新SIMA制备坯料触变挤压AZ61镁合金零件的组织与性能

来源期刊:中国有色金属学报(英文版)2013年第3期

论文作者:姜巨福 王 迎 柳 君 曲建俊 杜之明 罗守靖

文章页码:576 - 585

Key words:AZ61 magnesium alloy; semisolid billets; new strain induced melt activation; thixo-extrusion

摘 要:新应变诱导熔化激活法被用来制备高质量的AZ61镁合金半固态坯料。利用光学显微镜和拉伸实验,研究触变挤压成形零件的微观组织与力学性能。结果表明:当施加的压力为784 MPa,保压时间为90 s,模具温度为450 °C时,半固态坯料能够完全充填模具型腔。与半固态等温处理方法相比,新SIMA法制备的半固态坯料触变挤压成形零件的抗拉强度和伸长率分别为300.5 MPa和22%;并且成形零件的微观组织晶粒细小、组织均匀。随着等温处理温度的升高和保温时间的延长,成形零件的抗拉强度和伸长率先增加后降低。当挤压道次从1增加至4时,成形零件的抗拉强度和伸长率明显增加。

Abstract: New strain induced melt activation (new SIMA) method was employed to prepare high-quality semisolid billet of AZ61 magnesium alloy. Optical microscopy and tensile test were used to study the microstructure and mechanical properties of the thixo-extruded component. The results showed that the optimal process parameters for achieving the complete filling status involved the applied pressure of 784 MPa, the pressure holding time of 90 s and the die temperature of 450 °C. Compared to semisolid isothermal treatment, high mechanical properties such as the tensile strength of 300.5 MPa and elongation of 22% and fine microstructure were obtained in the thixo-extruded parts. With increasing the isothermal temperature and holding time, the tensile strength and elongation were increased firstly and then decreased. When the press pass was increased from 1 to 4, the tensile strength and elongation of the thixo-extruded parts were greatly enhanced and microstructure was refined obviously.

Trans. Nonferrous Met. Soc. China 23(2013) 576-585

Ju-fu JIANG1, Ying WANG2, Jun LIU1, Jian-jun QU2, Zhi-ming DU1, Shou-jing LUO1

1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. School of Mechatronics Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 1 February 2012; accepted 5 April 2012

Abstract: New strain induced melt activation (new SIMA) method was employed to prepare high-quality semisolid billet of AZ61 magnesium alloy. Optical microscopy and tensile test were used to study the microstructure and mechanical properties of the thixo-extruded component. The results showed that the optimal process parameters for achieving the complete filling status involved the applied pressure of 784 MPa, the pressure holding time of 90 s and the die temperature of 450 °C. Compared to semisolid isothermal treatment, high mechanical properties such as the tensile strength of 300.5 MPa and elongation of 22% and fine microstructure were obtained in the thixo-extruded parts. With increasing the isothermal temperature and holding time, the tensile strength and elongation were increased firstly and then decreased. When the press pass was increased from 1 to 4, the tensile strength and elongation of the thixo-extruded parts were greatly enhanced and microstructure was refined obviously.

Key words: AZ61 magnesium alloy; semisolid billets; new strain induced melt activation; thixo-extrusion

1 Introduction

Thixoforming is a processing route of semisolid metal (SSM) [1,2]. In the past three decades, thixoforming has been accepted as a reliable process for manufacturing net shape components, especially for the automotive industry. Research on thixoforming technology has been done in recent years due to the advantages of high productivity, high mechanical properties, extension of the die life and cost savings. Thixoforming can be applied in various technical processes such as thixoforging, thixo-extrusion and thixocasting [3-5]. KIM et al [6] reported a novel thixo- extrusion process for Al wrought alloys. RIKHTEGAR and KETABCHI [7] investigated the mechanical properties of 7075 Al alloy formed by forward thixo- extrusion process. CHO and KANG [8] examined the mechanical properties and the microstructure evaluation of semisolid aluminum alloys in the thixoforming process and concluded that a dense microstructure was found at a lower die temperature. In addition, some research work was done in the fields such as thixoformability of AA6082 [9], thixo-extrusion of A357 [10], steel thixoforming [11,12], microstructure evolution of semisolid AZ91D magnesium alloy [13,14] and continuous semisolid extrusion process (CSEP) of magnesium alloys [15,16].

JIANG et al [17] developed a new method called “new SIMA” in which equal channel angular extrusion (ECAE) was applied in the fabrication of semisolid slurry of AZ91D magnesium alloy. However, research on thixoforming of AZ61 magnesium alloy semisolid billets prepared by new SIMA wasn’t reported. New SIMA is a potential method for preparing magnesium alloy semisolid billets. It is very valuable to study thixo-extruding of semisolid billets of AZ61 magnesium alloy prepared by new SIMA due to increasing applications of magnesium alloy parts.

In the present work, the thermo-mechanically based route, new SIMA method, was used to prepare the semisolid billets of AZ61 Mg alloy. The effects of different process parameters on the tensile properties, the microstructure of the thixo-extruded parts and the filling behavior of the semisolid billets were studied.

2 Experimental

AZ61 magnesium alloy was used as experiment material. It contains the composition of 6.5% Al, 0.35% Zn, 0.26% Mn, 0.1% Si, 0.003% Fe, 0.02% Cu, 0.01% Ni and balance Mg. Semisolid billet of AZ61 magnesium alloy was prepared by new SIMA method. Firstly, as-cast AZ61 magnesium alloy with the diameter of 57 mm and height of 120 mm was processed from 1 pass to 6 passes at 310 °C with an equal channel die. The equal channel die consisted of two channels with equal cross-section, intersecting at an angle of 90° (Fig. 1(a)). The equal channel’s perpendicular height was 150 mm. The horizontal length of the equal channel was 50 mm. The equal channel dies were made of 3Cr2W8V steel. Colloidal graphite with water was sprayed on the surface of equal channel dies used as lubricant. The as-cast AZ61 magnesium alloy was rotated by 90° between the consecutive passes. As indicated in Fig. 1(b), the as-cast ingots were firstly deformed by ECAE die to obtain severe plastic deformation. Then, these processed as-cast ingots were isothermally treated at semi-solid temperature in an electrical furnace. In addition, the thixo-extrusion experiments were done on a 2000 kN universal hydraulic press. Finally, the mechanical properties and microstructure of the formed parts were analyzed on an INSTRON 5582 universal testing machine Olympus optical microscope.

Fig. 1 Schematic diagram of ECAE die (a) and flow process diagram of thixo-extruded AZ61 parts (b)

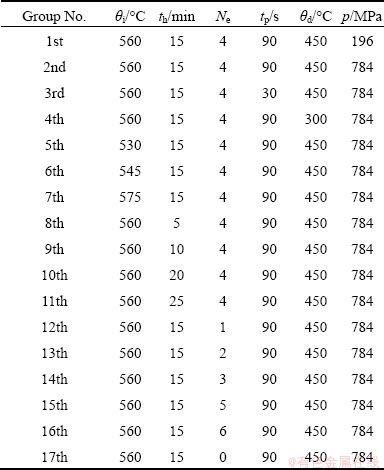

Then, these billets processed by ECAE were machined into some cylindrical samples with d57 mm × 25 mm. The process parameters in thixo- extrusion experiments involved the isothermal temperature (θi), holding time (th), press passes (Ne), applied pressure (p), pressure holding time (tp) and die temperature (θd). The thixo-extrusion experiments were divided into 17 groups, as shown in Table 1. Semisolid isothermal treatment (SSIT) was also employed to prepare billet to study the effect of various preparation methods on the microstructure and mechanical properties of the thixo-extruded component. As shown in Table 1, the semisolid billet of AZ61 magnesium alloy was fabricated by new SIMA in the former 16 groups. The semisolid billet of AZ61 magnesium alloy was prepared by SSIT for the 17th group.

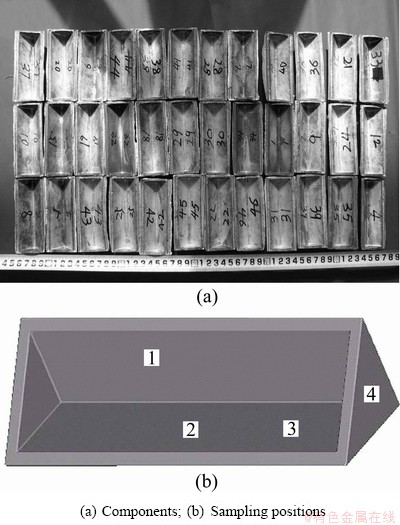

The thixo-extruded components are shown in Fig. 2(a). The microstructural samples were cut in positions 2, 3 and 4 (Fig. 2(b)). The microstructural samples were fabricated by the standard metallurgical technique, followed by etching in a solution of 4.2 g picronitric acid, 10 mL ethanediol, 70 mL ethanol and 10 mL distilled water. The tensile samples were cut from position 1, as indicated in Fig. 2(b). Four group samples were measured and the average value of the mechanical properties of the four samples was regarded as the final mechanical properties to improve the accuracy.

Table 1 Process parameters in divided experimental group during thixo-extrusion process

Fig. 2 Photographs of thixo-extruded components of AZ61 magnesium alloy and sampling positions

3 Results and discussion

3.1 Effect of process parameters on filling behavior

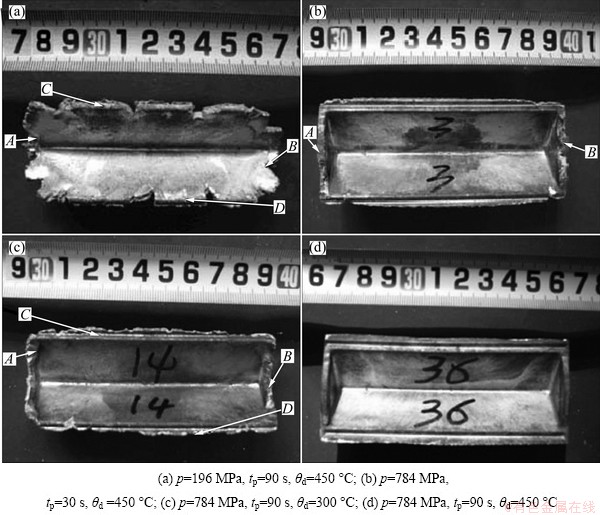

Figure 3 shows the filling status of semisolid billets prepared by new SIMA under various applied pressure, die temperature and pressure holding time. The incomplete filling status was found in the part when the applied pressure was 196 MPa, the pressure holding time was 90 s and the die temperature was 450 °C (Fig. 3(a)). As indicated in Fig. 3(a), incomplete filling status was found in regions A, B, C and D. On the contrary, Fig. 3(d) shows a complete filling, which indicates that the applied pressure has an important influence on the filling behavior of thixo-extruded components. When the semisolid billet of AZ61 magnesium alloy was formed, the applied pressure should be larger than the resistance force such as resistance to deformation and friction between the semisolid billet and the die surface. Moreover, only when the applied pressure was larger than the resistance force during thixo-extrusion, the complete filling could be obtained successfully.

Fig. 3 Photographs of formed parts after thixo-extrusion at different parameters

As shown in Fig. 3(a), when the applied pressure of 196 MPa was smaller than the resistance force during thixo-extrusion, it led to incomplete filling status. As shown in Fig. 3(b), the filing behavior of thixo-extrusion process was also affected by the pressure holding time. Unlike Fig. 3(a), incomplete filling phenomena were found only in regions A and B. When the semisolid billet was filling the die cavity, a minimum pressure holding time (critical pressure holding time) should be needed to obtain the complete filling of the die cavity. When the pressure holding time is below the critical pressure holding time, the incomplete filling status will be caused in thixo-extruded components. As indicated in Fig. 3(d), when the pressure holding time was 90 s, the complete filling was seen in the thixo-extruded parts. Figure 3(c) shows the incomplete filing status when the die temperature was 300 °C.

Incomplete filling phenomena were found only in regions A and B, which was the same to Fig. 3(b). Because the heat loss of the semisolid metal (SSM) increased upon contact with the die surface on filling from the die’s gate, incomplete filling is caused. To solve the incomplete filling phenomena, the heat loss of SSM should be minimized by increasing die temperature. When the optimal process parameters such as the applied pressure of 784 MPa, the pressure holding time of 90 s and the die temperature of 450 °C were selected in thixo-extrusion process, the complete filling was obtained successfully (Fig. 3(d)).

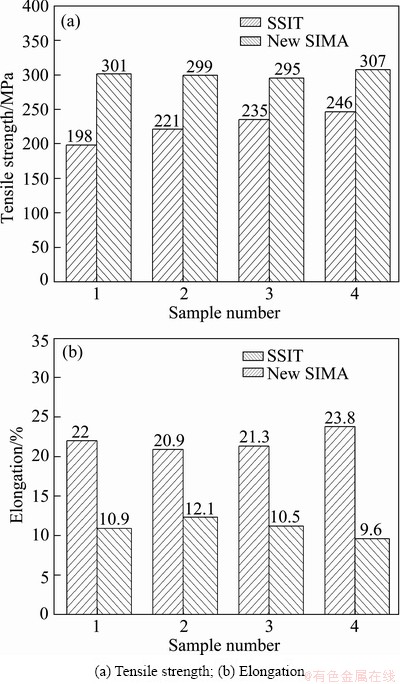

Fig. 4 Room temperature mechanical properties of components formed by thixo-extruding semisolid billets prepared by new SIMA and SSIT

3.2 Mechanical properties and microstructure of thixo-extruded part

Figure 4 shows the room temperature mechanical properties of the thixo-extruded components. The average tensile strength of the thixo-extruded components of the semisolid billet of AZ61 magnesium alloy prepared by new SIMA was 300.5 MPa. The average tensile strength of thixo-extruded components of the semisolid billet of AZ61 magnesium alloy prepared by SSIT was 225 MPa. The elongation of the components formed by thixo- extruding the semisolid billet of AZ61 magnesium alloy prepared by new SIMA was 22%.

However, the average tensile strength of the components formed by thixo-extruding the semisolid billet of AZ61 magnesium alloy prepared by SSIT was 10.8%. Compared with SSIT, the increasing extents of tensile strength and elongation of components formed by thixo-extruding the semisolid billet of AZ61 magnesium alloy prepared by new SIMA were 33.6% and 104%, respectively. It was demonstrated that new SIMA was a desired method for fabricating semisolid billet of AZ61 magnesium alloy.

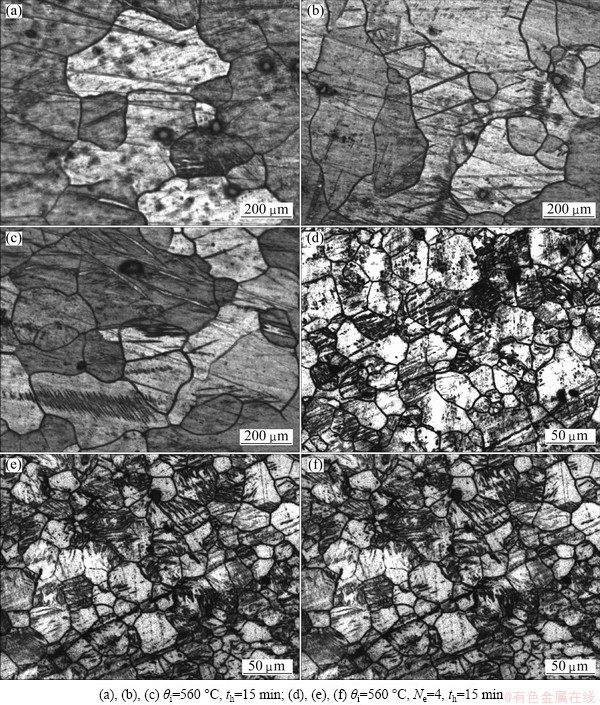

Figure 5 shows the microstructure of the components formed by thixo-extruding the semisolid billets prepared by SSIT and new SIMA. As shown in Figs. 5(a)-(c), the grain of components formed by thixo- extruding the semisolid billet prepared by SSIT was very coarse and the microstructure was inhomogeneous. The minimum grain size was below 100 μm and the maximum grain size was above 360 μm. The average gain size was above 280 μm.

On the contrary, as indicated in Figs. 5(d)-(f), the grain of the components formed by thixo-extruding the semisolid billet prepared by new SIMA was very fine and the microstructure was uniform. The grain size difference between the maximum and minimum grains was evidently decreased compared with SSIT. The maximum grain size was about 60 μm and the minimum grain size was about 10 μm. And the average grain size was about 42 μm. Different microstructures of semisolid billet prepared by SSIT and new SIMA lead to the differences in mechanical properties of the final components [17]. By using ECAE, as-cast magnesium alloy could be refined well and its mechanical properties were enhanced evidently [18]. Those magnesium alloys with sever plastic deformation (SPD) could been treated isothermally in the following semisolid state and semisolid billet with fine and well-spheroidized grains could be obtained [19]. Furthermore, the semisolid billet prepared by new SIMA contributes to obtaining high mechanical properties and fine and homogeneous microstructure in the thixoformed parts.

3.3 Effect of isothermal temperature on mechanical properties and microstructure

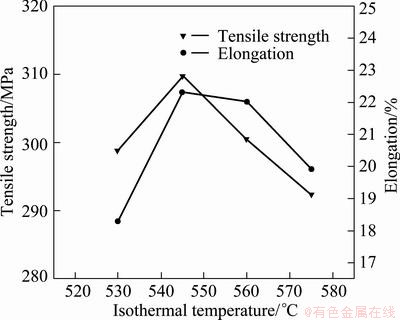

Figure 6 shows the effect of isothermal temperature on the mechanical properties of the thixo-extruded components. As shown in Fig. 6, with the increasing isothermal temperature, the tensile strength and elongation were increased firstly and then decreased. When the isothermal temperature was 545 °C, the mechanical properties of the thixo-extruded components were higher than those of the thixo-extruded components at other isothermal temperatures. It was indicated that there was an optimal isothermal temperature during the thixo-extrusion process.

Fig. 5 Microstructures of components formed by thixo-extruding semisolid billets prepared by SSIT (a, b, c) and new SIMA (d, e, f)

Fig. 6 Effect of isothermal temperature on mechanical properties of thixo-extruded components (Ne=4, th=15 min)

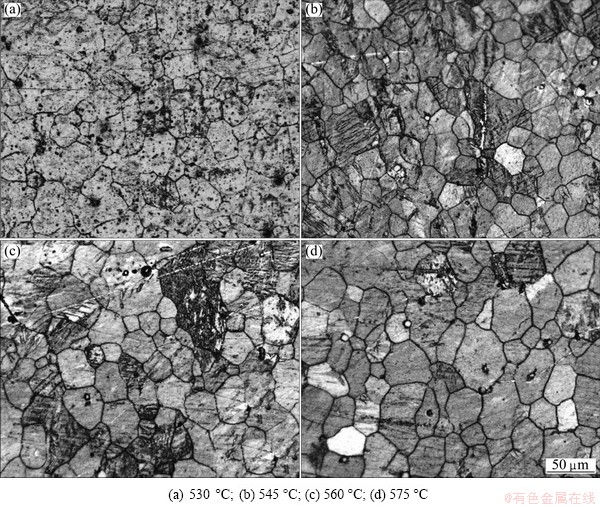

When the isothermal temperature was relatively low, semisolid billet contained low liquid fraction. As a result, solid grains in the semisolid billet could not be enclosed effectively by liquid phase and even some solid grains contacted with each other, which would affect the thixoforming process. It might lead to severe plastic deformation of solid grains. When the severe plastic deformation exceeded the critical deformation ability of these solid grains, the crack or fracture of solid grains was created. Consequently, if these cracks or fractures remained in the thixoformed components, it should be not beneficial to the mechanical properties of thixoformed components. When the isothermal temperature was elevated, the grain size of the semisolid billet was consequently coarsening, which would lead to the coarsening of the grains in the final thixo-extruded parts (Fig. 7). As indicated in Fig. 7, when the isothermal temperature was increased, the grains in the thixo- extruded parts were coarsening. As shown in Fig. 7(a), solid grain boundary was indistinct due to low liquid phase. When the isothermal temperature was increased to 545 °C (Fig. 7(b)), the solid grain boundary became distinct. With the further increase of isothermal temperature (Figs. 7(c) and (d)), the grain size grew up. Furthermore, the semisolid billet with high liquid fraction due to elevated isothermal temperature could not be easily carried into die cavity, which led to difficulties in performing the thixoforming [19].

Liquid phase might be squeezed out of the surface of the semisolid billet when the semisolid billet with relatively high liquid phase was thixo-extruded. As a result, it could lead to the different composition in outside and inside of the components, i.e. composition segregation, which would decrease the mechanical properties of the thixo-extruded components. Therefore, as shown in Fig. 6, when the isothermal temperature was increased from 545 °C to 575 °C, the mechanical properties were decreased due to the coarsening of microstructure and composition segregation.

Fig. 7 Microstructural evolution of thixo-extruded components at various isothermal temperature (Ne=4, th=15 min)

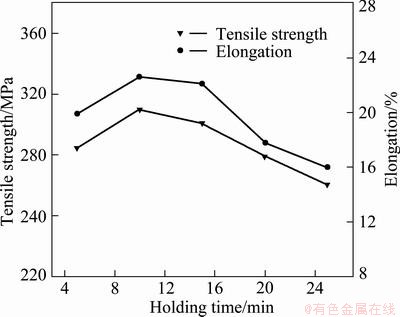

Fig. 8 Effect of holding time on mechanical properties of thixo-extruded components (θi=560 °C, Ne=4)

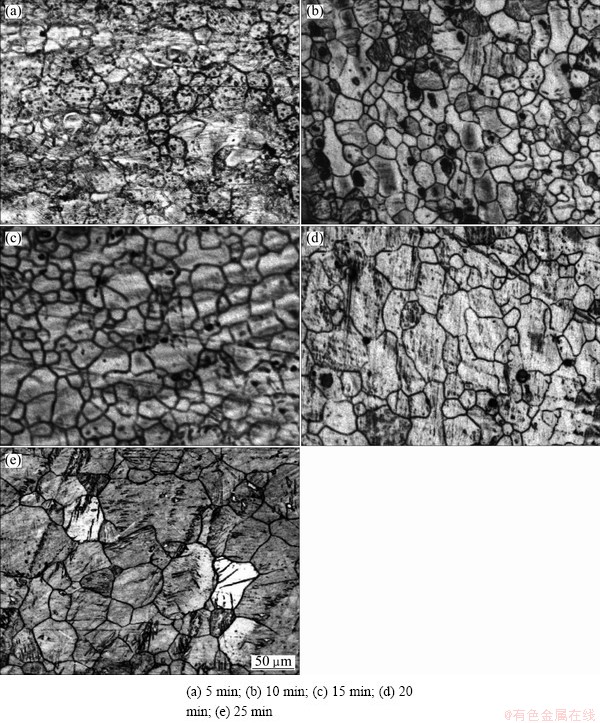

Fig. 9 Effect of holding time on microstructural evolution of thixo- he extruded components (θi=560 °C, Ne=4)

3.4 Effect of holding time on mechanical properties and microstructure

Figure 8 shows the effect of holding time on the mechanical properties of the thixo-extruded components. As shown in Fig. 8, when the holding time was increased from 5 min to 10 min, the tensile strength and elongation of the thixo-extruded components were increased. When the holding time was increased from 10 min to 25 min, the tensile strength and elongation of the thixo-extruded components were decreased. When the holding time was 10 min, the highest mechanical properties such as tensile strength of 309.6 MPa and elongation of 22.6% could be obtained.

Figure 9 shows the microstructure of the thixo- extruded components at various holding time. When the holding time was short (Fig. 9(a)), some solid grains had no enough time to become globular grains and the liquid phase could not surround the solid grains effectively. When the holding time was short, the mechanical properties of parts were relatively low (Fig. 8). The main reason should be attributed to the low liquid amount and casting perfect. When the holding time was increased, the solid grains of semisolid billet prepared by new SIMA were coarsening [17]. The coarsening of solid grains in semisolid billet caused by holding time would influence adversely the mechanical properties of the thixoformed parts. It led to the coarsening of solid grains in the microstructure of the thixo-extruded parts with the increasing holding time (Figs. 9(b)-(e)). Consequently, the mechanical properties of the thixo-extruded parts were decreased with the increasing holding time (Fig. 8).

3.5 Effect of press pass on mechanical properties and microstructure

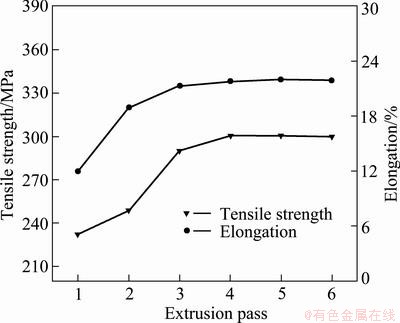

Figure 10 shows the effect of press pass on the mechanical properties of the thixo-extruded components. As shown in Fig. 10, with an increment in press pass, the tensile strength and elongation of the thixo-extruded components were enhanced evidently. When the press pass was increased from 1 to 4, the tensile strength was increased from 241.9 MPa to 300.5 MPa. The increasing extent was 24.2%. When the press pass was increased from 1 to 4, the elongation was increased from 13.9% to 22%. The increasing extent was 58.3%. Furthermore, it could be found that when the press pass was increased from 4 to 6, it had no obvious influence on the mechanical properties.

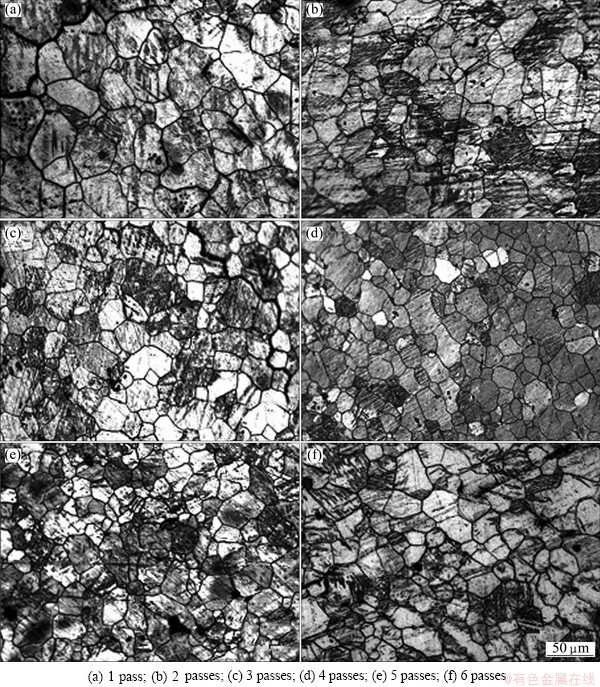

Figure 11 shows the effect of press pass on the microstructure of the thixo-extruded components. As shown in Fig. 11, solid grain was decreased evidently when the press pass was increased from 1 to 4 and the solid grain size was not changed obviously with further increase of press pass. It was demonstrated that the mechanical properties of the thixo-extruded components were increased evidently when the press pass was increased from 1 to 4 and were not changed obviously with further increase.

Fig. 10 Effect of extrusion pass on mechanical properties of thixo-extruded components (θi=560 °C, th=15 min)

Fig. 11 Effect of press passes on microstructural evolution of thixo-extruded components (θi=560 °C, th=15 min)

New SIMA method involved the combination of equal channel angular extrusion (ECAE) and semisolid isothermal treatment (SSIT), which could solve effectively the “strain induced” problems in obtaining severe plastic deformation of magnesium alloy [20].

Grain refinement of ECAE to the as-cast ingots was beneficial to obtaining a lot of fine and spherical solid particles in semisolid ingots. The total accumulated strain (equivalent strain) also increased with the increase of press pass, which led to the increase of dynamic recrystallization degree and further refinement of grains in the processed materials [18]. When the press pass was increased, the grain size of magnesium alloy processed by ECAE was decreased, leading to the decrease of the solid grain size of semisolid billet. As a result, the mechanical properties were increased due to the refined solid grains of the semisolid billet with the increasing press pass.

4 Conclusions

1) Applied pressure, pressure holding time and die temperature had essential effects on the filling behavior of semisolid billet of AZ61 magnesium alloy prepared by the new SIMA. When the optimal process parameters such as the applied pressure of 784 MPa, the pressure holding time of 90 s and the die temperature of 450 °C were selected in the thixo-extrusion process, the complete filling was obtained successfully.

2) The tensile strength of 300.5 MPa and elongation of 22% were obtained in the thixo-extruded components of the semisolid billet of AZ61 magnesium alloy prepared by the new SIMA. Compared with SSIT, the increasing extents of tensile strength and elongation of the thixo-extruded components of the semisolid billet of AZ61 magnesium alloy prepared by new SIMA were 33.6% and 104%, respectively.

3) When the isothermal temperature was 545 °C, the mechanical properties of the thixo-extruded components were higher than those of thixo-extruded components at other isothermal temperatures. With the increase in holding time, the mechanical properties of the thixo- extruded components were also firstly increased then followed by a decrease. When the press pass was increased from 1 to 4, the tensile strength and elongation of the thixo-extruded components were enhanced evidently. When the press pass was increased from 4 to 6, the mechanical properties were not changed obviously.

References

[1] FLEMINGS M C. Behavior of metal alloys in the semisolid state [J]. Metallurgical and Materials Transactions A, 1991, 22(5): 957-981.

[2] CHAYONG S, ATKINSON H V, KAPRANOS P. Thixoforming 7075 aluminum alloys [J]. Materials Science and Engineering A, 2005, 390(1-2): 3-12.

[3] KOPP R, NEUDENBERGER D, WIMMER M, WINNING G. Thixoforging basic experiment and optimized tool design [C]//BHASIN A K, MOORE J J, YOUNG K P, MIDSON S P. Proceeding of the Fifth International Conference on Semi-Solid Processing of Alloys and Composites. Colorado: Colorado School of Mines, 1998: 336-341.

[4] FREITASDE E, FERRANTE M, SILVA DA V F, FILHO BOSE W, SPINELLI D. Thixo-extrusion of an A356 alloy: Microstructural studies and high temperature fatigue behaviour [J]. Journal of Materials Processing Technology, 2004, 155-156: 1629-1633.

[5] CHEN C M, YANG C C, CHAO C G. Thixocasting of hypereutectic Al-25Si-2.5Cu-1Mg-0.5Mn alloys using densified powder compacts [J]. Materials Science and Engineering A, 2004, 366: 183-194.

[6] KIM S K, YOON Y Y, JO H H. Novel thixo-extrusion process for Al wrought alloys [J]. Journal of Materials Processing Technology, 2007, 187-188: 354-357.

[7] RIKHTEGAR F, KETABCHI M. Investigation of mechanical properties of 7075 Al alloy formed by forward thixo-extrusion process [J]. Materials & Design, 2010, 31(8): 3943-3948.

[8] CHO W G, KANG C G. Mechanical properties and their microstructure evaluation in the thixoforming process of semi-solid aluminum alloys [J]. Journal of Materials Processing Technology, 2000, 105(3): 269-277.

[9] BIROL Y. Comparison of thixoformability of AA6082 reheated from the as-cast and extruded states [J]. Journal of Alloys and Compounds, 2008, 461(1-2): 132-138.

[10] FORN A, VANEETVELD G, PIERRET J C, MENARGUES E, BAILE M T, CAMPILLO M, RASSILI A. Thixoextrusion of A357 aluminium alloy [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: s1005-s1009.

[11] RASSILI A, ATKINSON H V. A review on steel thixoforming [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(s3): s1048-s1054.

[12] PIERRET J C, RASSILI A, VANEETVELD G, LECOMTE- BECKERS J. Stability of steel thixoforming process [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(3): s937-S942.

[13] ZHANG Q Q, CAO Z Y, LIU Y B, ZHANG Y F, ZHANG L, ZHANG M L, WU R Z. Effect of asymmetrical deformation on the microstructure evolution of semisolid AZ91D alloy [J]. Materials Science and Engineering A, 2008, 488(1-2): 260-265.

[14] ZHANG Q Q, CAO Z Y, ZHANG Y F, SU G H, LIU Y B. Effect of compression ratio on the microstructure evolution of semisolid AZ91D alloy [J]. Journal of Materials Processing Technology, 2007, 184(1-4): 195-200.

[15] GUAN R G, CHEN L Q, LI J P, WANG F X. Dynamical solidification behaviors and metal flow during continuous semisolid extrusion process of AZ31 alloy [J]. Journal of Materials Science and Technology, 2009, 25(3): 395-400.

[16] GUAN Ren-guo, ZHAO Zhan-yong, SUN Xiao-ping, HUANG Hong-qian, DAI Chun-guang, ZHANG Qiu-sheng. Fabrication of AZ31 alloy wire by continuous semisolid extrusion process [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(s3): s729-s733.

[17] JIANG J F, WANG Y, LUO S J. Application of equal channel angular extrusion to semi-solid processing of magnesium alloy [J]. Materials Characterization, 2007, 58(2): 190-196.

[18] JIANG J F, WANG Y, QU J J, DU Z M, SUN Y, LUO S J. Microstructure evolution of AM60 magnesium alloy semisolid slurry prepared by new SIMA [J]. Journal of Alloys and Compounds, 2010, 497(1-2): 62-67.

[19] JIANG J F, LUO S J. Research on thixoforging magazine plate of AZ91D magnesium alloy in semi-solid state [J]. Solid State Phenomena, 2006, 116-117: 267-270.

[20] JIANG Ju-fu, LUO Shou-jing. Preparation of semi-solid billet of magnesium alloy and its thixoforming [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(1): 46-50.

姜巨福1,王 迎2,柳 君1,曲建俊2,杜之明1,罗守靖1

1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 哈尔滨工业大学 机电工程学院,哈尔滨 150001

摘 要:新应变诱导熔化激活法被用来制备高质量的AZ61镁合金半固态坯料。利用光学显微镜和拉伸实验,研究触变挤压成形零件的微观组织与力学性能。结果表明:当施加的压力为784 MPa,保压时间为90 s,模具温度为450 °C时,半固态坯料能够完全充填模具型腔。与半固态等温处理方法相比,新SIMA法制备的半固态坯料触变挤压成形零件的抗拉强度和伸长率分别为300.5 MPa和22%;并且成形零件的微观组织晶粒细小、组织均匀。随着等温处理温度的升高和保温时间的延长,成形零件的抗拉强度和伸长率先增加后降低。当挤压道次从1增加至4时,成形零件的抗拉强度和伸长率明显增加。

关键词:AZ61镁合金;半固态坯料;新应变诱导熔化激活;触变挤压

(Edited by Hua YANG)

Foundation item: Project (51075099) supported by the National Natural Science Foundation of China; Project (E201038) supported by the Natural Science Foundation of Heilongjiang Province, China; Project (20090460884) supported by the China Postdoctoral Science Foundation; Projects (HIT.NSRIF.2013007 and 2012038) supported by the Fundamental Research Funds for the Central Universities, China; Project (2011RFQXG010) supported by the Harbin City Young Scientists Foundation under the Grant; Project (LBH-T1102) supported by the Specially Postdoctoral Science Foundation of Heilongjiang Province, China

Corresponding author: Ju-fu JIANG; Tel: +86-451-86415464; E-mail: jiangjufu@hit.edu.cn

DOI: 10.1016/S1003-6326(13)62502-9