文章编号:1004-0609(2011)04-0769-08

BeO杂质形态与分布对金属铍力学性能的影响

许德美1, 2,秦高梧1,李 峰2,王东新2,夏洪先2,任玉平1,裴文利1

(1. 东北大学 材料各向异性与织构教育部重点实验室,沈阳110004;

2. 西北稀有金属材料研究院 宁夏自治区特种材料重点实验室,石嘴山 753000)

摘 要:研究热等静压金属铍材中BeO杂质分布状态和颗粒尺寸对金属铍力学性能的影响,并通过设计真空退火试验,进一步调控BeO杂质在铍基体中的分布,得出BeO杂质形态与分布对力学性能的影响规律。结果表明:相比于BeO含量,BeO杂质的分布和形态对金属铍力学性能的影响更为关键;当BeO粒子弥散分布时,位于晶界上BeO粒子的尺寸及间距是决定金属铍材强度与塑性的关键因素,粗大的BeO粒子(粒径大于300 nm)是导致铍材塑性低的主要原因之一;三叉晶界不致密BeO聚集态相当于在材料内部预制一定尺寸的微裂纹,也是影响铍材伸长率的主要因素。

关键词:BeO;Be; 三叉晶界;应力集中;塑性

中图分类号:TG146.2;TB383 文献标志码:A

Effects of morphology and distribution of BeO impurity on mechanical properties of metal beryllium

XU De-mei1, 2, QIN Gao-wu1, LI Feng2, WANG Dong-xin2, XIA Hong-xian2, REN Yu-ping1, PEI Wen-li1

(1. Key Laboratory for Anisotropy and Texture of Materials, Ministry of Education,

Northeastern University, Shenyang 110004, China;

2. Key Laboratory for Rare Materials, Ningxia Province, Northwest Rare Metal Materials Research Institute, Shizuishan 753000, China)

Abstract: The effects of the morphology and distribution of BeO impurity on the mechanical properties of metal beryllium in the powder hot isostatic pressed (HIPed) metal beryllium and the vacuum annealed ones were studied, and the general conclusions were obtained. The results show that the morphology and distribution of BeO impurity play more important roles than the BeO content in controlling mechanical properties of beryllium. When BeO particles monodisperse distribution in the beryllium matrix, BeO particle size and interparticle distance along the grain boundaries of Be are key factors to affect the strength and ductility of Be material, and BeO with size larger than 300 nm is the main reason of poor ductility of Be. BeO particles at the triple grain boundary junctions of Be, which is equivalent to the pre-fabricated microcracks inside, mainly lead to poor ductility of Be material.

Key words: BeO; Be; triple grain boundary junction; stress concentration; ductlity

近40年来,铍材制备技术的发展,尤其是金属铍粉末热等静压工艺的成熟与完善,使铍由脆性材料跻身于实用结构材料之列,应用在核技术和空间技术领域[1-2]。但采用粉末冶金工艺制备金属铍材时,由于铍氧化活性很高,极易在铍粉表面生成一层致密的BeO[3],在真空热压或热等静压固结铍粉的过程中,铍粉表层的BeO重新分布,大量BeO位于晶界,少量分布在晶内,难以去除和控制,成为铍材中的主要杂质,对铍材力学性能造成很大的影响。因此,长期以来有关BeO杂质的控制,都是国内外金属铍材研究的关键问题。

国外很多学者针对BeO杂质含量对金属铍材力学性能的影响做过大量的研究,如ALDINGER等[4]研究认为,减少BeO含量有助于提高材料的塑性;MARDER等[5]研究认为,同时减少晶粒度和BeO含量可以提高铍材的强度,且随着铍粉末粒度的减小,BeO的含量急剧增加,铍材会产生脆化效应,大大抵消晶粒细化的效果。目前,BeO杂质的研究方向是针对BeO分布状态和颗粒尺寸对铍材力学性能的影响,但这方面的研究在国际上还鲜见报道。我国对BeO杂质的研究与国外相比,有一定差距,无论是针对BeO杂质含量,还是BeO杂质的分布状态和颗粒尺寸对铍材力学性能的影响均缺乏系统的研究,仅在对金属铍的微屈服行为和机理研究中,发现BeO杂质是影响金属铍材微屈服强度的关键因素[6]。

本文作者研究了大量粉末热等静压工艺生产的铍材中BeO杂质分布和颗粒尺寸对力学性能的影响规律。在此基础上,选择高BeO含量的静压铍材作为研究对象,设计真空退火试验,保证退火前后铍材晶粒度保持不变,BeO杂质分布状态和颗粒尺寸发生较大的变化,并调整和控制BeO杂质在铍基体中的存在方式。以期明确BeO杂质形态对铍材力学性能的作用机理。

1 实验

1.1 试验材料的制备

试验铍材采用铍粉末冷热等静压工艺制备。粉末为气流冲击研磨铍粉,并对铍粉进行预处理,减少粉末中Fe、Al和Si等杂质的含量。试验材料经X射线探伤试验合格后,切取拉伸试验用试样和化学成分分析试样。将真空退火样品整体放入真空退火炉中,在10-5 Pa的真空度下,分别进行(750 ℃, 7 h)、(850 ℃, 7 h)和(970 ℃, 7 h)退火,退火完后切取拉伸试验用试样。

1.2 试验材料的分析

拉伸试样为国家标准金属铍材圆形非比例室温拉伸试样(d 6 mm×25 mm),在Instron4505材料试验机上测量室温力学性能,应变速率为1×10-7 m/s。切取拉伸断头一侧夹持部分制成X射线衍射试样,用Rigaku D/max-ⅢB型X射线衍射仪进行物相定性分析。切取拉伸断头另一侧的夹持部分,制成金相试样,采用MM6型金相显微镜,在偏振光下观察金相组织,测量晶粒度,同时利用CAMEBAX-MICRO型电子探针进行微区成分定性分析。将金相试样继续制成透射电镜用试样,在CM20型透射电子显微镜上,进行显微组织分析。拉伸试样断口截取后超声清洗,利用CAMEBAX-MICRO型电子探针观察断口组织和微区成分定性分析。试样化学成分分析均按国家或相应的军工标准执行。

2 结果与分析

2.1 试样的力学性能和Be的晶粒尺寸

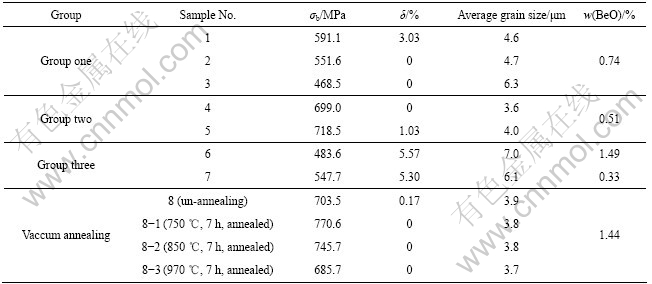

为了得出BeO杂质形态对铍材力学性能的影响规律,本文作者选择大量的热等静压铍材进行试验,并根据试样的BeO含量和力学性能将样品大致分为3组进行对比分析。同时为了消除晶粒度的影响,增加试样的可比性,每一组试样的晶粒度尽可能相近。第一组是BeO含量中等,强度相近,但伸长率相差较大的试样;第二组为低BeO含量,但力学性能却是高强低延的试样;第三组是BeO含量不同,但力学性能均为高伸长率的试样。由于分析的样品较多,为简单起见,仅在表1中给出每组试样的代表性结果,并为了便于表述,将其分别命名为样品1~7。

真空退火样品选择了高BeO含量的铍材进行试验,称为试样8,退火前后样品的力学性能、晶粒度和BeO含量如表1所列。

2.2 Be材中杂质元素的分析

X射线衍射结果表明除BeO外,所有试样中未发现有其它相的谱峰存在,如BeO、FeBe11、AlFeBe4、Be2SiO4及Be2C[7]。透射电镜能谱仪(EDS)对微观组织上出现的杂质相和电子探针波谱仪(WDS)对断口组织上出现的杂质相成分分析表明,有氧元素存在的杂质点,往往也存在微量的其它杂质元素Fe、Si和Al等,其中,Si含量在10-4左右,Al含量在5×10-5左右, Fe含量在8×10-4左右。电子探针对金相样品进行元素面扫描也未发现有其它化合物的集中出现。因此,可以判定本研究中试样的主要杂质相为BeO。

表1 样品的力学性能、晶粒尺寸和BeO含量

Table 1 Mechanical properties, average grain size and BeO content of samples

2.3 试样的显微组织

由于分析的样品较多,根据Be材中BeO含量、强度及塑性等特点归类出4组样品进行分析,如表1所列。

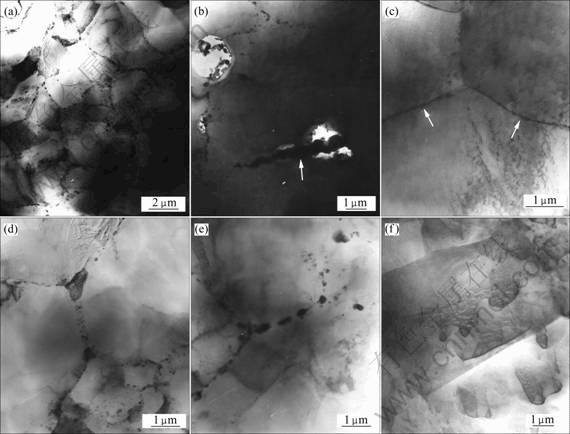

2.3.1中等BeO含量试样的力学性能与显微组织的关系

首先选择了BeO含量中等、强度和伸长率均良好的静压铍材进行显微组织分析,目的在于对BeO在铍基体中的分布状态有一个认识,试样1是其代表。试样1的显微组织如图1(a)所示。由图1(a)可知,BeO粒子大量弥散分布在晶界,少量弥散分布在晶内,颗粒尺寸在75 nm左右。说明弥散分布细小的BeO粒子对铍基体起着良好的第二相粒子强化作用。这种BeO形态与分布对铍材塑性的影响将结合真空退火样品8的分析结果将在2.3.4中分析。

静压铍材经常出现BeO含量中等,强度良好,但伸长率很差的Be材样品。为了增加可比性,选择强度和晶粒度与样品1相近的样品2作为其代表。显微组织分析发现,试样2中除BeO粒子大量弥散分布在晶界,少量弥散分布在晶内,在三叉晶界处聚集不致密的BeO颗粒,聚集的BeO颗粒尺寸平均约为400 nm,其周围孔洞的尺寸约在1 600 nm(见图1(b)),另外在晶界上出现BeO呈连续簇状分布形态(见图1(b)箭头所指)。说明三叉晶界处聚集的不致密BeO和晶界呈连续簇状BeO颗粒是导致材料伸长率降低的原因。

另外,发现少数零伸长率试样BeO在晶界上成连续薄膜状析出(见图1(c)箭头所指),如样品3。同时,该样品的强度较低(468.5 MPa),说明这种BeO形态不利于材料强度的提高。

2.3.2 低BeO含量试样的力学性能与显微组织的关系

通常而言,金属铍材的BeO含量越低,则伸长率越高。但静压铍材中经常出现BeO含量很低,但伸长率很差的情况,使通过降低BeO含量来提高材料塑性的工艺失效。因此,本文作者着重对这类样品的显微组织进行了分析,样品4和5是这类试样的代表。样品4的伸长率为0,其中BeO的分布状态与样品2的有共同之处,在三晶界处聚集尺寸平均约为400 nm的不致密的BeO颗粒,孔洞尺寸在1 800 nm左右。样品5的显微组织在三晶界处虽没有聚集不致密的BeO颗粒,但析出大颗粒的BeO,尺寸在300 nm左右(见图1(d)),其伸长率也不高,约为1.03%。

第二组的样品4和5的BeO含量为0.51%,低于第一组样品1和2的0.74%,但其抗拉强度明显高于第一组试样的,比较其中弥散分布的BeO颗粒尺寸发现,第二组试样的BeO粒子尺寸较小,在50 nm左右。该结果表明,相比于BeO含量,弥散而细小的BeO粒子分布状态对强度的影响更为重要,BeO粒子尺寸越小,强化效果越好。

2.3.3 BeO含量相差较大试样的力学性能与显微组织的关系

有时静压铍材也出现高BeO含量、但伸长率很好的试样,试样6是其代表。样品6中氧化铍含量为1.49%,是所有试样中最高的,但其伸长率为5.57%,还略高于样品7的5.30%,样品7中 BeO含量为0.33%,是所有试样中最低的。由此可见,BeO含量不是铍材伸长率好坏的决定性因素。另外,从晶粒度来看,样品6的晶粒度也略高于样品7的,因此,可以排除晶粒度带来的影响。

图1 BeO杂质的形态及分布

Fig.1 Morphologies and distribution of BeO impurity: (a) Sample 1, Distribution of BeO nanoparticles (NPs) with size about 75 nm along grain boundaries(GBs) of Be; (b) Sample 2, BeO NPs with size about 400 nm mainly at triple GB junction; (c) Sample 3, BeO thin films along GBs of Be; (d) Sample 5, Large sized BeO particles at triple GB junction; (e) Sample 6, Large sized BeO particles along GBs of Be; (f) Sample 7, No BeO along GBs of Be

观察样品6的显微组织发现,样品6中大部分晶界上弥散分布着大颗粒的BeO,颗粒尺寸多在200~250 nm之间(见图1(e)),几十纳米的BeO粒子较少,并且部分晶界上无BeO。样品7的显微组织大部分晶界上无BeO(见图1(f)),而少部分晶界有细小的BeO弥散分布,颗粒尺寸在50 nm左右。样品7的强度高于样品6的,表明样品7的强度与Be晶界上弥散分布几十纳米的BeO颗粒相关,这也进一步说明 BeO含量不是决定Be材强度的关键因素。

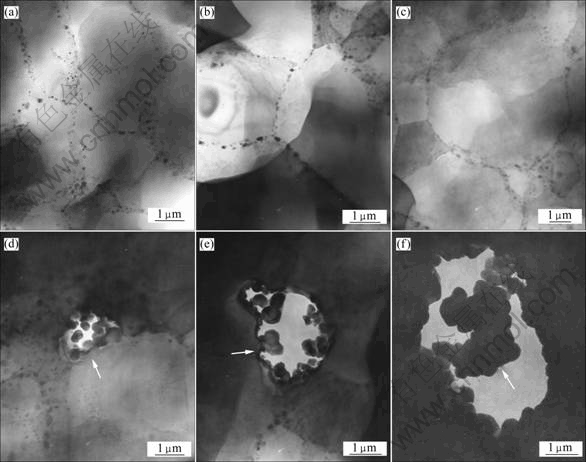

2.3.4 真空退火试样的力学性能与显微组织的关系

以上样品是来自于不同批次粉末和热等静压的铍材,为了使分析结果更为准确可靠,以进一步明晰细小弥散分布于晶界上的BeO和三晶界处聚集不致密的BeO颗粒对Be材力学性能影响,本研究选择高BeO含量的静压铍材(样品8)进行真空退火,以改变BeO的形貌与分布。

样品8的显微组织与样品1的相近,其中BeO粒子大量弥散分布在晶界,少量弥散分布在晶内,颗粒尺寸在75 nm左右。如表1所列,试样1的伸长率为3.03%、强度为591.1 MPa,而试样8的强度高达703.5 MPa、伸长率却为0.17%。在晶粒度方面,样品8的晶粒度也小于样品1的。因此,导致样品8的伸长率低于样品1的原因可能是BeO含量;样品8中BeO含量为1.44%,样品1中BeO含量为0.74%,说明在BeO粒子弥散分布、粒子尺寸大致相同的情况下,BeO含量越低,材料塑性越好;这与前人得到的结论是一样的。

真空退火后,材料晶粒尺寸没有明显改变,但BeO颗粒尺寸和分布发生较大变化。试样经750 ℃,7 h退火后,BeO粒子尺寸没有变化,但晶内的BeO明显减少,开始出现在三叉晶界处聚集成不致密的BeO颗粒形态(见图2(a)和(d))。试样经850 ℃、7 h退火后,晶内的BeO粒子基本消失,弥散分布在晶界上的BeO粒子开始长大,三叉晶界处聚集的BeO颗粒尺寸较经750 ℃、7 h退火试样的明显增大,数量明显增多(见图2(b)和(e))。试样经970 ℃、7 h退火后,晶界上弥散分布的BeO粒子明显减少,BeO几乎全部汇集到三叉晶界处(见图2(c)和(f))。

试样经750 ℃、7 h退火后,样品强度达到了退火前后的最高值,即770.6 MPa。在退火后内应力和位错消失的情况下,样品的强度提高,表明BeO粒子弥散分布在晶界比分布在晶内起到更好的强化作用。试样经850 ℃、7 h退火后,弥散分布的BeO颗粒开始长大,强度也有所下降,为745.7 MPa。试样经970 ℃、7 h退火后,晶界上分布的BeO颗粒变得稀少,但细小而弥散,因此,仍具有较大的强化作用,强度为 685.7 MPa。

试样经750 ℃、7 h退火后,在三叉晶界处出现不致密的BeO颗粒,材料的伸长率变为零,而此时聚集的BeO颗粒尺寸均在350 nm以下,孔洞尺寸在1 000 nm左右,数量也较少,表明三叉晶界聚集的不致密BeO颗粒对铍材塑性的影响非常严重。温度升高到970 ℃时,BeO颗粒尺寸已经达到微米级,孔洞尺寸最大达到了150 μm×30 μm(断口测量尺寸),但此时材料仍保持相当的强度,说明三叉晶界聚集的不致密的BeO颗粒对强度的影响不大。

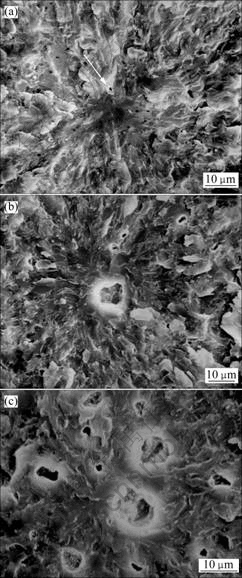

为了证明三叉晶界处聚集的BeO颗粒是造成铍材零伸长率的主要原因,对真空退火前后的样品进行断口分析。断口分析发现,退火前后拉伸断口微观组织均表现为通常铍所见解理断裂特征[8],但退火前断口组织上没有明显的孔洞存在,退火后断口组织中出现明显的孔洞,孔洞中存在细小不致密的颗粒,且随着热处理温度的提高,这些孔洞数量越来越多,孔洞尺寸越来越大(见图3),这与透射电镜三叉晶界聚集的BeO颗粒观察结果是一致的。波谱定性分析表明,这些孔洞含有大量O,少量的Si和Fe,另外,从图3中可以看出,这些不致密BeO粒子聚集孔洞组织无论尺寸大小,皆成为裂纹的起源处,750 ℃造成断裂的孔洞区域见图3(a)中箭头所指。由此可见,三叉晶界不致密BeO聚集态,是导致Be材伸长率为零的主要

图2 真空退火后Be材中BeO杂质的形态与分布

Fig.2 Morphologies and distribution of BeO impurity in Be after vacuum annealing: (a), (d) 750 ℃, 7 h; (b), (e) 850 ℃, 7 h; (c), (f) 970 ℃, 7 h

图3 退火后断口裂纹源中心的形貌

Fig.3 Morphologies of crack source center on facture surface of Be after vacuum annealing: (a) 750 ℃, 7 h; (b) 850 ℃, 7 h; (c) 970 ℃, 7 h

原因。

3 讨论

本文作者着重针对金属铍粉末冶金工艺中难以控制的BeO杂质分布和颗粒尺寸对铍材性能的影响进行了研究。为了保证晶粒度在真空退火前后保持不变,而BeO分布形态发生较大的变化,根据铍材的内应力(530~980 ℃)和再结晶退火(700~900 ℃)温度[3],制定本次试验的退火工艺;同时为了能够更好地观察到不同热处理温度下,BeO杂质在铍材基体上的变化趋势,选择高BeO含量的静压铍材进行真空退火试验,并使退火温度高达970 ℃。另外在制备材料的过程中,为了防止热等静压固结过程中生成AlFeBe4和Be2SiO4等相,给BeO分析结果造成影响,对粉末进行了预处理,降低了Fe、Al和Si杂质元素的含量。从最终的分析结果来看,这些最初的试验设计均达到预期的效果,所有试样中除了含BeO外,在XRD分析中均没有发现其它微合金相,且退火前后铍材的BeO颗粒尺寸和分布状态发生较大的变化,而Be材晶粒尺寸没有明显改变。

铍的c/a为1.567[9],这要求铍首先启动柱面滑移,但实际上铍的滑移仍以基面为主。铍基面具有最低的表面能γ(0001)=2.322 J/m2 [9],是铍中最容易发生解理的面,即铍的解理面和滑移面都是基面。铍属密排六方金属,仅有4个独立的滑移系,即基面的 和柱面的

和柱面的 。因此,铍缺乏有效的滑移系统进行滑移,当位错在基面运动时,极易在基面堆积位错产生应力。同时铍体积模量与剪切模量的比值也是所有密排六方金属中最低的,为0.87[9],低的比值意味着启动位错和分离原子面所需要的能量十分接近,即滑移在铍基面堆积位错造成的应力集中很容易达到分离原子面的力。铍的以上本性决定了铍位错运动的能力十分有限,一般仅在有限的范围内进行滑移后,基面堆积位错造成的应力就能导致铍材解理断裂。另一方面,铍材在产生应变的过程中,当有位错运动到晶界和BeO颗粒前,就会塞积产生应力,启动晶界另一边的位错源,产生最初的屈服[10]。这就是说,一方面铍容纳位错运动的能力十分有限,另一方面最初屈服是由晶界和BeO颗粒处位错塞积应力造成的,如果由于晶界和BeO杂质对位错运动的阻碍作用,使最初屈服时启动位错源的应力较大,则留给后续位错运动的空间减少,使铍本身有限的屈服过程不能发生,材料的伸长率降低,甚至启动位错源的力直接达到分离原子面的力,造成铍材解理断裂,伸长率为零。因此,Be晶界的性能和BeO粒子的形态与分布对铍材的塑性起着关键作用。当位错滑移到晶界处传递时,晶界上弥散分布的细小BeO颗粒会使位错运动变得更加困难。当晶界上无BeO时(见图1(f)),即在低BeO含量时,位错较易越过晶界进行滑移,利于Be材的塑性提高。基于同样的道理,当BeO粒子位于晶界时,与晶界共同作用对最初屈服时位错运动的钉扎作用,要比BeO单独位于晶内更为明显。故经750℃真空退火后,当晶内的BeO颗粒向晶界偏聚后,晶界处BeO增加,和晶界共同作用阻碍位错运动,比BeO单独位于晶内更能有效防止材料屈服,造成(750 ℃, 7 h)、(850 ℃, 7 h)退火后,Be材强度不但没有降低反而升高。另外,当晶界上BeO增多时,强度提高还涉及到下面提到的颗粒之间的间距问题。还有一点需要指出的是,当BeO粒子位于晶界时,除了能对最初屈服起到阻碍作用以外,也必将增加晶界滑动阻力,因而提高强度,降低伸长率。

。因此,铍缺乏有效的滑移系统进行滑移,当位错在基面运动时,极易在基面堆积位错产生应力。同时铍体积模量与剪切模量的比值也是所有密排六方金属中最低的,为0.87[9],低的比值意味着启动位错和分离原子面所需要的能量十分接近,即滑移在铍基面堆积位错造成的应力集中很容易达到分离原子面的力。铍的以上本性决定了铍位错运动的能力十分有限,一般仅在有限的范围内进行滑移后,基面堆积位错造成的应力就能导致铍材解理断裂。另一方面,铍材在产生应变的过程中,当有位错运动到晶界和BeO颗粒前,就会塞积产生应力,启动晶界另一边的位错源,产生最初的屈服[10]。这就是说,一方面铍容纳位错运动的能力十分有限,另一方面最初屈服是由晶界和BeO颗粒处位错塞积应力造成的,如果由于晶界和BeO杂质对位错运动的阻碍作用,使最初屈服时启动位错源的应力较大,则留给后续位错运动的空间减少,使铍本身有限的屈服过程不能发生,材料的伸长率降低,甚至启动位错源的力直接达到分离原子面的力,造成铍材解理断裂,伸长率为零。因此,Be晶界的性能和BeO粒子的形态与分布对铍材的塑性起着关键作用。当位错滑移到晶界处传递时,晶界上弥散分布的细小BeO颗粒会使位错运动变得更加困难。当晶界上无BeO时(见图1(f)),即在低BeO含量时,位错较易越过晶界进行滑移,利于Be材的塑性提高。基于同样的道理,当BeO粒子位于晶界时,与晶界共同作用对最初屈服时位错运动的钉扎作用,要比BeO单独位于晶内更为明显。故经750℃真空退火后,当晶内的BeO颗粒向晶界偏聚后,晶界处BeO增加,和晶界共同作用阻碍位错运动,比BeO单独位于晶内更能有效防止材料屈服,造成(750 ℃, 7 h)、(850 ℃, 7 h)退火后,Be材强度不但没有降低反而升高。另外,当晶界上BeO增多时,强度提高还涉及到下面提到的颗粒之间的间距问题。还有一点需要指出的是,当BeO粒子位于晶界时,除了能对最初屈服起到阻碍作用以外,也必将增加晶界滑动阻力,因而提高强度,降低伸长率。

BeO是六方纤锌矿晶型(ZnS变态),属于离子化合物晶体[12],难以变形,当位错运动到大量弥散分布在晶界,少量弥散在晶内的细小的BeO粒子(如图1(a))前时,位错不能够切过它们,只能以绕过他们的方式运动。此时BeO颗粒对金属铍塑性和强度的作用,与位错绕过它们的阻力有关,而这种阻力与第二相粒子的本性无关,只决定于粒子之间的间距L,τ =Gb/L[12] (式中,G为基体的剪切模量,b为位错的柏氏矢量,τ为位错绕过二相粒子时的阻力),即质点的间距越小,对位错运动的阻碍力越大,材料强度越高、塑性越差。根据以上分析,BeO含量就变得不重要,如样品6中BeO含量为1.49%,是所有样品中最高的,但由于BeO颗粒尺寸较大,在200~250 nm之间,使粒子间的间距增大(见图1(e)),对位错运动几乎没有阻碍作用,材料塑性很高;BeO颗粒尺寸均在75 nm左右的样品1和8,随着BeO含量的增多,颗粒之间的间距下降,材料强度升高而塑性下降;对于经退火处理后的样品8-1、8-2,随着热处理温度的提高,在BeO总量不变的情况下,三叉晶界聚集处不致密的BeO快速长大并增多,弥散分布在晶界上BeO减少,故样品8-2的强度较样品8-1的有所降低;在样品4和5中,虽然BeO含量很低,但其BeO颗粒尺寸相比于样品1的小,弥散分布度高,BeO颗粒之间的间距减少,因而取得比BeO含量高的样品1更好的强化效果,材料强度提高。

BeO颗粒尺寸细小时,弥散分布的BeO粒子对铍材主要起到第二相粒子强化作用,但随着颗粒尺寸的增大,这种强化作用变成脆化。钟景明等[6]以及WEBSTER等[13]认为BeO颗粒就是应力集中点。当BeO杂质颗粒尺寸增大,就会明显加剧BeO和铍失配造成的应力集中,铍和BeO都是脆性材料,应力集中不能通过晶面滑移释放,对材料产生明显的脆化效应。在应力集中不明显的细小杂质处,界面脱离过程是缓慢的,即解理裂纹的形核是缓慢的,BeO主要表现为对位错的阻挡作用。当BeO颗粒尺寸增大,局部局域的应力集中和外加应力场联合作用可以直接造成界面分离,在每个BeO颗粒周围优先形成微孔,形成解理裂纹晶核。以上是BeO和铍基体界面连续的情况,如果两者的界面不连续,则不连续的界面相当于微裂纹,对铍材伸长率的影响更加严重。同时局部区域的应力集中也会使BeO周围的铍基体优先发生解理,加上在界面分离或界面不连续所形成的微裂纹,使解理裂纹晶核尺寸很容易达到裂纹扩展临界点,材料的伸长率降低。如样品3在BeO含量较低的情况下,出现大的单颗粒BeO后(见图1(c)),伸长率降至1.03%。还需要指出的是,虽然随着BeO颗粒尺寸的增加,应力集中增加,但只要BeO与铍基体失配造成的应力集中,不足以加重微裂纹的形核,对塑性是没有影响的。如虽然样品6的BeO颗粒尺寸在200~250 nm之间,但其塑性良好。从样品3和6的BeO颗粒尺寸来看,BeO颗粒在300 nm左右时,应该是BeO杂质强化和脆化铍基体的临界尺寸。

铍材在三叉晶界出现不致密BeO颗粒聚集态之后,材料的伸长率为零,表现为完全的脆性。从三叉晶界聚集的不致密BeO杂质颗粒(见图2(a))和断口裂纹源中心处不致密BeO杂质颗粒(见图3)可以看到,BeO与铍基体脱离,存在于孔洞内部。因此,三叉晶界聚集的不致密BeO杂质颗粒成为裂纹源与应力集中无关。但在外力的作用下,三叉晶界聚集的不致密BeO杂质颗粒周围孔洞相当于在材料内部预制一定尺寸的微裂纹,从而导致Be材塑性很低。

三叉晶界BeO聚集态能否成为解理裂纹核心,取决于拉伸时局部区域的应力状态,也就是材料局部应力须达到萌生微裂纹所需的力,另外,在三叉晶界BeO聚集的地方还存在Si和Fe等元素,这与WEBSTER等[13]和KUMAR等[14]报道的Si元素能促进BeO颗粒长大的结论相吻合。

晶界上BeO成膜状析出后,对Be材的塑性不利。这种薄膜状组织造成晶界的结合强度降低,甚至低于铍材的屈服强度,在拉伸时造成晶界分离,使铍解理断裂变成晶间断裂,材料强度下降的同时,伸长率为零。这种晶间断裂现象在早期的铍材中较为常见。

4 结论

1) 细小BeO颗粒的弥散分布对力学性能的作用,取决于BeO颗粒之间的间距,而不是BeO含量。因此,相比于BeO含量,BeO的颗粒尺寸和分布对力学性能的影响更为关键。

2) 当弥散分布的BeO粒子尺寸小于300 nm时,不会对Be材的塑性产生负面影响,BeO主要表现为对铍基体的强化作用,但随着BeO颗粒尺寸的进一步增大,应力集中加剧,材料会表现出明显的脆性。

3) Be材料内部三叉晶界处不致密BeO颗粒周围的孔洞,相当于在材料内部预制一定尺寸的裂纹,是导致铍材零伸长率的主要原因。

REFERENCES

[1] CLENEBT P. How the beryllium industry is building new markets by applying isostatic processing technologies[C]// Proceedings of the 4th International Conference on Isostatic Pressing. Stratford-upon-Avon, UK: Metal Powder Report Publishing Services Ltd, 1990: 18.1-18.11.

[2] Roskill Information Services Ltd. The economics of beryllium[M]. London: Roskill Information Services Ltd, 2001: 111-119.

[3] 聂大钧. 铍粉末冶金与加工技术[M]. 北京: 中国有色金属工业总公司职工教育教材编审办公室, 1986: 2, 181-182.

NIE Da-jun. Beryllium powder metallurgy and processing technology[M]. Beijing: Staff Education Textbook Editorial Office of China Nonferrous Metals Corporation, 1986: 2, 181-182.

[4] ALDINGER F, GOLD E, PETZOW G. Effect of oxide and grain size in high-purity beryllium[C]// Beryllium 1977, the 4th International Conference on Beryllium. London: The Royal Society, 1977: 14.1-14.11.

[5] MARDER J. Metals Handbook (Volume 7): Power Metallurgy[M]. Ohio: American Society of Metals, 169-172.

[6] 钟景明, 高 勇, 王东新, 王学泽, 王零森. 金属铍的微屈服行为和机理[J]. 中国有色金属学报, 2004, 14(10): 1637-1641.

ZHONG Jing-ming, GAO Yong, WANG Dong-xin, WANG Xue-ze, WANG Ling-sen. Micro-yield behavior and mechanism of beryllium metal[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(10): 1637-1641.

[7] STONEHOUSE A J. Beryllium science and technology (Volume 1)[M]. New York: Plenum Press, 1979: 181-204.

[8] WEBSTER D. Physical metallurgy of beryllium[C]// Beryllium 1977, the 4th International Conference on Beryllium. London: The Royal Society, 1977: 1.1-1.12.

[9] LAROSE J. Pressure effects on the flow and fracture properties of Be-Al alloys[D]. USA, Case Western Reserve University, 2001: 7.

[10] MARSCHALL C W, MARINGER R E, CEPOLLINA F J. Dimensional stability and micromechanical properties of materials research use in an orbiting astronomical observatory[C]// 13th Structure, Structure Dynamics and Materials Conference. Texas: AIAA, 1972: 72-235.

[11] 高陇桥. 氧化铍陶瓷[M]. 北京: 冶金工业出版社, 2006: 9.

GAO Long-jiao. BeO ceramics[M]. Beijing: Metallurgical Industry Press, 2006: 9.

[12] 石德珂. 材料科学基础[M]. 2版. 北京: 机械工业出版社, 2003: 347.

SHI De-ke. Foundations of materials science[M]. 2nd ed. Beijing: China Machine Press, 2003: 347.

[13] WEBER D, GREENE R L, LAWLEY R W, LONDON G J. Factors affecting the tensile strength, elongation and impact resistance of low oxide, hot isostatically pressed beryllium block[J]. Metallurgical Transactions A, 1976, 7: 851-856.

[14] KUMAR K, MCCARTHY J. VANDE J B. Correlation of microyield behavior with silicon in X-520 and HIP-50 beryllium[J]. Metallurgical Transactions A, 1985, 16: 807-814.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(11062010, 50761006);宁夏自然科学基金资助项目(NZ08177, NZ0946);科技人员服务企业行动项目(2009GJG30043)

收稿日期:2010-04-16;修订日期:2010-07-29

通信作者:秦高梧,教授,博士;电话:024-83683772;E-mail: qingw@smm.neu.edu.cn