DOI: 10.11817/j.issn.1672-7207.2017.06.006

超临界马氏体不锈钢热变形行为

王梦寒,王瑞,王根田,孟烈

(重庆大学 材料科学与工程学院,重庆,400044)

摘要:在Gleeble-3500热模拟试验机上对超临界马氏体不锈钢进行等温压缩试验,研究其高温流变行为,获得超临界马氏体不锈钢在温度为900~1 150 ℃、变形速率为0.005~5 s-1时合金的热变形行为和组织演变。通过对实验数据的分析、拟合建立材料的高温流变模型,并分析Johnson-Cook(JC) 模型和Arrhenius模型对超临界马氏体不锈钢的适用性。研究结果表明:修正后的JC模型和Arrhenius模型具有更高的精度。在应变速率较高时,修正的JC模型的预测值更接近实验值;在应变速率较低时,应变补偿的Arrhenius模型的预测值更接近实验值。载荷预测结果与实验值拟合程度较好,表明建立的模型能够描述材料的高温流变行为。

关键词:马氏体不锈钢;流变应力;Arrhenius模型;本构模型

中图分类号:TG146.2 文献标志码:A 文章编号:1672-7207(2017)06-1448-10

Hot behavior of supercritical martensitic stainless steel at elevated temperature

WANG Menghan, WANG Rui, WANG Gentian, MENG Lie

(College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China)

Abstract: Isothermal hot compression tests of supercritical martensitic steel were performed on a Gleeble-3500 thermo-mechanical simulator at the temperature range of 900-1 150 ℃ and the strain rate range of 0.005-5 s-1 to obtain the flow stress-strain curves. Based on the experimental data, modified constitutive models were developed, and the suitability of Johnson-Cook (JC) and Arrhenius flow stress models to the studied steel was discussed. The results indicate that the modified constitutive models are more accurate in predicting the flow stress. The modified JC model is more accurate under high strain rate conditions, while the Arrhenius model is more accurate at low strain rate conditions. The values of experimental load and predicted load show a good agreement, indicating that the developed model is adequate to describe the flow behavior of the steel.

Key words: martensitic stainless steel; flow stress; Arrhenius model; constitutive model

随着现代社会对能源的需求的不断扩大,大功率、高参数、高热效率已经成为汽轮机发展的趋势[1-2]。与传统的汽轮机相比,超临界汽轮机的蒸汽温度和蒸汽压力均得到了提高,因此,特殊的工作环境对材料有了更高的要求。马氏体不锈钢具有较好的耐蚀性、抗拉强度、可焊接性等优良性能,因此,马氏体不锈钢在石油天然气传输管道、造船、汽轮机叶片等行业具有广泛的应用,为了确定材料在高温、高应变速率和大应变条件下的力学行为,建立在此条件下的本构模型,对研究材料在高温变形条件下的成形机理具有重要的意义。目前,国内外关于超临界马氏体不锈钢的研究主要集中在热处理、合金元素、可焊接性等方面。陈亚宁[3]对轧制大型材生产过程中影响δ铁素体含量的因素进行了分析与讨论。佐辉等[4]研究了钢中δ-铁素体含量的影响因素,并且分析了不同的淬火、回火温度对材料的力学性能的影响。丁建生等[5]研究了热处理对材料组织性能的影响,分析了材料热处理后的强度与冲击韧度之间的关系。而对材料高温下的变形规律的研究却鲜见报道。为此,本文作者通过对2Cr11Mo1VNbN 马氏体不锈钢进行高温压缩实验,研究了在900~1 150 ℃、变形速率为0.005~5 s-1时材料的变形情况,建立描述材料性能的本构方程,并对建立的模型的精确度进行验证,为超临界马氏体不锈钢热锻造模拟工艺的数值模拟及热成形工艺的制定提供参考。

1 材料和实验方法

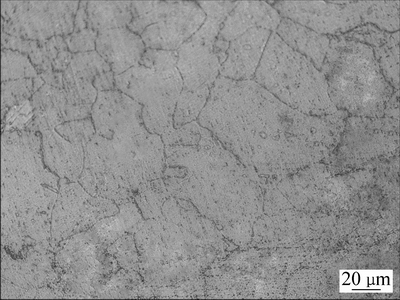

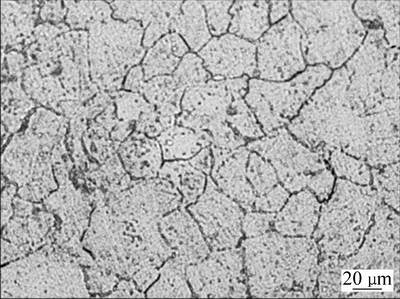

实验试样选用2Cr11Mo1VNbN马氏体不锈钢,通过线切割制成直径×长度为8 mm×12 mm的圆柱体,其原始组织如图1 所示。在Gleeble-3500热模拟试验机上进行高温热压缩实验。实验设计热压缩变形温度为900,1 000,1 100和1 150 ℃,应变速率为0.005,0.05,0.5和5 s-1。试样压缩前首先以10 ℃/s的速度加热到1 200 ℃,保温3 min,以得到均匀的奥氏体组织,然后以20 ℃/s的冷却速度降温至变形温度并保温2 min以消除试样内部的温度梯度,随后在设定的温度和应变速率下进行等温压缩,变形结束后对试样进行迅速冷却以保留其高温变形组织。

图1 试样的原始光学显微组织

Fig. 1 Original optical microstructure of steel

2 实验结果分析

2.1 流变应力曲线

图2所示为2Cr11Mo1VNbN钢在不同变形条件下的等温压缩的真实应力-应变曲线。由图2可知:材料的流变应力对变形温度、应变量和应变速率较为敏感,随着变形程度增加,流变应力增加到某一峰值,然后逐渐降低到某一稳态值,表明在热变形过程中材料发生了动态再结晶,从而使得材料的流变应力降低[6-9]。在初始变形阶段,由于变形量较小,只有少量的组织发生了动态回复,由动态回复造成的软化作用远远小于加工硬化作用,导致材料的流变应力随着应变的增加而迅速增大。随着变形量增大,材料内部发生了明显的动态回复和动态再结晶行为,由此带来的软化作用越来越明显,逐渐超过了加工硬化作用,使得材料的流变应力逐渐下降。当材料内部的软化行为与加工硬化行为达到动态平衡时,材料的流变应力趋于平稳。在同一应变温度下,流变应力随着应变速率的升高而增大,这是因为随着应变速率的增大,位错增殖速度增大,位错运动阻力增大,从而使得流变应力增大;在同一应变速率下,流变应力随着温度的升高而降低,这是由于温度的升高使得原子运动具有更大的驱动力,原子的扩散速度加快,位错运动的阻力变小,从而使得变形抗力降低。

2.2 Johnson-Cook模型

JC本构模型[10]考虑了大应变、应变速率和温度对材料的影响,其本构模型表达式如下:

(1)

(1)

其中:σ为流动应力;ε为等效应变; 为相对等效塑性应变速率;

为相对等效塑性应变速率; 为参考应变速率;

为参考应变速率; 为应变速率;T*为相对参考温度;

为应变速率;T*为相对参考温度; ,Tm为金属的熔点,Tr为参考温度;参数A,B,C,n,m为待定的材料参数。通常,取最小应变速率0.005 s-1,参考温度取最低实验温度900 ℃。

,Tm为金属的熔点,Tr为参考温度;参数A,B,C,n,m为待定的材料参数。通常,取最小应变速率0.005 s-1,参考温度取最低实验温度900 ℃。

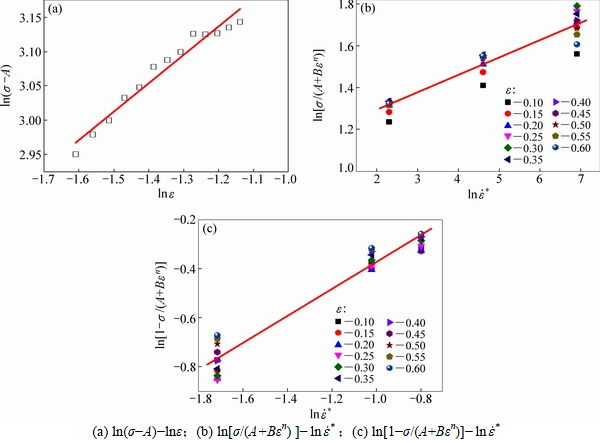

当温度为900 ℃,应变速率为0.005 s-1时,将应力、应变代入式(1)中,利用最小二乘法拟合求得n和B,如图3(a)所示,n=0.414,B=37.87。然后保持n和B不变,将900 ℃时应变速率为0.005,0.05,0.5,5 s-1代入式(1)。通过拟合得到C=0.083,如图3(b)所示。然后将应变为0.1~0.6(间隔0.05)条件下的热压缩实验数据代入式(1),利用最小二乘法拟合可得m=0.549,如图3(c)所示。

图2 不同变形条件下的2Cr11Mo1VNbN钢真实应力-应变曲线

Fig. 2 True stress-true strain curves of 2Cr11Mo1VNbN steel under different conditions

图3 ln(σ-A)-lnε,ln[σ/(A+Bεn) ]- 和ln[1-σ/(A+Bεn)]-

和ln[1-σ/(A+Bεn)]- 线性拟合关系

线性拟合关系

Fig. 3 Relationship among ln(σ-A)-lnε, ln[σ/(A+Bεn) ]- and ln[1-σ/(A+Bεn)]-

and ln[1-σ/(A+Bεn)]-

将拟合求得的n,B,m代入式(1),即可得出材料高温下的Johnson-Cook本构模型:

(2)

(2)

建立的JC模型的预测效果如图4所示。

通过对比JC模型的预测值与实验真实应力-应变曲线对比发现,建立的JC模型不能很好地预测材料的流变应力,因此,建立的模型需要进行修正。

2.3 JC模型修正

JC模型的基础上,LIN等[11]对模型进行了改进,提出如下模型:

(3)

(3)

式中:B0,B1,B2,B3,C1,λ1,λ2为材料常数;T为变形温度;Tr一般取最低实验温度。与式(1)相比,式(3)等号右侧的3项分别表示塑性应变、应变速率和温度-应变速率对流变应力的影响水平。

通过将不同条件下的实验数据代入式(3),通过σ/(B0+B1ε+B2ε2+B3ε3)- ,

,

关系的最小二乘线性拟合,分别求得B0=124.44 MPa,B1=267.90 MPa,B2=-617.13 MPa,B3=449.12 MPa,C=0.104 84,λ1=-0.005 6 和 λ2=0.000 39。因此,修正后的JC流变应力本构模型可以表示为

关系的最小二乘线性拟合,分别求得B0=124.44 MPa,B1=267.90 MPa,B2=-617.13 MPa,B3=449.12 MPa,C=0.104 84,λ1=-0.005 6 和 λ2=0.000 39。因此,修正后的JC流变应力本构模型可以表示为

(4)

(4)

修正后的JC模型的预测值与实验数据对比结果如图5所示。由图5可以看到,修正后的JC本构模型能够较好地逼近实验得到的应力应变曲线。

2.4 Arrhenius流变应力模型

金属材料在高温变形过程中,材料的流变应力主要受变形量、变形温度和应变速率影响。在金属塑性变形过程中,流变应力模型可以通过双曲正弦模型[12-14]表示:

(5)

(5)

在不同的应力水平下,流变应力与应变速率有如下关系:

(6)

(6)

其中:A,β和α为与温度无关的材料常数, ;n为应力指数;α为应力水平参数;Q为材料的热变形激活能(kJ·mol-1);R为摩尔气体常数(8.314 J·mol-1·K-1);T为热力学温度(K)。

;n为应力指数;α为应力水平参数;Q为材料的热变形激活能(kJ·mol-1);R为摩尔气体常数(8.314 J·mol-1·K-1);T为热力学温度(K)。

图4 不同变形条件下JC模型预测结果与实验结果的比较

Fig. 4 Comparison of JC model prediction results and experimental results under different conditions

图5 修正后的JC流变应力模型的预测结果与实验结果的对比

Fig. 5 Comparison between experimental flow stress with prediction result of modified JC model

根据Zener-Hollomon提出的理论,变形温度和应变速率对流变应力的影响可以用Z参数因子表示[15-21]:

(7)

(7)

将式(6)代入式(5),并对公式两边取对数可以得到:

(8)

(8)

(9)

(9)

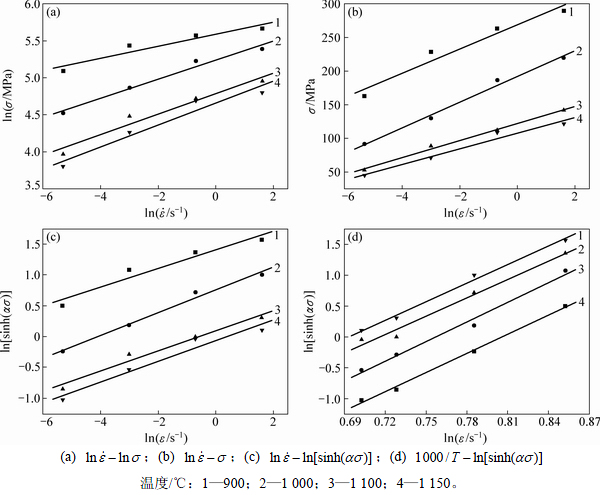

取不同应变下的流动应力,分别作 ,

, 的关系曲线,如图6(a)和6(b)所示。当变形温度一定时,

的关系曲线,如图6(a)和6(b)所示。当变形温度一定时, 分别与lnσ和σ成线性关系,利用偏微分可求得材料常数n和β。采用最小二乘法进行线性回归,得到n=5.992 5,β=0.066 6,

分别与lnσ和σ成线性关系,利用偏微分可求得材料常数n和β。采用最小二乘法进行线性回归,得到n=5.992 5,β=0.066 6, 。

。

当应变速率为常数时,假定在很小的范围内变形激活能Q保持不变,对式(5)取对数可以得到

(10)

(10)

当变形温度和应变速率一定时,利用偏微分可以求得:

(11)

(11)

(12)

(12)

根据式(11)和(12)可知 和

和 拟合曲线斜率即为n和Q,可以得到:n=5.992 5,Q=509.71 kJ/mol,如图6(c)和6(d)所示。从而求得A=1.00×1019。分别将Q,α,n 和A 代入式(5)和(7),即可得到超临界马氏体不锈钢的高温流变应力模型:

拟合曲线斜率即为n和Q,可以得到:n=5.992 5,Q=509.71 kJ/mol,如图6(c)和6(d)所示。从而求得A=1.00×1019。分别将Q,α,n 和A 代入式(5)和(7),即可得到超临界马氏体不锈钢的高温流变应力模型:

(13)

(13)

(14)

(14)

(15)

(15)

式中:σp为变形过程中应力峰值。

图6  ,

, ,

, 和

和 线性拟合关系

线性拟合关系

Fig. 6 Relationship between  and lnσ,

and lnσ,  and σ,

and σ,  and ln[sinh(ασ)], 1 000/T and ln[sinh(ασ)]

and ln[sinh(ασ)], 1 000/T and ln[sinh(ασ)]

考虑应变对合金热变形时流变应力的影响,用不同应变下(0.1~0.65,间隔0.05)计算求得的材料参数Q,α,n 和lnA来建立合金的Arrhenius本构模型。经过分析和计算,得出各参数与应变之间存在一定函数关系,如图7所示。各参数随应变变化的五次多项式拟合函数关系式如式(16)所示。由图7可知,在应变较小时,α 随应变的增加而逐渐减小,然后趋于稳定。Q,n和lnA则随应变的增加而逐渐减小。说明超临界马氏体不锈钢的热变形激活能Q 等材料参数都不是常数,而是随应变的改变而发生变化。

(16)

(16)

考虑应变补偿的Arrhenius本构方程预测结果与实验结果对比如图8所示。从图8可以看出:建立的本构方程的预测结果与实验值较为接近,表明应变补偿的本构方程能够很好地预测材料的高温流变行为。由于在高温变形下材料流动行为的非线性[23-24],在温度为1 150 ℃、应变速率为0.5 s-1时,模型预测结果要低于实验结果,在其他条件下,模型预测结果能够与实验结果很好地吻合。因此,建立的本构模型能够为该材料高温下成形工艺中的温度、变形量、变形速度等工艺参数的制定提供参考。

2.5 模型精度比较

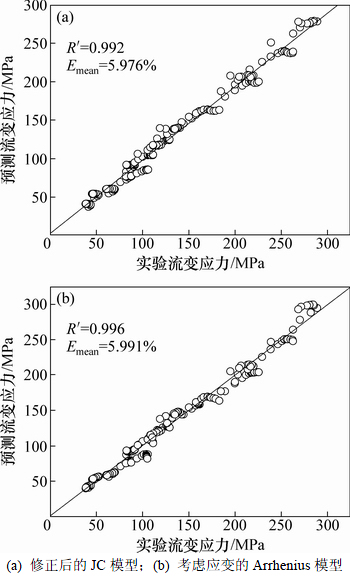

为了验证修正后的JC模型与引入ε的Arrhenius本构模型预测流变应力的准确性,分别对2个模型的预测结果与实验结果进行对比,如图8所示,通过式(17)和(18)中的相关系数(R′)和平均相对误差Emean可以对模型的预测精确度进行评价:

(17)

(17)

(18)

(18)

图7 五次多项式拟合α,n,Q,ln A随ε的变化

Fig. 7 Relationships of the fifth times polynomial fit between material constants α, n, Q, lnA and strain

图8 建立的Arrhenius流变应力模型的预测结果与实验数据的对比

Fig. 8 Comparison between the experimental flow stress data with the prediction of Arrhenius model

式中:Ei为实验所获得的流动应力;Pi为使用模型预测的流动应力; 和

和 分别为实验所获得的流动应力平均值和预测流动应力的平均值;N为用于统计的实验数据数量。

分别为实验所获得的流动应力平均值和预测流动应力的平均值;N为用于统计的实验数据数量。

实验结果与预测结果的对比如图9所示。结果显示:修正后的JC模型和应变补偿的Arrhenius模型能很好地预测材料的高温流变应力,修正的JC模型预测值与实验值相关系数R′及平均相对误差分别为0.992和5.978%,考虑应变的Arrhenius模型预测值与实验值相关系数R′及平均相对误差分别为0.996和5.991%。在应变速率较高条件下,修正的JC模型的预测值更接近实验值;在应变速率较低时,考虑应变的Arrhenius模型的预测值更接近实验值。

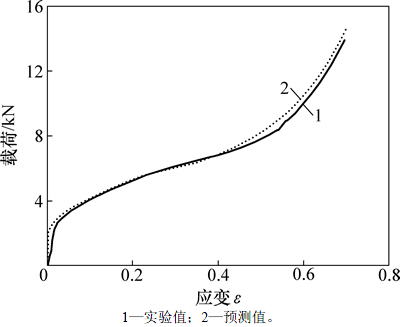

图10所示为压缩变形载荷的实验结果与模拟结果对比。通过对比可以发现,在变形的初始阶段,预测结果与实际结果的差值较大,随着变形的继续进行,材料由弹性变形阶段进入塑性变形阶段,预测结果与实验结果的一致性较好,表明建立的本构模型的精度高,能够准确地描述材料的高温流变行为。

图9 实验值与模型预测结果的比较

Fig. 9 Comparison between predicted and experimental results

图11所示为1 000 ℃, =0.05 s-1,ε=0.7条件下材料的光学显微组织。通过与图1(a)中材料的原始光学显微组织的对比可以发现,原始的粗大的晶粒组织经过高温条件下变形以后,晶粒组织变得均匀,平均晶粒粒径减小,从而验证了该条件下材料发生了再结晶行为,使得材料的流变应力降低,平均晶粒粒径减小,为细化晶粒、优化材料的成形工艺参数提供依据。

=0.05 s-1,ε=0.7条件下材料的光学显微组织。通过与图1(a)中材料的原始光学显微组织的对比可以发现,原始的粗大的晶粒组织经过高温条件下变形以后,晶粒组织变得均匀,平均晶粒粒径减小,从而验证了该条件下材料发生了再结晶行为,使得材料的流变应力降低,平均晶粒粒径减小,为细化晶粒、优化材料的成形工艺参数提供依据。

图10 在1 100 ℃, =0.05 s-1,ε=0.7条件下载荷的实验值与预测值对比

=0.05 s-1,ε=0.7条件下载荷的实验值与预测值对比

Fig. 10 Comparison between experimental and predicted results at 1 100 ℃,  =0.05 s-1, ε=0.7

=0.05 s-1, ε=0.7

图11 在1 000 ℃, =0.05 s-1,ε=0.7条件下试样的光学显微组织

=0.05 s-1,ε=0.7条件下试样的光学显微组织

Fig. 11 Optical microstructure of samples at 1 100 ℃,  =0.05 s-1, ε=0.7

=0.05 s-1, ε=0.7

3 结论

1) 超临界马氏体不锈钢在温度为900~1 150 ℃、应变速率为0.005 s-1时的流变应力主要受变形温度、应变和应变速率的影响。在相同的温度下,材料的流变应力随着应变速率的升高而增大;在相同应变速率条件下,材料的流变应力随着温度升高而降低。

2) 基于材料的热压缩实验结果,分别建立了材料的高温流变应力的JC和Arrhenius流变应力模型。为了提高模型预测的准确度,对建立的模型进行修正、优化,通过对比发现,修正后的模型能够很好地预测材料的高温流变应力。

3) 在应变速率较高的条件下(ε=5 s-1),修正的JC模型的预测值更接近实验值;在应变速率较低时(ε=0.005 s-1),应变补偿的Arrhenius模型的预测值更接近实验值。当应变速率在0.005~5 s-1范围内时,2个模型均能准确地反映材料的流变应力。

参考文献:

[1] 赵成志, 魏双胜, 高亚龙, 等. 超临界与超超临界汽轮机耐热钢的研究进展[J]. 钢铁研究学报, 2007, 19(9): 1-5.

ZHAO Chengzhi, WEI Shuangsheng, GAO Yalong, et al. Progress of heat-resistant steel for supercritical and ultra-supercritical steam turbine[J]. Journal of Iron and Steel Research, 2007, 19(9): 1-5.

[2] 刘玉荣, 业冬, 徐军, 等. 13Cr超级马氏体不锈钢组织[J]. 材料热处理学报, 2011, 32(12): 66-71.

LIU Yurong, YE Dong, XU Jun, et al. Microstructure of 13Cr super martensitic stainless stee[J]. Tran Mater Heat Treatment, 2011, 32(12): 66-71.

[3] 陈亚宁. 叶片钢2Cr11Mo1VNbN 轧制大型材δ铁素体含量的控制[J]. 特钢技术, 2010, 62(16): 18-23.

CHEN Yaning. Controlling on δ ferrite content in heavy section bars of blade steel 2Cr11Mo1VNbN[J]. Special Steel Technology, 2010, 62(16): 18-23.

[4] 佐辉, 崔海霞. 汽轮机叶片用钢2Cr11Mo1VNbN 的研制开发[J]. 特钢技术, 2007, 13(2): 1-3.

ZUO Hui, CUI Haixia. Investigation and development of steel 2Cr11Mo1VNbN for turbine blade[J]. Special Steel Technology, 2007, 13(2): 1-3.

[5] 丁建生, 王泽忠, 刘蔺勋. 热处理对超(超)临界材料组织性能的影响[J]. 铸造技术, 2011, 32(7): 930-932.

DING Jiansheng, WANG Zezhong, LIU Linxun. Study on the Effects of Heat Treatment on Structure and Properties of Ultra-supercritical Materials[J]. Foundry Technology, 2011, 32(7): 930-932.

[6] 张毅, 柴哲, 许倩倩, 等. Cu-Cr-Zr-Ag 合金高温热变形及组织演变[J]. 材料热处理学报, 2015, 36(4): 44-48.

ZHANG Yi, CHAI Zhe, XU Qianqian, et al. High temperature deformation behavior and microstructure of Cu-Cr-Zr-Ag alloy[J]. Tran Mater Heat Treatment, 2015, 36(4): 44-48.

[7] 东赟鹏, 于秋颖, 方爽, 等. TA7 钛合金高温流变行为研究[J]. 航空材料学报, 2015, 35(1): 13-19.

DONG Yunpeng, YU Qiuying, FANG Shuang, et al. Plastic deformation behavior of TA7 titanium alloy[J]. Journal of Aeronautical Materials, 2015, 35(1): 13-19.

[8] 王健, 杨海涛, 王小巩, 等. X70HD 抗大变形管线钢热变形行为[J]. 材料热处理学报, 2015, 36(1): 211-216.

WANG Jian, YANG Haitao, WANG Xiaogong, et al. Hot deformation behavior of X70HD pipeline steel with high deformability[J]. Tran Mater Heat Treatment, 2015, 36(1): 211-216.

[9] 刘俊雄, 吴向东, 万敏, 等. 基于修正的Arrhenius方程钛合金高温本构方程研究[J]. 材料科学与工艺, 2015, 23(3): 7-11.

LIU Junxiong, WU Xiangdong, WAN Min, et al. Study on hot deformation behavior of titanium alloy by modified Arrhenius equation[J]. Materials Science & Technology, 2015, 23(3): 7-11.

[10] LIN Yongcheng, CHEN Xiaoming. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working[J]. Mater Des, 2011, 32: 1733-1759.

[11] LIN Yongcheng, CHEN Xiaoming, GE Liu. A modified Johnson-Cook model for tensile behaviors of typical high-strength alloy steel[J]. Mater Sci Eng A, 2010, 527(26): 6980-6986.

[12] MCQUEEN H J, YUE S, Ryan N D, et al. Hot working characteristics of steels in austenitics state[J]. J Mater Process Technol, 1995, 53(1/2): 293-310.

[13] ZHANG Peng, HU Chao, ZHU Qiang, et al. Hot compression deformation and constitutive modeling of GH4698 alloy[J]. Mater Des, 2015, 65: 1153-1160.

[14] FENG Wei, FU Youheng. High temperature deformation behavior and constitutive modeling for 20CrMnTiH steel[J]. Mater Des, 2014, 57: 465-471.

[15] 王迎, 潘清林, 张宇玮, 等. GH4169 镍基高温合金热压缩变形行为和加工图[J]. 中南大学学报(自然科学版), 2014, 45(11): 3752-3761.

WANG Ying, PAN Qinglin, ZHANG Yuwei, et al. Hot deformation behavior and processing map of GH4169 superalloy[J]. Journal of Central South University (Science and Technology), 2014, 45(11): 3752-3761.

[16] 戚延龄, 夏长清, 王志辉, 等. Ti62421s 钛合金的热变形行为及加工图[J]. 中南大学学报(自然科学版), 2012, 43(5): 1662-1671.

QI Yanling, XIA Changqing, WANG Zhihui, et al. Deformation behavior and processing map of high temperature deformation of Ti62421s alloy[J]. Journal of Central South University (Science and Technology), 2012, 43(5): 1662-1671.

[17] GHAVAM M H, MORAKABATI M, ABBASI S M, et al. Flow behavior modeling of IMI834 titanium alloy during hot tensile deformation[J]. Trans Nonferrous Met Soc China, 2015, 25(3): 748-758.

[18] REN Facai, CHEN Jun, CHEN Fei. Constitutive modelling of hot deformation behaviour of X20Cr13 martensitic stainless steel with strain effect[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(5) 1407-1413.

[19] ZHOU Jing, WANG Baoyu, HUANG Mingdong. Two constitutive descriptions of boron steel 22MnB5 at high temperature[J]. Materials & Design, 2014, 63(2): 738-748.

[20] FENG Wei, FU Youheng. High temperature deformation behavior and constitutive modelling for 20CrMnTiH steel[J]. Materials & Design, 2014, 57(5): 465-471.

[21] XIAO Yanhong, CUI Zhenshan, YIN Hongbin, et al. High temperature deformation behavior and constitutive modelling for 05Cr17Ni4Cu4Nb stainless steel[J]. Procedia Engineering, 2014, 81: 1277-1282.

[22] LIANG Xiaopeng, LIU Yong, LI Huizhong, et al. Constitutive relationship for high temperature deformation of powder metallurgy Ti-47Al-2Cr-2Nb-0.2W alloy[J]. Mater Des, 2012; 37: 40-47.

[23] SEN I, KOTTADA R S, RAMAMUTY U. High temperature deformation processing maps for boron modified Ti-6Al-4V alloys[J]. Mater Sci Eng A, 2010, 527(23): 6157-6165.

(编辑 赵俊)

收稿日期:2016-06-15;修回日期:2016-09-10

基金项目(Foundation item):中央高校基本科研业务费专项资金资助项目(CDJZR14130006)(Project(CDJZR14130006) supported by the Fundamental Research Funds for the Central Universities)

通信作者:王梦寒,博士,副教授,硕士生导师,从事金属塑性成形工艺及模具 CAD/CAE/CAM技术研究;E-mail:cquwmh@163.com