DOI: 10.11817/j.issn.1672-7207.2019.06.006

含BaSO4钴基自润滑复合材料的制备及高温摩擦学性能

王文杰1, 2, 3,崔功军1, 2, 3,杨振伟1, 2, 3,师睿博1, 2, 3

(1. 太原理工大学 机械学院,山西 太原,030024;

2. 山西省矿山流体控制工程实验室,山西 太原,030024;

3. 矿山流体控制国家地方联合工程实验室,山西 太原,030024)

摘要:采用热压烧结技术制备3种含不同BaSO4质量分数的钴基自润滑复合材料,研究其在室温到1 000 ℃范围内的摩擦学性能。在载荷为15 N、滑动速度为0.19 m/s的条件下,采用球-盘式高温摩擦试验机与Si3N4陶瓷球配副研究复合材料的高温摩擦学性能。采用X线衍射仪和扫描电镜等分析复合材料的物相成分和摩擦表面形貌。研究结果表明:随着BaSO4质量分数的增加,复合材料的硬度和密度逐渐降低。从室温到800 ℃,复合材料的摩擦因数逐渐降低,这是由于随着温度的上升,复合材料的摩擦表面逐渐形成了由铬酸盐、钼酸盐和氧化物等组成的润滑膜,使得复合材料在高温条件下具有了较优良的减摩耐磨性能。在3种钴基复合材料中,含10% BaSO4的钴基自润滑复合材料在400~800 ℃范围内的摩擦学性能较好。

关键词:钴基自润滑复合材料;高温;摩擦;磨损

中图分类号:TH117.3 文献标志码:文献标识码:A 文章编号:1672-7207(2019)06-1306-08

Preparation and high temperature tribological properties of cobalt-BaSO4 self-lubricating composites

WANG Wenjie1, 2, 3, CUI Gongjun1, 2, 3, YANG Zhenwei1, 2, 3, SHI Ruibo1, 2, 3

(1. School of Mechanical Engineering, Taiyuan University of Technology, Taiyuan 030024, China;

2. Shanxi Mine Fluid Control Engineering Laboratory, Taiyuan 030024, China;

3. National Joint Engineering Laboratory for Mine Fluid Control, Taiyuan 030024, China)

Abstract: Three kinds of cobalt-based self-lubricating composites with different mass fractions of BaSO4 were prepared by hot pressing sintering technique. The tribological properties were studied from room temperature to 1 000 ℃. Under the load of 15 N and sliding speed of 0.19 m/s, the high-temperature tribological properties of composites sliding against Si3N4 ceramic ball were studied by using ball-on-disk high-temperature tribo-tester. The phase and worn surfaces of composites were analyzed by X-ray diffractometry and scanning electron microscopy. The results show that the hardness and density of the composites decrease with the increase of mass fractions of BaSO4 in the composites. The friction coefficient of composites gradually decreases from room temperature to 800 ℃, because the friction surfaces of composites gradually form the lubricating film which is composed of chromate, molybdate and oxide as the temperature rises, and the composites have superior anti-friction and wear resistance at high temperature. By comparing the three composites, the tribological properties of cobalt-based self-lubricating composites containing 10% BaSO4 are better in the range of 400-800 ℃.

Key words: cobalt-based self-lubricating composite; high temperature; friction; wear

近年来,虽然我国的某些重点型号飞机已经服役或者即将服役,但是依然存在高可靠性及高功率航空发动机严重缺失的问题[1]。在高温(温度>500 ℃)环境下,大量的发动机热端机械部件在高温、高压、高速及高载条件下工作,如燃气涡轮密封、高温轴承、轴套、缸壁等,此时润滑油脂难以提供有效润滑,其润滑形式属于边界润滑,导致零部件磨损严重[2-4],这已成为影响系统可靠性和寿命的关键问题之一。钴基合金由于其优异的高温强度和耐磨性在航空发动机领域普遍使用[5-7]。近些年,钴基合金的研究已取得了一些进展,MURRAY等[8]研究了CeF3高温时对钴合金的摩擦学性能的影响,发现CeF3在500 ℃以上能起到有效润滑作用。WANG等[9]研究了钇在室温到650 ℃的范围内对钨铬钴合金磨损性能的影响,发现添加钇后,钨铬钴合金的耐磨性和机械力学性能得到明显改善。研究结果表明,当钇加入钨铬钴合金时,氧化膜的氧化度大大提高,这可能有助于提高钨铬钴合金在高温下的性能。但是,这些钴基复合材料制备时所用的原料成本高,制备难度大且工艺流程较为复杂,故急需研究出一种新型的钴基自润滑复合材料[10-13]。BaSO4材料成本较低,与钼酸盐等固体润滑剂可发生协同效应,能在高温阶段为钴基合金提供很好的润滑作用[14]。目前,BaSO4对钴基自润滑复合材料摩擦学性能的影响的研究较少。因此,本文作者以BaSO4作为润滑相,Cr和Mo作为强化相,研究不同BaSO4质量分数的Co-Cr-Mo-BaSO4钴基自润滑复合材料在室温到1 000 ℃下的摩擦学性能[15]。

1 实验

1.1 材料制备

本实验采用的Co粉、Cr粉、Mo粉和BaSO4粉均由国药集团化学试剂有限公司生产,纯度均大于99%。本研究制备了3种不同BaSO4质量分数的钴基复合材料,其配比见表1。使用电子天平分别称量各组分的质量,将配好的原料在行星球磨机上进行混料,转速为350 r/min,混合时间为3 h。然后,将混匀的粉末置于直径30 mm的石墨模具中,将模具放入热压真空烧结炉中,当温度上升到 1 000 ℃时,保温20 min,再加压至28 MPa,保温保压30 min后开始降温,600 ℃时,卸掉压力,样品随炉冷却至室温。试样由线切割加工为直径×厚度为30 mm×4 mm的圆片,选取0.125,0.025和0.017 mm的砂纸对样品进行逐级打磨抛光,之后进行摩擦磨损性能试验。

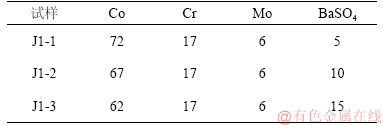

表1 复合材料的成分(质量分数)

Table 1 Composition of composites%

1.2 材料性能测试

根据阿基米德原理,利用电子天平测定样品的密度。通过HVS-1000Z型数字显微维氏硬度计测试样品的维氏硬度,在样品上选取10个不同的位置测试并计算出10组数据的平均值作为试样的硬度。采用HT-1000型高温摩擦磨损试验机测试样品的摩擦学性能,通过软件实时记录摩擦因数。摩擦试验条件如下:载荷为15 N,线速度为0.19 m/s,测试温度分别为室温、200、400、600、800和1 000 ℃,滑动时间为20 min。在每个温度下做2组试验,样品的摩擦因数取其稳定摩擦磨损阶段的平均值。使用2207轮廓仪在样品的磨痕上取3~4个测量部位,将所测得的截面积求平均值,然后由平均值与磨痕长度求得磨损体积。样品的磨损率W的计算公式为

W=V/(F·S)

其中:V为样品的磨损体积,mm3;F为载荷,N;S为滑动距离,m[16]。通过JSM-IT300型电子显微镜对试样的磨损表面形貌进行观察,采用XRD-6100型X线衍射仪分析试样的相组成。

2 结果与讨论

2.1 成分分析

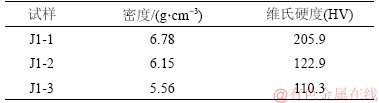

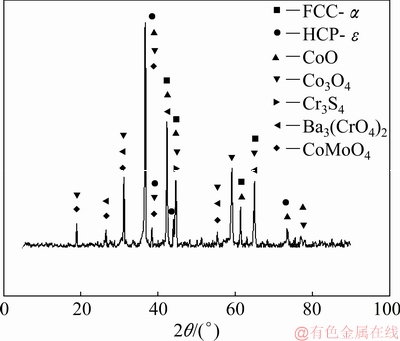

图1所示为3种不同BaSO4质量分数的钴基自润滑复合材料的XRD谱图。由图1可以看出:在1 000 ℃烧结后,复合材料主要由Co-Cr-Cr2O3固溶体(FCC-α和HCP-ε),MoS2,Ba3(CrO3)2和CoMoO3等相组成;Cr2O3和CoMoO3由Co,Cr和Mo在高温下氧化生成;BaSO4在高温下分解为BaO和SO3,BaO与Cr2O3反应生成Ba3(CrO3)2,同时,SO3和Mo反应生成MoS2和氧气。Ba3(CrO3)2和CoMoO3等可起到协同润滑作用,提高复合材料的高温摩擦磨损性能[17]。

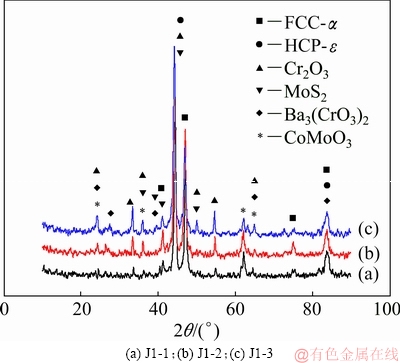

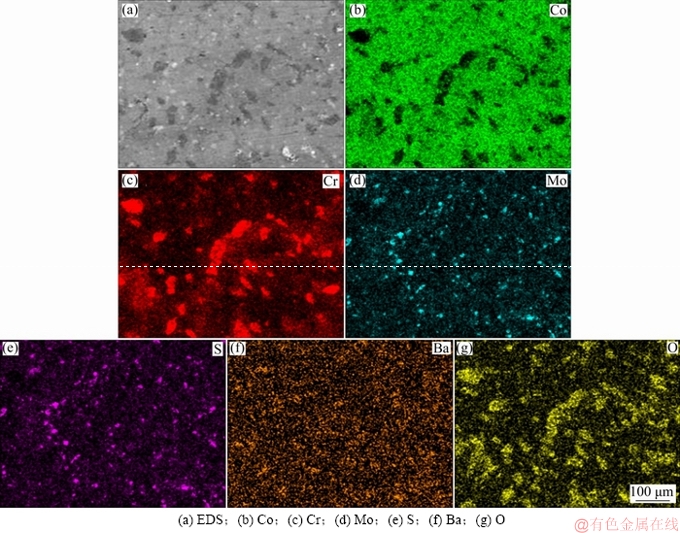

图2所示为试样J1-1的背散射电子图像(BEI)和元素的面分布。由图2可以观察到不同的相位分布在试样J1-1中,灰色部分为连续的Co合金相,其中,分散着Cr和Mo元素(见图2(a)~(d)),这表明Co,Cr和Mo元素形成了固溶。深灰色部分分布着大量的Cr和O元素,其为Cr经高温烧结后形成的氧化物Cr2O3(见图2(a),(c)和(g))。白色部分主要分布着Mo和S元素,为高温条件下化学反应生成的MoS2(见图2(a),(d)和(e))[17-18]。

2.2 力学性能

3种复合材料的力学性能如表2所示。从表2可以看出:随着BaSO4质量分数增加,试样的密度降低,造成这种密度变化的原因是BaSO4的密度比Co粉的密度小[19]。同样,试样的硬度也随着BaSO4质量分数的增大而减小,这和在烧结过程中BaSO4的部分分解有关。试样的硬度主要受Mo元素和Cr元素的强化作用和S元素的弱化作用影响,试样J1-1的硬度较大,这是因为Mo和Cr对材料的固溶强化作用。随着BaSO4质量分数增多,S的弱化作用增强,Mo和Cr的固溶强化作用减弱,最终表现为硬度降低,因此试样J1-2和J1-3的硬度较小。由此可见,要保证复合材料的硬度必须适当控制BaSO4的添加量[20]。

表2 复合材料的力学性能

Table 2 Mechanical properties of composites

图1 复合材料的XRD谱图

Fig. 1 XRD patterns of composites

2.3 摩擦磨损性能

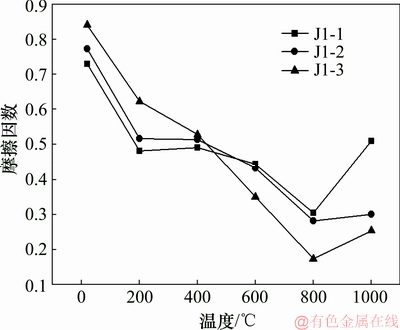

图3所示为3种试样在不同温度下的摩擦因数变化曲线。在室温至800 ℃的范围内,3种试样的摩擦因数均表现出随着温度升高,摩擦因数逐渐降低的趋势,这是由于铬酸盐和钼酸盐在高温下起到了润滑作用。在室温下,试样J1-1表现出比试样J1-2和J1-3更低的摩擦因数,约为0.73。在400 ℃时,3种试样的摩擦因数相近,约为0.51。而在800 ℃时,试样J1-3的摩擦因数较试样J1-1和J1-2的更低,约为0.17。这说明随着BaSO4质量分数增加,复合材料的高温摩擦性能明显得到了改善。而在1 000 ℃时,复合材料的摩擦因数则开始呈现出上升趋势,这可能与温度过高,润滑膜开始分解,失去了润滑作用有关[21]。

图2 试样J1-1的背散射电子图像(BEI)及元素面分布

Fig. 2 Backscatter electronic image (BEI) and elemental surface distribution of J1-1

图3 复合材料在不同温度下的摩擦因数曲线

Fig. 3 Vibration of friction coefficient of sintering composites at different temperatures

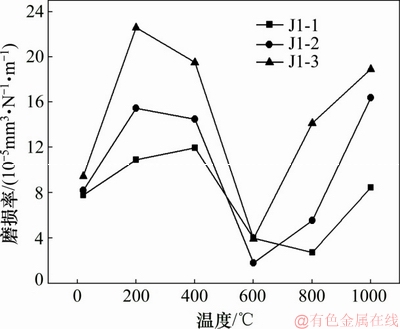

图4 复合材料在不同温度下的磨损率曲线

Fig. 4 Vibration of wear rate of sintering composites at different temperatures

图4所示为3种试样在室温到1 000 ℃下的磨损率变化曲线。从图4可以发现:在室温至1 000 ℃的范围内,除600 ℃外,试样J1-1的磨损率比J1-2和J1-3的磨损率都低,这主要是因为试样J1-2和J1-3中BaSO4的质量分数较试样J1-1的有所增加,导致试样J1-1的密度和硬度相对较大,故试样J1-1的磨损率比试样J1-2和J1-3的小。随温度升高,3种复合材料的磨损率表现出相同的变化趋势。室温时,3种复合材料的磨损率均在10-5 mm3/(N m)数量级,为轻微磨损;随着温度升高至200 ℃,复合材料的硬度逐渐降低,同时材料表面的氧化层开始形成但未完全覆盖表面,抗变形能力减弱,故3种复合材料的磨损率急速升高;而当温度从200 ℃上升到600 ℃时,磨损开始减小,特别是从400 ℃升温到600 ℃时,复合材料的磨损率迅速下降,这主要是因为随着温度的升高,磨损表面形成的钼酸盐和铬酸盐等,如Ba3(CrO4)2和CoMoO4等,逐渐表现出了润滑效果;在800 ℃时,试样J1-1的磨损率还保持下降趋势,而试样J1-2和J1-3的磨损率则有所升高。1 000 ℃时,3种复合材料的磨损率都呈现出上升的趋势,这是由于温度过高,材料软化使得摩擦表面塑性变形较大造成的[17]。

m)数量级,为轻微磨损;随着温度升高至200 ℃,复合材料的硬度逐渐降低,同时材料表面的氧化层开始形成但未完全覆盖表面,抗变形能力减弱,故3种复合材料的磨损率急速升高;而当温度从200 ℃上升到600 ℃时,磨损开始减小,特别是从400 ℃升温到600 ℃时,复合材料的磨损率迅速下降,这主要是因为随着温度的升高,磨损表面形成的钼酸盐和铬酸盐等,如Ba3(CrO4)2和CoMoO4等,逐渐表现出了润滑效果;在800 ℃时,试样J1-1的磨损率还保持下降趋势,而试样J1-2和J1-3的磨损率则有所升高。1 000 ℃时,3种复合材料的磨损率都呈现出上升的趋势,这是由于温度过高,材料软化使得摩擦表面塑性变形较大造成的[17]。

2.4 磨损机理

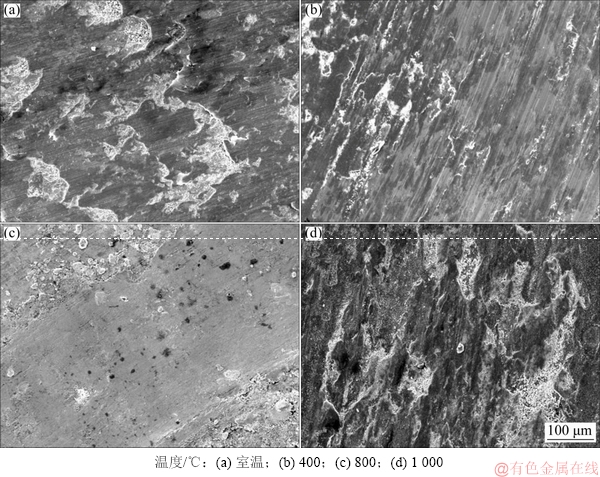

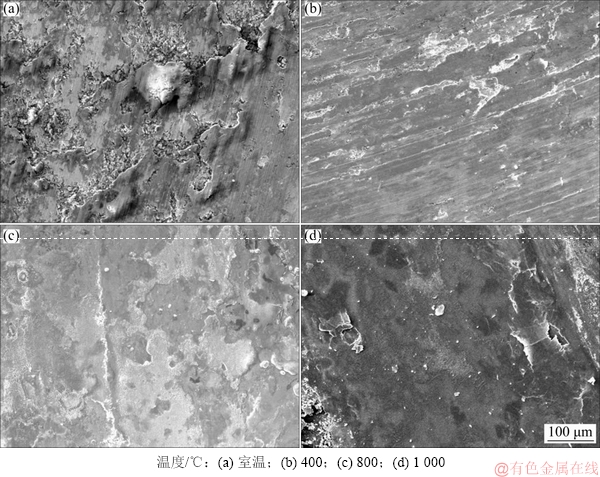

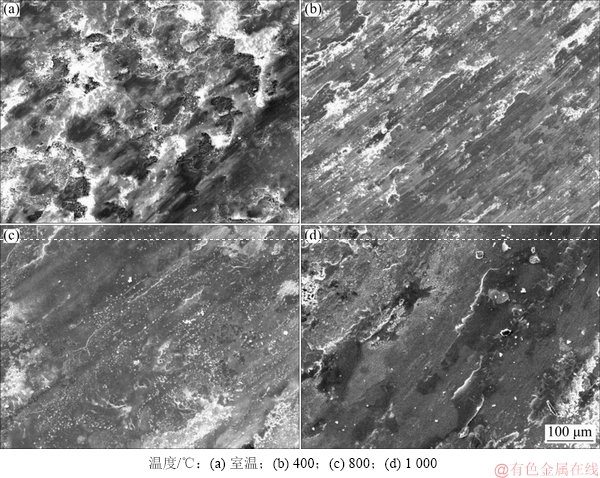

3种试样的SEM磨损表面形貌如图5~7所示。由图5(a)、图6(a)和图7(a)可知:在室温下,3种复合材料表现出相似的磨损机理,磨损表面磨屑较多,且存在少量的裂纹和轻微犁沟,磨损机理主要为磨粒磨损[22]。随着温度从室温升到400 ℃,磨损表面上开始形成不连续的润滑膜,这种润滑膜的形成可以阻止基体直接与对偶接触,增加基体与对偶间的润滑性,同时,磨损表面上出现了明显的犁沟,磨损机理主要为犁沟磨损[23](图5(b)、图6(b)和图7(b))。在600~1 000 ℃内,Co,Ba3(CrO3)2和CoMoO3在高温下与氧气反应,在磨痕上逐渐形成了新的氧化物,钼酸盐和铬酸盐,如CoO,Co3O4,Ba3(CrO4)2和CoMoO4等(见图8),可作为高温固体润滑剂,提供润滑作用[24]。在800 ℃时,复合材料摩擦表面形成了比较光滑和完整的润滑膜,其主要由铬酸盐、钼酸盐及氧化物等组成,使得复合材料的摩擦因数和磨损率较低,具有优异的高温摩擦学性能,其磨损机理主要为氧化磨损(见图5(c)、图6(c)和图7(c))。在1 000 ℃时,摩擦表面上的润滑膜开始出现裂纹,甚至有剥落现象,这可能是温度过高,润滑膜开始分解所致(见图5(d)、图6(d)和图7(d))。

图5 不同温度下试样J1-1的磨损表面SEM图片

Fig. 5 SEM images of worn surfaces of J1-1 at different temperatures

图6 不同温度下试样J1-2的磨损表面SEM图片

Fig. 6 SEM images of worn surfaces of J1-2 at different temperatures

图7 不同温度下试样J1-3的磨损表面SEM图片

Fig. 7 SEM images of worn surfaces of J1-3 at different temperatures

图8 1 000 ℃下试样J1-2磨痕的XRD谱图

Fig. 8 XRD pattern of wear track of J1-2 at 1 000 ℃

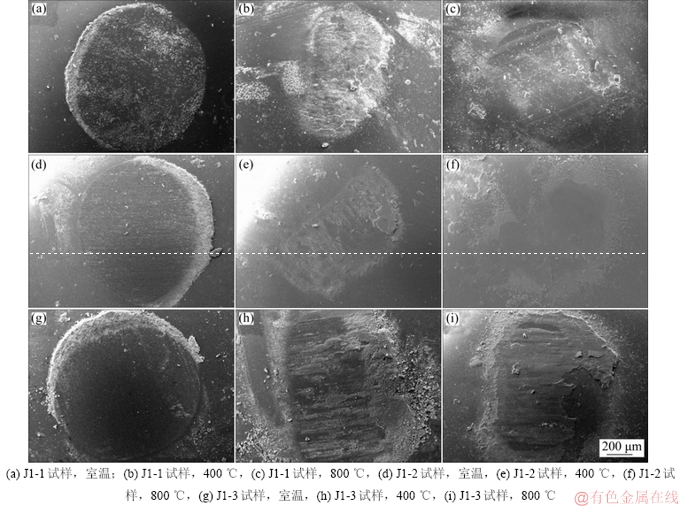

图9所示为对偶Si3N4陶瓷球与试样在不同温度下对磨后的磨损形貌图片。从图9可以看出:随着温度的上升,Si3N4球的磨损面积逐渐减小,这意味着Si3N4球在温度较高时的磨损较低[25]。在室温时,摩擦面上存在大量的磨屑,这说明此时复合材料的磨损机理主要为磨粒磨损(见图9(a),(d)和(g));在400 ℃时,摩擦面上开始出现材料转移,对偶件的摩擦面上有不连续的润滑膜,这应该是复合材料上产生的润滑膜剥落所致,同时,摩擦面上有犁沟磨损的痕迹(见图9(b),(e)和(h))[18];在800 ℃时,Si3N4球的磨损面上有连续的润滑膜覆盖,这是由于在800 ℃时,复合材料的磨损面形成了完整的润滑膜(见图9(c),(f)和(i))。不同温度下对偶Si3N4陶瓷球的摩擦学行为与3种试样的摩擦学行为相符。

图9 Si3N4陶瓷球在不同温度下的磨损表面形貌

Fig. 9 Worn surfaces of Si3N4 ceramic balls at different temperatures

3 结论

1) 利用热压烧结方法制备了3种不同BaSO4质量分数的钴基自润滑复合材料。3种复合材料的相组成几乎没有差别,主要为Co-Cr-Mo固溶体,Cr2O3,MoS2,Ba3(CrO3)2和CoMoO3等。

2) 在相同试验条件下,室温至800℃范围内,3种试样的摩擦因数随着试验温度的升高而逐渐下降,且在高温下,BaSO4含量较高的试样J1-3的摩擦因数最低。同时,在室温至1 000 ℃范围内,试样J1-1的磨损率较试样J1-2和J1-3的更低,这可能是硬度变化对其磨损率的影响,复合材料中BaSO4所占比例越多,硬度越低。说明BaSO4对于钴基自润滑复合材料的高温润滑性能有较大影响。

3) 3种钴基自润滑复合材料中,含10%BaSO4的复合材料在400~800 ℃范围内摩擦学性能较好。

4) 在室温时,3种钴基自润滑复合材料的摩擦机理主要为磨粒磨损,在400 ℃时,为犁沟磨损,在800 ℃时,为氧化磨损。

参考文献:

[1] 陈光. 航空发动机发展综述[J]. 航空制造技术, 2000(6): 24-27, 34.

CHEN Guang. Survey on aero-engine development[J]. Aeronautical Manufacturing Technology, 2000(6): 24-27, 34.

[2] DA SILVA L J , D’OLIVEIRA A S C M. NiCrSiBC coatings: effect of dilution on microstructure and high temperature tribological behavior[J]. Wear, 2016, 350/351: 130-140.

[3] PAUSCHITZ A, ROY M, FRANEK F. Mechanisms of sliding wear of metals and alloys at elevated temperatures[J]. Tribology International, 2008, 41(7): 584-602.

[4] 张楷, 刘益才, 谢海波, 等. 热端温度对热声发动机性能影响的数值研究[J]. 中南大学学报(自然科学版), 2015, 46(10): 3936-3943.

ZHANG Kai, LIU Yicai, XIE Haibo, et al. Numerical research on effect of hot end temperature on thermoacoustic engine performance[J]. Journal of Central South University(Science and Technology), 2015, 46(10): 3936-3943.

[5] KASHANI H, AMADEH A, GHASEMI H M. Room and high temperature wear behaviors of nickel and cobalt base weld overlay coatings on hot forging dies[J]. Wear, 2007, 262(7/8): 800-806.

[6] KORASHY A, ATTIA H, THOMSON V, et al. Characterization of fretting wear of cobalt-based superalloys at high temperature for aero-engine combustor components[J]. Wear, 2015, 330/331: 327-337.

[7] SCHARF T W, PRASAD S V, KOTULA P G, et al. Elevated temperature tribology of cobalt and tantalum-based alloys[J]. Wear, 2015, 330/331: 199-208.

[8] MURRAY S F, CALABRESE S J. Low speed sliding behavior of metal-ceramic couples at temperatures up to 800℃[J]. Lubrication Engineering, 1993, 49(5): 955-964.

[9] WANG L, LI D Y. Effects of yttrium on microstructure, mechanical properties and high-temperature wear behavior of cast Stellite 6 alloy[J]. Wear, 2003, 255(1/2/3/4/5/6): 535-544.

[10] SUZUKI A. High-temperature strength and deformation of γ/γ' two-phase Co-Al-W-base alloys[J]. Acta Materialia, 2008, 56(6): 1288-1297.

[11] 刘明凯, 任秋荣, 李向召. 水泥基压电复合材料的制备及其性能研究[J]. 制造业自动化, 2011, 33(11): 97-100.

LIU Mingkai, REN Qiurong, LI Xiangzhao. Study on fabrication and properties cement-based piezoelectric composites[J]. Manufacturing Automation, 2011, 33(11): 97-100.

[12] 郑亮, 谷臣清, 于保正, 等. 低Cr高W铸造镍基高温合金的高温氧化行为及Ta的合金化作用[J]. 航空材料学报, 2005, 25(5): 1-7.

ZHENG Liang, GU Chenqing, YU Baozheng, et al. High-temperature oxidation behavior of low Cr and high W content cast Ni-base superalloys and the effect of Ta alloying[J]. Journal of Aeronautical Materials, 2005, 25(5): 1-7.

[13] 沈胜利, 张芬. 机床用新型钴基金属复合材料的制备与性能研究[J]. 制造业自动化, 2015(7): 26-28.

SHEN Shengli, ZHANG Fen. Preparation and properties of the new-type Co-based metal cobalt fund composite materials for machine tools[J]. Manufacturing Automation, 2015(7): 26-28.

[14] 毛冲冲. 硫酸盐固体润滑材料的制备与高温润滑机理研究[D]. 哈尔滨:哈尔滨工业大学材料科学与工程学院, 2016.

MAO Chongchong. Preparation of sulfate solid lubricant materials and lubrication mechanism at high temperature[D]. Harbin: Harbin Institute of Technology. School of Materials Science and Engineering, 2016.

[15] 刘胜明, 汤爱涛, 赵子鹏. 添加Co, Ni和Mo对钛铁矿原位合成Al2O3-Ti(C,N)-Fe复合材料的影响[J]. 中南大学学报(自然科学版), 2014, 45(8): 2589-2595.

LIU Shengming, TANG Aitao, ZHAO Zipeng. Influence of Co, Ni and Mo on microstructure and properties of Al2O3-Ti(C,N)-Fe composites by ilmenite in-situ synthesis from ilmenite[J]. Journal of Central South University(Science and Technology), 2014, 45(8): 2589-2595.

[16] CUI G, HAN J, WU G. High-temperature wear behavior of self-lubricating Co matrix alloys prepared by P/M[J]. Wear, 2016, 346/347: 116-123.

[17] 陕钰, 刘峰, 汪建义, 等. NiCrW-Al2O3-SrCO3-Ag金属陶瓷复合材料的高温摩擦学性能研究[J]. 摩擦学学报, 2015, 35(6): 707-713.

SHAN Yu, LIU Feng, WANG Jianyi, et al. High-temperature tribological properties of NiCrW-Al2O3-SrCO3-Ag cement composites[J]. Journal of Tribology, 2015, 35(6): 707-713.

[18] 郭志成, 李长生, 唐华, 等. Fe-Ni基高温自润滑复合材料摩擦磨损特性研究[J]. 摩擦学学报, 2013, 33(3): 253-261.

GUO Zhicheng, LI Changsheng, TANG Hua, et al. Tribological properties of Fe-Ni matrix solid self-lubricant composite at high temperature[J]. Tribology, 2013, 33(3): 253-261.

[19] 王天国, 梁启超, 覃群. Al2O3含量对铜基粉末冶金摩擦材料摩擦磨损性能的影响[J]. 粉末冶金工业, 2016, 26(1): 46-50.

WANG Tianguo, LIANG Qichao, QU Qun. Effect of Al2O3 content on friction and wear properties of copper-based powder metallurgy friction materials[J]. Powder Metallurgy Industry, 2016, 26(1): 46-50.

[20] 董丽荣, 李长生, 丁巧党, 等. LaF3与MoS2对镍铬基复合材料摩擦学特性的影响[J]. 润滑与密封, 2007, 32(10): 55-61.

DONG Lirong, LI Changsheng, DING qiaodang, et al. Effect of LaF3 and MoS2 on tribological properties of Ni-Cr based composite[J]. Lubrication Engineering, 2007, 32(10): 55-61.

[21] 屈盛官, 袁志敏, 赖福强, 等. 中重型车辆离合器摩擦副材料的高温摩擦磨损性能[J]. 中南大学学报(自然科学版), 2018, 49(5): 1087-1094.

QU Shengguan, YUAN Zhimin, LAI Fuqiang, et al. Friction and wear properties for clutch friction materials in medium-heavy-duty vehicle at high temperature[J]. Journal of Central South University(Science and Technology), 2018, 49(5): 1087-1094.

[22] 甄金明, 李斐, 朱圣宇, 等. Ti对镍基高温自润滑复合材料力学和摩擦学性能的影响[J]. 摩擦学学报, 2014, 34(5): 586-591.

ZHEN Jinming, LI Fei, ZHU Shengyu, et al. The influence of Ti on mechanical and tribological properties of nickel-based high-temperature self-lubricating composites[J]. Tribology, 2014, 34(5): 586-591.

[23] 黄文翔, 韩靖, 戴光泽, 等. 铝含量对铜基石墨粉末冶金材料性能的影响[J]. 润滑与密封, 2018, 43(1): 30-36.

HUANG Wenxiang, HAN Jing, DAI Guangze, et al. Effects of Al content on properties of Cu-matix graphite powder metallurgy materials[J]. Lubrication Engineering, 2018, 43(1): 30-36.

[24] 尹洪. 镍基高温自润滑复合材料的摩擦学行为研究[D].哈尔滨: 哈尔滨工业大学材料科学与工程学院, 2015: 10-31.

YIN Hong. Study on tribological behavior of nickel based high temperature self-lubricating composites[D]. Harbin: Harbin Institute of Technology. School of Materials Science and Engineering, 2015: 10-31.

[25] 李惠, 焦雷, 陆鹏程, 等. CuCo2Be合金表面等离子喷涂Cr3C2-NiCr/NiAl复合涂层不同温度下的摩擦磨损特性[J]. 稀有金属材料与工程, 2018, 47(2): 588-593.

LI Hui, JIAO Lei, LU Pengcheng, et al.Friction and wear properties of plasma sprayed Cr3C2-NiCr/NiAl composite coating on CuCo2Be alloy at different temperatures[J].Rare Metal Materials and Engineering, 2018, 47(2): 588-593.

(编辑 赵俊)

收稿日期: 2018 -09 -18; 修回日期: 2018 -11 -23

基金项目(Foundation item):国家自然科学基金资助项目(51775365)(Project(51775365) supported by the National Natural Science Foundation of China)

通信作者:崔功军,博士,副教授,从事机械摩擦学研究;E-mail:cuigongjun@tyut.edu.cn