文章编号:1004-0609(2007)10-1656-05

Ti2AlNb基合金表面渗铬层结构及其摩擦学性能

吴红艳1,张平则1,李建亮2,马士剑1,徐 重1

(1. 南京航空航天大学 材料科学与技术学院,南京 210016;

2. 南京理工大学 材料科学与工程系,南京 210094)

摘 要:采用双层辉光等离子表面合金化技术对Ti2AlNb基合金进行表面渗Cr处理,结果表明:经过离子渗铬处理后可获得约25 μm的表面合金层;渗层中Cr含量随渗层深度呈梯度变化,且由于原子扩散能力的差异,在渗层的不同区域形成不同相,结合XRD和XPS分析技术,证实表层以含Cr2Nb的Laves相和Al8Cr5相为主; 渗层硬度值由外层的HV0.11 125逐渐过渡到基体的HV0.1400左右;渗Cr处理后合金室温摩擦因数由原来的0.24降低到0.15,由于硬质Cr2Nb和Al8Cr5相起到支撑载荷的作用,降低粘着磨损,室温磨损率降低60%以上;高温条件下由于氧化和摩擦磨损的共同作用,摩擦因数变化不大,磨损率降低20%。

关键词:Ti2AlNb基合金;双辉等离子表面合金化;摩擦;磨损

中图分类号:TG 174.445 文献标识码:A

Microstructure and tribological properties of

surface plasma chromising layer of Ti2AlNb-based alloy

WU Hong-yan1, ZHANG Ping-ze1, LI Jian-liang2, MA Shi-jian1, XU Zhong1

(1. School of Materials Science and Technology, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China;

2. Department of Materials Science and Engineering, Nanjing University of Science and Technology, Nanjing 210094, China)

Abstract: Surface chromising was performed on the Ti2AlNb-based (O phase) alloy using the double glow plasma process to enhance its wear-resistance. The results show that the thickness of alloying layer is approximately 25 μm by surface plasma chromising. The content of chromium of the alloying layer distributes gradually. The various phases distribute in different areas due to the diffusion of atomics under high temperature. The Cr2Nb with Laves phase and Al8Cr5 phases with high hardness are in the sub-surface while new disorder O-phases (Ti 25.36Al 18.44Nb) with low hardness dispersed at the interface of alloying layer and substrate. The micro-hardness of chromising layer decreases gradually from HV0.1 1 125 to about HV0.1 400. Pin-on-disk wear test indicates that friction coefficient at room temperature decreases from 0.24 to 0.15 and wear rate is only about 30% of that of matrix at room temperature, while wear rate at elevated temperature deduces by 20% after chromising.

Key words: Ti2AlNb-based alloy; double glow plasma surface alloying; friction; wear

Ti2AlNb基合金是在α-Ti3Al基础上发展的一种新型金属间化合物[1],因具有高的比强度和耐蚀性能, 而成为航空航天领域研究的热点[2],但是其硬度较低(HV0.1290~400),耐磨性尚不能满足要求。目前在Ti2AlNb基合金中加入一定量的Cr、Mo、W和V等元素主要是改善合金的室温脆性、断裂韧性[3]和高温抗蠕变性[4]等,而关于提高其硬度和表面耐磨性方面的研究较少,表面合金化是提高Ti2AlNb基合金硬度的一种经济且有效的方法[5]。当一定含量的Cr加入到Ti-Al-Nb 系合金中,Cr主要取代Al的位置,同时部分取代Ti和Al的位置,经过原子的重新占位形成富Al的Al-Cr化合物和Cr-Nb化合物等,有助于提高合金的硬度[6-7]。本文作者拟采用具有中国原创性的双层辉光离子渗金属技术[8]在Ti2AlNb 基合金表面渗Cr,从而起到改善合金基体硬度和耐磨性的目的,并且对渗层组织结构、原子扩散以及渗层显微硬度和耐磨性等方面进行系统研究。

1 实验

在自制的10 kW多功能双层辉光离子渗金属炉中对基材Ti22Al25Nb合金表面进行渗Cr处理[9]。纯Cr板(d 100 mm×5 mm,纯度99.9%)作源极,Ti22Al25Nb合金(10 mm×10 mm×4 mm)作阴极,极间距20 mm。抽真空至2.2×10-2 Pa,充保护气体99.9%的高纯氩气达35 Pa。源极电压为900~950 V,基体(阴极)电压350~450 V,基体温度960 ℃,保温4 h。

采用扫描电子显微镜(SEM)进行渗层组织形貌观察,结合能谱仪(EDS)和XPS测定渗层微区合金元素的分布;采用Rigaku Y-Q4型X射线衍射仪进行渗层相分析;用HXS-1000A型显微硬度仪测量渗层的硬度。MG-2000高温摩擦磨损试验机测试涂层摩擦性能,采用销-盘式配副,配副材料镍铬合金(d 45 mm×5 mm,Ra=0.5 μm)盘作下试样,渗Cr和未渗Cr的合金销(d 5 mm×10 mm)作上试样,载荷20 N,速度0.4 m/s,环境温度分别为室温和500 ℃,滑行距离250 m, 磨损量通过精度为0.1 mg的分析天平称量。

2 结果与分析

2.1 表面合金层的组织和相组成

Ti2AlNb基合金表面渗Cr层可分为两个区域,由表及里依次为线状分布的沉积层及致密的合金扩散层(图1(a))。另外,图1(b)中EDS线扫描结果表明渗层中Cr元素沿深度方向逐渐降低,从表面到基体连续变化,在整个渗层中没有成分的突变点,表面合金渗层与基体冶金结合,不存在类似于涂镀层的表面改性层与基体的结合性问题[10]。Ti2AlNb基合金自身的原子发生了扩散转移,Nb原子的扩散主要通过向最近邻的Ti亚晶格处跳跃来完成[11],而渗Cr过程中钛合金基体表面受到离子轰击,空位浓度增加,有利于Nb原子向表层扩散[12],从而在表层形成Nb-Cr化合物。由EDS点分析可知,最外层断续分布的白色线状物含有少量Nb,实际上是偏聚表层的Nb与外来原子Cr形成的Nb-Cr化合物及单质Cr的沉积。

图1 Ti2AlNb渗Cr后的截面组织(a)、成分分布(b)及析出相的能谱分析(c)

Fig.1 Cross-sectional microstructure (a) and composition distribution after Ti2AlNb chromising (b) and energy spectroscopy of precipitation phase (c)

图1(c)所示为析出相的EDS结果,可知该析出相成分为Ti25.36Al-18.44Nb的无序O相,与原来的Ti22Al25Nb相成分相比,Al含量增多,Nb含量减 少[13]。有序O相中钛、铌、铝以一定的化学计量比(50?25?25)分别占据α(8g)、β(4c2)和γ(4c1)中的一个亚点阵,但是在非化学计量比的条件下,有序O相将变为无序O相,此时钛、铌、铝分别占据多个亚点阵[14]。

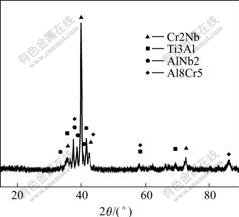

由渗层的射线衍射谱(图2)可知,渗层组织中除了含Ti3Al、AlNb2化合物外,还含Cr2Nb和Al8Cr5中间相[15]。图3(a)~(d)所示分别为元素Ti、Al、Nb和Cr的XPS曲线。图3(a)中Cr 2p3轨道处的键能 573.84 eV与单质Cr或铬合金有关,而在图3(b)中键能为77.4 eV的Al 2p轨道与相同键能的Cr 3s轨道重合且被加强,由此可判断铝铬合金的存在。另外,键能为71.72 eV和74.55 eV的Al的2p轨道与键能为205.6 eV的Nb3 d3轨道及Ti的2p轨道可分别形成Al-Nb合金和Ti-Al合金,结合XRD分析可证实渗层中的合金成分分别为Al8Cr5、AlNb2、Ti3Al和Cr2Nb相。

图2 渗Cr层的X射线衍射谱

Fig.2 XRD pattern of chromising layer

图3 元素的XPS谱

Fig.3 XPS patterns of binding energy of Cr 2p (a); Al 2p (b); Ti 2p (c) and Nb 3d

2.2 表面合金层的硬度分布

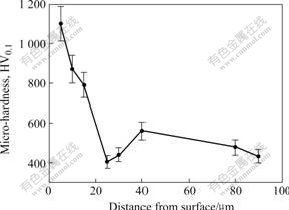

由图4所示为表面渗Cr层的硬度分布。图4可以看出,渗Cr层的显微硬度值由最外表层的HV0.11 125逐渐降低到基体的约HV0.1400左右,且该曲线的变化规律与图1(a)渗层中Cr含量的分布变化规律一致。由于表层Cr含量最高,大部分Cr元素都固溶于渗层组织中,形成Laves相Cr2Nb和Al8Cr5硬质相,因此显微硬度沿渗层向基体呈梯度分布,距表层25 μm处硬度最低,之后Cr含量几乎降为0(见图1(a))。这主要是无序O相析出,降低渗层的硬度,可知,渗层的有效厚度为25 μm。

图4 表面渗Cr层的硬度分布

Fig.4 Distribution of Micro-hardness of surface chromising layer

2.3 渗铬层的摩擦学性能

图5所示为渗Cr前后Ti2AlNb基合金与镍基合金配副时室温和500 ℃的摩擦因数和磨损率。与未渗Cr合金相比,渗铬后合金室温摩擦因数由0.24降低到0.15(图5(a)),高温摩擦因数相差不大(图5(b));室温磨损率降低为原来的40%左右,而高温磨损率降低幅度较小,仅为20%(图5(c))。结合渗Cr后渗层组织的变化可知,由于Laves相Cr2Nb和Al8Cr5硬质相的形成提高了表面硬度也降低了粘着程度,且渗层成分梯度分布与基体结合牢固,不易剥落,使得Ti2AlNb基合金经表面等离子渗铬后摩擦磨损性能得到明显改善。

图5 渗Cr前后Ti2AlNb的摩擦因数和磨损率

Fig.5 Friction coefficient of substrate and chromising layer: (a) Fraction coefficient at RT; (b) Fraction coefficient at 500 ℃; (c) Wear rate

图6(a)和(b)所示分别为Ti2AlNb基合金等离子渗C合金化前后的室温磨损表面形貌,图6(c)和(d)所示分别为500 ℃时的磨损表面形貌。可看出未渗铬的基体表面粘着倾向严重,且存在较深犁沟,主要是表层脱落形成磨粒,从而导致软基体表面磨损较为严重;而经过渗铬处理的表面磨痕细小且表面平整,由于硬质Cr2Nb和Al8Cr5相起到支撑载荷的作用,降低粘着磨损,所以耐磨性能得到大幅度提高;而高温下由于合金基体的氧化和配副材料镍合金的选择性转移,使得高温磨损机理比较复杂,但未渗铬的磨损表面存在转移的氧化物,但由于基体较软,转移膜被很快磨损掉,磨粒磨损严重,而渗铬处理后,硬的渗层有力地支撑了转移膜,所以几乎观察不到磨痕,磨损率低。

图6 室温为500 ℃时Ti2AlNb基合金的磨损表面形貌

Fig.6 Worn surface morphologies of Ti2AlNb-based alloy: (a) Ti2AlNb-based alloy, RT; (b) Chromising layer, RT; (c) Ti2AlNb-based alloy, 500 ℃; (d) Chromising layer, 500 ℃

3 结论

1) 采用双层辉光等离子渗金属技术,在Ti2AlNb基体合金表面制备出Cr-Nb合金层和Al-Cr合金层,合金层成分及硬度均呈梯度分布,有效渗层厚度为25 μm.

2) 由于温度的影响以及不同原子间扩散能力的差异在渗层形成含Cr2Nb的Laves相及富Al的Al8Cr5相。

3) 等离子表面渗铬处理后由于表面生成高硬的Cr2Nb和Al8Cr5相,使得Ti2AlNb基合金的室温摩擦因数由0.24降低到0.15,磨损率降低了60%以上,高温磨损率降低了20%,表现出良好的减摩耐磨效果。

REFERENCES

[1] Nandy T K, Banerjee D. Creep of the orthorhombic phase based on the intermetallic Ti2AlNb[J]. Intermetallics, 2000, 8: 915-928.

[2] Chen G L, Wang J G, Ni X D, Lin J P, Wang Y L. A new intermetallic compound in TiAl+Nb composition area of the Ti-Al-Nb ternary system[J]. Intermetallics, 2005, 13: 329-336.

[3] 毛 勇, 李世琼, 张建伟, 彭继华, 邹敦叙, 仲增墉. Ti-22Al-20Nb-7Ta合金的显微组织和力学性能研究[J]. 金属学报, 2000, 36(2): 135-140.

MAO Yong, LI Shi-qiong, ZHANG Jian-wei, PENG Ji-hua, ZOU Dun-xu, ZHONG Zeng-yong. Study on microstructure and mechanical properties of Ti22Al20Nb7Ta intermetallic alloy[J]. Acta Metallurgica Sinica, 2000, 36(2): 135-140.

[4] Yanga S J, Nama S W, Hagiwarab M. Investigation of creep deformation mechanisms and environmental effects on creep resistance in a Ti2AlNb based intermetallic alloy[J]. Intermetallics, 2004, 12: 261-274.

[5] 王华明, 于利根, 刘秀波. TiAl合金激光表面合金化涂层的组织与耐磨性[J]. 中国有色金属学报, 2000, 10(6): 785-789.

WANG Hua-ming, YU Li-gen, LIU Xiu-bo. Microstructures and wear resistance of laser surface alloyed composite coatings on TiAl alloy[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(6): 785-789.

[6] Music D, Kreissig U. Electronic structure and mechanical properties of Cr7C3[J]. Physics Letters A, 2004, 326: 473-476.

[7] 王西涛, 倪晓东,陈国良. TiAl+Nb系Nb原子有序占位方式的计算[J]. 北京科技大学学报, 1997, 19(1): 55-58.

WANG Xi-tao, NI Xiao-dong, CHEN Guo-liang. Calculation of Nb ordering occupation in TiAl+Nb system[J]. Jorunal of University of Science and Technology Beijing, 1997, 19(1): 55-58.

[8] LIU Xiao-ping, XU Zhong, WU Wei, LIANG Wen-ping. Plasma surface alloying with molybdenum and carburization of TiAl based alloys[]. Trans Nonferrous Met Soc China, 2005, 15(3): 420-424.

[9] 张平则, 李忠厚, 贺志勇, 等. Ti-6Al-4V表面双层辉光离子渗Cr研究[J]. 兵器材料科学与工程, 2005, 28(5): 17-20.

ZHANG Ping-ze, LI Zhong-hou, HE Zhi-yong, et al. Surface chromizing of Ti-6Al-4V by double glow plasma surface alloying technology[J]. Ordnance Material Science and Engineering, 2005, 28(5): 17-20.

[10] Sergiy D , Frank H, Christian K, Christian H. Niobium and titanium diffusion in the high niobium-containing Ti-54Al-10Nb alloy[J]. Intermetallics, 2006, 14: 1-8.

[11] Breuer J, Wilger T, Friesel M, et al. Interstitial and substitutional diffusion of metallic solutes in Ti3Al[J]. Intermetallics, 1999, 7: 381-388.

[12] Muraleedharan Nandy K. Banerjee T K. Phase stability and ordering behavior of the O phase in Ti-Al-Nb alloys[J]. Intermetallics, 1995, 3(3): 187-99.

[13] WU Bo, SHEN Jian-yun, CHU Mao-you, SHANG Shun-li. The ordering behavior of the O phase in Ti2AlNb-based alloys[J]. Intermetallics, 2002, 10: 979-984.

[14] Jiang C, Sordelet D J, Gleeson B. Site preference of ternary alloying elements in Ni3Al: A first-principles study[J]. Acta Materialia, 2006, 54: 1147-1154.

基金项目:江苏省自然科学基金资助项目(BK2005128)

收稿日期:2007-01-23;修订日期:2007-05-17

通讯作者:张平则,副教授,博士;电话:025-52112904-83132;E-mail: pzzhang@nuaa.edu.cn

(编辑 龙怀中)