钼合金表面MoSi2涂层的制备工艺和形成机理

李鹏飞,范景莲,成会朝,田家敏,成创功

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘要:采用包埋渗硅法在钼合金表面上制备MoSi2涂层,研究粉料成分、粒度和反应时间对涂层厚度的影响,分析MoSi2涂层的形成机理。研究结果表明:随着粉料中硅粉和活化剂粉末含量的增加,涂层的厚度呈现先增加后降低趋势;粉料中活化剂的质量分数为10%时,能够制备厚度为130 μm的涂层;高能球磨能够提高粉末的表面活性,促进涂层生长,球磨30 h的硅粉粉料在高温下渗硅15 h后,涂层厚度能够达到160 μm。MoSi2涂层的生长受扩散反应过程控制,形成的涂层包括2层:外层为MoSi2层,内层为Mo5Si3过渡层。

关键词:MoSi2涂层;催化剂;球磨时间;形成机理

中图分类号:TG146.412 文献标志码:A 文章编号:1672-7207(2012)07-2506-07

Preparation and formation mechanism of MoSi2 coating on molybdenum alloy

LI Peng-fei, FAN Jing-lian, CHENG Hui-chao, TIAN Jia-min, CHENG Chuang-gong

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: A MoSi2 coating on molybdenum alloy was prepared by pack cementation. The effect of powder component, silicon powder particle size and time on the thickness of MoSi2 coating was studied. The formation mechanism of MoSi2 coating was analyzed. The results show that as the amount of silicon powder and catalyst powder increases, the thickness of the coating increases at first and then decreases. The thickness of coating can grow to 130 μm when the content of catalyst is 10%. The fine silicon powder promotes the growth of the coating and the thickness of the coating can grow to 160 μm after siliconizing at elevated temperature for 15 h when the silicon powder is milled for 30 h. The process of MoSi2 coating growing is controlled by diffusion. The coating includes two layers: the outer MoSi2 layer and the inner Mo5Si3 transition layer.

Key words: MoSi2 coating; catalyst; milling time; formation mechanism

钼及钼合金具有低的热膨胀系数、较高的硬度和高温强度,广泛应用于电工电子、仪器仪表、国防军工和航空航天等领域[1-3]。但钼及钼合金在空气中400 ℃以上便开始形成氧化物,造成性能的下降;高于750 ℃时氧化物挥发,并随着温度升高,氧化加剧,形成白色烟雾状MoO3,使得钼及钼合金在高温领域的应用受到限制[4-5]。目前国内外学者主要是采用硅化物涂层、铝化物涂层和硼化物涂层等涂层体系[6-8],使得钼及钼合金具备抗氧化性能。美国和日本等系统地研究了MoSi2的氧化行为,发现MoSi2涂层较其他类型涂层在1 000~1 500 ℃具有更好的高温抗氧化性能[9-11],是航空航天和核工业等高科技领域苛刻环境下服役零部件的重要涂层材料之一。硅化物涂层可以通过包埋渗硅、料浆熔烧和化学气相沉积等方法制备,其中包埋渗硅法较其他方法具有工艺简单,对设备要求低,不受样品形状限制等优点[11-12]。目前国内外没有对包埋渗硅法中粉料成分和粒度等因素对制备MoSi2涂层影响的相关报道。因此,本文作者在氢气气氛中,采用包埋渗硅法在钼合金表面制备MoSi2涂层,研究粉料成分、粒度和反应时间等因素对涂层厚度的影响,并通过热力学计算和动力学分析研究MoSi2涂层的形成机理。

1 实验方法

采用粉末冶金方法制备出长×宽×高为38 mm× 5 mm×5 mm的钼合金样品。首先利用砂纸对样品打磨抛光,然后酒精清洗干净烘干后用精密电子天平对样品称重,制备出涂层基体。将粉料按一定的比例均匀混合,装入干净的刚玉坩埚,并将钼合金基体埋入粉料;最后把坩埚密封,置于1 200 ℃下的氢气气氛钼丝炉中进行包埋渗硅。

采用捷克NOVA TM NanoSEM230超高分辨率场发射扫描电镜对涂层厚度进行分析,利用背散射电子成像和线扫描分析涂层中的相分布和成分变化;采用日产JEOL公司的JSM-5600LV型扫描电镜对涂层的表面形貌和显微组织进行检测分析,并利用EDX对涂层进行成分分析;采用日产3014-2Z型X线衍射仪对样品表面进行物相分析。

2 结果与讨论

2.1 粉料成分对涂层厚度的影响

2.1.1硅粉含量对涂层厚度的影响

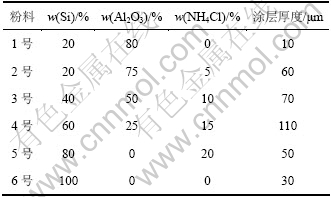

表1所示为不同成分粉料包埋渗硅15 h后制备出涂层厚度的数据。1号和2号粉料比较,添加少量NH4Cl后,涂层厚度有较大幅度增长,说明NH4Cl能起到好的活化作用,促进了涂层的形成;随着硅粉和NH4Cl含量的增加,涂层厚度先增加后降低,说明活化剂和硅粉的量存在最优值;当粉料中只有硅粉时,涂层较薄。图1所示为不同成分粉料制备出涂层截面的BSE图。涂层分为2层,外层厚度随着粉料的变化而变化,内层厚度基本不变;硅粉含量为60%时,涂层较为致密,涂层中基本没有孔洞和裂纹等缺陷,并且厚度达到116 μm。

表1 不同成分粉料制备出涂层的厚度

Table 1 Thickness of coating prepared by different contents of powders

图1 不同成分粉料制备出涂层截面的BSE图

Fig.1 Cross-sectional BSE image of coating prepared by different powders

2.1.2 催化剂含量对涂层厚度的影响

表2所示为质量分数为60%Si粉和不同催化剂含量粉料经过15 h高温渗硅后涂层厚度的数据表。随着NH4Cl活化剂含量的降低,涂层厚度缓慢增加;活化剂添加量为10%时涂层厚度达到130 μm,说明活化剂含量为10%时,能够满足粉料中活化作用的需要。

表2 不同催化剂含量粉料制备出涂层的厚度

Table 2 Thickness of coatings prepared by different contents of catalyst

2.2 硅粉粒度对涂层厚度的影响

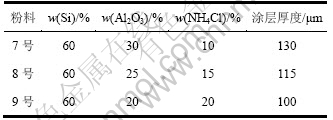

采用高能球磨对硅粉进行细化,制备出不同粒度的硅粉,研究硅粉粒度对涂层厚度的影响。分别对原始硅粉球磨15 h和30 h,然后采用7号粉料的比例,制备出均匀的粉料;在相同条件下包埋渗硅15 h后制备出涂层。图2所示为经不同球磨时间后硅粉的SEM图。原始粉末粒径在7~8 μm,有较少细颗粒粉末;经过15 h球磨后,粒径在5~6 μm,细颗粒粉末增多;经过30 h球磨后,粒径在3~4 μm,细颗粒粉末更多,并且粉末粒度趋于一致。图3所示为不同粒度硅粉粉料制备涂层截面的BSE图。随着球磨时间延长,硅粉粒度变小,制备的涂层厚度增加;并且涂层均匀致密,基本没有裂纹和空洞等缺陷。

2.3 涂层形成机理

2.3.1 MoSi2涂层形成的热力学分析

包埋渗硅过程中可能发生如下反应:

NH4Cl(s)=NH3(g)+HCl(g) (1)

Si(s)+HCl(g)=SiCl(g)+ H2(g) (2)

H2(g) (2)

Si(s)+2HCl(g)=SiCl2(g)+H2(g) (3)

Si(s)+3HCl(g)=SiCl3+ (g) (4)

(g) (4)

Si(s)+4HCl(g)=SiCl4(g)+2H2(g) (5)

2SiCl2(g)+Mo(s)+2H2(g)=MoSi2(s)+4HCl(g) (6)

MoSi2+ =

= (7)

(7)

+

+ =MoSi2 (8)

=MoSi2 (8)

MoSi2+5Mo=2Mo3Si (9)

+

+ =

= (10)

(10)

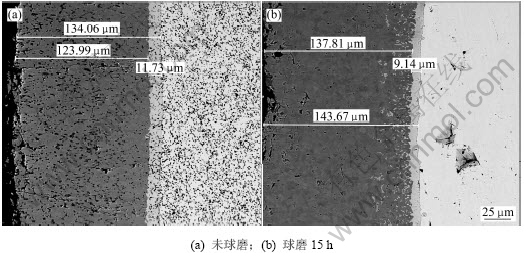

图4所示为式(2)~(10)的反应吉布斯自由能随温度变化的关系图。根据热力学数据[13]计算,反应(2)和(10)在恒温恒压的情况下不可能发生。MoSi2和Mo基体发生反应可能生成Mo5Si3和Mo3Si相,而生成Mo5Si3相的吉布斯自由能较小,说明其较Mo3Si相更稳定;Mo5Si3相和基体生成Mo3Si反应吉布斯自由能大于0,使得反应不可能在时恒温恒压的条件下进行。

图2 不同球磨时间硅粉的SEM图

Fig.2 SEM images of silicon powder after different milled time

图3 不同粒度硅粉粉料涂层截面的BSE图

Fig.3 Cross-sectional BSE images of coating prepared by different particle sizes of silicon

图4 式(2)~(10)的反应吉布斯自由能随温度变化的关系图

Fig.4 Changing curves of ΔG in equations (2)-(10) at different temperatures

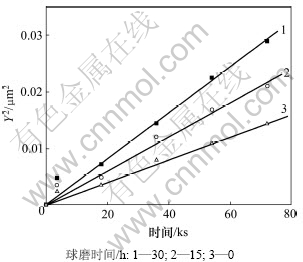

2.3.2 涂层形成的动力学分析

图5所示为不同球磨时间硅粉制备的涂层厚度与反应时间关系图。在1 200 ℃包埋渗硅过程中,MoSi2涂层的增长速度和活化反应时间接近抛物线型,证明其涂层的形成受反应扩散过程控制[14]。涂层厚度和反应时间的关系式用下式表示:

式中:Y为涂层的厚度,μm;K为涂层增长的速率常数,μm2/s;t为时间,s。涂层厚度和反应时间的关系和式(11)符合得较好,并且1 200 ℃时30 h,15 h和0 h球磨硅粉制备MoSi2涂层的增长速率常数分别为4.0×10-13 ,3.0×10-13和2.0×10-13 m2/s,与文献报道中的速率常数接近[14]。硅粉经过球磨后其粒度变小,表面活性增强,与卤化物在高温下更容易反应,从而易于使得密封容器中能够产生更高浓度的硅卤化物。根据1 200 ℃时MoSi2形成的吉布斯自由能计算出硅的活度范围在0.007 49~1[15],MoSi2涂层表面硅浓度的变化对硅活度有较大的改变,使得不同球磨时间硅粉对涂层增长速率常数有较大的影响。

图5 不同球磨时间制备的涂层厚度与反应时间关系图

Fig.5 A linear regression fit to respective plots of coatings thickness versus deposition time

2.3.3 涂层的形成机理

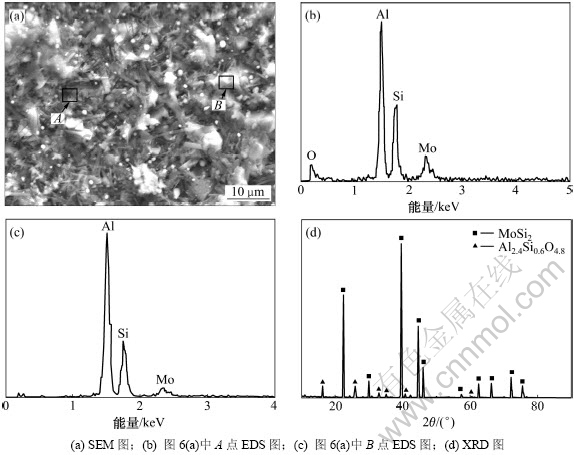

图6所示为渗硅15 h(30 h球磨硅粉)涂层表面的SEM,EDS和XRD图。表面有较多的白色区域,EDS分析其含Mo,Al,O和Si元素,其中Al元素含量较 高;暗色区域EDS能谱显示:其Al和O含量较白色区域降低,Mo和Si元素含量增加。包埋法的粉料由Si粉、Al2O3粉和催化剂组成,涂层在高温形成的 过程 中,Al2O3粉容易黏附在涂层的表面,所以 EDS分析中出现了较强Al和O峰。结合XRD分析, MoSi2峰值很强,Al2.4Si0.6O4.8峰值较低,证明形成了MoSi2层。

包埋渗硅过程中,首先活性剂发生分解生成HCl,而HCl能够与硅粉发生反应生成气态硅的卤化物,如反应(1)和(3)~(5)。硅的卤化物可以与钼基体发生反应生成MoSi2层;当MoSi2层达到一定厚度时硅的卤化物不能直接和钼反应生成MoSi2,只能通过扩散Si原子与钼基体逐渐反应;通过热力学计算发现,钼基体容易和MoSi2层发生反应形成过渡区域,当硅原子扩散至过渡区域时,形成MoSi2相,而过渡区域也随即向钼基体扩展,这和不同时间涂层截面的BSE图 一致。

图7所示为球磨30 h硅粉包埋渗硅15 h后涂层截面的BSE,EDS和线扫描图。涂层明显分为2层,结合图6中的XRD分析可知:外层为MoSi2层,内层为过渡区域,其中硅和钼原子比稳定在3:5左右,说明其是Mo5Si3相。结合EDS分析,在涂层中没有Al出现,说明Al2O3只是黏附在涂层的表面。涂层中没有发现Mo3Si相,主要是由于Mo5Si3相较Mo3Si相更加稳定,并且Mo5Si3和钼基体恒温恒压包埋渗硅下不可能形成Mo3Si相,这也和反应吉布斯自由能计算的结果一致。

图6 涂层表面的SEM,EDS和XRD图

Fig.6 SEM, EDS and XRD image of coating surface

图7 球磨30 h硅粉涂层截面的BSE、EDS和线扫描图

Fig.7 Cross-sectional element line scanning, BSE image and EDS of coating

3 结论

(1) 随着包埋渗硅粉料中硅粉和催化剂粉末含量的增加,涂层的厚度呈现先增加后降低趋势;在硅粉含量为60%时,涂层厚度达到110 μm;催化剂含量为10%时,涂层厚度增加至130 μm。

(2) 随着硅粉球磨时间的增加,粉末表面活性增大,使得密封容器中能够产生更高浓度的硅卤化物,促进涂层的增长;1 200 ℃包埋渗硅15 h时能够制备160 μm左右的涂层。

(3) 根据热力学和动力学计算,涂层的增长受反应扩散过程控制;并且涂层分为2层,外层为MoSi2层,内层为Mo5Si3过渡层。

参考文献:

[1] Filacchioni G, Casagrande E, de Angelis U, et al. Effect of strain rate on the tensile properties of TZM and Mo-5%Re[J]. Journal of Nuclear Materials, 2002, 307/308/309/310/311(1): 705-709.

[2] Xu J H, Leonhardt T, Farrell J, et al. Anomalous strain-rate effect on plasticity of a Mo-Re alloy at room temperature[J]. Material Science and Engineering A. 2008, 479(1/2): 76-82.

[3] 成会朝, 范景莲, 刘涛, 等. TZM 钼合金制备技术及研究进展[J]. 中国钼业, 2008, 32(6): 40-45.

CHENG Hui-chao, FAN Jing-lian, LIU Tao, et al. Preparation and research development of TZM molybdenum alloys[J]. China Molybdenum Industry, 2008, 32(6): 40-45.

[4] 臧纯勇, 汤慧萍, 王建永, 等. 钼金属高温抗氧化能力的研究概况[J]. 材料热处理技术, 2008, 37(24): 125-128.

ZANG Chun-yong, TANG Hui-ping, WANG Jian-yong, et al. Research survey on oxidation resistance of molybdenum at high-temperature[J]. Material & Heat Treatment, 2008, 37(24): 125-128.

[5] Peng D Q, Bai X D, Zhou Q G, et al. The oxidation behaviour of molybdenum ion-implanted zircalloy-4 in air at 600 ℃[J]. Vacuum, 2004, 75: 121-131.

[6] Majumdar S, Sharma I G, Suri A K. Development of oxidation resistant coatings on Mo-30W alloy[J]. Refractory Metals & Hard Materials, 2008, 26: 549-554.

[7] Yoon J K, Doh J M, Byun J Y, et al. Formation of MoSi2-SiC composite coatings by chemical vapor deposition of Si on the surface of Mo2C layer formed by carburizing of Mo substrate[J]. Surface and Coatings Technology, 2003, 173: 39-46.

[8] Tabaru T, Shobu K, Hirai H, et al. Influences of Al content and secondary phase of Mo5(Si,Al)3 on the oxidation resistance of Al-rich Mo(Si,Al)2-base composites[J]. Intermetallics, 2003, 11: 721-733.

[9] Yanagihara K, Maruyama T, Nagata K. Effect of third elements on the pesting suppression of Mo-Si-X intermetallics (X = Al, Ti, Ta, Zr and Y)[J]. Intermetallics, 1996, 4: 133-139.

[10] Paswan S, Mitra R, Roy S K. Oxidation behaviour of the Mo-Si-B and Mo-Si-B-Al alloys in the temperature range of 700 ℃-1 300 ℃[J]. Intermetallics, 2007, 15: 1217-1227.

[11] Yokota H, Kudoh T, Suzukic T. Oxidation resistance of boronized MoSi2[J]. Surface and Coatings Technology, 2003, 169/170: 171-173.

[12] Majumdar S, Sharma I G, Raveendra S, et al. In situ chemical vapour co-deposition of Al and Si to form diffusion coating on TZM[J]. Materials Science and Engineering A, 2008, 492: 211-217.

[13] 伊赫桑·巴伦. 纯物质热化学手册[M]. 程乃良, 牛四通, 徐桂英, 译. 北京: 科学出版社, 2003: 209-1804.

Ihsan Barin. Thermochemical date of pure substance[M]. CHENG Nai-liang, NIU Si-tong, XU Gui-ying, transl. Beijing: Science Press, 2003: 209-1804.

[14] Ito K, Hayashi T, Yokobayashi M, et al. Evolution kinetics and microstructure of MoSi2 and MoSi surface layers on two-phase Mo-9Si-18B alloy during pack-cementation and high- temperature oxidation[J]. Intermetallics, 2004, 12: 407-415.

[15] Yoon J K, Kim G H, Byun J Y, et al. Effect of Cl/H input ratio on the growth rate of MoSi2 coatings formed by chemical vapor deposition of Si on Mo substrates from SiCl4-H2 precursor gases[J]. Surface and Coatings Technology, 2003, 172: 176-183.

(编辑 何运斌)

收稿日期:2011-03-22;修回日期:2011-05-06

基金项目:国家杰出青年科学基金资助项目(50925416);教育部博士点基金资助项目(20090162110032)

通信作者:范景莲(1967-),女,湖南澧县人,教授,从事难熔合金方面的研究;电话:0731-88836652,E-mail: fjl@csu.edu.cn