DOI: 10.11817/j.issn.1672-7207.2018.06.003

操作参数对直接提钒焙烧竖炉热工特性的影响

高建业1,骆旭峰1,孙用军1,2,董辉1

(1. 东北大学 国家环境保护生态工业重点实验室,辽宁 沈阳,110819;

2. 中航商用航空发动机有限责任公司,上海,200241)

摘要:以局部热力学非平衡模型为基础,建立钒钛磁铁矿直接提钒焙烧竖炉三维稳态气固传热模型,借助Fluent软件的UDF功能,将竖炉内的化学反应热以内热源的形式编译到能量方程中,并利用实验获得的料层压降公式修正动量方程源项中的黏性和惯性力项系数,开展竖炉操作参数对炉内热工行为的影响研究。研究结果表明:在生产可调范围内,随着球团当量直径的减小,在焙烧段内球团温度会随之升高,在冷却段内球团温度会随之降低,且竖炉保温段延长;对于产能为330 t/a的中试竖炉,其适宜的操作参数为:冷却空气流量544 m3/t,竖炉下部气固水当量比约0.95;焙烧风流量1 082 m3/t,焙烧风与冷却风配比2:1;球团当量直径46 mm。

关键词:钒钛磁铁矿;焙烧竖炉;移动床;气固传热;数值计算

中图分类号:TF 841.3;TF 521.1 文献标志码:A 文章编号:1672-7207(2018)06-1325-08

Influence of operation parameters on thermal characteristics of roasting shaft furnace for direct extracting vanadium

GAO Jianye1, LUO Xufeng1, SUN Yongjun1,2, DONG Hui1

(1. SEP Key Laboratory on Eco-industry, Northeastern University, Shenyang 110819, China;

2. AVIC Commercial Aircraft Engine Co., Ltd., Shanghai 200241, China)

Abstract: Based on the local thermodynamic non-equilibrium model, the three-dimensional stable-state gas-solid heat transfer model of roasting shaft furnace for compact extracting vanadium was established. By virtue of user-defined functions in Fluent, the chemical reaction heat was defined within the solid energy equation in the form of heat source, and the air resistance coefficients in the source terms of momentum equation were corrected and defined by the layer pressure drop formula in shaft furnace. The effect of operation parameters on the thermal behavior in shaft furnace was conducted. The results show that in the adjustable production range, the pellet temperature decreases in the roasting section and increases in the cooling section with the increase of pellet diameter, besides, the soaking section is extended. For a given pilot scale roasting shaft furnace of 330 t/a, the suitable operating parameters are as follows: cooling air volume is 544 m3/t, the gas solid water equivalent is approximately 0.95, the roasting air volume is 1 082 m3/t, the ratio of roasting air volume and cooling air volume is 2, and the suitable pellet diameter is 46 mm.

Key words: vanadium titanium magnetite; roasting shaft furnace; moving bed; gas-solid heat transfer; numerical simulation

直接提钒是针对于辽西高钒钛低铁型钒钛磁铁精矿提出的,直接从精矿生产钒制品的短流程工艺。作为该工艺的核心设备,直接提钒焙烧竖炉是针对于现有回转窑内物料填充率低、原料适应性差等缺点,借鉴钢铁领域球团竖炉,提出的一种竖式焙烧设备,其具有体积小、初始投资低、运行便利等优点[1-2]。从热工角度而言,直接提钒焙烧竖炉是一种典型的气固逆流竖式颗粒床层,属移动床层范畴;竖炉内进行着钒钛磁铁矿球团与空气的气固换热,并伴随氧化焙烧反应。根据炉窑3类变量关系[3-4],焙烧竖炉的操作参数变化影响着炉内的气体流动与气固传热过程,进而影响着球团的焙烧质量与产量。基于此,开展竖炉内操作参数变化对竖炉炉温分布的影响研究,可为强化竖炉焙烧效果和优化竖炉热工制度奠定基础。就床层本质而言,焙烧竖炉属大颗粒随机填充床层,可借鉴大颗粒填充床内气固流动与传热的相关研究[5-14]。LEONG等[5]采用局部热平衡模型和多孔介质模型,研究了空隙率分布对料层内气体流动和气固传热的影响,但没有考虑冷却空气和料层间的对流换热。AL-SUMAILY 等[6]分别采用局部热力学平衡模型和非平衡模型分析了填充床内颗粒粒径对流体流动和气固换热的影响,详细对比了不同模型的气体和固体温度变化规律,模拟结果得出局部非热力学平衡模型更适用于描述填充床内气固热交换过程。GHADI等[7]基于多孔介质理论和局部热非平衡模型建立了Midrex竖炉二维轴对称气固稳态流动和传热数值模型,研究了双气喷吹系统对竖炉内反应的影响。ZHOU等[8-9]基于多孔介质模型建立了高炉二维稳态气固传热模型,并将高炉内气固换热与气体流动过程进行耦合,讨论了不同料层分布和入口条件对高炉软熔带形状的影响。蒋鹭等[10]基于欧拉多相流模型,建立了南钢球团竖炉的三维数理模型,并探讨了不同操作参数对竖炉炉温和焙烧产物Fe2O3生产率的影响规律。BLUHM-DRENHAUS等[11-13]采用离散单元法与流体动力学耦合模型,研究了石灰竖窑内的传热传质过程。ZHANG等[14]根据多孔介质模型和局部热非平衡模型,建立烧结矿冷却过程的三维非稳态换热模型,讨论了颗粒直径、入口空气流速等因素的影响趋势,得出了最佳余热回收效果下的匹配参数,但模型中动量方程源项基于经典Ergun经验关联式,与实际工况存在误差。综上所述,目前,有关移动床气固传热数值计算多基于多孔介质和局部热非平衡模型,但模型中动量方程源项基于传统经验关联式,缺乏针对性。有关钒钛磁铁矿直接提钒焙烧竖炉内气固传热的稳态研究还鲜有文献报道。基于此,本文作者以局部热力学非平衡模型为基础,将竖炉内化学反应热以内热源的形式定义在能量方程中,并将在自制实验平台获得的料层压降公式定义到动量方程源项中,建立直接提钒焙烧竖炉的三维稳态数值模型,研究并分析竖炉操作参数对竖炉热工行为的影响,在保障钒钛冶金要求和企业节能降耗的前提下,获得中试焙烧竖炉适宜的操作参数,为后续中试焙烧工艺的改进奠定基础。

1 模型的建立

1.1 物理模型及其假设条件

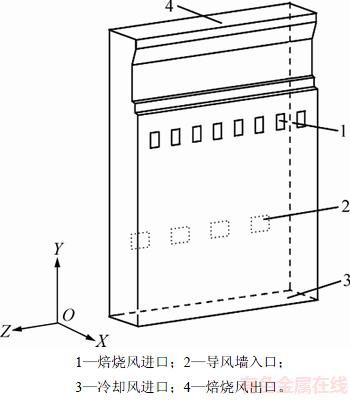

生球团矿从竖炉顶部进入,经预热后下行,在燃烧室出口与焙烧风进行热量交换,并在下行均热过程中逐步完成金属元素的结晶转化过程,而后继续向下运动被上行的冷却风冷却,最终经排料口排出;冷却风自竖炉底部鼓入,一部分直接上行,完成球团冷却后用于补充球团氧化所需气氛,另一部分进入导风墙后上行,在顶部与焙烧风汇集,用于预热生球团矿。

竖炉结构参照辽宁某地中试竖炉,其平面图如图1所示,考虑到竖炉炉型左右对称,探究其一侧炉腔内的温度场及流场分布即可确定竖炉整体的工作状态,为简化模型,取竖炉的一半作工况分析(图1中虚线区域)。图2所示为通过笛卡儿坐标系建立竖炉一侧的三维物理模型,竖炉炉身高为6.4 m,宽为1.1 m,长为2.5 m,其X轴从竖炉内导风墙指向竖炉外壁燃烧室,Y轴沿竖炉高度方向向上,Z轴沿竖炉宽度方向从里侧指向外侧。

由于竖炉内球团颗粒的填充结构类似于多孔介质,可将球团堆积区域假设为多孔介质区域来进行数值计算。考虑到焙烧竖炉内气流流动和气固传热过程的复杂性,在保证计算精度的前提下,对焙烧竖炉的物理模型进行如下假设:

1) 竖炉内钒矿球团为各相同性多孔介质,竖炉底部气流分布均匀;

2) 钒钛磁铁矿焙烧竖炉运行工况稳定,各参数在一定范围内认为恒定;

3) 将焙烧竖炉内的气体看作不可压缩流体,其密度变化符合理想气体状态方程,气体流动过程视为单相流体稳态流动。

图1 直接提钒焙烧竖炉结构示意图

Fig. 1 Structural diagram of roasting shaft furnace for direct extracting vanadium

图2 直接提钒焙烧竖炉三维物理模型

Fig. 2 Three-dimensional physical model of roasting shaft furnace for direct extracting vanadium

1.2 控制方程

钒钛磁铁矿直接提钒焙烧竖炉内气固传热与气体流动控制方程如下。

1) 连续性方程:

(1)

(1)

2) 动量方程:

(2)

(2)

式中:ρf为空气密度,kg/m3;ui,uj分别为在i,j方向上的气体速度,m/s;Pij为表面压力,包括静压力和气体黏性压力,Pa;gi为气体在i方向上的体积作用力,N/m3;fi为作用在单位体积气体上的反方向阻力,N/m3。

在动量守恒方程(2)中增加动量损失源项Si,用来描述气体流经竖炉内多孔介质时的动量输运过程。

(3)

(3)

式中:1/α为黏性阻力系数;C2为惯性阻力系数;μ为气体动力黏度,Pa·s;u为气体流动速度,m/s。

通过实验获得描述焙烧竖炉内气流阻力特性的修正Ergun方程[15],基于此定义多孔介质区域黏性阻力系数和惯性阻力系数。

(4)

(4)

(5)

(5)

(6)

(6)

式中:ε为床层空隙率;dp为钒钛磁铁矿球团当量直径,m。

3) 能量方程。采用局部非平衡热力学稳态双能量方程求解竖炉内钒钛磁铁矿球团与气体间的换热过 程[16],对竖炉内气体和钒钛磁铁矿球团分别建立能量方程。

气相:

(7)

(7)

固相:

(8)

(8)

式中:ρs为钒钛磁铁矿球团的密度,kg/m3;cs和cp分别为钒钛磁铁矿球团和空气的比热容,J/(kg·K);us和uf分别为颗粒下移速度和气体表观流速,m/s;Ts和Tf分别为钒钛磁铁矿球团和空气温度,K;λs和λf分别为钒钛磁铁矿球团和空气的导热系数,W/(m·K);hv为气固对流体积换热系数[4],W/(m3·K);Φ为钒钛磁铁矿球团焙烧化学反应内热源项,W/m3。

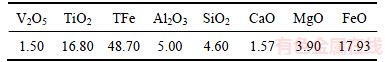

钒钛磁铁精矿经造球形成的球团,表1所示为测得的钒钛磁铁矿球团成分。

表1 钒钛磁铁矿球团成分(质量分数)

Table 1 Composition ratio of vanadium titanium magnetite pellets %

钒钛磁铁矿焙烧和保温是固体矿在氧化气氛下从低温加热到高温再维持高温环境的连续过程[17],主要的化学反应及其化学反应热如表2所示。

表2 竖炉内化学反应

Table 2 Chemical reactions in shaft furnace

根据上述化学反应,计算实际工况下的化学反应需氧量以控制竖炉内冷风上行量,并通过计算化学反应放热量确定固相能量方程中源项,编写UDF程序,将化学反应热嵌入计算模型中。

1.3 边界条件

竖炉冷却风入口采用速度入口边界条件,其入口速度由鼓风机流量确定。导风墙下出口和竖炉顶部出口设为压力出口,由于竖炉顶部设有引风机,开启时使得竖炉顶部和导风墙内形成负压环境,实地测得现场竖炉出口压力约为0 Pa,导风墙内压力约为0 Pa。竖炉焙烧风入口采用速度入口边界条件,其入口速度由助燃风机流量和燃烧产物分析确定。由于竖炉生产过程中,壁面设有保温材料,竖炉壁面设置为绝热面,不考虑通过该面的散热损失。

1.4 模型计算方法

根据焙烧竖炉内气固传热特点,采用多孔介质移动床稳态传热模型,并将焙烧过程化学反应放热转化为传热内热源;湍流模型选用Standard k-ε双方程模型[18];能量传输模型采用移动床局部热非平衡模型;压力插补格式采用STANDARD格式;采用压力与速度耦合的SIMPLE算法;采用结构化网格,计算区域网格划分总数为256 624个。

1.5 模型验证

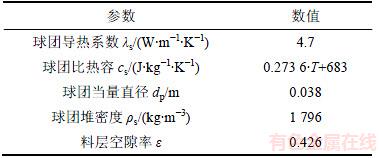

现场中试竖炉一侧的球团矿处理量为2.78 t/h,运行时焙烧风流量和温度分别为3 456 m3/h和1 373 K,冷却风流量和温度分别为3 024 m3/h和300 K。钒钛磁铁矿球团物性参数如表3所示,该产量条件下竖炉内的化学反应内热源为665 W/m3。

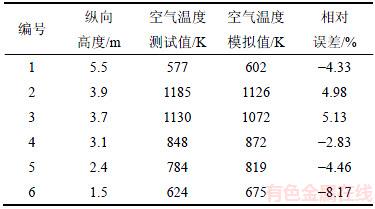

考虑中试现场对连续下料的钒钛磁铁矿测温难以实现,通过在竖炉纵向高度不同位置处开孔,采用抽气式热电偶测量竖炉内的气体温度,并与模拟结果对比来验证模型可靠性。表4所示为正常运行工况下中试焙烧竖炉在高度方向不同位置中心点处的空气温度测量值和计算值的对比情况。可见:平均相对误差为4.98%,在误差允许范围之内。因此,直接提钒焙烧竖炉数值模拟模型可靠,可用于探究炉内气固传热过程的数值研究。

表3 钒钛磁铁矿球团物性参数

Table 3 Core parameters of vanadium titanium magnetite pellets

表4 炉内空气温度测量值和数值模拟结果对比

Table 4 Comparison of measured temperature and numerical simulation of gas in furnace

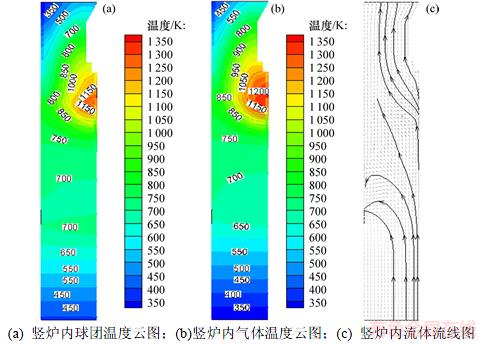

2 模拟结果与分析

根据课题组前期研究,辽西新型钒钛磁铁矿适宜的焙烧温度为1 100~1 200 K[19]。现场中试竖炉在正常运行工况下球团和气体温度在X-O-Y平面的分布规律如图3(a)和(b)所示。将竖炉球团温度达到1 100 K的床层到火口中心线的区域称为焙烧段。由图3可知:生球团矿从竖炉顶部进入后,先被预热至约850 K,而后由高温焙烧风继续加热至温度最高约1 150 K,越靠近焙烧口,球团温度越高,竖炉焙烧段满足焙烧温度要求的区域面积较小,该高度位置球团平均温度约为975 K,球团均热过程温度较低,约为700 K,不利于球团矿中金属元素结晶转化过程,导致竖炉产量降低。

从图3(c)可以看出:冷却风从竖炉底部鼓入后,在上行过程中气流分为2股,其中大部分气流折回并从导风口流出进入导风墙内,少量气流继续上行与焙烧风汇聚,用于补充球团焙烧所需氧化气氛,最终从竖炉顶部流出;焙烧风供入竖炉后向周围穿行加热钒钛磁铁矿球团,但由于焙烧风未能穿透料层,其分布存在不均匀性,导致在同一高度截面上在靠近焙烧风口球团温度较高,而远离焙烧风口的温度较低,最终该部分气体在完成完球团预热后从竖炉上口排出。

图3 焙烧竖炉内温度及速度分布云图

Fig. 3 Temperature and velocity distributions in roasting shaft furnace

针对竖炉焙烧温度偏低,焙烧时间较短的实际情况,本文通过研究竖炉操作参数变化对炉内球团温度分布的影响,确定焙烧竖炉适宜的操作参数是优化竖炉热工制度,改善竖炉焙烧效果的基础。影响焙烧竖炉热交换效果的热工参数主要有冷却风流量QL、焙烧风流量QB和球团颗粒直径dp,现场竖炉生产1 t熟球团矿的冷却风流量为1 088 m3/t,焙烧风量保持在1 244 m3/t,球团颗粒直径为38 mm,针对现有中试竖炉炉温偏低的情况,在生产可调节范围内,设计数值计算工况如表5所示,以探索改进竖炉焙烧效果的方案。

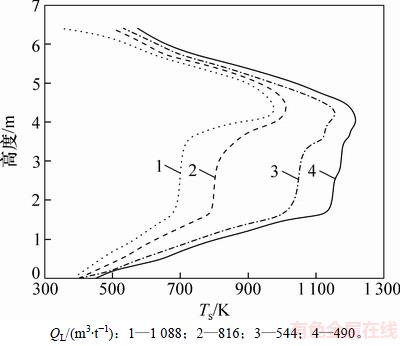

2.1 冷却风流量对温度分布影响规律

冷却风流量过高可能是导致竖炉焙烧温度偏低的原因之一。现有竖炉生产1 t熟球团矿的冷却风流量为1 088 m3/t,模拟冷却风流量分别为816,544和490 m3/t时的竖炉内球团温度场分布规律,并与实际工况进行对比分析。图4所示为焙烧风量保持1 244 m3/t,冷却风流量不同时,球团在不同竖炉高度位置的平均温度分布规律。

由图4可知:随着冷却风流量的降低,竖炉内的球团整体温度提升。因为在保持焙烧风流量不变的条件下,减小冷却风流量,竖炉内冷却风与球团矿间的气固换热效果削弱,冷却风带走的热量减少,导致竖炉内球团温度升高。当冷却风流量为816 m3/t时,竖炉加热段平均温度低于1 000 K,竖炉均热段温度低于800 K,竖炉焙烧温度依然偏低,不满足焙烧工艺要求;当冷却风流量为544 m3/t时,竖炉焙烧球团的温度为1 100~1 150 K,满足焙烧温度要求,且不会造成球团融化黏连的现象,此外,保温段的整体温度均在1 050 K以上,满足钒矿球团保温温度和保温时间的要求[20]。当冷却风流量为490 m3/t时,竖炉加热段焙烧球团的温度超过1 200 K,导致竖炉内靠近火口处球团温度过高,球团融化黏连的现象严重,不利于球团的焙烧生产。因此,在保持现有焙烧风流量不变的条件下,降低冷却风流量有利于改善现有竖炉炉温偏低的现象。冷却风流量维持在544 m3/t时较为适宜,竖炉内整体温度分布达到钒钛冶金要求。

表5 操作参数影响分析工况

Table 5 Operating parameters for condition analysis

图4 不同冷却风流量条件下球团平均温度沿高度方向的分布曲线

Fig. 4 Curves of pellet mean temperature distribution changing with different cooling air volumes along height direction of shaft furnace

2.2 焙烧风流量对温度分布影响规律

冷却风流量为保持在544 m3/t,在生产可调节范围内,模拟焙烧风流量为1 244,1 157,1 082和995 m3/t时竖炉内的球团温度场分布规律。不同焙烧风流量条件下,球团平均温度沿竖炉高度方向的分布规律如图5所示。

由图5可知:随着焙烧风流量的降低,竖炉预热、加热过程球团温度逐渐降低;焙烧风的减少对竖炉均热段和冷却段球团温度的分布影响很小。因为随着焙烧风量的减少,供入竖炉焙烧段内的热量减少,竖炉焙烧段温度降低,上行用于预热球团的焙烧风量减少,导致预热段温度降低。在竖炉均热段球团发生氧化反应,并逐步完成结晶转化过程,在此过程中球团温度主要由化学反应释放的热量保持,因此在降低焙烧风风量时,球团温度基本保持不变。

从图5还可以看出:当焙烧风流量为995 m3/t时,竖炉加热段球团温度低于1 100 K,不满足焙烧温度要求,且竖炉冷却段的温度较低,进入导风墙的冷却风温度随之降低,致使新入炉的球团矿得不到充分预热;当焙烧风流量保持在1 082 m3/t和1 157 m3/t时,竖炉加热段球团温度均处于1 100~1 150 K,满足焙烧温度要求,并且竖炉冷却段的温度适宜,能够使新入炉的生矿球团得到充分预热,满足生矿球团的预热、焙烧要求;当焙烧风流量为1 244 m3/t时,竖炉加热段球团温度过高,易出现球团融化黏连的现象,因此,焙烧风流量保持在1 082~1 157 m3/t时较为适宜。但考虑到增加焙烧风流量,竖炉能耗随之增加,经综合考虑,焙烧风流量应保持在1 082 m3/t。

因此,当冷却风流量保持在544 m3/t时,焙烧竖炉预热、加热段球团温度随着焙烧风流量的降低而降低,焙烧风流量保持在1 082 m3/t时,竖炉内球团温度分布达到钒钛冶金要求,此外,焙烧风流量的降低大幅减小了焙烧竖炉的能耗,有利于企业节能降耗。

图5 不同焙烧风流量条件下球团平均温度沿高度方向的分布曲线

Fig. 5 Curves of pellet mean temperature distribution changing with different roasting wind volumes along height direction of shaft furnace

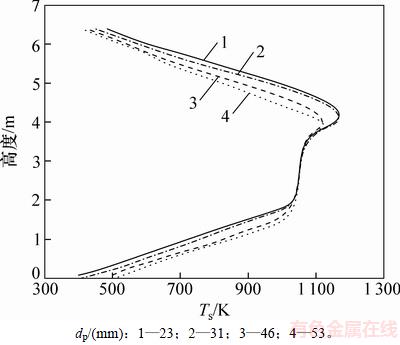

2.3 球团直径对温度分布影响规律

球团颗粒直径是影响球团温度分布的重要参数,因其直接影响球团在竖炉内的填充效果,影响着竖炉内空隙率的分布规律,进而影响着竖炉内的气体流动和气固传热过程。基于此,在冷却风流量544 m3/t,焙烧风流量1 082 m3/t的条件下,分别模拟球团颗粒直径为23,31,46和53 mm情况下的竖炉内球团温度的分布。图6所示为不同球团颗粒直径条件下,球团平均温度沿竖炉高度方向的分布规律。由图6可知:在竖炉预热段、加热段,随着球团颗粒直径的减小,球团温度逐渐升高,焙烧段整体温度随之提高。这是因为:在预热段、加热段,随着球团颗粒直径的减小,球团的比表面积变大,与焙烧风间的换热面积增加,球团从焙烧风吸收的热量增加,进而导致球团温度升高。但随着球团颗粒直径的减小,竖炉内空隙率逐渐减小,气体流经料层的阻力损失增加,导致风机耗电增加。改变球团颗粒直径,对竖炉均热段的球团温度的影响不大,但随球团直径的增大均热段的长度变长,均热段的延长有利于球团充分发生氧化反应完成结晶转化过程;在竖炉冷却段,球团温度随着颗粒直径的增加而逐渐升高,这是因为,随着颗粒直径的增加,球团矿比表面积减小,与冷却风间的换热减少,被冷却风带走的热量减少,导致球团的温度升高。

图6 不同球团颗粒直径条件下球团平均温度沿竖炉高度方向的分布曲线

Fig. 6 Curves of pellet mean temperature distribution changing with different pellet diameters along height direction of shaft furnace

从图6还可以看出:球团颗粒直径为23 mm和31 mm时,竖炉加热段平均温度均高于1 200 K,易出现球团融化黏连的现象,不利于球团生产;球团直径为46 mm和53 mm时,竖炉加热、均热过程温度适宜。但当球团直径增大到53 mm时,球团出口温度达到530 K,不满足球团的出炉的温度要求。因此,综合考虑上述因素,当冷却风流量保持在544 m3/t,焙烧风流量为1 082 m3/t时,球团适宜的直径为46 mm,经计算可得此时竖炉下部气固水当量比约为0.95。

3 结论

1) 以局部热力学非平衡模型为基础,建立钒矿焙烧竖炉的三维稳态气固传热模型,计算焙烧竖炉在正常运行条件下炉内各段气体温度与实际测量值间的相对误差在8.17%以下,验证了数值模型的可靠性。

2) 随着焙烧风流量的增加,竖炉预热、加热段球团温度升高,竖炉均热、冷却段球团温度基本保持不变;随着冷却风流量的减少,竖炉整体温度升高;随着球团颗粒直径的减小,竖炉预热段、加热段球团温度逐渐升高,竖炉均热段的球团温度变化不大,但均热段的高度缩短,竖炉冷却段的球团温度随着球团颗粒直径的减小而降低。

3) 对于产能为330 t/a的中试竖炉,其适宜的操作参数为:冷却风流量544 m3/t,竖炉下部气固水当量比0.95;焙烧风流量1 082 m3/t,焙烧风与冷却风配比2:1;球团颗粒直径46 mm。

参考文献:

[1] 张井凡, 董辉, 蔡九菊, 等. 一种竖炉式氧化钠化焙烧方法及装置: 中国, 201110371297.9[P]. 2012-04-11.

ZHANG Jingfan, DONG Hui, CAI Jiuju, et al. Method and device of oxidation-sodium roasting with shaft furnace type: China, 201110371297.9[P]. 2012-04-11.

[2] 董辉, 冯军胜, 李鹏, 等. 一种新型钒氧化钠化焙烧竖炉的研究[J]. 工业炉, 2012, 34(6): 5-8.

DONG Hui, FENG Junsheng, LI Peng, et al. Research of a new-style roasting shaft furnace of vanadium oxide[J].Industrial Furnace, 2012, 34(6): 5-8.

[3] 董辉, 冯军胜, 李朋, 等. 球团竖炉结构参数影响炉内气体流动的数值模拟[J]. 东北大学学报(自然科学版), 2013, 34(7): 980-984.

DONG Hui, FENG Junsheng, LI Peng, et al. Numerical simulation on gas flow affected by constructional parameters of pelletizing shaft furnaces[J]. Journal of Northeastern University (Natural Science), 2013, 34(7): 980-984.

[4] 王国胜, 董辉, 蔡九菊. 球团竖炉热工过程解析与模拟[J]. 钢铁, 2004, 39(4): 60-63.

WANG Guosheng, DONG Hui, CAI Jiuju. Analysis and simulation of thermo process in pelletizing shaft furnace[J]. Iron and Steel, 2004, 39(4): 60-63.

[5] LEONG J C, JIN K W, SHIAU J S, et al. Effect of sinter layer porosity distribution on flow and temperature fields in a sinter cooler[J]. International Journal of Minerals, Metallurgy and Materials, 2009, 16(3): 265-272.

[6] AL-SUMAILY G F, NAKAYAMA A, SHERIDAN J, et al. The effect of porous media particle size on forced convection from a circular cylinder without assuming local thermal equilibrium between phases[J]. International Journal of Heat and Mass Transfer, 2012, 55: 3366-3378.

[7] GHADI A Z, VALIPOUR M S, BIGLARI M. CFD simulation of two-phase gas-particle flow in the Midrex shaft furnace: the effect of twin gas injection system on the performance of the reactor[J]. International Journal of Hydrogen Energy, 2017, 42(1): 103-118.

[8] ZHOU P, LI H L, SHI P Y, et al. Simulation of the transfer process in the blast furnace shaft with layered burden[J]. Applied Thermal Engineering, 2016, 95: 296-302.

[9] FU D, CHEN Y, ZHAO Y F, et al. CFD modeling of multiphase reacting flow in blast furnace shaft with layered burden[J]. Applied Thermal Engineering, 2014, 66: 298-308.

[10] 蒋鹭, 黄山, 王天才, 等. 球团竖炉气固流动与焙烧过程耦合的三维数值模拟[J]. 东南大学学报(自然科学版), 2012, 42(2): 301-307.

JIANG Lu, HUANG Shan, WANG Tiancai, et al. Three-dimensional numerical simulation of gas-solid flow and roasting process coupling in pelletizing shaft furnace[J]. Journal of Southeast University (Natural Science Edition), 2012, 42(2): 301-307.

[11] BLUHM-DRENHAUS T, SIMSEK E, WIRTZ S, et al. A coupled fluid dynamic-discrete element simulation of heat and mass transfer in a lime shaft kiln[J]. Chemical Engineering Science, 2010, 65: 2821-2834.

[12] KRAUSE B, LIEDMANN B, WIESE J, et al. Coupled three dimensional DEM-CFD simulation of a lime shaft kiln-calcination, particle movement and gas phase flow field[J]. Chemical Engineering Science, 2015, 134: 834-849.

[13] KRAUSE B, LIEDMANN B, WIESE J, et al. 3D-DEM-CFD simulation of heat and mass transfer, gas combustion and calcination in an intermittent operating lime shaft kiln[J]. International Journal of Thermal Sciences, 2017, 117: 121-135.

[14] ZHANG X H, CHEN Z, ZHANG J Y, et al. Simulation and optimization of waste heat recovery in sinter cooling process[J]. Applied Thermal Engineering, 2013, 54(1): 7-15.

[15] 孙用军. 辽西钒钛磁铁矿直接提钒焙烧竖炉气固传热数值计算[D]. 沈阳: 东北大学冶金学院, 2015: 30-31.

SUN Yongjun. Numerical study of gas-solid heat transfer on roasting shaft furnace for vanadium titano-magnetite in western Liaoning province[D]. Shenyang: Northeastern University. School of Metallurgy, 2015: 30-31.

[16] MAHMOUDI Y, MAEREFAT M. Analytical investigation of heat transfer enhancement in a channel partially filled with a porous material under local thermal non-equilibrium condition[J]. International Journal of Thermal Sciences, 2011, 50 (12): 2386-2401.

[17] 黄道鑫. 提钒炼钢[M]. 北京: 冶金工业出版社, 2000: 57-58.

HUANG Daoxin. Vanadium abstracting steelmaking[M]. Beijing: Metallurgical Industry Press, 2000: 57-58.

[18] NAKAYAMA A, KUWAHARA F. A general macroscopic turbulence model for flows in packed beds, channels, pipes, and rod bundles[J]. Journal of Fluids Engineering, 2008, 130(10): 1135-1150.

[19] 邵颖聪. 辽西钒钛磁铁矿直接提钒焙烧浸出工艺及竖炉热工过程研究[D]. 沈阳: 东北大学冶金学院, 2015: 18-29.

SHAO Yingcong. Experimental study on roasting and leaching process of compact extracting vanadium process and analysis on thermo process in roasting shaft furnace[D]. Shenyang: Northeastern University. School of Metallurgy, 2015: 18-29.

[20] 张一敏. 球团理论与工艺[M]. 北京: 冶金工业出版社, 2008: 116-129.

ZHANG Yimin. Pellets theory and technology[M]. Beijing: Metallurgical Industry Press, 2008: 116-129.

(编辑 赵俊)

收稿日期:2017-06-06;修回日期:2017-08-08

基金项目(Foundation item):国家科技支撑计划项目(2015BAB18B00)(Project(2015BAB18B00) supported by the National Science and Technology Support Project of China)

通信作者:董辉,博士,教授,从事工业炉窑热工行为研究;E-mail:Dongh@mail.neu.edu.cn