Trans. Nonferrous Met. Soc. China 23(2013) 329-334

Effect of hot deformation conditions on grain structure and properties of 7085 aluminum alloy

Song-yi CHEN, Kang-hua CHEN, Le JIA, Guo-sheng PENG

State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China

Received 8 November 2011; accepted 21 March 2012

Abstract: The influences of deformation conditions on grain structure and properties of 7085 aluminum alloy were investigated by optical microscopy and transmission electron microscopy in combination with tensile and fracture toughness tests. The results show that the volume fraction of dynamic recrystallization increased with the decrease of Zener-Hollomon (Z) parameter, and the volume fraction of static recrystallization increased with the increasing of Z parameter. The strength and fracture toughness of the alloy after solution and aging treatment first increased and then decreased with the increase of Z parameter. The microstructure map was established on the basis of microstructure evolution during deformation and solution heat treatment. The optimization deformation conditions were acquired under Z parameters of 1.2×1010-9.1×1012.

Key words: 7085 aluminum alloy; Zener-Hollomon parameter; hot deformation; grain structure; dynamic recrystallization; static recrystallization

1 Introduction

Al-Zn-Mg-Cu alloy with high strength and fracture toughness has been widely used as the structure materials in aerospace field [1,2]. The properties are significantly influenced by the grain structure [3-5], such as recrystallized grains having decreased strength and fracture toughness. The Zener-Hollomon parameter (Z) is an important parameter for controlling and forecasting grain structure in the deformation process, and it is related to the couple effect of deformation temperature and strain rate ( . The correlations between Z values and grain structure were reported by many researchers. DENG et al [6] reported that the subgrain size increased with the decrease of Z values. ZHAO and TSUCHIDA [7] demonstrated that the crystalline orientation distribution of compressed and solution heat-treated sample was stable at small Z parameter. Although the flow stress, deformation mechanism and grain boundary orientation of 7xxx aluminum alloy have been investigated [8-17], there is little research about the influence of Z parameter on the microstructure evolution during deformation and subsequent solution heat treatment. The purpose of this work is to study the effect of hot deformation conditions on deformation and solution heat treatment microstructure. The correlations among hot deformation parameters, microstructure and properties are also discussed.

. The correlations between Z values and grain structure were reported by many researchers. DENG et al [6] reported that the subgrain size increased with the decrease of Z values. ZHAO and TSUCHIDA [7] demonstrated that the crystalline orientation distribution of compressed and solution heat-treated sample was stable at small Z parameter. Although the flow stress, deformation mechanism and grain boundary orientation of 7xxx aluminum alloy have been investigated [8-17], there is little research about the influence of Z parameter on the microstructure evolution during deformation and subsequent solution heat treatment. The purpose of this work is to study the effect of hot deformation conditions on deformation and solution heat treatment microstructure. The correlations among hot deformation parameters, microstructure and properties are also discussed.

2 Experimental

The experiments were carried out on 7085 aluminum alloy with main chemical compositions of 7.5% Zn, 1.6% Mg, 1.5% Cu, 0.12% Zr and Al balance (mass fraction). Cylindrical samples with 10 mm in diameter and 15 mm in height were machined from the homogenized billets. Compression tests were carried out at deformation temperature of 350-450 °C with strain rate of 0.0001-1 s-1. Before compression, the samples were heated to deformation temperature at a heating rate of 10 °C/s and held at the temperature for 3 min. The strain of the samples was 1.38 and the samples were quenched immediately after compression. In order to reduce the frictional force between the specimens and the press indenters, a graphite lubricant was used during the isothermal compression tests.

The microstructures of samples were examined using optical microscopy (OM) and transmission electron microscopy (TEM). Samples for OM observation were chemically etched in Graff’s reagent (1 mL HF + 16 mL HNO3 + 3 g CrO3 + 83 mL H2O). The volume fraction of the recrystallized grains was measured on the optical micrographs by using area counting. The average grain size was measured by the mean linear intercept method, and the value was the average of as much as 100 grains. Thin foils for TEM observation were prepared by mechanical polishing to 100 μm and final twin-jet electro polishing in a solution of 25% HNO3 + 75% CH3OH at -25 °C.

The specimens for properties testing were isothermally compressed at various temperatures and strain rate of 0.005 s-1 with strain of 1.38. Specimens were solution treated at 470 °C for 1 h and artificially aged at 120 °C for 24 h. Mechanical properties tests were performed on smooth plate specimens by an Instron 3369 test machine at room temperature with tensile speed of 2 mm/min. The gauge length and thickness of the specimen were 25 mm and 2 mm, respectively. The V-shaping method was used to determine the fracture toughness.

3 Results

3.1 Deformation microstructure

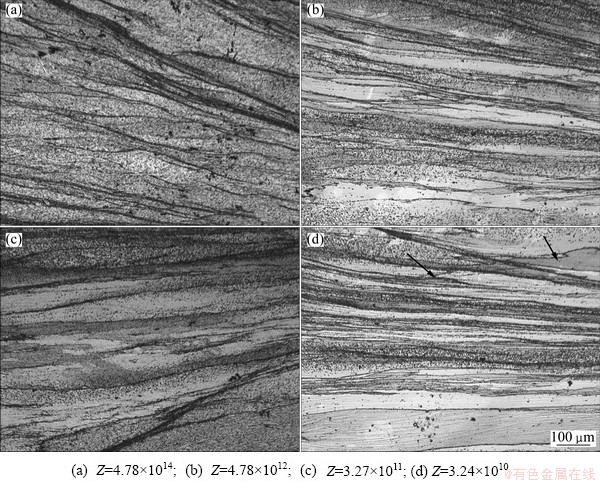

Figure 1 shows the typical optical micrographs of the alloy deformed under different Zener-Hollomon (Z) parameters. The initial grains are elongated and a number of second particles are distributed within the grains. Under high and intermediate Z parameters, there are no recrystallized grains along the grain boundaries (Figs. 1(a) and (b)). As it is compressed under low Z parameter, a small volume fraction of recrystallized grains is observed along the grain boundaries, indicating the occurrence of dynamic recrystallization (Fig. 1(d)).

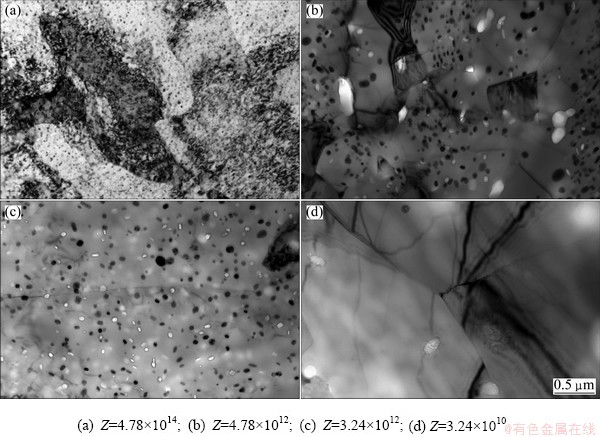

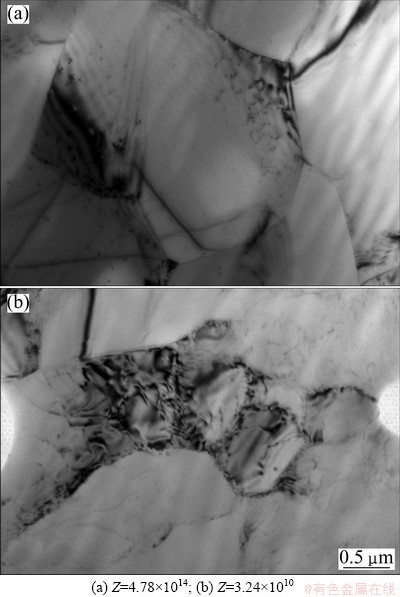

The TEM microstructures of the alloy deformed under different Zener-Hollomon (Z) parameters are shown in Fig. 2. The high density dislocations tangle with precipitates under high Z parameter (Fig. 2(a)), and the dislocation slightly decreases and the precipitates coarsen under intermediate Z parameter (Figs. 2(b) and (c)). As it is compressed under low Z parameter, the dislocation annihilates and the subgrains grow (Fig. 2(d))

3.2 Solution heat treatment microstructure

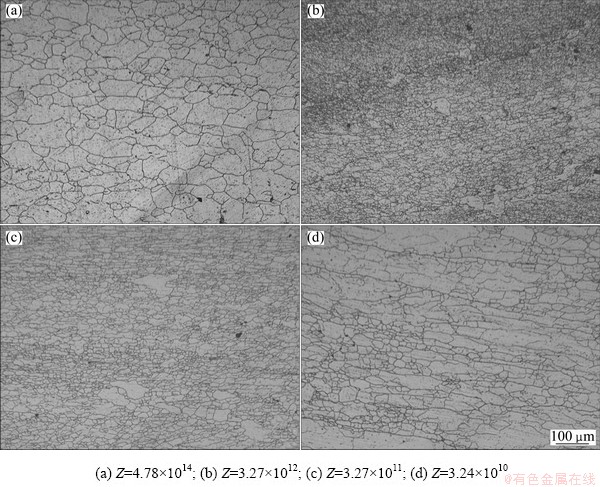

Figure 3 shows the typical optical micrographs of the alloy deformed under different Z parameters, followed by solution heat treatment at 470 °C for 1 h. In the figures, the large bright areas are the recrystallized regions, while the black areas are the unrecrystallized regions. At high Z parameter, it is full recrystallization (100%) and the average grain size is 53 μm (Fig. 3(a)). The volume fraction of the recrystallized grains (25%) and the average grain size (about 18 μm) are significantly decreased as it is compressed under intermediate Z parameter (Fig. 3(b)). At a low Z parameter (Fig. 3(d)), the volume fraction of the recrystallized grains (18%) does not obviously change while the average grain size increases (about 25 μm).

Fig. 1 Optical microstructures of specimens deformed under different Z parameters

Fig. 2 TEM images of specimens deformed under different Z parameters

Fig. 3 Optical microstructures of specimens deformed under different Z parameters, followed by solution heat treatment at 470 °C for 1 h

TEM microstructures of the specimens deformed under different Z parameters, followed by solution heat treatment at 470 °C for 1 h are shown in Fig. 4. The microstructures are obviously different with those under the deformation conditions. The dislocation and the second particles are dissolved and the subgrains are grown. At a high Z parameter, the subgrains are larger than those at a low Z parameter.

Fig. 4 TEM images of specimens deformed under different Z parameters, followed by solution heat treatment at 470 °C for 1 h

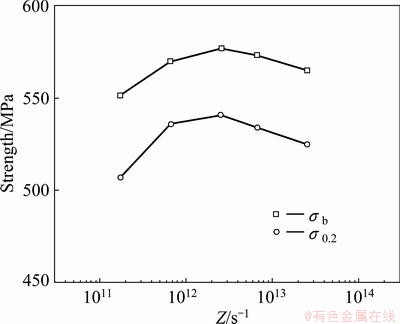

Fig. 5 Correlation between strength and Z parameters of alloy after solution and aging heat treatment

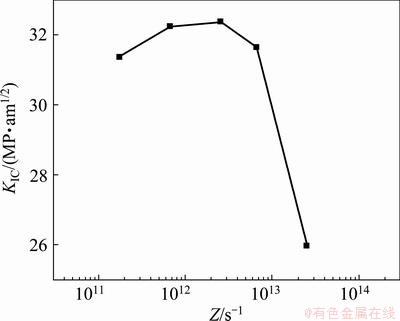

Fig. 6 Correlation between fracture toughness and Z parameters of alloy after solution and aging heat treatment

3.3 Properties

Figures 5 and 6 show the strength and fracture toughness of the alloy deformed under different Z parameters, followed by solution heat treatment at 470 °C for 1 h and T6 aging treatment. The strength and fracture toughness first increase and then decrease with increasing Z parameters. It is also observed that compared to the intermediate and low Z parameters, the fracture toughness of specimens with the high Z parameter decreases rapidly.

4 Discussion

In the deformation process, the deformation energy of the material is mainly in the form of dislocations, and it is depended on the hot processing parameters, such as temperature and strain rate. The energy releases through recovery, recrystallization and grain growth. The extent of dynamic recovery increases with the decrease of Zener-Hollomon parameter. Dynamic recrystallization occurs while the dislocation density in a deformation matrix reaches a critical level [18]. Therefore, the main mechanism during deformation processing is dynamic recovery to dynamic recrystallization with the decrease of Zener-Hollomon parameters.

The microstructures of the solution heat-treated samples were obviously different compared with that of the deformation samples. The elongated grains were transformed into recrystallized grains and subgrains, and the second particles dissolved. The high stored energy of deformation grain under high Z parameter induced the static recrystallization during high temperature solution heat treatment, and under some conditions led to full recrystallization. It is indicated that the high Z parameter compression can stimulate recrystallization process during solution heat treatment. However, for the low Z parameter samples, the volume fraction of static recrystallization was less than that of high Z parameter sample, which was attributed to the dislocation annihilation during the deformation process due to dynamic recovery and dynamic recrystallization.

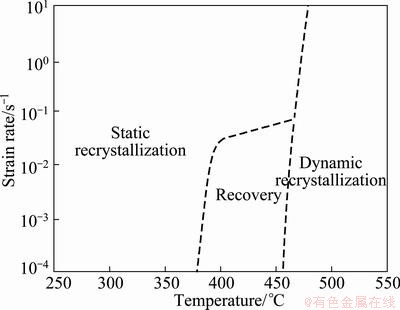

From the above microstructure observation, the microstructure evolution during the deformation and subsequently solution heat treatment can be classed into the dynamic recrystallization, recovery and static recrystallization. Figure 7 shows the microstructure map of the alloy after hot deformation and solution heat treatment under different deformation parameters. The static recrystallization zones corresponded to high Z parameters (temperature below 380 °C and strain rate higher than 0.1 s-1). The dynamic recrystallization zone related to low Z parameter (temperature above 450 °C). The other compression conditions are recovery zone.

The strength and fracture toughness were significantly affected by the recrystallization grain size and the volume fraction of recrystallization. The high strength or low Z regions were related to the partial or unrecrystallized substructure, while the low strength levels were associated with the complete recrystallization structures. The rapid decreasing of fracture toughness with increasing Z parameters was attributed to the high volume fraction of recrystallization and it is susceptible to intergranular fracture.

Fig. 7 Microstructure map of alloy after deformation and solution heat treatment

Combining with the microstructure map, the strength and fracture toughness, it is observed that deformation parameters were lied on the recovery dominated zone with optimization properties. Therefore, the optimization deformation condition was under Z parameters of 1.2×1010-9.1×1012.

5 Conclusions

1) The volume fraction of dynamic recrystallization increased with the decrease of Zener-Hollomon (Z) parameter, and the volume fraction of static recrystallization increased with the increasing of Z.

2) The strength and fracture toughness first increased and then decreased with the increase of Z after solution and aging treatment.

3) Based on the microstructure evolution during deformation and solution treatment, the microstructure map was established. The optimized deformation condition was under Z parameters of 1.2×1010-9.1×1012 based on grain structure and properties.

References

[1] HEINZ A, HASZLER A, KEIDEL C, MOLDENHAUER S, BENEDICTUS R, MILLER W S. Recent development in aluminum alloys for aerospace applications [J]. Material Science and Engineering A, 2000, 280(3): 102-107.

[2] WARNER T. Recently-developed aluminum solutions for aerospace applications [J]. Material Science Forum, 2006, 519-521(2): 1271-1278.

[3] DORWARD R C, BEERNTSEN D J. Grain structure and quench-rate effects on strength and toughness of AA7050 Al-Zn-Mg-Cu-Zr alloy plate [J]. Metallurgical and Materials Transactions A, 1995, 26(9): 2481-2484.

[4] DESHPANDE N U, GOKHALEG A M, DENZER D K, LIU J. Relationship between fracture toughness, fracture path, and microstructure of 7050 aluminum alloy: Part I. Quantitative characterization [J]. Metallurgical and Materials Transactions A, 1998, 29(4): 1191-1201.

[5] BOBBY KANNA M, RAJA V S. Enhancing stress corrosion cracking resistance in Al-Zn-Mg-Cu-Zr alloy through inhibiting recrystallization [J]. Engineering Fracture Mechanics, 2010, 77(2): 249-256.

[6] DENG Y, YIN Z M, HUANG J W. Hot deformation behavior and microstructural evolution of homogenized 7050 aluminum alloy during compression at elevated temperature [J]. Material Science and Engineering A, 2011, 528(3): 1780-1786.

[7] ZHAO P Z, TSUCHIDA T. Effect of fabrication conditions and Cr, Zr contents on the grain structure of 7075 and 6061 aluminum alloys [J]. Materials Science and Engineering A, 2009, 499(1-2): 78-82.

[8] KOU Lin-yuan, JIN Neng-ping, ZHANG Hui, HAN Yi, WU Wen-xiang, LI Luo-xing. Flow stress behavior of 7150 aluminum alloy during hot compression deformation at elevated temperature [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 43-48. (in Chinese)

[9] LI Jun-peng, SHEN Jian, YAN Xiao-dong, MAO Bai-ping, YAN Liang-ming. Recrystallization behavior of 7050 aluminum alloy during multi-pass hot compression process [J]. The Chinese Journal of Nonferrous Metals, 2009, 19(10): 1754-1757. (in Chinese)

[10] HU Hui-e, YANG Li, ZHEN Liang, SHAO Wen-zhu, ZHANG Bao-you. Relationship between boundary misorientation angle and true strain during high temperature deformation of 7050 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(4): 795-798.

[11] JIN N P, ZHANG H, HAN Y, WU W X,CHEN J H. Hot deformation behavior of 7150 aluminum alloy during compression at elevated temperature [J]. Materials Characterization, 2009, 60(6): 530-536.

[12] LIU S D, YOU J H, ZHANG X M, DENG, Y L, YUAN Y B. Influence of cooling rate after homogenization on the flow behavior of aluminum alloy 7050 under hot compression [J]. Materials Science and Engineering A, 2010, 527(4-5): 1200-1205.

[13] ZHEN L, HU H, WANG X, ZHANG B, SHAO W. Distribution characterization of boundary misorientation angle of 7050 aluminum alloy after high-temperature compression [J]. Journal of Materials Processing Technology, 2009, 209(2): 754-761.

[14] SHEPPARD T, JACKSON A. Constitutive equations for use in prediction of flow stress during extrusion of aluminum alloys [J]. Materials Science and Technology, 1997, 13(3): 203-209.

[15] CERRI E, EVANGELISTA E, FORCELLESE A, McQUEEN H J. Comparative hot workability of 702 and 7075 alloys after different pretreatments [J]. Materials Science and Engineering A, 1995, 197(2): 181-198.

[16] CHEN S, CHEN K, PENG G, CHEN X, CENG Q. Effect of heat treatment on hot deformation behavior and microstructure evolution of 7085 aluminum alloy [J]. Journal of Alloys and Compounds, 2012, 537(1): 338-345.

[17] LUO J, LI M, MU B. The correlation between flow behavior and microstructural evolution of 7050 aluminum alloy [J]. Materials Science and Engineering A, 2011, 530(1): 559-564.

热变形条件对7085铝合金晶粒结构和性能的影响

陈送义,陈康华,贾 乐,彭国胜

中南大学 粉末冶金国家重点实验室,长沙 410083

摘 要:通过光学显微镜、透射电镜和力学与断裂性能测试,研究热变形条件对7085铝合金晶粒结构和性能的影响。结果表明,动态再结晶的体积分数随着Z值的减少而增加,静态再结晶的体积分数随着Z值的减少而降低。经固溶时效后,合金的力学性能和断裂性能随着Z值的增加先升高后降低。建立了综合变形和固溶过程中的显微组织演化图。在考虑显微组织和性能的基础上,合金优化的Z参数变形条件为1.2×1010-9.1×1012.

关键词:7085铝合金;Z参数;热变形;晶粒结构;动态再结晶;静态再结晶

(Edited by Sai-qian YUAN)

Foundation item: Projects (2010CB731701, 2012CB619502) supported by National Basic Research Program of China; Project (51021063) supported by Creative Research Group of National Natural Science Foundation of China; Project (CX2012B043) supported by Hunan Provincial Innovation Foundation for Postgraduate

Corresponding author: Kang-hua CHEN; Tel: +86-731-88830714; Fax: +86-731-88710855; E-mail: khchen@mail.csu.edu.cn

DOI: 10.1016/S1003-6326(13)62465-6