DOI: 10.11817/j.issn.1672-7207.2019.02.001

不同转速率下球磨机内钢球的碰撞研究

李腾飞,林蜀勇,张博,张家明,焦芬,覃文庆,张雁生

(中南大学 资源加工与生物工程学院,湖南 长沙,410083)

摘要:以最外层钢球为例进行理论计算,并采用有效内直径为5.35 m的球磨机进行离散元法(DEM)模拟,研究转速率对球磨机内钢球运动状态及内部碰撞情况的影响。研究结果表明:当钢球作抛落运动时,脱离角、落回角、钢球下落高度、在落回点的动能及冲击矿石的能量和研磨矿石的能量均与转速率有关;增大转速率,作抛落运动的钢球数明显增多,磨机内发生高能量碰撞的次数及平均碰撞能量均增大,有利于破碎硬度及粒度较大的矿石;但随着转速率增大,钢球-钢球、钢球-衬板之间碰撞能量占比增大,而钢球-矿石之间碰撞能量占比减小,从而降低磨机的能量利用率,增大磨矿过程的钢耗,减小衬板寿命。

关键词:转速率;离散元法(DEM);球磨机;碰撞

中图分类号:TD921 文献标志码:A 文章编号:1672-7207(2019)02-0251-06

Study on collisions of steel balls in grinding mill at different rotation speeds

LI Tengfei, LIN Shuyong, ZHANG Bo, ZHANG Jiaming, JIAO Fen, QIN Wenqing, ZHANG Yansheng

(School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: Through theoretical calculations of steel balls in the outmost layer and DEM (discrete element method) simulations on ball grinding mill of which the effective internal diameter is 5.35 m, the effects of rotation speeds on the motion of steel balls and collisions in the ball mill were studied. The results show that the leaving angle, the landing angle, the falling height of steel balls, the kinetic energy at the landing point, the impact energy and the attrition energy depend on rotation speed of ball grinding mill when the steel ball is thrown off. The numbers of balls in throwing motion increase obviously with the increase of rotation speed, and the frequency of high collision energy and average collision energy also increase with the increase of rotation speed, which is beneficial to the grinding of the harder and larger size of ore. However, the energy loss proportion of ball-ball and ball-liner collisions is promoted. The energy loss proportion of ball-rock collisions is reduced, which will reduce the energy utilization of mill and the service life of liner, and will increase the loss of steel.

Key words: rotation speed; DEM (discrete element method); ball grinding mill; collision

球磨作业在矿物加工领域具有重要地位,其目的是将有用矿物与脉石矿物充分解离并达到合适的粒度。由于能量利用率低(4%~8%),磨矿作业的运作成本约占选矿厂运作成本的50%[1],所以,即使很小的磨矿工艺改进(调节磨机转速、合理装补球制度等)对提高球磨作业的效率、降低选矿成本和提高选别指标具有重大现实意义[2]。磨机转速率对磨机内钢球的运动状态有很大影响。当介质充填率一定时,随着磨机转速率增加,磨机内的钢球可能由泻落变为抛落,甚至出现离心运动状态,从而产生不同的磨矿效果。国内外研究者就转速率对磨矿效果的影响研究较多,如:邹伟东[3]研究了转速率对球磨机粉磨效果的影响,并指出转速越大,作抛落运动的介质数量越多,球磨介质的抛落点高度越高,对矿石产生的冲击破碎作用越强;BIAN等[4]发现磨机转速对磨机扭矩和功率消耗也有较大影响。本文作者主要通过DEM(discrete element method)模拟揭示转速率对球磨机内碰撞情况及钢球的运动状态的影响。球磨机运行时,内部主要有矿石-矿石、矿石-衬板、介质-矿石、介质-衬板、介质-介质这5种碰撞形式。而介质与介质、衬板之间的碰撞不会对矿石产生破碎作用,反而会增加金属消耗,称为无用碰撞。当碰撞能量足够大时,1次碰撞就可以对矿石产生破碎作用,或矿石在低能量下多次碰撞发生破碎行为,称为有贡献的有用碰撞。而当碰撞能量过小时,无论发生多少次碰撞,矿石都不会被破碎,称为无贡献的有用碰撞。因此,控制碰撞能量的分布对优化磨矿效果非常重要。离散元法模拟中采用最大冲击能量、动能和碰撞能量损失[5]这3种参数描述碰撞能量。REFAHI等[6-8]在模拟中均采用碰撞能量损失,本文作者也通过碰撞能量损失描述碰撞能量。碰撞能量损失由颗粒间非弹性碰撞引起,可由下式计算得到[1]:

(1)

(1)

其中:Fn和Fs分别为颗粒间法向接触力和切向接触力;tcontact为碰撞过程的接触时间;En和Es分别为法向和切向碰撞能量损失;ζn和ζs分别为法向和切向压缩位移。

1 转速率ψ

球磨机转速率 (其中,n为磨机实际转速,nc为磨机临界转速)。以最外层钢球为例,探究转速率对钢球运动行为的影响。图1所示为磨机最外层钢球的抛落运动轨迹。

(其中,n为磨机实际转速,nc为磨机临界转速)。以最外层钢球为例,探究转速率对钢球运动行为的影响。图1所示为磨机最外层钢球的抛落运动轨迹。

图1中,钢球从B到A的轨迹为圆运动轨迹,而从A到C再到B的轨迹为抛落线运动轨迹。钢球脱离角α反映钢球上升的高度,α越小,表示球上升越高。对于最外层钢球而言,脱离角α仅与转速率有关,即α=arcos(ψ2)。落回角β=3α-π/2=3arcos(ψ2)-π/2。脱离角α和落回角β是钢球作抛落运动的2个重要参数[9],均与磨机转速率ψ有关。

图1 最外层钢球抛落运动轨迹

Fig. 1 Throwing motion trajectory of steel ball in outermost layer

磨矿过程是功能转变的过程,钢球落下时的动能决定着破碎矿石时的能量,此动能决定于钢球的质量m和落下时的高度H。钢球下落高度H的绝对值为

H=4.5Rsin2αcosα=4.5Rψ2sin2(arcos(ψ2)) (2)

当钢球到达落回点B时,x方向的速度vx为

=(vcosα)2=gRψ6 (3)

=(vcosα)2=gRψ6 (3)

=(3vsinα)2=9gRψ2sin2(arcosψ2) (4)

=(3vsinα)2=9gRψ2sin2(arcosψ2) (4)

=gRψ2(9-8ψ4) (5)

=gRψ2(9-8ψ4) (5)

落回点的动能为

(6)

(6)

将vB分解成沿打击线径向分速度vn和法向分速度vt,动能也分成冲击矿石的能量和磨剥矿石的能量2部分:

vn=8vsin3αcosα=8ψ3 sin3(arcosψ2) (7)

sin3(arcosψ2) (7)

vt=v+4vsin2αcos2α=ψ +

+

4ψ sin2(arcosψ2)cos(2arcosψ2) (8)

sin2(arcosψ2)cos(2arcosψ2) (8)

则冲击矿石的能量En= mv2 n,磨剥矿石的能量Et=

mv2 n,磨剥矿石的能量Et= mv2 t。

mv2 t。

2 DEM模拟

离散元法(DEM)已被广泛应用于球磨机的仿真模拟[10-13]。用离散元法软件对球磨机介质运动进行仿真模拟,可以直观地看到球磨机内部介质的运动情况,为球磨机介质运动的研究提供了极大便利[14]。本文采用有效内直径为5.35 m的球磨机轴向切片(厚度为 0.50 m)代替整体模型进行仿真,仿真参数见表1和表2。

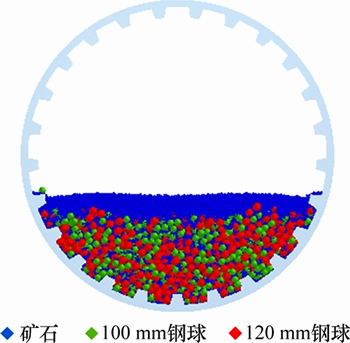

图2所示为填充率为35%的球磨机初始状态。磨机内装有直径为100 mm和120 mm的钢球各560个,直径为20,25和30 mm的矿石各10 000个。仿真中,颗粒与颗粒之间的接触模型选取 Hertz-Mindlin(无滑动)模型,颗粒与几何体之间的接触模型选取Hertz-Mindlin with Archard Wear模型。总仿真时间为15 s,时间步长为瑞利时间步长的27%,磨机的临界转速为18.335 r/min,研究转速率分别为65%,75%和85%(实际转速为11.92,13.75和15.58 r/min)球磨机内的碰撞情况。

表1 材料参数

Table 1 Parameters of materials

表2 接触参数

Table 2 Parameters of interactions

图2 填充率为35%时的球磨机初始状态

Fig. 2 Initial status of ball grinding mill when filling rate is 35%

3 结果与讨论

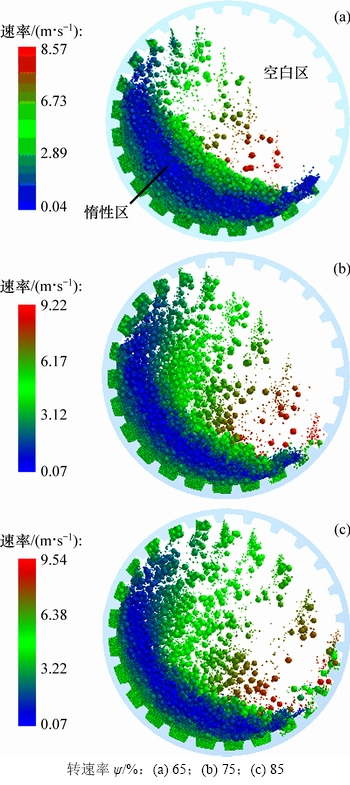

图3所示为球磨机在不同转速率下介质运动状态模拟结果。从图3可见:在转速率为65%时,钢球开始随筒体从筒体的底部移动至肩部,由于重力作用,大部分钢球又泻落至底部,仅有少数钢球作抛落运动冲击到载荷区;当转速率增加至75%和85%时,作抛落运动的钢球明显增多,而且外层钢球的脱离点也升高,钢球的运动速度也有所增大。这表明当转速率增大时,磨机内高能量碰撞的次数及平均碰撞能量损失增大,有利于破碎硬度及粒度较大的矿石。但从图3(c)可见:一部分钢球不能有效冲击到载荷区,而是直接碰撞到裸露的衬板上。这些无用碰撞增加钢耗,减小衬板寿命,在实际生产中应避免这种情况。图3中惰性区域内的钢球和矿石运动速度很低,磨矿作用较弱,发生碰撞的次数和碰撞能量也较低。空白区内没有介质和物料,因此,不会发生任何碰撞。随着磨机转速率增大,惰性区和空白区面积均减小,这有利于磨机有效容积的充分利用。

图3 在不同转速率下球磨机内钢球运动状态模拟

Fig. 3 Motion simulations of steel balls in ball grinding mill at different rotation speeds

平均碰撞能量损失随转速率变化关系见图4。为了使研究结果具有可靠性,增加了转速率为70%和80%的平均碰撞能量损失与转速率的关系。平均碰撞能量损失与转速率之间呈现很好的线性关系,决定系数R2大于0.990 0,平均碰撞能量损失由转速率为65%时的69.2 mJ线性增加到转速率为85%时的97.3 mJ。

图4 不同转速率下平均碰撞能量损失

Fig. 4 Variation of average collision energy loss at different rotation speeds

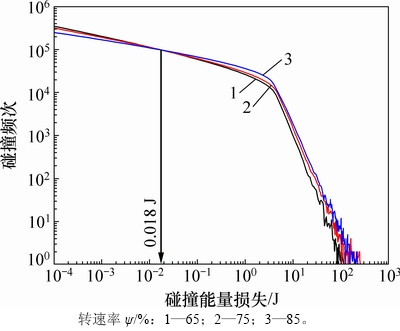

由仿真得到磨机稳定运转后8.5 s内总碰撞能量谱如图5所示。由图5可知:磨机内发生的碰撞次数较多,但多为低能量碰撞,而且球磨机内部碰撞频次随碰撞能量损失的增加而降低。WEERASEKARA等[15]指出低于0.1%的碰撞可以造成矿石的1次碰撞破碎,有2%的碰撞可以对矿石产生累计破碎效应。仿真结果表明:基于高能量单次冲击破碎矿石的粉碎机理对反应磨机内真实的碰撞环境有一定局限性;碰撞能量损失小于0.018 J的碰撞频次随着转速率增加有所减少,而碰撞能量损失高于0.018 J的碰撞频次随转速率增加而增加;在较高转速率下,高能量碰撞次数较多,但这些高能量的碰撞可能大部分来自钢球和钢球之间的碰撞,所以,要通过合理装补球制度来减弱钢球与钢球之间的碰撞。碰撞过程能量损失包含法向成分的能量损失和切向成分的能量损失,法向成分的能量损失用于冲击破碎矿石,而切向成分的能量损失用于研磨矿石。不同转速率下法向和切向的碰撞能量损失谱见图6。从图6可知:发生法向碰撞的碰撞频次随着转速率增加而增加,这有利于矿石的冲击破碎作用;当碰撞能量损失小于0.95 J时,切向碰撞频次随着转速率增加有所减少,而当碰撞能量损失高于0.95 J时,切向碰撞频次随转速率增加而增加。比较图6(a)和(b)可知:在这3种转速率下,在碰撞过程中,切向碰撞在碰撞过程中占主导地位,这意味着研磨作用对矿石破碎起重要作用。

图5 不同转速率下总碰撞能量损失谱

Fig. 5 Energy loss spectra for all collisions at different rotation speeds

图6 不同转速率下法向和切向碰撞能量损失谱

Fig. 6 Energy loss spectra for normal collisions and tangential collisions at different rotation speeds

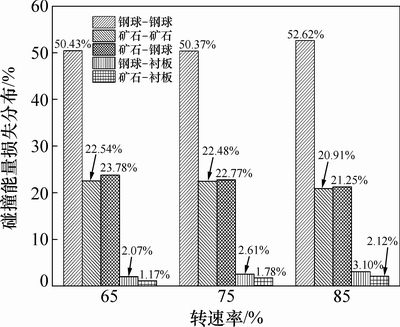

磨机消耗的能量主要用于3个方面[16-19]:破碎位于钢球间隙中的矿石、衬板的磨损、钢球的磨损。矿石-矿石、矿石-钢球和矿石-衬板之间的碰撞会可能对矿石产生破碎作用,矿石-衬板、钢球-衬板之间的碰撞会造成衬板磨损,矿石-钢球、钢球-钢球之间的碰撞会造成钢球磨损。DEM可以预测这些碰撞过程能量损失。不同转速率下球磨机内碰撞能量损失分布如图7所示。从图7可见钢球-钢球之间碰撞耗散的能量占总能量的50%以上,这也解释了磨机能量利用率低和钢耗高的原因。其中,当转速率为85%时,钢球-钢球之间碰撞损失的能量占比最高,这说明85%转速率时钢耗最高且噪音最大。矿石-矿石之间碰撞由于碰撞频次高,其损失的能量占到总能量的20%以上。但由于矿石之间的单次碰撞能量损失很低,所以,对矿石并没有破碎作用或仅有微弱的研磨作用。矿石的破碎作用主要来自于钢球-矿石之间的碰撞。由图7可见:当转速率为65%时,钢球-矿石碰撞损失能量占比分别比转速率为75%和85%的碰撞损失能量高1.01%和2.53%,说明转速率为65%相对于转速率为75%和85%有较高的磨机有效能量利用率,这对磨矿过程节能降耗具有重要意义,并且当转速率为65%时,有衬板参与的碰撞形式损失能量占比最低,说明较高转速下磨机的衬板磨损严重,衬板寿命减少。

图7 不同转速率下碰撞能量损失分布

Fig. 7 Collision energy loss distribution at different rotation speeds

4 结论

1) 转速率是球磨机磨矿过程中重要的参数条件。转速率对球磨机内钢球运动状态和钢球作抛落运动时下落高度与落回点的动能有重要影响,因此,不同转速率下产生的磨矿效果不同。

2) 当转速率增大时,抛落运动的钢球数明显增多,高能量碰撞频次也增多。平均碰撞能量损失与转速率之间呈现很好的正相关线性关系。但当转速率增大时,钢球-钢球、钢球-衬板之间碰撞能量占比增大,这不利于磨机功率的有效利用,同时也会增大钢耗,减小衬板寿命。

3) 球磨机内发生的碰撞次数较多,但多为低能量碰撞,高能量碰撞次数很少,这表明基于高能量单次冲击破碎矿石的粉碎机理对于反映磨机内真实的碰撞环境有一定局限性,同时,切向碰撞在碰撞过程中占主导地位,这也表明研磨作用对矿石破碎起重要作用。

参考文献:

[1] WANG M H, YANG R Y, YU A B. DEM investigation of energy distribution and particle breakage in tumbling ball mills[J]. Powder Technology, 2012, 223: 83-91.

[2] 吴彩斌. 破碎统计力学原理及转移概率在装补球制度中的应用研究[D]. 昆明: 昆明理工大学国土资源工程学院, 2002: 4-10.

WU Caibin. Application study about crushing statistic mechanics principle and transition probability on load-addition ball system[D]. Kunming: Kunming University of Science and Technology. Faculty of Land Resources Engineering, 2002: 4-10.

[3] 邹伟东. 转速和填充率对球磨机粉磨效果的影响[D]. 广州: 华南理工大学材料科学与工程学院, 2016: 23-30.

ZOU Weidong. The influence of rotation speed and filling rate on ball mill grinding effect[D]. Guangzhou: South China University of Technology. School of Materials Science and Engineering, 2016: 23-30.

[4] BIAN Xiaolei, WANG Guoqiang, WANG Hongdi, et al. Effect of lifters and mill speed on particle behaviour,torque,and power consumption of a tumbling ball mill: experimental study and DEM simulation[J]. Minerals Engineering, 2017, 105: 22-35.

[5] TAVARES L M. A review of advanced ball mill modelling[J]. KONA Powder and Particle Journal, 2017, 34: 106-124.

[6] REFAHI A, AGHAZADEH MOHANDESI J, REZAI B. Discrete element modeling for predicting breakage behavior and fracture energy of a single particle in a jaw crusher[J]. International Journal of Mineral Processing, 2010, 94: 83-91.

[7] TONGAMP W, KANO J, SUZUTA Y, et al. Relation between mechanochemical dechlorination rate of polyvinyl chloride and mill power consumption[J]. Journal of Material Cycles and Waste Management, 2009, 11(1): 32-37.

[8] CLEARY P W, MORRISON R D. Understanding fine ore breakage in a laboratory scale ball mill using DEM[J]. Minerals Engineering, 2011, 24: 352-366.

[9] 段希祥. 碎矿与磨矿[M]. 北京: 冶金工业出版社, 2006: 160-175.

DUAN Xixiang. Crushing and grinding[M]. Beijing: Metallurgical Industry Press, 2006: 160-175.

[10] DONG H, MOYS M H. Assessment of discrete element method for one ball bouncing in a grinding mill[J]. International Journal of Mineral Processing, 2002, 65: 213-226.

[11] CLEARY P W. A multiscale method for including fine particle effects in DEM models of grinding mills[J]. Minerals Engineering, 2015, 84: 88-99.

[12] SINNOTT M D, CLEARY P W, MORRISON R D. Combined DEM and SPH simulation of overflow ball mill discharge and trommel flow[J]. Minerals Engineering, 2017, 108: 93-108.

[13] ICHINKHORLOO B, BOR A, UYANGA B, et al. Particle morphology change and different experimental condition analysis during composites fabrication process by conventional ball mill with discrete element method(DEM) Simulation[J]. Korean Journal of Materials Research, 2016, 26(11): 611-622.

[14] 卢建坤. 基于离散单元法的大型球磨机介质运动分析及参数优化[D]. 洛阳: 河南科技大学机电工程学院, 2013: 49-55.

LU Jiankun. Kinematical analysis & parameters optimization of large tumbling ball mill’ media based on the discrete element method[D]. Luoyang: Henan University of Science and Technology. School of Mechanical and Electrical Engineering, 2013: 49-55.

[15] WEERASEKARA N S, POWELL M S, CLEARY P W, et al. The contribution of DEM to the science of comminution[J]. Powder Technology, 2013, 248: 3-24.

[16] CLEARY P W. Ball motion, axial segregation and power consumption in a full scale two chamber cement mill[J]. Minerals Engineering, 2009, 22: 809-820.

[17] SATO A, KANO J, SAITO F. Analysis of abrasion mechanism of grinding media in planetary mill with DEM simulation[J]. Advanced Powder Technology, 2017, 21: 212-216.

[18] PENG Yuxing, LI Tongqing, ZHU Zhencai, et al. Discrete element method simulations of load behavior with mono-sized iron ore particles in a ball mill[J]. Advances in Mechanical Engineering, 2017, 9(5): 1-10.

[19] JACOB W, COOPER D R, GUTOWSKI T, et al. The efficiency of copper ore comminution: A thermodynamic exergy analysis[J]. Minerals Engineering, 2017, 109: 21-31.

(编辑 陈灿华)

收稿日期:2018-03-15;修回日期:2018-05-10

基金项目(Foundation item):国家自然科学基金资助项目(51204207);中南大学研究生自主探索创新基金资助项目(2017zzts370)(Project(51204207) supported by the National Natural Science Foundation of China; Project(2017zzts370) supported by the Independent Research-innovation Foundation of Central South University)

通信作者:张雁生,博士,副教授,从事矿物加工和生物冶金研究;E-mail:zhangyansheng405@126.com