富Ce混合稀土对铝基混杂复合材料耐磨性能的影响

杜 军1, 李文芳1, 刘贯军1, 2

(1. 华南理工大学 机械工程学院, 广州 510641;

2. 河南科技学院 机电学院, 新乡 453003)

摘 要: 用挤压铸造法制备Al2O3短纤维石墨颗粒混杂增强ZL109复合材料, 并研究富Ce混合稀土对该混杂复合材料耐磨性能的影响。 结果表明: 适量稀土元素可在一定程度上改善该混杂复合材料的耐磨性能, 特别在低载荷下, 其作用更为显著; 稀土对复合材料磨损机制的影响与载荷有关, 在较低的载荷下, 犁沟磨损是复合材料的主要磨损机制, 并存在轻微的剥层破坏; 但在较大载荷下, 稀土元素加入后, 特别是稀土含量高于0.6%后, 复合材料的磨损机制由犁沟磨损转变为严重的剥落磨损, 复合材料耐磨性反而降低, 这可能与稀土含量高时富含稀土的针状相析出有关。

关键词: 稀土; 金属基复合材料; 耐磨性能 中图分类号: TB332; TH117.3

文献标识码: A

Effect of Ce riched rare earth on wear resistance of aluminum-based hybrid composites

DU Jun1, LI Wen-fang1, LIU Guan-jun1, 2

(1. School of Mechanical Engineering, South China University of Technology,Guangzhou 510641, China;

2. Mechanical and Electrical Department, Henan Institute of Science and Technology,Xinxiang 453003, China)

Abstract: The ZL109 aluminum-alloy-based hybrid composites reinforced with 8% alumina short fibre and 10% graphite particle (volume fraction) were fabricated by squeeze-casting process. The effect of rare earth enriched with Ce on wear resistance of the hybrid composites was investigated. The results show that the addition of RE elements can improve the wear resistance of the hybrid composites and there exists better effect at low load specially. The optimum range of RE content is 0.3%-0.6%(mass fraction). The effects of RE on wear mechanisms of the hybrid composites relate closely with the applied load. The ploughing wear is the dominant wear mechanisms of the hybrid composites at low load and there exists slight delamination. However, the dominant wear mechanisms shift to severe delamination when the RE content exceeds 0.6% at high load, and the wear resistance of the hybrid composites decrease, which relates to the precipitation of needle-shaped phase enriched RE elements during heat-treating of the composites with high RE content.

Key words: rare earth; metal matrix composites; wear resistance

金属基复合材料以其优异的综合性能一直受到广大研究者的高度重视[1-3]。 其中利用混杂效应将耐磨增强体和具有减摩性的增强体混杂铝合金复合材料是当前金属基复合材料研究的一个重要方面[4, 5]。 稀土元素以其独特的性质在金属材料[6, 7]和复合材料[8]中受到广泛重视。 但稀土元素在金属基复合材料中的作用具有双重性, 当稀土元素的加入对复合材料的界面结合状况、 组织稳定性和力学性能等方面产生良好的影响时,便称其为有用的微合金化添加剂; 但当添加稀土元素降低材料性能时, 视其为杂质原子。 因此, 针对如何利用稀土元素提高金属基复合材料的综合性能具有重要的理论意义和实用价值。 于思荣等[9]和赵平等[10]先后研究了稀土对金属基复合材料组织和力学性能的影响规律, 但稀土在铝基混杂复合材料中的研究与应用方面的研究还较为少见。 本文作者探讨富Ce混合稀土对Al2O3短纤维和石墨颗粒混杂增强ZL109复合材料组织和耐磨性能的影响, 并揭示了稀土对该混杂复合材料磨损机制的影响规律。

1 实验

1.1 材料及方法

ZL109合金的成分为11.0%~13.0%Si、 0.8%~1.5%Mg、 0.5%~1.5%Cu、 0.5%~1.5%Ni、 Al为余量(质量分数)。 富Ce混合稀土的成分为50.5%Ce、 26.7%La、 15.1%Nd、 5.2%Pr(质量分数)。 实验前将混合稀土与纯铝配制成Al-10%RE的中间合金。 本研究选用2种增强体, 一种为洛阳耐火材料研究院生产的含量为80%Al2O3短纤维, 其直径为8~12μm; 另一种为吉林炭素厂生产的石墨颗粒Gr, 其粒径为76~88μm。

利用搅拌法在水介质中将Al2O3短纤维分散后过滤, 与含有适当浓度的粘结剂溶液混合继续搅拌, 并加入Gr颗粒, 待搅拌混合均匀后倒入模具并压制成一定尺寸的长方体形预制体, 湿态预制体经烘干后在还原性介质中焙烧, 得到具有一定强度的预制体。 利用TDY33-200 t型液态模锻液压机挤压铸造制备复合材料, 其工艺参数为模具预热温度为300℃、 预制体预热温度为400℃、 浇注温度为700℃、 挤压压力为55MPa、 保压时间为60s。

为考察稀土加入量的影响, 本研究中将Al2O3短纤维和Gr颗粒的体积分数分别固定为8%和10%, 将复合材料简记为8%Al2O3f+10%Grp/ ZL109, 而稀土加入量(质量分数)依次为0、 0.3%、 0.6%和0.9%。 将含有不同稀土含量的复合材料经510℃, 4h固溶和170℃, 6h时效处理。

1.2 干滑动摩擦磨损测试

在MM-200型磨损试验机上进行环-块式干滑动摩擦磨损实验。 磨损试样块的尺寸为10mm×10mm×10mm, 摩擦副为经淬火加低温回火处理后的环状GCr15, 尺寸为d47mm×10mm, 表面硬度为62HRC。 实验所用滑动速度为1.0m/s, 载荷取为80、 120和160N。 用精度为0.1mm的读数显微镜测量出试样磨痕宽度, 并折算成磨损体积损失。 每一实验数据是3次实验的平均值。 利用LEO 1530 VP型扫描电镜和Oxford型能谱仪分别进行磨损表面形貌和成分的观察和分析。

2 结果与分析

2.1 复合材料的显微组织

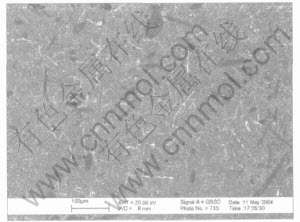

用上述方法制备的混杂复合材料其增强体混杂分布均匀, 加入稀土后其组织明显细化, 但当稀土含量超过0.6%时, 经热处理后的基体中将会有针状相析出, 特别是当稀土加入量达到0.9%后, 针状相的数量明显增加(见图1)。 能谱分析表明, 这些白色针状相为富含Ce、 Ld及Cu、 Mg、 Ni等元素组成的析出物。 赵平等[10]在其研究中也发现了类似的针状析出物。

图1 含0.9%稀土混杂复合材料针状相的TEM像

Fig.1 TEM image of needle-shaped phase in hybrid composite containing 0.9%RE

2.2 复合材料的力学性能

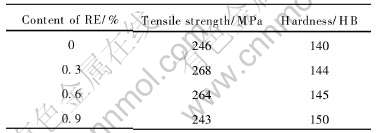

表1所列为不同稀土含量混杂复合材料的力学性能。 由表1可看出, 当复合材料中加入少量(0.3%)稀土后, 其强度提高了近10%; 但进一步提高稀土的加入量后, 强度反而略有下降; 当加入量达到0.9%后, 其强度与未加稀土的复合材料强度相当; 而复合材料的硬度随着稀土加入量的提高略有升高。 导致以上结果的原因可能与加入过量稀土后析出大量针状相有关。

表1 不同稀土含量混杂复合材料的力学性能

Table 1 Mechanical properties of hybrid composites with different RE contents

2.3 复合材料的摩擦磨损性能

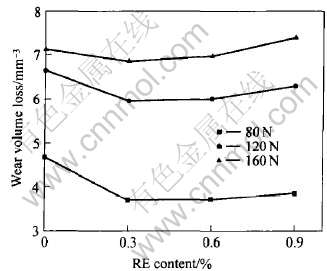

图2所示为不同载荷下稀土含量对复合材料磨损体积损失的影响。 由图2可看出, 当载荷较低(80N)时, 加入较低含量(0.3%)的稀土即可使复合材料的磨损体积损失明显降低; 随着载荷的逐渐增加, 稀土加入对复合材料磨损体积损失的影响逐渐降低。 在3种不同载荷下, 稀土含量在0.3%~0.6%之间变化对复合材料的磨损体积损失影响并不显著, 但当稀土加入量为0.9%时, 复合材料的磨损体积损失略有增大, 特别在高载荷(160N)时更为明显。 可见, 加入少量稀土元素可在一定程度上改善Al2O3短纤维和石墨颗粒混杂增强ZL109复合材料的耐磨性能, 特别在较低载荷下, 其作用更为显著, 但稀土的加入量不宜太高。

图2 不同载荷下稀土含量对复合材料磨损体积损失的影响

Fig.2 Effect of RE content on wear volume loss of composites under different applied loads (Sliding distance 900m)

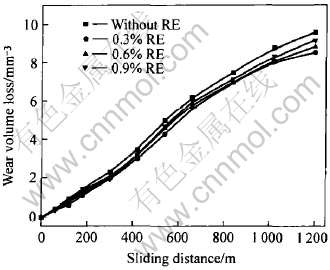

图3所示为磨损距离对不同稀土含量复合材料磨损体积损失的影响。 由图3可看出, 随着磨损距离的增加, 具有不同稀土含量复合材料的磨损体积损失逐渐增大, 在120N的磨损载荷下, 与含有稀土的复合材料相比, 不含稀土复合材料的磨损体积含量稍大, 而不同稀土含量复合材料的磨损体积损失没有显著区别。

图3 磨损距离对不同稀土含量复合材料磨损体积损失的影响

Fig.3 Effect of sliding distance on wear volume loss of composites with different RE contents(Applied load 120N)

2.4 复合材料的磨损形貌

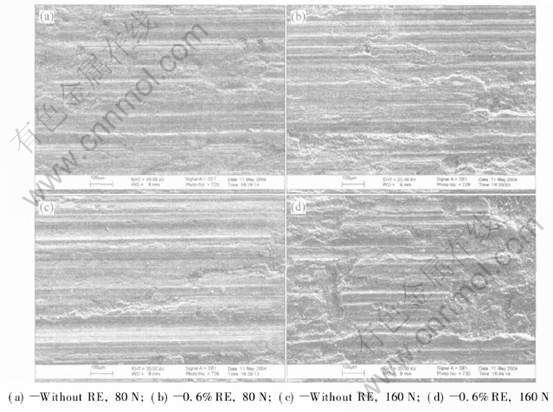

图4所示为未加稀土和加入0.6%稀土的混杂复合材料在80N和160N载荷下磨损900m后磨损表面形貌的SEM像。 由图4可见, 在较低的载荷下, 复合材料表面较为光滑, 存在连续而较为光滑的犁沟, 并伴随有少量剥落坑, 少量犁沟由于剥落坑的存在而中断。 比较图4(a)和(b)可以看出, 在较低载荷下, 加入适量稀土后, 复合材料磨损表面犁沟相对细小, 剥落坑也小一些。 但在较大的载荷(160N)下, 未加稀土的混杂复合材料磨损表面仍为犁沟, 但犁沟比低载荷(80N)时更为宽大, 同时也伴随着少量的剥落坑; 而加入适量(0.6%)稀土复合材料的磨损表面较为粗糙, 存在大量的剥落坑。 由此可看出, 稀土对本研究中的混杂复合材料磨损机制的影响与载荷密切相关。 在较低的载荷下, 无论复合材料中是否加入稀土, 犁沟磨损是其主要的磨损机制, 并存在轻微的剥层破坏; 但在较大的载荷下, 稀土的加入对复合材料的磨损机制影响较大, 在没有稀土存在的条件下, 犁沟磨损是其主要的磨损机制。 但在复合材料中加入稀土后, 特别是当稀土含量超过0.6%后, 其磨损机制发生了很大的变化, 严重剥落磨损是其主要的磨损机制, 从而导致复合材料磨损体积损失上升, 耐磨性下降。

图4 复合材料磨损表面形貌的SEM像

Fig.4 SEM images of worn surfaces of hybrid composites (sliding distance 900m)

硬质的陶瓷增强体在复合材料中可以强化基体, 改善基体性能, 在复合材料磨损过程中可以有效地起到阻碍基体塑性变形, 支撑和承载作用[11, 12], 并改变摩擦副与基体之间的接触特性, 减小粘着磨损产生的可能性, 从而使基体合金耐磨性提高。 而在其中混杂Gr软质相以后, 磨损过程中的挤压力和切向摩擦力将使Gr颗粒在铝合金复合材料磨损表面发生涂抹并逐渐铺展而形成一层自润滑薄膜[13], 此时复合材料的摩擦系数和摩擦表面温度将会大幅度降低。 由于两种增强体的协同作用将使基体合金的耐磨性能和粘着抗力大幅度提高[14, 15]。 但是, 由于增强体与基体合金间的润湿性往往较差, 基体与增强体之间较低的界面结合强度将会制约复合材料各种性能的进一步提高, 如在磨损过程中, 增强体在摩擦力的剪切作用下而易于剥落, 从而导致严重剥层磨损的产生, 加剧复合材料的磨损。

大量研究[8-10]表明, 少量的稀土元素会极大地影响金属基复合材料中基体的组织和性能及界面结合状况, 一方面, 稀土加入后可使Al基体晶粒细化, 从而提高基体综合机械性能; 另一方面, 由于稀土元素在铝基体中的溶解度极低, 经过凝固过程溶质的再分配, 稀土元素将在晶界处富集, 稀土元素的这种特性, 使它也在纤维和基体间的界面富集, 从而有效地改善基体合金同纤维间的润湿和结合。 由于稀土元素在复合材料中的作用, 在复合材料中加入适量(0.3%)的稀土后, 复合材料的强度适当提高, 其耐磨性能在较低载荷下时得到一定改善。 但由于稀土元素在合金中的固溶度很小, 不能固溶的稀土原子将会与合金元素作用从而以化合物的形态出现, 结果如图1所示。 赵平等[10]在其研究中也发现了类似的针状析出相, 并发现这些针状相在界面析出后有利于复合材料高温强度性能的提高。 而本研究的结果表明, 当稀土含量较高并析出大量针状相以后, 复合材料磨损表面存在大量的剥落坑(图4(d)), 这对复合材料耐磨性能的提高反而不利。

3 结论

1) 适量稀土元素可在一定程度上改善Al2O3短纤维和石墨颗粒混杂增强ZL109复合材料的耐磨性能, 特别在较低载荷下, 其作用更为显著, 但稀土的加入量不宜太高。

2) 稀土对混杂复合材料磨损机制的影响与载荷密切相关。 在较低的载荷下, 犁沟磨损是复合材料的主要磨损机制, 并存在轻微的剥层破坏; 但在较大的载荷下, 当稀土加入后, 特别当稀土含量高于0.6%时, 复合材料的磨损机制由犁沟磨损转变为严重的剥落磨损, 复合材料的耐磨性反而降低, 这可能与稀土含量较高时复合材料基体中析出富含稀土的针状相有关。

REFERENCES

[1]张雪囡, 耿林, 郑镇洙, 等. SiCw和纳米SiCp混杂增强铝基复合材料的制备与评价[J]. 中国有色金属学报, 2004, 14(7): 1101-1105.

ZHANG Xue-nan, GENG Lin, ZHENG Zhen-zhu, et al. Fabrication and properties of particles reinforced aluminum matrix composites in-situ synthesized in Al-Zr-O-B system[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1101-1105.

[2]高明霞, 潘颐, Oliveria F J, 等. 自发熔渗法制备TiC/NiAl复合材料和其微观组织特征[J]. 复合材料学报, 2004, 21(5): 11-15.

GAO Ming-xia, PAN Yi, Oliveria F J, et al. Pressureless melt infiltration processing and the microstructure characteristics of TiC/NiAl composites[J]. Acta Materiae Compositae Sinica, 2004, 21(5): 11-15.

[3]杜之明, 程远胜, 罗守靖, 等. 压力下浸渗半固态致密法制备Al2O3sf·SiCp/Al复合材料[J]. 中国有色金属学报, 2004, 14(12): 2079-2084.

DU Zhi-ming, CHENG Yuan-sheng, LUO Shou -jing, et al. Preparation of Al2O3sf·SiCp/Al composites by infiltration-semi-solid densification under pressure [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(12): 2079-2084.

[4]Ames W, Alpas A T. Wear mechanism in hybrid composites of graphite-silicon alloy(Al-7pctSi-0.3pct Mg)[J]. Metall Mater Trans, 1995, 26A: 85-98.

[5]Liu Y H, Du J, Yu S R. High temperature friction and wear behavior of Al2O3 and/or carbon short fibre reinforced Al-12Si alloy composites[J]. Wear, 2004, 256(3-4): 275-285.

[6]倪红军, 黄明宇, 朱昱. 稀土熔剂对Al-10%Pb合金组织和性能的影响[J]. 中国有色金属学报, 2004, 14(7): 1117-1122.

NI Hong-jun, HUANG Ming-yu, ZHU Yu. Effects of rare earth flux on microstructure and properties of Al-10%Pb alloy melt[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1117-1122.

[7]周海涛, 曾小勤, 刘文法, 等. 稀土铈对AZ61变形镁合金组织和力学性能的影响[J]. 中国有色金属学报, 2004, 14(1): 99-104.

ZHOU Hai-tao, ZENG Xiao-qin, LIU Wen-fa, et al. Effect of Ce on microstructures and mechanical properties of AZ61 wrought magnesium[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 99-104.

[8]崔春翔, 吴人洁, 王浩伟. 稀土元素的热力学特性及在金属基复合材料中的应用[J]. 稀有金属材料与工程, 1997, 26(3): 53-58.

CUI Chun-xiang, WU Ren-jie, WANG Hao-wei. Thermodynamic characteristics of rare-earth element and its application in metals matrix composites[J]. Rare Metal Materials and Engineering, 1997, 26(3): 53-58.

[9]于思荣, 何镇明, 任露泉. 加铈ZA22-Al2O3短纤维复合材料抗拉强度的理论分析[J]. 中国稀土学报, 1998, 16(2): 134-138.

YU Si-rong, HE Zheng-ming, REN Lu-quan. Theoretical analyses on tensile strength of ZA22/Al2O3 short fiber composites added with Ce [J]. Journal of the Chinese Rare Earth Society, 1998, 16(2): 134-138.

[10]赵平, 高升吉, 沈保罗, 等. 富镧混合稀土对莫来石增强ZL109复合材料高温性能的影响[J]. 稀土, 1999, 20(5): 27-30.

ZHAO Ping, GAO Sheng-jie, SHEN Bao-luo, et al. Influence of La riched rare earth on elevated temperature tensile strength of mullite fibre reinforced ZL109 matrix composite[J]. Chinese Rare Earths, 1999, 20(5): 27-30.

[11]Yu S R, He Z M, Chen K. Dry sliding friction and wear behaviour of fibre reinforced zinc-based alloy composites[J]. Wear, 1996, 198(1): 108-114.

[12]戈晓岚, 许晓静, 蔡兰, 等. SiCp含量和尺寸对Al基复合材料摩擦学特性的影响[J]. 中国有色金属学报, 2005, 15(3): 458-462.

GE Xiao-lan, XU Xiao-jing, CAI Lan, et al. Effect of grain size and content of SiCp on tribology characterization of SiCp/ Al composites[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(3): 458-462.

[13]Liu Y B, Rohatgi P K, Rays S. Tribological characteristics of aluminum-50% graphite composite [J]. Metall Trans, 1993, 24A: 151-155.

[14]杜军, 刘耀辉, 朱先勇, 等. ZL109铝合金及其复合材料干滑动磨损表面及亚表面的观察与分析)[J]. 稀有金属材料与工程, 2004, 33(2): 202-212.

DU Jun, LIU Yao-hui, ZHU Xian-yong, et al. Observations and analysis of worn surface and subsurface of ZL109 aluminum alloy and its composites in dry sliding friction and wear[J]. Rare Metal Materials and Engineering, 2004, 33(2): 202-212.

[15]LIU Yao-hui, DU Jun, YU Si-rong. High temperature friction and wear behavior of Al2O3 and/or carbon short fibre reinforced Al-12Si alloy composites[J]. Wear, 2004, 256(3-4): 275-285.

(编辑 李艳红)

基金项目: 广东省科技攻关计划资助项目(2003B12102); 广东省自然科学基金资助项目(980563); 华南理工大学自然科学基金资助项目(305-E5040440)

收稿日期: 2004-10-19; 修订日期: 2005-09-26

作者简介: 杜 军(1975-), 男, 讲师, 博士

通讯作者: 杜 军, 博士; 电话: 020-87114269; 传真: 020-87111132; E-mail: tandujun@sina.com