The effects of cooling rate (v), processing time (t) and circular index (N) on the microstructure and mechanical properties of composites were studied by orthogonal experimental method. The composite was studied by differential scanning calorimetry (DSC) under cryogenic condition, and the microstructure of composite was studied by SEM and TEM. The result shows that when the specimen is heated from the cryogenic temperature (77 K) to about 165 K, there will be an obvious exothermic peak. The phase transforms from matrix to S phase (Al2CuMg). There are amounts of fine precipitates in the composites, the main components are regarded as η (MgZn2) and η′(MgZn2′) phases. With increasing the v, t and N, the amount of η′ phase that is unstable but hard will decrease, while the stable but soft η phase will increase. Compared with the sample without CACT, the average tensile strength (σb), impact toughness (ak) and elongation (δ) of the sample with CACT have been enhanced by 14.7%,10.9% and 50%, respectively. The main fracture mechanism is dimple one. When the samples with high σb and ak are acquired, the optimal CACT parameters are: v=1 ℃/min; t=24 h and N=1 or 2. When the samples with superior elongation are acquired, the corresponding CACT parameters are: v=10 ℃/min, t=36 h and N=1. The strengthening mechanisms of CACT composite are precipitation strengthening, dislocation strengthening and fine crystalline strengthening.

Key words: in-situ aluminum matrix composite; cryogenic aging circular treatment; microstructure; mechanical property

7xxx系铝合金为Al-Zn-Mg-Cu合金,是航空航天领域使用的一种重要金属材料,具有超高强度和良好塑性,在合金基础上对其进行原位颗粒增强的目的在于进一步提高合金的力学性能,以进一步提高合金的安全使用下限值。一般地变形铝合金在原位复合浇铸完成后需进行挤压或者轧制,再实施固溶与时效常规热处理,但常出现时效过程中应力释放不完全、材料的力学性能提高幅度有限的问题[1-4]。

深冷处理又称超低温处理,通常以液氮为介质将材料置于-100 ℃以下,通过调节不同冷处理参数对材料进行改性调控。目前,国外深冷处理工艺一般使用在钢的工业生产中,钢材在冷处理过程中发生残余奥氏体向马氏体的转变,从而提高钢材的力学性能[5-8],而深冷处理在铝合金等有色金属、合金及其复合材料中的研究尚未成熟,特别是对低温处理过程中的相变特征、材料的显微组织演变规律等的报道还有待完善[9-12]。崔光华[13]研究了深冷处理对SiCp颗粒增强铝基复合材料性能的影响,发现一次深冷处理后复合材料的抗拉强度和屈服强度均提高了约10%,硬度提高了12%;同时深冷处理降低了由于颗粒和基体热膨胀系数不匹配而在外界引入的热错配应力,降低了复合材料的界面热阻,提高了热导率。王秋成等[14]研究了深冷处理对7050铝合金残余应力的影响,发现将铝合金构件浸入液氮中进行深冷后,铝合金内部的残余应力消除率达到58%。本文作者以原位颗粒增强7055铝基复合材料作为研究对象,采用深冷-时效循环处理方法,研究不同降温速度、处理时间和循环次数下复合材料的显微组织演变规律和性能特性,为探索深冷处理技术在高性能新材料研发领域的应用提供实验数据和理论基础。

1 实验

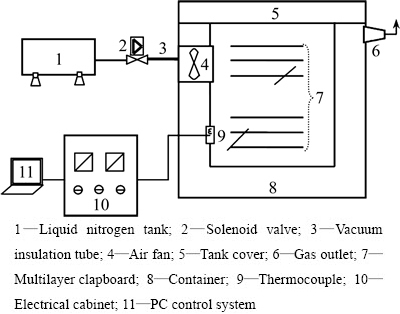

制备复合材料的原料包括工业7055铝合金、氟锆酸钾(K2ZrF6)、氟钛酸钾(K2TiF6)等。将7055铝合金置于中频感应炉中熔炼,同时将K2ZrF6和K2TiF6在250 ℃下进行烘干,然后在740~750 ℃下用石墨钟罩将反应物压入熔体中进行原位反应,持续2~3 min后进行精炼、细化、扒渣,在710~720 ℃时进行浇铸。对铸件进行(450 ℃,24 h)的均质热处理后进行挤压比为16:1的热挤压和T6热处理,之后对试样进行不同参数下的深冷时效循环处理(CACT)。图1所示为深冷处理箱的结构示意图。实验装置设备采用了对流换热冷却系统,即液氮经喷管喷出以后在深冷箱内直接产生气化,利用气化潜热以及低温氮气吸热,使工件得到降温,并通过液氮输入量的控制和设备内部的风机转速来控制降温速度,从而可以调节处理温度和降温速度。

图1 深冷处理箱的结构示意图

Fig. 1 Schematic diagram of cryogenic treatment container

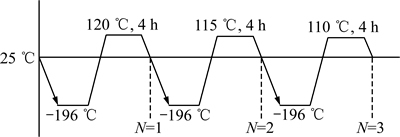

深冷时效循环处理主要考察降温速度(v)、处理时间(t)和循环次数(N)3个因素对复合材料显微组织和性能的影响。特别指出循环次数不是简单的重复深冷处理,而是每次深冷处理结束后,还要将试样升温到一定温度进行保温,类似时效过程。图2所示为循环处理的工艺路线。

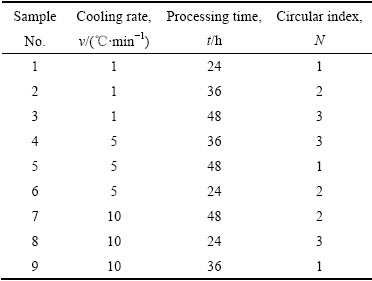

由于CACT的研究涉及3个因素,每个因素又设计了3个水平,因此采用L9(34)正交实验设计法来设计实验。表1所列为深冷时效循环处理实验的正交设计。观察CACT后复合材料的显微组织,并测试复合材料的力学性能,再按照表1分析实验结果,优化参数组合,并进行CACT的作用机制分析。

图2 循环处理的工艺路线

Fig. 2 Process route of circular processing

表1 复合材料深冷时效循环处理实验正交设计

Table 1 Orthogonal design for cryogenic aging circular treatment on composites

采用Thermo-CALC软件计算深冷处理过程中物相的质量变化;采用DSC204示差扫描量热仪研究深冷时效过程可能发生的相变,升温制度为:先从室温降温至深冷处理温度,然后再升温至时效温度。采用带有能谱仪(EDS)的JSM-7001F型扫描电子显微镜观察复合材料中颗粒新貌和大小;采用JEOL-JEM- 2100(HR)透射电镜观察显微组织中的析出相特征,用D/max-2500PC型XRD测试半高宽值以获得试样内部的位错密度。根据Dunn公式可知峰半高宽度的平方与位错密度成正比,如式(1)所示:

(1)

(1)

式中:ρ为位错密度;L为峰半高宽;b为伯格斯矢量的模。

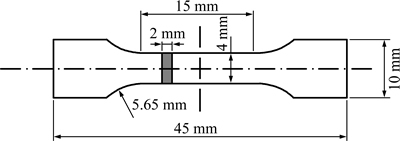

在ESH250型万能拉伸试验机上进行室温拉伸试验,图3所示为拉伸试样示意图。

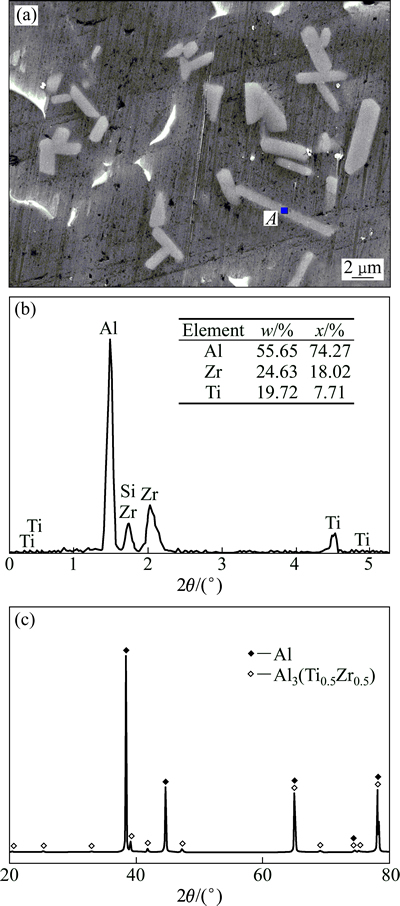

图4(a)所示为原位反应后复合材料的显微组织,图4(b)所示为图4(a)中A位置的EDS谱,图4(c)所示为复合材料的XRD谱(因为基体中合金相种类和数量多,为了表征颗粒组分和种类,所以在XRD中去除了合金相峰)。由图4可知复合材料中的金属间化合物为Al3(Ti0.5Zr0.5),显微组织为棒状,颗粒平均尺寸为微米级。

图3 拉伸试样示意图

Fig. 3 Schematic diagram of tensile specimen

图4 复合材料中金属间化合物颗粒的SEM像(a),位置A的EDS谱(b)和XRD谱(c)

Fig. 4 SEM image (a), corresponding EDS pattern of position A (b) and XRD pattern (c) of intermetallic compounds particles

2 结果与讨论

2.1 深冷时效循环处理复合材料过程中的相变

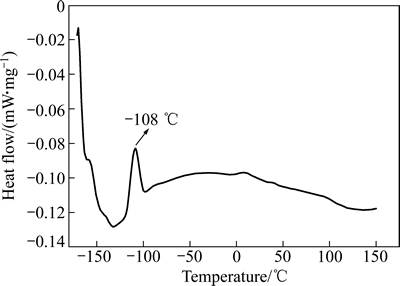

图5所示为从深冷处理温度升温至时效温度时材料的DSC曲线。由图5可以看出,从冷处理温度升温过程中样品在-108 ℃左右时均会出现一个明显的放热峰,因此可知在-108 ℃会有新相的生成,并在此之后生成的新相逐步溶解,即低温处理改变了复合材料的相变过程。

图5 低温处理时复合材料的DSC曲线

Fig. 5 DSC curve of composite treated by cryogenic treatment

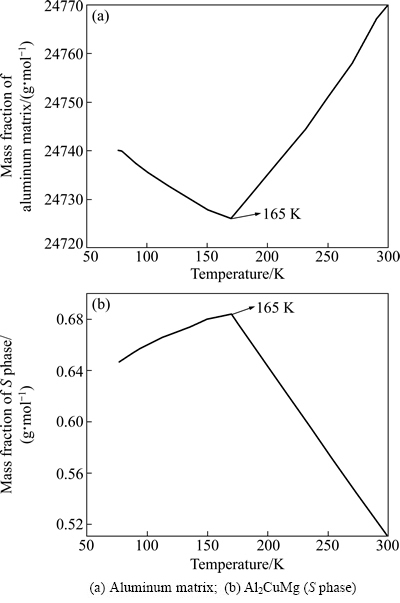

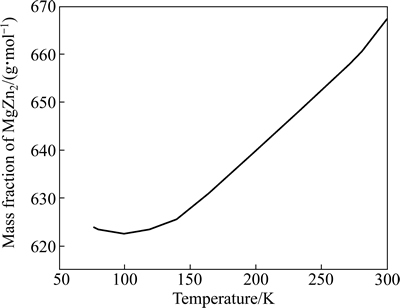

辅以Thermo-Calc计算结果讨论相变过程。图6所示为基体和Al2CuMg(S相)在室温到深冷处理温度(77~300 K)时物相含量与温度关系。

由图6可见,升温过程中从77 K升温至165 K阶段,基体含量(BPN)逐渐减小;从165 K继续升温时,基体含量增加,说明在77 K升温到165 K过程中,基体中的铝被逐渐消耗生成了其他相。观察发现Al2CuMg(S相)的质量变化规律与基体正好相反,即从77 K升温到165 K过程中Al2CuMg质量逐渐增加,当温度高于165 K时,Al2CuMg质量下降。结合热分析和热计算结果说明:165 K时发生的放热相变,是基体中的Al元素结合Cu和Mg元素生成Al2CuMg的过程,是从77 K开始到165 K左右结束;随着温度继续升高,S相逐步溶解。关于S相在深冷处理过程中的行为特征还有待深入研究。

2.2 深冷时效循环处理后复合材料的显微组织

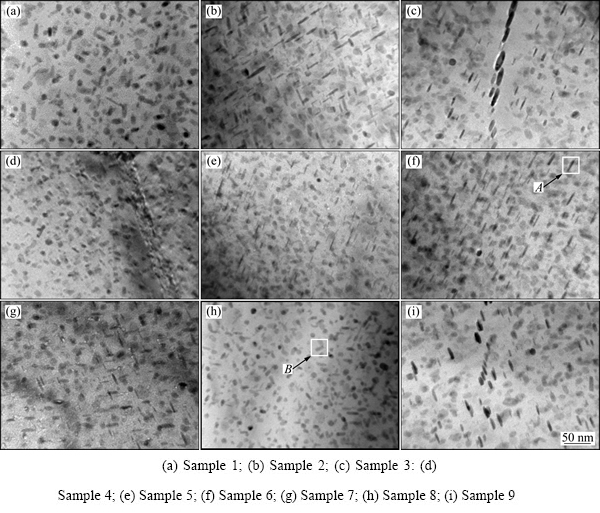

图7所示为深冷时效循环处理复合材料中的析出相TEM像。

图6 7055铝合金中不同相含量与温度的关系

Fig. 6 Relationships between mass fraction of different phases in 7055Al alloy and temperature

按照正交实验分析方法研究v,t,N 3个因子3个水平的分别作用效果,按照析出相数量由多到少的顺序依次为:v1、v2、v3;t1、t2、t3;N1、N2、N3。A1-Zn-Mg-Cu系合金时效过程中沉淀相析出顺序为:α相(过饱和固溶体)→GP区→η′相(MgZn2)→η相(MgZn2),在冷处理条件下,析出相主要组分是MgZn2。MgZn2有两种存在状态:一种是非平衡的MgZn2相,即η′相,与基体半共格,是主要强化相,呈针状(见图7(f)中位置A);第二种存在状态是平衡的MgZn2相,即η相,呈六方结构,与基体非共格,呈片状或块状(见图7(h)中位置B)。η相稳定,但是硬度较小,强化作用不够显著。正交分析结果表明:当v从1、5增加到10 ℃/min、t从24、36增加到48 h时,低硬度的η稳定相数量增多,成为主要强化相。

图8所示为通过Thermo-calc软件计算得到的MgZn2相在300~77K间质量分数与温度的关系,此时MgZn2相平均质量分数为6.5%。平衡降温过程中MgZn2相的析出量有所减少,降幅为0.5%~1%。通过热力学分析可知,随着温度的下降,合金元素Mg和Zn在合金中溶解度下降,会同时增加内部结构的稳定程度,有助于提高材料的尺寸稳定性和耐磨性等与材料内部能量状态有关的物理化学性能。特别地,当温度升高到300 K时,质量分数为0.5%~1%的细小MgZn2相会沿着孔洞再次析出。尽管质量分数的变化绝对值只有0.5%~1%,但是因为MgZn2相尺寸细小,所以仍保持着较高的体积分数;而且在较低温条件下,原子扩散速度慢、距离短,不利于MgZn2相的长大,会导致新析出相尺寸减小[15-16]。

图7 深冷时效循环处理复合材料中基体析出相的TEM像

Fig. 7 TEM images of matrix precipitates in different samples treated by CACT

图8 7075铝合金中MgZn2相质量分数与温度的关系

Fig. 8 Relationship between mass fraction of MgZn2 precipitates in 7055Al alloy and temperature

2.3 深冷处理后复合材料的力学性能

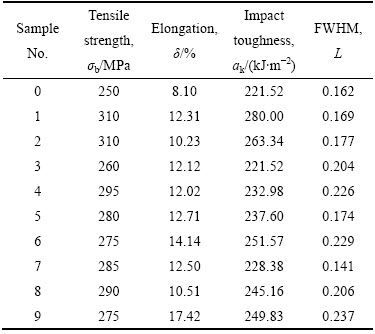

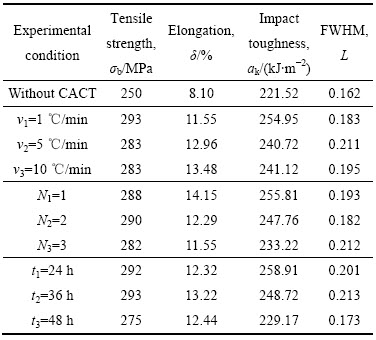

表2所列为深冷时效循环处理后复合材料的力学性能的正交实验原始结果,其中试样0为未进行深冷的空白样品,FWHM是XRD衍射结果中的半高宽值。可以看出经深冷处理后材料抗拉强度和冲击韧性有小幅增加,伸长率得到较大幅度的提升。从平均效果看,CACT复合材料较空白样品试样的抗拉强度提高14.7%,伸长率提高50%,冲击韧性提高10.9%。

表3所列为深冷时效循环处理后复合材料力学性能正交处理的分析结果。根据正交实验分析结果可知:深冷时效循环处理复合材料具有高强度和高冲击韧性特征的优化工艺参数为:v=1 ℃/min,N=1(或2),t=24 h;复合材料具有高塑性的优化工艺参数为:v=10 ℃/min,N=1,t=36 h。

表2 深冷时效循环处理后复合材料力学性能的正交实验原始结果

Table 2 Original mechanical properties of composites treated by CACT using orthogonal method

表3 深冷时效循环处理后复合材料力学性能正交处理分析结果

Table 3 Orthogonal analysis results of mechanical properties of composites treated by CACT

深冷循环处理后复合材料的强韧化机制主要有析出相强化、位错强化、细晶强化等,材料冷处理参数、力学性能间的对应关系需要从显微组织上进行分析。

图7所示的显微组织结果表明:随着深冷强度增加(即冷却速度增加、处理时间延长、循环次数增多)后,性质稳定但是强度小的η相数量增加,会导致复合材料强韧性下降,强韧化机制主要是析出强化作用。

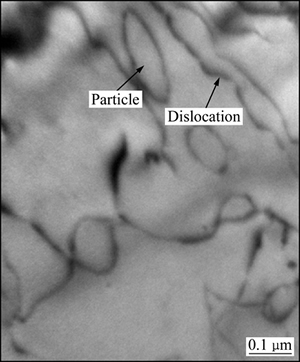

与空白样对比,当v=1 ℃/min、N=1、t=24 h时,半高宽值L较高,对应较高的位错密度,此时强韧化机制主要是位错强化作用。在颗粒增强铝基复合材料中,位错强化主要表现为Orowan强化机制,其对提高材料抗拉强度的贡献值σo如式(2)所示

(2)

(2)

式中:G为基体的剪切模量;b为伯格斯矢量的模;c为泊松比;D为颗粒的平均直径。根据式(2)可知小尺寸颗粒更有益于发挥Orowan强化机制。

图9所示为深冷处理后试样中典型的Orowan位错环显微组织[17]。

图9 CACT 铝基复合材料中的典型位错环组织

Fig. 9 Microstructure of typical dislocation loops in CACT aluminum matrix composite

复合材料高伸长率时的优化工艺参数为:v=10 ℃/min、N=1、t的影响较小(可忽略)。从位错密度来看,当v=1、5和10 ℃/min时,半高宽分别为0.183、0.211和0.195;当v=10 ℃/min时,半高宽值居中,位错密度处于中间值。当N=1、2和3时,半高宽分别为0.193、0.182和0.212;当N=1时,半高宽值居中,位错密度处于中间值。该条件下对应材料较高的伸长率和塑性。分析认为当位错密度低时,生成的纳米亚晶组织少,不易发挥细晶强化作用;而当位错密度高时,容易出现位错缠结和局部团簇现象,不利于改善塑性;而当位错密度适中时易生成高密度纳米亚晶组织,起到细晶效果。在拉伸过程中,细晶材料塑性变形趋于均匀,应力集中程度减小;同时晶界面积大,晶界曲折度增加,减缓了裂纹的扩展,使得材料能承受更大的应力和应变作用。此时强韧化机制主要为细晶强化的作用。

2.4 拉伸断口形貌

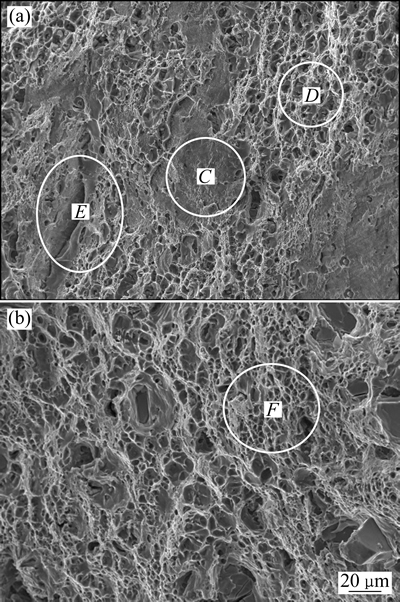

图10所示为经深冷处理前后复合材料的拉伸断口SEM像。由图10(a)可以看出,未经冷处理的复合材料的拉伸端口韧窝较少(见图10(a)中区域D),有较大范围的脆性断裂平台(见图10(a)中区域C),同时可以看到脆性断裂裂纹(见图10(a)中区域E),断裂类型为韧窝和准解理型的混合型断裂特征。

经深冷处理的复合材料韧窝数量明显增多,而且在局部区域呈现出大量细小韧窝,未发现脆性断裂平台、断裂裂纹等脆性断裂特征,为典型的韧窝型断裂特征(见图10(b)中区域F)。因此,从拉伸断口SEM像可以看出,深冷处理后的样品较之未深冷处理样品呈现出更好的韧性,从拉伸数据上分析,则表现在较好的伸长率,这与上述拉伸数据的结果是吻合的。

图10 深冷时效循环处理前后铝基复合材料拉伸断口SEM像

Fig. 10 Tensile fracture SEM images of aluminum matrix composite without CACT (a) and with CACT (b)

3 结论

1) 在深冷时效处理过程中,热分析观察到Al3(Ti0.5Zr0.5)铝基复合材料在165 K左右时内部出现相变,通过热计算分析认为此时生成了大量Al2CuMg(S相)。

2) 深冷处理后,复合材料内部的细小析出相明显增多,分析认为主要是η相(MgZn2)和η′相(MgZn2′);基体析出相以高硬度的η′相为主要增强相,随着深冷程度的增加(即降温速度v增加,处理时间t延长,循环次数N增多),基体中的η′相含量减少,低硬度的η相含量增多,可得深冷处理强韧化适合缓慢减温(1 ℃/min),处理时间不宜过长(不超过24 h),且循环次数不宜过多(不超过2次)。

3) 深冷处理后复合材料的力学性能得到增强,与未深冷处理材料相比,平均抗拉强度提高了14.7%,伸长率提高50%,冲击韧性提高10.9%。当复合材料的强度和韧性最高时对应的优化参数为:v=1 ℃/min、t=24 h、N=1(或2);当复合材料的延伸率最高时对应的优化参数为:v=10 ℃/min、t=36 h、N=1。

4) 强韧化机制为析出相强化、位错强化和细晶强化。未经深冷处理样品的拉伸断口为韧窝和准解理型的混合拉伸断口,深冷处理后样品的拉伸断口为典型的韧窝型拉伸断口。

REFERENCES

[1] LI Gui-rong, WANG Hong-ming, YUAN Xue-ting, ZHAO Yu-tao. Microstructure of nanometer Al2O3 particles reinforced aluminum matrix composites processed by high pulsed electromagnetic field[J]. Materials Letters, 2013, 99: 50-53.

[2] WANG Hong-ming, LI Gui-rong, ZHAO Yu-tao, ZHANG Zhao. Microstructure, billet surface quality and tensile property of (Al2O3+Al3Zr)p/Al composites in situ synthesized with electromagnetic field[J]. Journal of Alloys and Compounds, 2011, 509(18): 5696-5700.

[3] 李桂荣, 赵玉涛, 戴起勋, 程晓农, 曹建峰, 王宏明, 刘忠德, 陈 刚. 铸造工艺对(Al3Zr+Al2O3)p/A356原位复合材料组织和性能的影响[J]. 中国有色金属学报, 2006, 16(12): 2060-2065.

LI Gui-rong, ZHAO Yu-tao, DAI Qi-xun, CHENG Xiao-nong, CAO Jian-feng, WANG Hong-ming, LIU Zhong-de, CHEN Gang. Effect of casting technologies on microstructures and properties of (Al3Zr+Al2O3)p/A356 in situ composites[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(12): 2060-2065.

[4] 王宏明, 李桂荣, 赵玉涛, 戴起勋. 电磁铸造法制备的(Al2O3+Al3Zr)p/A359复合材料的磨损行为[J]. 稀有金属材料与工程, 2006, 35(4): 669-672.

WANG Hong-ming, LI Gui-rong, ZHAO Yu-tao, DAI Qi-xun. Wear behavior of (Al2O3+Al3Zr)p/A359 composites by in-situ electromagnetic casting[J]. Rare Metal Materials and Engineering, 2006, 35(4): 669-672.

[5] BENSELY A, SENTHILKUMAR D, LAL D M, NAGARAJAN G, RAJADURAI A. Effect of cryogenic treatment on tensile behavior of case carburized steel-815M17[J]. Materials Characterization, 2007, 58(5): 485-491.

[6] LI Shao-hong, XIE Yin-zi, WU Xiao-chun. Hardness and toughness investigations of deep cryogenic treated cold work die steel[J]. Cryogenics, 2010, 50(2): 89-92.

[7] 陈 鼎, 黎文献. 铝和铝合金的深冷处理[J]. 中国有色金属学报, 2000, 10(6): 891-895.

CHEN Ding, LI Wen-xian. Cryogenic treatment of Al and Al alloys[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(6): 891-895.

[8] WANG Ping, LU Wei, WANG Yue-hui, LIU Jian-hua, ZHANG Rui-jun. Effects of cryogenic treatment on the thermal physical properties of Cu76.12Al23.88 alloy[J]. Rare Metals, 2011, 30(6): 644-649.

[9] LI Gui-rong, WANG Hong-ming, CAI Yun, ZHAO Yu-tao, WANG Jun-jie, GILL S P A. Microstructure and mechanical properties of AZ91 magnesium alloy subject to deep cryogenic treatments[J]. International Journal of Minerals Metallurgy and Materials, 2013, 20(9): 896-901.

[10] ROMETSCH P A, ZHANG Yong, KNIGHT S. Heat treatment of 7XXX series aluminium alloys-some recent developments[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2003-2017.

[11] PAPAZIAN J M. Calorimetric studies of precipitation and dissolution kinetics in aluminum alloys 2219 and 7075[J]. Metallurgical Transactions A, 1982, 13(5): 761-769.

[12] ROBSON J D, PRANGNELL P B. Modelling Al3Zr dispersoid precipitation in multicomponent aluminium alloys[J]. Materials Science and Engineering A, 2003, 352(1): 240-250.

[13] 崔光华. 深冷处理对铝基复合材料性能的影响[D]. 上海: 上海交通大学, 2009.

CUI Guang-hua. Influence of cryogenic treatment on properties of aluminum matrix composites[D]. Shanghai: Shanghai Jiao Tong University, 2009.

[14] 王秋成, 柯映林. 深冷处理消除7050铝合金残余应力的研究[J]. 浙江大学学报(工学版), 2003, 37(6): 120-123.

WANG Qiu-cheng, KE Ying-lin. Relief of residual stresses in 7050 aluminum alloy by deep cryogenic treatment[J]. Journal of Zhejiang University (Engineering Science), 2003, 37(6): 120-123.

[15] AKHBARIZADEH A, GOLOZAR M A, SHAFEIE A, KHOLGHY M. Effects of austenizing time on wear behavior of D6 tool steel after deep cryogenic treatment[J]. Journal of Iron and Steel Research, International, 2009, 16(6): 29-32.

[16] 曾 渝. 超高强Al-Zn-Mg-Cu-Zr合金组织与性能研究[D]. 长沙: 中南大学, 2004.

ZENG Yu. Study on microstructure and properties of ultra-high strength Al-Zn-Mg-Cu-Zr alloy[D]. Changsha: Central South University, 2004.

[17] 黄依娜, 万发荣, 焦治杰. 利用透射电镜衬度像变化判定位错环类型及注氢纯铁中形成的位错环分析[J]. 物理学报, 2011, 60(3): 503-514.

HUANG Yi-na, WAN Fa-rong, JIAO Zhi-jie. The typical identification of dislocation loops by TEM and the loop formation in pure Fe implanted with H+[J]. Acta Physica Sinica, 2011, 60(3): 503-514.

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51371091,51001054,51174099,51174098);江苏省自然科学基金资助项目(BK2011533);金属基复合材料国家重点实验室开放基金资助项目(MMC-KF12-06)

收稿日期:2014-10-09;修订日期:2015-01-09

通信作者:李桂荣,副教授,博士;电话:18652886379;E-mail:liguirong@ujs.edu.cn