J. Cent. South Univ. Technol. (2011) 18: 1917-1923

DOI: 10.1007/s11771-011-0923-z

Lower fuel consumption model and

air-flow segregation feeding system for sintering

JIANG Yuan(江源)1, 2, HUANG Zhu-cheng(黄柱成)3, XU Bin(许斌)3, JIANG Tao(姜涛)3

1. Civil & Environment and Engineering School,University of Science and Technology Beijing, Beijing 100083, China;

2. China Nonferrous Metal Mining (Group) Co., Ltd., Beijing 100029, China;

3. School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2011

Abstract: In order to utilize the spontaneous accumulation of heat (SAH) reasonably and obtain the high quality sinter with low energy consumption, a lower fuel consumption modeling based on raw materials of a certain steel works was built. An air-flow segregation feeding (ASF) experimental equipment was designed to simulate strand feeding process and calculate the lower fuel consumption quantity. Compared with baseline test, the ASF experimental equipment was adopted. The results of sinter pot tests show that the solid fuel consumption is lower than that in baseline test, which is decreased by 5.8%. Meanwhile, other sinter indexes, such as pan yeild, tumbler strength and strand productivity are improved. The mineralogical examination indicates that the mineral compositions and micostructures are improved in sinter.

Key words: fuel consumption; spontaneous accumulation of heat; air-flow segregation feeding; sinter

1 Introduction

Since 1980s, the technique of sintering with large bed depth has been developed. The height of sinter bed increased from approximately 200 mm to more than 600 mm gradually. With the increase of the bed depth, the effect of spontaneous accumulation of heat (SAH) was enhanced. The quantity of SAH occupies 35% gross heat incomes of combustion zone when the bed depth reached 200 mm. When the bed depth increased to 500 mm, the quantity of SAH occupies more than 60% [1-3]. SAH leads to uneven heat distribution along the bed depth, which causes the temperature of upper sintering ore to reach 1 200 °C, and the lower sintering ore to reach 1 600 °C [4-5]. Because of the uneven heat distribution, the upper sinter is underburnt and the lower sinter is superfusion, and then the quality of sinter is influenced and the heat energy is wasted. Often, the energy consumption of sintering process in steel industry is approximately 10% [6], and the solid fuel consumption occupies about 75%-80% of the energy consumption of sintering process [7]. Thus, the fuel cost of the total processing cost is about 40%, which is the maximum item [8]. It is an essential issue to reduce the fuel consumption and output of sinter without lowering the quality.

With the development of computer, automation and sintering system, most of researchers focused on the essential factors correlated with the quality of sinter during the sintering process in recent years. KNOYKO [9] firstly proposed the concept of SAH in sintering process in 1979, and ZUO [10] gave a comprehensive mathematical analysis of the ventilation property of materials in sintering process in 1982. In 1986, KANJILAL and ROSE [11] summarized all the control parameters involved in sintering process. In 1999, PATISSON et al [12] made a mathematical model to simulate the sintering process. In 2005 and 2006, other scientists bulit discrete particle model to simulate the solid flow at high temperature [13-15]. In 2008, BARTELS et al [16] proposed the detection and prevention methods and built the fusing model at high temperature. Although these researchers summarized the important parameters and simulated the sintering progress accurately, the issues how to utilize the SAH and reduce the fuel adding amount about which the sintering manufacturers concern is still unclear.

The technology of segregated feed can realize the reasonable fuel distribution and acquire the sinters of low energy consumption, high quality and output [17-19]. The methods of segregated feed mainly include: deflector plate, improved screening segregation feeding (ISF), electromagnetic segregated feeder, multilayer segregation feeder, roller-feeder, and air flow segregation feeding (ASF) [20-22]. There are a few researches about ASF technology in western countries, and the applications of ASF technology are rare in China [23-25].

Through the analysis of SAH distribution along the bed depth, two innovation methods are presented in this work. Firstly, a lower fuel consumption model is built to evaluate the reasonable fuel adding amount. Secondly, an experimental equipment of ASF is designed to realize the results of theoretical model.

2 Materials and research methods

2.1 Materials

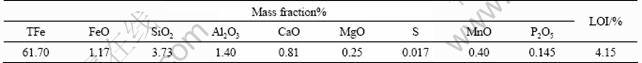

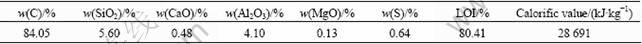

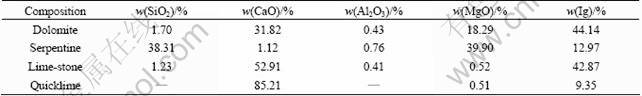

The chemical compositions of mixed ore, coke breeze and flux are shown in Tables 1-3.

The contents of total Fe (TFe), SiO2 and FeO of the mixed ore are 61.70%, 3.73% and 1.17% respectively, as shown in Table 1. It is concluded that the iron ore concentrate is a kind of hematite. It is shown in Table 2 that the carbon content of coke breeze is 84.05% and calorific value is 28 691 kJ/kg.

The minimum content of SiO2 in flux is 1.23% in lime-stone and the maximum content is 38.31% in dolomite. The minimum content of CaO in flux is 1.12% in serpentine and the maximum content of CaO is 85.21% in quicklime. The content of MgO in dolomite is maximum in flux. All of these are shown in Table 3.

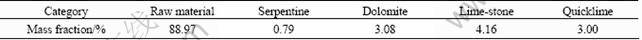

The mass fractions of mixed ore, fuel and flux are shown in Table 4.

2.2 Research methods

2.2.1 Lower fuel consumption model

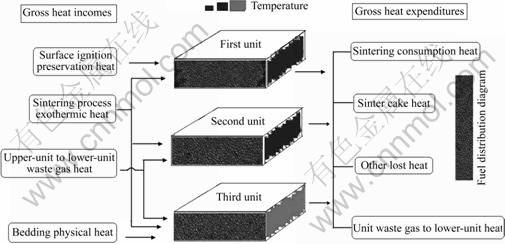

In order to obtain the sinter of low energy consumption, high quality and output, the regularity of heat distribution and heat storage was analyzed along the height of sinter bed. Gross heat incomes of sinter bed includes surface ignition preservation heat, sintering process exothermic heat, upper-unit to lower-unit waste gas heat and bedding physical heat. Gross heat expenditures of sinter bed includes sintering consumption heat, sinter cake heat, others lost heat, and unit waste gas to lower-unit heat. The SAH schematic diagram of three units is shown in Fig.1.

The 600 mm-high sinter bed was equally divided into three units. The height of each unit was 200 mm. Both of the length and width of each unit were 1 000 mm. Surface ignition preservation heat could only influence the first unit. Bedding physical heat could only influence the third unit. Other heat items were divided into three layers on average. About 97% waste gas heat of the first unit passed to the second unit, as a part of the gross heat incomes of the second unit. The other 3% waste gas heat of the first unit and 81% waste gas heat of the second unit are taken as a part of the gross heat incomes of the third unit [2-3, 9].

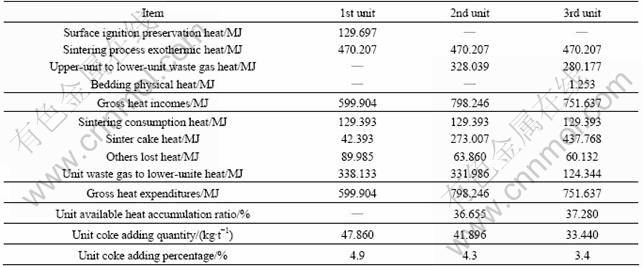

According to contrast test [2-3], adding 4.6% of coke breeze in mixed ore was optimum. The heat balance of each unit, unit available heat accumulation ratio and unit coke adding quantity were calculated respectively. The results of the lower fuel consumption model are shown in Table 5.

The available heat accumulation equals the difference that upper-unit to lower-unit waste gas heat minus sinter cake heat. The available heat accumulation ratio (AHAR) means the percentage of available heat accumulation in the gross heat incomes of each unit. The formula of AHAR is as follow [2-3]:

(1)

(1)

where ηAHAR is the available heat accumulation ratio of unit; Q1 is the upper-unit to lower-unit waste gas heat, MJ; QSCH is the sinter cake heat of unit, MJ; QGHI is the gross heat incomes, MJ.

Table 1 Chemical compositions of mixed ore

Table 2 Chemical compositions and calorific value of coke breeze

Table 3 Chemical compositions of flux

Table 4 Mass fraction of mixed ore, fuel and flux

Fig.1 Schematic diagram for spontaneous heat accumulation of three units

Table 5 Results of lower fuel consumption modeling

From Table 5, the AHAR increases from 36.66% in the 2nd unit to 37.28% in the 3rd unit. And the unit coke adding quantity decreases from 47.86 kg/t in the 1st unit to 33.44 kg/t in the 3rd unit. The unit coke adding percentage is as follows: 4.9% in the 1st unit, 4.3% in the 2nd unit, 3.4% in the 3rd unit.

2.2.2 Experiment principle and flowsheet of ASF

ASF can realize the reasonable fuel adding amount of the lower fuel consumption model.

1) ASF experiment principle

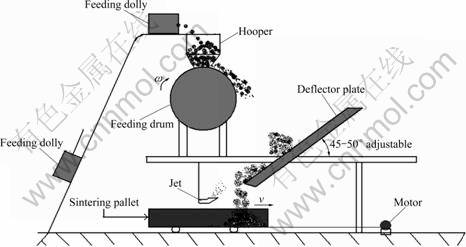

Based on the fluid mechanics principle and sintering practice, ASF device was designed. ASF device comprises feeding dolly, hopper, feeding drum, deflector plate, sintering pallet and jet [26-29]. The schematic diagram of ASF equipments is shown in Fig.2.

The sinter mixture was transferred by the feeding dolly into the hopper. The manual valve was designed under the hopper, in order to adjust the amount of baiting. Under the rotary driving force of feeding drum, the mix dropped from the feeding drum to the deflector plate. Under the impact of air flow, the mix entered from the deflector plate into the sintering pallet. The rotational speed of the feeding drum, the dip angle of the deflector plate and the running velocity of the sintering pallet were adjustable.

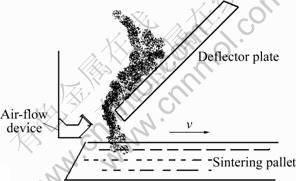

The movement of the particles of mix under the impact of air flow was divided into vertical vertical componentvertical componentcomponent and horizontal component. If the diameter of particles was smaller, the density of particles was lower, and the air flow was faster, the vertical drop speed of particles would be lowered and the particles would drop on the upper of sintering pallet, the horizontal speed of particles would faster and the particles would fly much further. The diameter of jet was definited, so the velocity of air flow was controlled by adjusting the volume of air flow. The air flow device schematic diagram is shown in Fig.3.

Fig.2 Schematic diagram of ASF equipments

Fig.3 Schematic diagram for air flow device

2) Experimental procedure

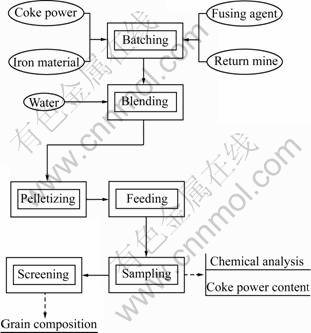

The flowsheet of ASF experiments is shown in Fig.4.

(1) Batching and blending: Quality batching method was used. The main feed was blended three times by manpower. After that, water was added. Then, the main feed was blended three times again.

(2) The mix was pelletized in the d 600 mm×1 400 mm drum mixer for 3 min, and the rotational speed of drum mixer was 15 r/min.

(3) Feeding: The mix flew through feeding drum, fell on the deflector plate, and dropped on the sintering pallet under the action of air flow. By adjusting the rotational speed of feeding drum and the velocity of sintering pellet, the heap of mix was just formed in the middle of sintering pellet.

(4) Sampling: Sampling point for the centerline of the mix was located 30 mm in the offside position. The mix was divided into three sampling layers along the height of sintering pellet. The 500 g mix would be taken as a sample by sample splitting device in each sampling unit. And the quality percentage of particles larger than 3 mm in each sample would be assayed.

Fig.4 ASF experimental flowsheet

(5) Screening: Particle size was assayed in each sampling by standard sample screen. The sizes of griddles were 8, 5, 3, 1, 0.5 cm from top to bottom, respectively. The formula of particle mean size was

where ri means the percentage of granulometric

where ri means the percentage of granulometric

class; di means the diameter of granulometric class.

(6) Sampling and assaying the carbon content in each unit.

2.2.3 Sintering experiment method

In order to confirm the accuracy of the lower fuel consumption modeling and the validity of ASF method, the sinter pot tests were conducted. After interval sampling from sintering pallet every 200 mm along the height of the sinter bed, the sinter pot feeding was proceeded, and then igniting and sintering. The parameters of sintering process are as follows: bedding material of 20 mm, the thickness of raw material layer of 600 mm, ignition temperature of 1 100 °C, ignition time of 2 min, ignition suction of 5 kPa, sinter suction of 10 kPa, chilling suction of 5 kPa, and chilling time of 5 min. Sinter was divided into three units for sampling. The samples of sinter were analyzed by Labor Lux12 POL partial inverse amphibious microscope and JSM-5600LV scanning electron microscope.

3 Results and discussion

3.1 ASF experiments

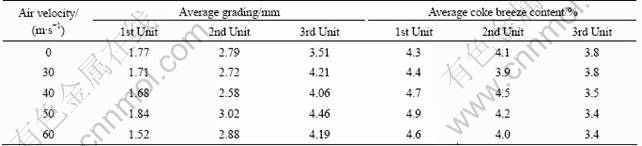

The effect of air flow velocity on average particle size and average coke breeze content of each unit is shown in Table 6. When the scope of air flow velocity is 30-60 m/s, it is effective to realize the granule segregation. The faster the air flow velocity is, the more obvious the fuel segregation will be. In the case that the air flow velocity is 0 m/s, the rangeability of segregation changes slightly. When the air flow velocity is 60 m/s, the rangeability of segregation reaches the maximum. When the air flow velocity is less than 30 m/s, the coke breeze content of each unit is not obviously changed. With the increasing of air flow velocity, the effect of coke segregation is gradually obvious.

From Table 6, when the air flow velocity is 40 m/s, the effect of fuel segregation is obvious. When the air flow velocity is 50 m/s, the effect of fuel segregation is up to the maximum. When the air flow velocity is 60 m/s, the coke breeze content significantly decreases in the upper and middle units because smaller and lighter coke breeze is missing under the impact of air flow.

3.2 Sintering experiment

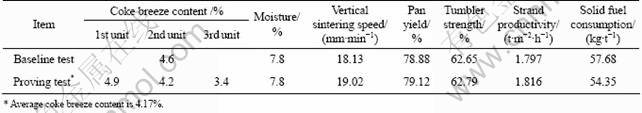

According to the optimized dosage experiments of coke breeze and water in sinter feed mixture, the optimum dosage of coke breeze and water are 4.6%, 7.8% respectively, used as baseline test. In baseline test, ordinary feeding is adopted and the coke breeze content of each unit is equal. As it shown in Table 6, when the air flow velocity is 50 m/s, the effect of fuel segregation is obvious and the particle mean size is suitable, which is used in proving test.

In the baseline test, coke breeze content of each unit is consistent. In the proving test, coke breeze content of each unit is 4.9% in the 1st unit, 4.2% in the 2nd unit, 3.4% in the 3rd unit, respectively, and the average coke breeze content is 4.17%. The results of coke breeze content and proximate analysis of sinter are shown in Table 7.

In order to utilize SAH, the dosage of fuel is reasonably decreased from top to bottom. From Table 7, the vertical sintering speed of proving test is 19.02 mm/min, and solid fuel consumption is 54.35 kg/t. Compared with the baseline test, the vertical sintering speed of proving test increases by 4.9%, the solid fuel consumption decreases by 5.8%, and the pan yield, tumbler strength and strand productivity increase slightly.

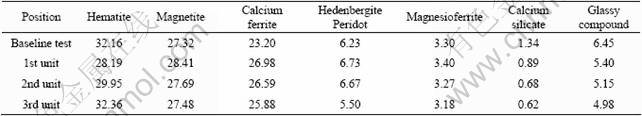

3.3 Mineralogical examination

Mineral compositions of samples are shown in Table 8. Because the amount of fuel decreases from top to bottom, overburning in the lower sinter decreases. The content of calcium ferrite in the samples of proving test decreases from 26.98% in the 1st unit to 25.88% in the 3rd unit, the content of calcium silicate decreases from 0.89% in the 1st unit to 0.62% in the 3rd unit, and the content of glassy compound decreases from 5.40% in the 1st unit to 4.98% in the 3rd unit.

It is concluded that the content of calcium ferrite in the samples of proving test in each unit is higher than that in the sample of baseline test, while the content of calcium silicate and glassy compound is lower. The reason is that with the reduction of the dosage of fuel along the height of sinter bed, the oxygen content is heightened and the time of high temperature in sintering process is prolonged.

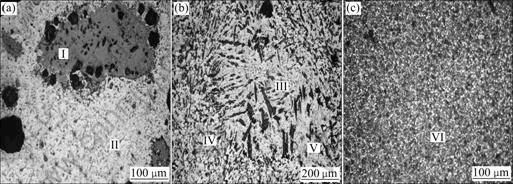

The calcium ferrite of strip-structure and corrosion structure is distinctly increased in the 1st unit by mineralogical examination. The microstructures of samples of each unit in proving test are shown in Fig.5.

Table 6 Effect of air-flow velocity on average partical size and average coke powder content of each unit

Table 7 Results of coke breeze content and proximate analysis of sinter

Table 8 Mineral compositions of samples (mass fraction, %)

Fig.5 Microstructures of samples of each unit in proving test (I—Kirschsteinite; II—Calcium ferrite; III—Calcium silicate; IV—Fe3O4; V—Fe2O3; VI—Fe2O3 and Fe3O4 interweaved-structure): (a) First unit mineragraphy; (b) Second unit mineragraphy; (c) Third unit mineragraphy

The calcium ferrite is interconnected but not hardened, and the amount of micro holes increases. It is shown in Fig.5(a) that in sinter the kirschsteinite is formed, which cements with other minerals and improves the strength of sinter. Large quantities of the calcium ferrite of corrosion structure form in the 2nd unit and distribute uniformly. In some micro-areas, the calcium ferrite of strip-structure is found, the quantity of which in the 2nd unit is less than that in the 1st unit. It is shown in Fig.5(b) that calcium silicate crystal of bamboo leaf shape is found. The interweaved-structure of Fe2O3 and Fe3O4 is shown in Fig.5(c). With the application of ASF experimental equpiment, the fuel comsumption from top to bottom decreases along the sinter bed. Not only does the solid fuel consumption decrease, but also the mineral composition and structure are improved.

4 Conclusions

1) The lower fuel consumption model analyzes and utilizes the SAH in deep-bed sintering reasonably. So the dosage of fuel adding decreases from the 1st unit to the 3rd unit along the height of sinter bed. According to the lower fuel consumption modeling, relevant equipment parameters of ASF are adjusted to obtain the content of coke breeze in each unit. The calculated contents of coke breeze in the lower fuel consumption modeling are 4.9% in 1st unit, 4.3% in 2nd unit, 3.4% in 3rd unit, respectively. The average coke breeze content is 4.17%.

2) The ASF device is designed, based on the fluid mechanics principle and sintering practice. When the air-flow velocity is in the scope of 30-60 m/s, it will have the significant effect on granule segregation. The faster the air flow velocity is, the more effective the fuel segregation will be. However, the smaller and lighter coke breeze is missing when the air flow velocity reaches 60 m/s. When the air flow velocity is 50 m/s, the dosages of coke breeze are as follows: 4.9% in the 1st Unit, 4.2% in the 2nd Unit, 3.4% in the 3rd Unit, which are almost in accord with the calculated results by the lower fuel consumption modeling.

3) Compared with the baseline test, the vertical sintering speed in proving test increases by 4.9%, the solid fuel consumption decreases by 5.8%. And other sinter indexes increase slightly, such as pan yield, tumbler strength and strand productivity.

4) The mineralogical examination shows that the content of calcium ferrite in proving test samples is higher than that in baseline test sample and the contents of calcium silicate and glassy compound in proving test samples are lower than those in baseline test sample. It is analytically deduced that overburning in the lower sinter bed is avoided. From the interweaved-structure of Fe2O3 and Fe3O4 and the compact structure of calcium silicate crystal, it is concluded that sinter of high quality and output is obtained with the use of ASF experimental equipment.

References

[1] YANG W, CHOI S, CHOI E S, RI D W, KIM S. Combustion characteristics in an iron ore sintering bed-evaluation of fuel substitution [J]. Combustion and Flame, 2006, 145(3): 447-463.

[2] HUANG Zhu-cheng, JIANG Yuan, MAO Xiao-ming, XU Bin, GUO Yu-feng, JIANG Tao. Fuel appropriate distribution in iron ore sintering [J]. J Cent South Univ: Science and Technology, 2006, 37(5): 884-890. (in Chinese)

[3] JIANG Yuan. The study of fue appropriate distribution in iron ore sintering [D]. Changsha: Central South University, 2006: 21-42. (in Chinese)

[4] JANG J Y, CHIU Y W. 3-D Transient conjugated heat transfer and fluid flow analysis for the cooling process of sintered bed [J]. Applied Thermal Engineering. 2009, 29(14/15): 2895-2903.

[5] FORMOSO A. The improvement of measuring methods of moisture and volatile matter with coke breeze in sintering [J]. Sintering and Pelletizing, 1995, 20(4): 32-37.

[6] FERNANDEZ LLORENTE M J, ESCALADA CUADRADO R, MURILLO LAPLAZA J M, CARRASCO GARCIA J E. Combustion in bubbling fluidised bed with bed material of limestone to reduce the biomass ash agglomeration and sintering [J]. Fuel, 2006, 85(14/15): 2081-2092.

[7] FU Ju-yin, JIANG Tao, ZHU De-qing. Sintering and pelletizing [M]. Changsha: Central South University of Technology Press, 1996: 14-28. (in Chinese)

[8] YIN Rui-ming, FAN Jing-lian, LIU Xun. Preparation and sintering of nano Fe coated Si3N4 composite powders [J]. Journal of Central South University of Technology, 2009, 16(2): 0184-0189.

[9] KNOYKO A K. The study of heat accumulation in the sinter ore [J]. Cmaib, 1979, 4(3): 245-247.

[10] ZUO Teng-jun. Consideration on the granulation and the bed- permeability model of sinter raw materials [C]. Tet su-to-Hagane, 1982, 68(15): 2174-2181.

[11] KANJILAL P P, ROSE E. Application of adaptive prediction and control methods for improved operation of the sintering process [J]. Ironmaking and Steelmaking, 1986, 13(6): 289-293.

[12] PATISSON F, BELLOT J P, ABLITAER D. Mathematical modeling of iron ore sintering process [J]. Ironmaking and Steelmaking, 1999, 18(2): 89-95.

[13] ZHOU Z, ZHU H, YU A,WRIGHT B, PINSON D, ZULLI P. Discrete particle simulation of solid flow in a model blast furnace [J]. ISIJ Int, 2005, 45(12): 1828-1837.

[14] CHO K, BISWAS P. A geometrical sintering model (GSM) to predict surface area change [J]. Aerosol Science, 2006, 37: 1378-1387.

[15] HUTCHINSON R G, FLECK N A, COCKS A C F. A sintering model for thermal barrier coatings [J]. Acta Materiallia, 2006, 54(5): 1297- 1306.

[16] BARTELS M, LIN W, NIJENHUIS J, KAPTEIJN F, VAN O J. Agglomeration in fluidized beds at high temperatures: Mechanisms, detection and prevention [J]. Prog Energ Combust Sci, 2008, 34(5): 633-666.

[17] YANG S C. Density effect on mixing and segregation processes in a vibrated binary granular mixture [J]. Powder Technol, 2006, 164(2): 65-74.

[18] TANG P, PURI V M. An innovative device for quantification of percolation and sieving segregation patterns single component and multiple size fractions [J]. Part Sci Technol, 2005, 23(4): 335-350.

[19] KETTERHAGEN W R, CURTIS J S, WASSGRE C R, HANCOCK B C. Modeling granular segregation in flow from quasi-three- dimensional wedge-shaped hoppers [J]. Power Technology, 2008, 179(3): 126-143.

[20] GUO Y, WU C Y, KAFUI K D, THORNTON C. Numerical analysis of density-induced segregation during die filling [J]. Power Technology, 2009, 197(1/2): 111-119.

[21] SHI Q, SUN G, HOU M, LU K. Density-driven segregation in vertically vibrated binary granular mixtures [J]. Phys Rev E, 2007, 75(06): 1302-1305.

[22] KETTERHAGEN W R, CURTIS J S, WASSGREN C R. KONG A, NARAYAN P J, HANCOCK B C. Granular segregation in discharging cylindrical hoppers: A discrete element and experimental study [J]. Chem Eng Sci, 2007, 62(22): 6423-6439.

[23] ZIGAN S, THORPE R B, TUZUN U, ENSTAD G G, BATTISTIN F. Theoretical and experimental testing of a scaling rule for air current segregation of alumina powder in cylindrical silos [J]. Powder Technol, 2008, 183(1): 133-145.

[24] KETTERHAGEN W R, CURTIS J S, WASSGRE C R. Stress results from two-dimensional granular shear flow simulations using various collision models [J]. Phys Rev, E. 2005, 71(06): 3307-3317.

[25] WU C Y, COCK A C F. Numerical and experimental investigations of the flow of powder into a confined space [J]. Mech Mater, 2006, 38(4): 304-324.

[26] VENKATARAMANA R, GUPTA S S, KAPUR P C. A combined model for granule size distribution and cold bed permeability in the wet stage of iron ore sintering process [J]. Int J Miner Process, 1999, 57(1): 43-58.

[27] CHANG Liang-liang. The investigation on the fluid mechanics principle of air-blow feeding and the technological development [D]. Changsha: Central South University, 2007: 30-39. (in Chinese)

[28] CHANG Liang-liang, XU Bin, JIANG Tao. Research of air-flow feeding in sinter [J]. Mining and Metallurgical Engineering, 2007, 27(2): 54-57. (in Chinese)

[29] SCHNEIDER L C R, SINKA I C, COCKS A C F. Characterisation of the flow behaviour of pharmaceutical powders using a model die-shoe filling system [J]. Powder Technol, 2007, 243(1): 59-71.

(Edited by DENG Lü-xiang)

Foundation item: Project(NECT-04-0748) supported by New Century Excellent Talents Program of China

Received date: 2010-10-21; Accepted date: 2011-03-11

Corresponding author: JIANG Yuan, PhD; Tel: +86-10-84426056; E-mail: jiangyuan0223@163.com