基于Archard理论的挤压次数对模具磨损量的影响分析

林高用,冯 迪,郑小燕,杨 伟,孙利平

(中南大学 材料科学与工程学院 有色金属材料科学与工程教育部重点实验室,湖南 长沙,410083)

摘 要:针对前次挤压对后次挤压的模具磨损有着显著影响,模具的总磨损量并不与单次磨损量呈简单的线性关系,将考虑温度影响的Archard磨损计算修正模型与有限元数值模拟分析方法相结合,预测铝合金挤压过程中模具表面磨损最严重的部位,建立该部位磨损量与挤压次数之间的确切关系,并由此提出一种考虑挤压次数影响的总磨损量计算公式。

关键词:挤压;模具磨损;Archard理论;有限元

中图分类号:TG375+.41 文献标识码:A 文章编号:1672-7207(2009)05-1245-07

Analysis of influence of extrusion times on

total die wear based on Archard theory

LIN Gao-yong, FENG Di, ZHENG Xiao-yan, YANG Wei, SUN Li-ping

(Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education,

School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Based on the fact that under discontinuous extrusion condition, former passes often have great effect on the next ones, so that the relationship between die wear of single process and total wear is not linear, the position with the largest amount of wear on the die surface was predicted, and the relationship between the extrusion times and the total die wear was estimated by combining modified Archard model which considered the influence of temperature on the die wear behaviors and finite element method (FEM) technology. As a result, an equation for evaluating the total die wear which considers the effects of extrusion times was established.

Key words: extrusion; die wear; Archard theory; finite element method (FEM)

在金属加工过程中,导致模具失效的因素主要有磨损、塑性变形以及断裂。其中,由于断裂和塑性变形而导致的模具失效,可以通过模具的合理设计、模具材料的合理选择来减少,但是,模具的磨损是由模具与工件的接触而造成的,因此,由于磨损而导致的模具失效难以控制[1]。对于铝合金挤压模具,磨损成为影响其寿命的首要因素,世界上每年有超过70%的模具因为磨损而失效[2]。

人们从1953年起广泛使用Archard理论对模具磨损进行分析[3-6]。在此理论中,磨损量与磨损因子[7]、模具表面法向压力和材料相对模具的滑移距离[8-9]成正比,与模具的硬度成反比。此后,国内外许多学者对该磨损理论的修正、磨损预测以及减小磨损量等进行了大量研究。Lee等[10-11] 对Archard理论进行了修正,考虑温度以及时间对模具硬度和磨损因子的影响;Eriksen[12]提出通过优化模具设计来减小磨损量;Lee等[13]在Archard理论的基础上研究了冷挤压中模具锥度以及压下量对磨损量的影响以及模具磨损的分布情况;周杰等[14]利用 Archard理论分析了模具硬度、初始温度和润滑条件在一次成形后对模具磨损的影响规律;王雷刚等[15]利用修正的Archard理论对比分析了锥形和弧形2种挤压模具型腔的磨损。这些研究对实际生产中单次挤压时模具磨损量的预测有着直接的指导意义,但是,对于多次成形后的总磨损量的计算,国内外研究者往往采取简单的求和方法,即用第1次计算得到的磨损量乘以总的挤压次数,这与实际结果有所偏差。在实际生产中,模具往往要在高温高应力状态下工作,模具的温度逐渐升高,导致硬度逐渐下降;其次,在长时间高温高压作用下,铝合金中的Fe,Si和V等溶质原子渗透到模具表面而产生焊合作用,在模具表面粘附一层金属,这些金属不断形成,又不断被破坏,经多次反复磨损,而引起模具失效。在计算模具失效前的总磨损量时,应该考虑前一次挤压对下一次挤压的影响,在此,本文作者在修正的Archard模型的基础上,通过有限元模拟[16]分析在铝合金挤压中,多次挤压对模具磨损的影响,并利用模拟结果拟合出计算任一次挤压的磨损量和多次挤压总磨损量的公式,以期达到更加精确预测模具寿命的目的。

1 Archard磨损模型及其修正

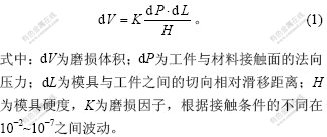

Archard模型一般公式如下:

模型参数意义如图1所示。

图1 Archard模型参数示意图

Fig.1 Parameters scheme of Archard model

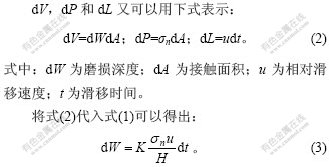

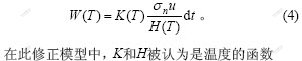

在此理论中,Archard认为磨损因子K以及模具硬度H为常量。但事实上,模具材料的硬度以及接触条件都是与温度有密切相关的,在热加工过程中,这一现象体现得更加明显,模具会随着模具温度的升高发生软化,导致模具的硬度降低以及模具与工件的接触面粗糙程度增加,从而增加模具的磨损。对于铝合金的挤压,模具温度一般都在400 ℃以上,此时,Archard模型已经不再适用。针对这种情况,Hahamir等[3]利用H13模具钢为研究材料,对Archard模型进行了修正,将温度作为影响K及H的因素进行考虑,提出了在考虑温度软化影响下的磨损计算公式:

可以分别通过高温磨损实验和高温硬度实验得到的数据,拟合出K(T)和H(T) 的公式。Lee等[10]给出了确切的表达式:

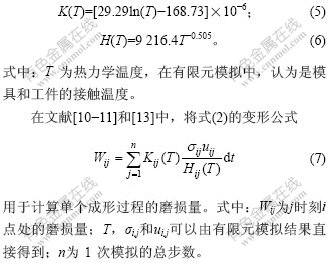

利用式(3)和(4)就可以计算出1次模拟(即模具使用1次时)模具的磨损量。然后,通过求和的方法来计算模具失效前的临界磨损,以此来预测模具寿命。

本文在计算第1次挤压磨损量仍采用如式(7)的方法,但是,考虑前次挤压对后续挤压的影响,在式(7)基础上提出了任意1次挤压的磨损计算公式以及多次挤压后模具总磨损量的计算公式。

2 实验方案及总磨损量计算公式的提出

2.1 有限元模拟实验

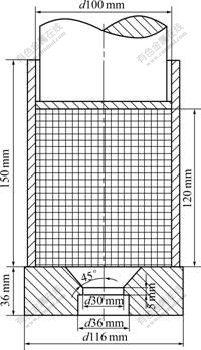

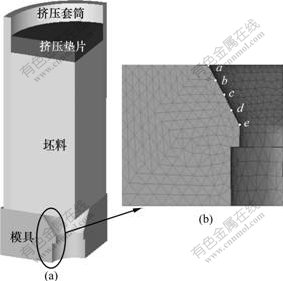

模具的截面图见图2,有限元模型见图3。为了能够正确使用磨损因子和硬度的计算式(5)和(6),模拟的初始条件与文献[10]中的相同,见表1,其中在H13钢表面渗氮以增加其硬度,渗氮层厚度约为0.24 mm。单次挤压模拟时间步为55步。由于模型轴对称,为加快计算速度,只取模型的1/4进行模拟(图3),图中,a,b,c,d和e为有限元目标节点,其中e点位于挤压模具的模口入口处。

图2 挤压模具截面图

Fig.2 Sectional drawing of extrusion model

(a) 整个模型的1/4;(b) 1/4下模的有限元网格图

图3 有限元模型

Fig.3 Finite element model

本次实验分2步进行:

a. 模拟铝合金的挤压过程,从模拟结果中对所选取的目标节点(图3),提取出计算磨损量所需的参数T,σi,j和ui,j,利用式(5)和(6)计算出某有限元节点处在一定温度下的硬度和磨损因子,再利用式(7)计算单次挤压的模具磨损量。

b. 将第1次模拟结果中模具的温度场及磨损状态保存为STL文件作为第2次模拟的模具初始条件,再导入初始坯料进行模拟,如此反复,可得到模具磨损量随挤压次数增加而变化的关系,最后拟合出公式。

2.2 有限元模拟结果及讨论

2.2.1 磨损分布

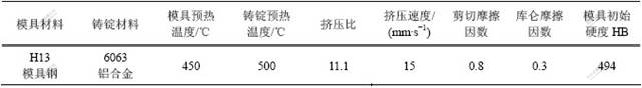

图4所示为第1和第5次挤压模拟结束时,影响模具磨损量的各个参数物理场云图对比。

由图4可以看出:对于某一次挤压,从模面到模孔入口,工件与模具表面相对滑移速度、温度、法向压力逐渐增大,其中,相对滑移速度和温度增幅较大,法向压力增幅较小。对于不同次数挤压,随着挤压次数的增加,模具温度逐渐增大,但是,增幅逐渐减小,而相对滑移速度和法向压力则变化不大。

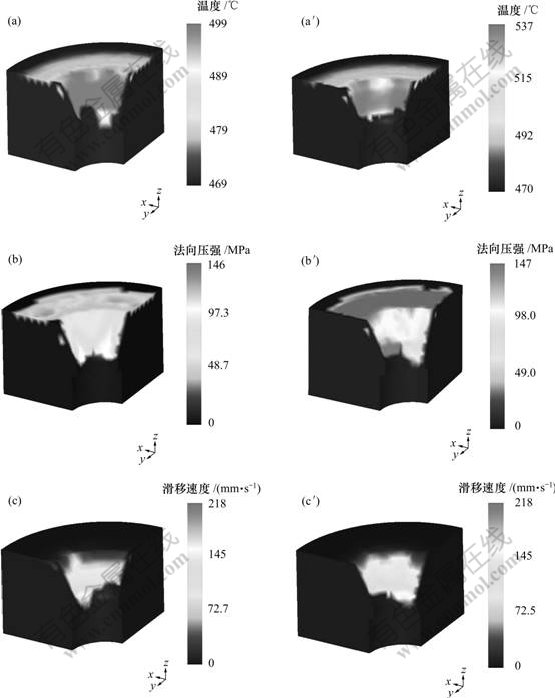

表1 模拟初始条件

Table 1 Initial conditions of simulation

(a) 第1次挤压结束时模具温度场;(a′) 第5次挤压结束时模具温度场;

(b) 第1次挤压结束时模具比压场;(b′) 第5次挤压结束时模具比压场;

(c) 第1次挤压结束时工件与模具相对滑移速度场;(c′) 第5次挤压结束时工件与模具相对滑移速度场

图4 影响磨损的各参量对比云图

Fig.4 Comparison diagrams of parameters affecting die wear

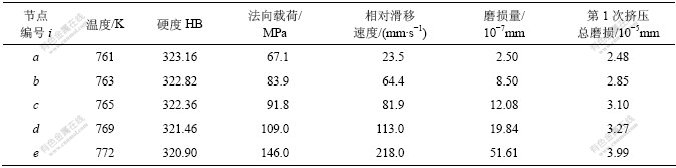

表2所示为各目标节点在第1次挤压模拟最后一时间步(第55步)的磨损量Wi,55(i=a,b,c,d和e)及第1次挤压模拟过程各目标节点的总磨损量Wi,j (i=a,b,c,d,e;j=1,2,…,54,55),图5所示为各目标节点磨损量的变化曲线。

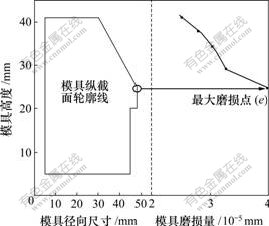

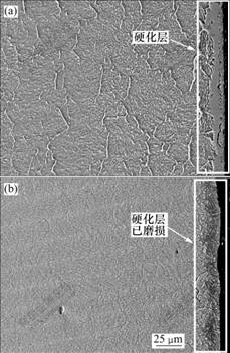

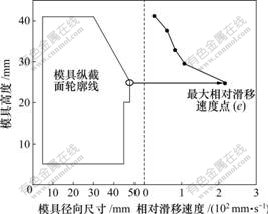

由图5可知,位于模孔入口处的e点磨损最严重,与其他位置相比,磨损量最大值相差1.51×10-5 mm。该处模具承受法向载荷最大,且被挤压金属与模具相对滑移速度远远比其他部位的高(见表2)。图6所示为硬化层磨损的SEM像,可以看出模具不同部位渗氮白亮层的不同磨损情况。各节点的相对滑移速度曲线如图7所示,可见,当滑移时间相同时,相对滑移距离增大,因此,磨损增大。由此可知,模具模孔入口处磨损最严重。因此,在以下讨论中,以磨损量最大的e点为目标节点,对其在多次挤压中相同时间段的磨损量差值进行计算,从而得出磨损总量的计算公式。

表2 各目标节点第1次模拟最后1步(55)磨损量和第1次模拟总磨损量

Table 2 Wear amount of last step(55) and total in first simulation of each goal node

图5 模具锥面上不同部位磨损深度对比

Fig.5 Comparison of wear depth at different positions on die pyramidal face

2.2.2 总磨损量计算公式

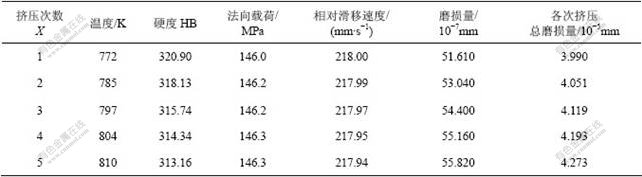

表3所示为e点在各次挤压模拟最后一时间步(第55步)的磨损量We,55(X)(X=1, 2, 3, 4, 5),(其中X为挤压次数),以及各次挤压模拟中e点处的总磨损量We,j(X) (j =1, 2, …, 54, 55;X=1, 2, 3, 4, 5)。从表3可知,随着挤压次数的增加,模具的磨损量在逐渐增大。

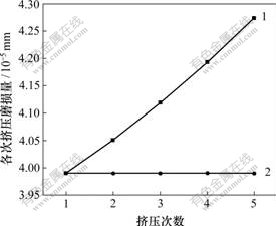

图8所示为使用经修正Archard模型计算的e点在各次挤压中的磨损量We,j(X)曲线与以往计算方法得出的磨损量曲线的对比。

(a) 模面处磨损; (b) 模孔入口处磨损

图6 挤压模不同部位表面硬化层磨损的SEM像

Fig.6 SEM images of model wear in hard coat at different positions

图7 模具锥面不同部位与坯料的相对滑移速度对比

Fig.7 Comparison of relative sliding velocity between workpiece and different positions on die pyramidal face

表3 e点在各次模拟最后1步的磨损量和各次总磨损量

Table 3 Wear amount of last step (55) and total in each simulation of node e

1—经修正的曲线;2—原始方法曲线

图8 不同挤压次数的磨损量

Fig.8 Wear of different extrusion times

以上分析了在多次挤压下,模具磨损量的变化趋势。利用表3和图8中的数据,结合数值分析的方法,可以拟合出多次挤压后,模具任意1次挤压的磨损量和多次挤压模具总磨损量的计算公式,以此更准确地预测模具使用寿命。

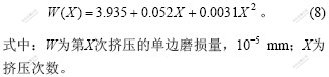

模具失效前某一次挤压的单边磨损量计算公式为:

由于本次模拟所取模型对称,故第X次挤压的磨损量应为2W。

n次挤压的总磨损量计算可以通过下式得出:

对于表面渗氮层厚度为0.24 mm的模具,以磨损最严重的模孔入口处为基准,利用式(8)和(9)进行计算,待渗层被磨损至模具尺寸超差大约需要2 413次,若按原方法不考虑挤压次数对磨损的影响,则需要 3 007次。与实际情况相比较,按式(8)和(9)所得计算结果更接近。需要指出的是,本研究所针对的模具材料为H13钢,该热作模具钢表面有远远高于基体硬度的渗氮层,当硬度较高的渗层完全磨损后,基体的磨损规律并不在本公式考虑范围之内。

影响模具磨损的因素多且复杂,本文限于条件,在计算模型中只考虑温度对磨损因子K和模具表面硬度H的影响,而尚未综合考虑挤压速度、挤压时间及模具表面状态等因素,因此,对模具使用寿命的预测存在一定误差。对模具磨损量的精确预测还有待于进一步研究。

3 结 论

a. 模具磨损最严重的部位为模孔入口处。

b. 随着挤压次数的增加,模具的表面温度上升,温升导致模具硬度下降和磨损因子的增大,使得下一次挤压的模具磨损量高于上一次挤压磨损量,但是,温度的上升速度呈递减趋势,因此,模具的磨损增速逐渐减小。

c. 随着挤压次数的增加,模具表面与工件的接触压力有上升趋势,两者相对滑移速度呈下降趋势,其综合作用仍然使下一次挤压的模具磨损量增大,磨损增速逐渐减小。

d. 利用模拟实验数据进行拟合,建立了一次挤压过程磨损量的计算公式和多次挤压后总磨损量计算 公式。

参考文献:

[1] Kang J H, Park I W, Jae J S, et al. A study on a die wear model considering thermal softening (Ⅰ): Construction of the wear model[J]. Journal of Materials Processing Technology, 1999, 96(1/3): 53-58.

[2] Cser L, Geiger M, Lange K. Tool life and tool quality in bulk metal forming[J]. CIRP Annals-Manufacturing Technology, 1992, 41(2): 667-675.

[3] Jahamir S, Suh N P. The delamination theory of wear and the wear of a composite surface[J]. Wear, 1975, 32(1): 33-49.

[4] Chowdhury, Roy S K, Pollock H M. Adhesion between metal surfaces: the effect of surface roughness[J]. Wear, 1981, 66(3): 307-321.

[5] Jensen M R, Damborg F F, Nielsen K B. Applying the fininte element model for determination of tool wear in conventional deep-drawing[J]. Journal of Materials Processing Technology, 1998, 83(1/3): 98-105.

[6] Archard J F. Microscopic aspects of adhesion and lubrication[J]. Tribology International, 1982, 15(5): 242.

[7] Ghosh A K. A method for determining the coefficient of friction in punch streching of sheet metals[J]. Int J Mech Sci, 1977, 10(8): 457-470.

[8] Rigney D A. Comments on the sliding wear of metals[J]. Tribol Int, 1997, 30(5): 361-367.

[9] Rigney D A, Chen L H, Naylor G S. Wear process in sliding systems[J]. Wear, 1984,100(1/3): 195-219.

[10] Lee R S, Jou J L. Application of numerical simulation for wear analysis of warm forging[J]. Journal of Materials Processing Technology, 2003, 140(1/3): 43-48.

[11] Kang J H, Park I W, Jae J S, et al. A study on die wear model considering thermal softening (Ⅱ): Application of the suggested wear model[J]. Journal of Materials Processing Technology, 1999, 94(2/3): 183-188.

[12] Eriksen M. The influence of die geometry on tool wear in deep drawing[J]. Wear, 1997, 207(1/2): 10-15.

[13] Lee G A, Im Y T. Finite-element investigation of the wear and elastic deformation of dies in metal forming[J]. Journal of Materials Processing Technology, 1999, 89/90(10): 123-127.

[14] 周 杰, 赵 军, 安治国. 热挤压磨损规律及磨损对模具寿命的影响[J]. 中国机械工程, 2007, 18(17): 2112-2115.

ZHOU Jie, ZHAO Jun, AN Zhi-guo. Wear rule and effects on the die service life during hot extrusion[J]. Chinese Mechanical Engineering, 2007, 18(17): 2112-2115.

[15] 王雷刚, 黄 瑶, 孙宪萍, 等. 基于修正Archard磨损理论的挤压模具磨损分析[J]. 润滑与密封, 2006(3): 10-12.

WANG Lei-gang, HUANG Yao, SUN Xian-ping, et al. Wear analysis of extrusion die based on archard’s theory[J]. Lubrication Engineering, 2006(3): 10-12.

[16] 林高用, 周 佳, 郑小燕, 等. X5214铝合金型材挤压过程的数值模拟[J]. 中南大学学报: 自然科学版, 2008, 39(4): 748-754.

LIN Gao-yong, ZHOU Jia, ZHENG Xiao-yang, et al. Numerical simulation of extrusion process of X5214 aluminum alloy profile[J]. Journal of Central South University: Science and Technology, 2008, 39(4): 748-754.

收稿日期:2008-09-04;修回日期:2008-12-03

基金项目:国家高技术研究发展计划项目(2007AA03Z517)

通信作者:林高用(1966-),男,湖南洞口人,博士,教授,从事材料加工、材料损伤与断裂、数值模拟等研究;电话:0731-88830266;E-mail: gylin6609@yahoo.com.cn