纳米BeO粉体的二步烧结

王小锋1, 2,王日初2,彭超群2,王志勇2

(1. 中南大学 冶金与环境学院,湖南 长沙,410083;

2. 中南大学 材料科学与工程学院,湖南 长沙,410083)

摘要:为拟制烧结后期的晶粒生长,采用二步烧结方法研究纳米BeO粉体的烧结。采用2个常规烧结实验确定每步烧结的温度范围之后,研究纳米BeO粉体的二步烧结工艺,通过扫描电子显微镜和图像分析软件研究烧结过程中微观组织结构的变化,采用激光导热仪测试材料的热导率,并分析纳米BeO粉体的二步烧结机制。研究结果表明:第1步的烧结温度(t1)范围为1 450 ℃≤C.rsity, Changsha 410083, Chi8na;, Central South t1≤1 500 ℃;第2步的烧结温度(t2)范围为1 300 ℃≤t2≤1 400 ℃;较合适的二步烧结工艺为:(1 450 ℃,1 min)+(1 400 ℃,25 h),该工艺下所得陶瓷的微观组织结构较均匀,致密度和热导率均较高,分别为96.6%和237 W/(m×K);在纳米BeO粉体的二步烧结过程中,晶界扩散和体扩散等利于致密化的机制起主要作用。

关键词:二步烧结;纳米BeO;烧结机理;热导率

中图分类号:TF123 文献标志码:A 文章编号:1672-7207(2014)04-1043-09

Two-step sintering of BeO nanopowder

WANG Xiaofeng1, 2, WANG Richu2, PENG Chaoqun2, WANG Zhiyong2

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: In order to control the grain growth during the final stage of sintering, two-step sintering method was employed to consolidate BeO nanoparticles. Experiments were conducted to determine the appropriate temperatures for each step, and then the two-step sintering process of BeO was studied. The two-step sintering regimes were also analyzed. The results show that temperature ranges for the first step sintering (t1) and the second step sintering (t2) are 1 450-1 500 ℃ and 1 300-1 400 ℃, respectively, the optimized two-step sintering process is (1 450 ℃, 1 min)+(1 400 ℃, 25 h), BeO ceramic with well-proportioned microstructure and comfortable relative density (96.6%) is achieved and its thermal conductivity is 237 W/(m×K), and the sintering mechanism of nano-BeO is grain boundary diffusion and volume diffusion.

Key words: two-step sintering; nano-BeO; sintering mechanism; thermal conductivity

BeO陶瓷因其具有高热导率、优良的介电性能和良好的工艺适应性等电子封装特性,一直是制备高导热元部件的主流陶瓷材料[1-3]。但是BeO的熔点高达(2 570±20) ℃[1],采用普通微米级粉体制备BeO陶瓷的烧结温度很高,所以较难获得高致密的性能优异的材料[1, 3]。因此,为了降低烧结温度,Wang等[4]采用了纳米级BeO粉体来制备陶瓷材料。但是,纳米粉体在常规烧结过程中极易发生长大,形成较多的孔洞,所以获得的材料的相对密度也不高,热导率仅为186.6 W/(m·K)[5]。为了抑制纳米粉体在烧结过程中的快速生长,Chen等[5]提出了一种特殊烧结工艺,即二步烧结。所谓的二步烧结即先将采用纳米粉体制备的坯体升温到较高的温度(t1),然后快速降温至较低温度(t2)并长时间保温。在该工艺工程中,对晶粒生长贡献较大的晶界迁移被抑制但贡献较小的晶界扩散仍然能够进行,因此通过二步烧结能够获得纳米晶陶瓷。Chen等[5]将二步烧结用于纳米Y2O3粉体的烧结,并获得晶粒尺寸为60 nm左右的纳米晶陶瓷。目前,二步烧结已成为纳米粉体烧结的研究热点,被广泛用于Y2O3[6],Al2O3[7-8],ZrO2[9-10],ZnO[11-12],Si3N4[13],HAP[14]和BaTiO3[15]等粉体。为控制烧结过程中微观组织结构的变化,获得细晶致密的陶瓷,本文作者研究纳米BeO粉体的二步烧结。首先通过2个常规实验确定坯体相对密度和晶粒尺寸与烧结温度之间的关系,得出适合进行纳米BeO粉体坯体的二步烧结温度t1和t2的范围,然后在该范围内制定二步烧结工艺进行实验,并采用扫描电镜和激光导热仪分析样品的微观组织与导热性能,最后分析纳米BeO粉体的烧结机理。

1 实验材料与过程

实验原料为本实验室采用聚丙烯酰胺凝胶法制备的纳米级BeO粉体[4],平均粒度为22 nm。将纳米级BeO粉体采用聚乙烯醇(PVA)造粒后,在200 MPa下进行钢模冷压成型,压制压力为200 MPa,保压时间为30 s。坯体尺寸(直径×厚度)为10.5 mm×3 mm。

坯体的烧结直接在高温炉内进行。常规烧结时,升温速率为10 ℃/min。二步烧结时,升温速率为15 ℃/min,降温速率为50 ℃/min。为确定二步烧结工艺,先通过2个常规烧结实验研究坯体相对密度和微观组织结构随着烧结温度和时间的变化情况。第1个实验为将纳米级BeO粉体的坯体在1 300~1 450 ℃的温度条件下分别烧结0.5~4.0 h;第2个实验为将坯体在1 000~1 680 ℃的温度范围内分别保温1 min。根据常规烧结实验结果,制定的二步烧结工艺如表1所示。

采用法国飞利浦公司生产的场发射扫描电镜(FE-SEM, Sirion 2000)观察BeO烧结体的微观组织结构。通过软件测量扫描电镜照片中的晶粒尺寸,从而得到烧结体的平均晶粒尺寸。每次测量的晶粒数不少于50个。根据阿基米德原理,采用排水法测量坯体的密度,并计算其相对密度。BeO的理论密度为3.01 g/cm3[1]。利用激光脉冲法(闪光法,Flash Method)测量试样的室温热扩散率并计算得到试样的热导率,所用仪器为JR-3激光导热仪。

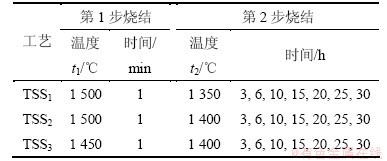

表1 BeO的二步烧结工艺

Table 1 Processes for two-step sintering of BeO

2 结果与讨论

2.1 二步烧结温度范围的确定

在二步烧结过程中,第1步烧结的主要目的是获得较高密度的坯体,而第2步则是保持坯体致密化进行的同时晶粒尺寸不发生长大。因此,这2步烧结过程均与烧结温度有很大关系。Chen等[5, 14]关于纳米Y2O3二步烧结的研究表明:当第1步烧结后坯体的相对密度高于75%之后,坯体内部的孔洞处于不稳定的状态,具有收缩的趋势。但是Li等[7]在研究纳米Al2O3的二步烧结时发现,如果相对密度低于82%,那么坯体在第2步烧结过程中无论烧结时间多长均不能获得致密体。Durán等[11]甚至认为纳米ZnO粉体的坯体经过第1步烧结后的相对密度应高于92%,并认为烧结温度t1应该足够高。考虑到纳米BeO晶粒生长迅速[16]的特点,在相对密度为92%的坯体中,闭合孔洞很可能已经形成,晶粒也已经长得较大。因此,将坯体相对密度高于75%作为选择t1的标准。

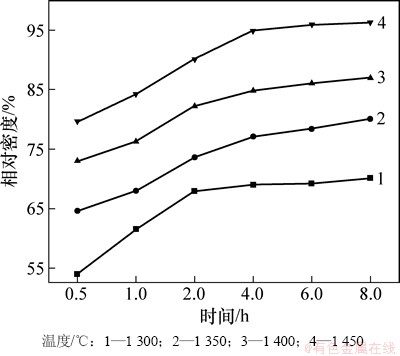

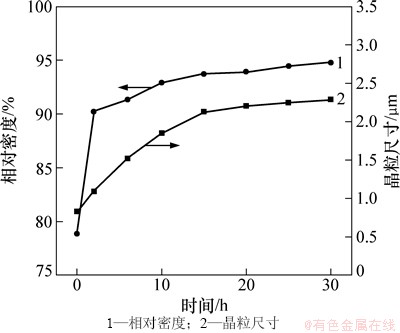

图1所示为在不同温度的烧结过程中BeO 坯体相对密度的变化情况。由图1可见:随着烧结时间的延长,相对密度逐渐增加,并且在烧结初期阶段致密化速度较快。坯体在1 450 ℃烧结0.5 h之后的相对密度为79.6%,略高于判断标准75%。因此,纳米BeO粉体二步烧结时第1步的温度t1应该高于1 450 ℃。

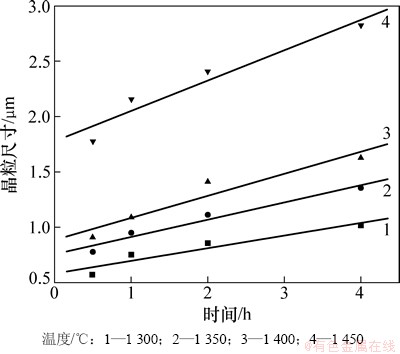

图2所示为在不同温度的烧结过程中BeO 坯体平均晶粒尺寸的变化情况。由图2可见:在相同条件下,随着烧结温度的升高,晶粒尺寸逐渐增加。当烧结温度为1 300 ℃时,晶粒尺寸始终小于1 μm,而当烧结温度为1 450 ℃时,坯体初始时刻的晶粒尺寸已经大于1 μm,为1.77 μm。由热力学理论可知,烧结本征驱动力DE(过剩表面能)与晶粒(颗粒)尺寸d之间存在如下关系[17]:

图1 在不同温度下烧结BeO 坯体的相对密度随时间的变化

Fig. 1 Relative density of specimens as a function of sintering time at various temperatures

(1)

(1)

式中:γsv为固-气表面能,J/m2;Wm为摩尔质量,g/mol;Sp为比表面积;ρth为理论密度。晶粒尺寸越细,比表面积越大,则烧结致密化驱动力也越大。因此,为了保证第2步的烧结致密化驱动力,晶粒尺寸应该较细,所以温度t1应该较低。

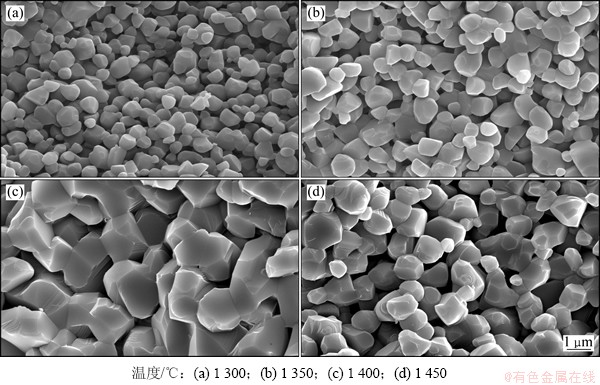

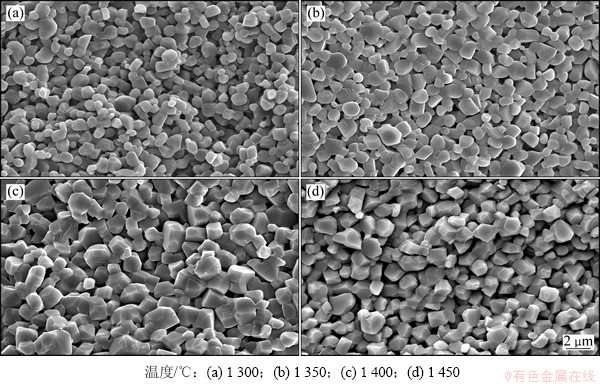

此外,烧结温度对晶粒形貌还有很大的影响。图3和图4所示分别为BeO 坯体在不同温度下烧结0.5和2 h后的扫描电镜照片。可见:随着烧结温度的升高,晶粒形貌由边缘圆滑的类球形逐渐转变为不规则的形状。这表明晶粒生长所需的能量上升,进而坯体致密化驱动力增加。也就是说,在二步烧结的低温烧结阶段延长烧结时间,如果坯体的晶粒形状越不规则,那么也不容易获得致密陶瓷。因此从晶粒形貌上来看,第1步烧结也应该在较低温度下进行。

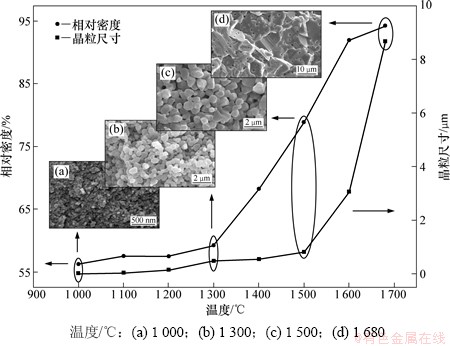

图5所示为纳米BeO 坯体在不同温度下烧结

1 min后的相对密度、晶粒尺寸和微观组织结构。可见:随着烧结温度的升高,坯体的晶粒尺寸逐渐增加,同时开放孔洞数量减少但闭合孔洞数量增加,从而相对密度也逐渐增加。当烧结温度为1 000 ℃时,坯体晶粒尺寸和相对密度分别为0.045 μm和56.3%。升高烧结温度200 ℃,坯体晶粒尺寸和相对密度分别增加至0.5 μm和59.3%。当烧结温度高于1 300 ℃之后,坯体晶粒尺寸增加速率小幅度提高,但是致密化速率急剧升高。当烧结温度增至1 500 ℃时,坯体晶粒为类球形且尺寸为0.835 μm,同时相对密度为78.9%,已高于75%。此后,继续升高烧结温度,晶粒尺寸增加速率也较大幅度地提高。所以,在坯体保持高速率致密化的同时,晶粒尺寸也以较高的速率增加。当烧结温度增至1 680 ℃时,坯体相对密度达到94.3%,晶粒尺寸增至8.67 μm,但是晶粒内部存在很多孔洞。因此,为了满足经过第1步烧结后坯体相对密度高于75%且晶粒较细的要求,t1应低于1 500 ℃。可见:对采用纳米BeO粉体制备的坯体进行二步烧结时,第1步的烧结温度t1范围为1 450 ℃≤t1≤1 500 ℃。

图2 在不同温度下烧结BeO 坯体的晶粒尺寸随时间的变化

Fig. 2 Grain size of specimens as a function of sintering time at various temperatures

图3 BeO 坯体在不同温度下烧结0.5 h的微观组织结构

Fig. 3 Microstructures of specimens sintered for 0.5 h at various temperatures

图4 BeO 坯体在不同温度下烧结2 h的微观组织结构

Fig. 4 Microstructures of specimens sintered for 2 h at various temperatures

图5 在不同温度下烧结1 min的样品的相对密度、晶粒尺寸和微观组织结构

Fig. 5 Relative densities, grain sizes and microstructure of specimens sintered at various temperatures for 1 min

由图2还可知:在所有烧结温度条件下,晶粒尺寸与时间呈线性关系。对其中的数据进行线性拟合可知[18]:1 300,1 350,1 400和1 450 ℃等温度的晶粒生长速率(斜率)分别为0.115,0.155,0.198和0.274 μm/h。而晶粒生长速率过快则容易将孔洞包裹,形成闭合的晶内孔,导致难以获得细晶高致密陶瓷,所以纳米BeO粉体二步烧结时第2步的温度t2应该较低。但是t2过低也不能获得致密陶瓷[12]。因此,综合考虑晶粒形貌与晶粒生长速率,确定t2的范围为不高于1 400 ℃。

此外,由图5还可知:当烧结温度较高时,在坯体保持高速率致密化的同时,晶粒尺寸也以较高的速率增加。特别是,当烧结温度高于1 300 ℃时,坯体晶粒尺寸增加速率小幅度提高,但是致密化速率急剧升高。因此,为了达到坯体晶粒生长速率较低且致密化速率较高的目的,t2应介于1 300~1 500 ℃之间。

2.2 纳米BeO粉体的二步烧结

根据上述研究结果制定如下的二步烧结工艺(记为TSS1):先将坯体以15 ℃/min的速率升至1 500 ℃(t1)并保温1 min(为确保炉内温度已到达该温度),然后以50 ℃/min的速率降至1 350 ℃(t2),随后在该温度下30 h。在低温烧结的30 h内,每间隔一定时间从炉内取出一组样品,并确低温烧结时间分别为3,6,10,15,20,25和30 h。

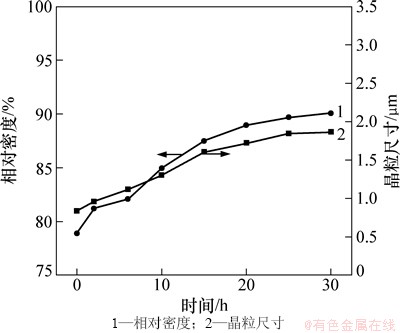

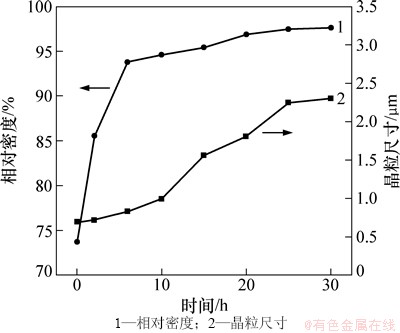

图6所示为按照二步烧结工艺TSS1进行时BeO坯体的平均相对密度和晶粒尺寸的变化情况。由图6可见:随着烧结的进行,晶粒尺寸逐渐增加并且在烧结后期(15 h之后)增至1.6 μm之后以非常缓慢是速率增加。同时,相对密度逐渐缓慢增加,但是其均较低,直到延长烧结时间至30 h时才刚达到90%。所以,在二步烧结工艺TSS1的进行过程中,虽然晶粒的生长被拟制,但是BeO坯体的相对密度始终较低。出现这种情况的原因可能是第2步烧结温度t2过低造成的。因此,在其他条件不变的情况下,调整二步烧结工艺将t2升高到1 400 ℃(记为TSS2)。

图7所示为按照调整后的二步烧结工艺TSS2进行时相对密度和晶粒尺寸的变化情况。由图7可见:在整个烧结过程中,相对密度和晶粒尺寸的变化趋势基本相同:在烧结前期(前10 h之内),两者均以较快的速率增加,而当烧结时间长于10 h之后,两者又极其缓慢地增加。特别是当烧结时间为25~30 h时,相对密度94.5%几乎保持不变,而晶粒尺寸则维持在2.25 μm左右。这是因为在烧结初始时刻晶粒尺寸相对较大,烧结驱动力相对较低(式(1)),从而不足以支持长时间的第2步烧结,所以在烧结后期相对密度和晶粒尺寸均非常缓慢增加甚至不变。因此,在二步烧结工艺TSS2的基础上,调整二步烧结工艺将t1降为1 450 ℃(记为TSS3)。

图6 采用二步烧结工艺TSS1烧结的样品的相对密度和晶粒尺寸

Fig. 6 Relative densities and grain sizes of specimens sintered by TSS1 process

图7 采用二步烧结工艺TSS2烧结的纳米BeO 坯体的相对密度和晶粒尺寸

Fig. 7 Relative densities and grain sizes of nano-BeO specimens sintered by TSS2 process

图8所示为TSS3过程中相对密度和晶粒尺寸的变化情况。由图8可见:在整个烧结过程中,相对密度逐步地从73.7%上升至96.6%。晶粒尺寸也逐步增加,但增加速率为先较慢,然后较快,最后又较慢。Wang等[6, 14]将烧结初期坯体发生致密化而晶粒尺寸变化不大的阶段称为“孕育期”(induction time)。因为第2步烧结的温度较低,温度的激活作用不够,所以晶粒不会急剧长大。在此前提下,在烧结初期,坯体的相对密度相对较低(孔隙率较高),大量的气孔对晶界移动存在钉扎作用,因此晶粒以很慢的速率长大;在烧结中期,坯体发生致密化,气孔数量减少,从而钉扎作用减弱,因此晶粒长大速率较快;在烧结末期,虽然相对密度较高,气孔钉扎作用很弱,但尺寸较大的晶粒难以继续生长[12]。当然,相对密度和晶粒尺寸的变化情况与烧结机制有关。

图8 采用二步烧结工艺TSS3烧结的样品的相对密度和晶粒尺寸

Fig. 8 Relative densities and grain sizes of specimens sintered by TSS3 process

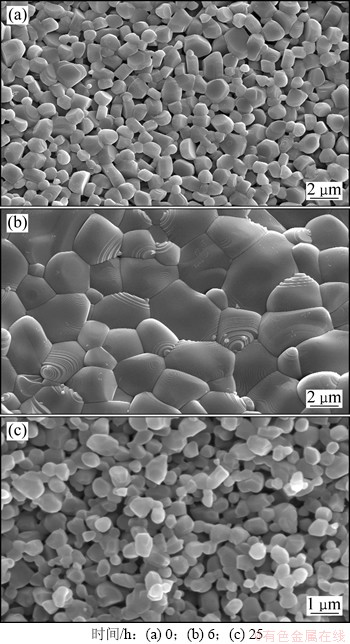

2.3 BeO陶瓷的微观组织与导热性能

图9所示为第2步烧结时间为0,6和25 h的扫描电镜照片。由图9可知:在TSS3的第2步烧结初始时刻(0 h),晶粒形貌为类球形;继续烧结6 h后,晶粒之间已互相接触,并且在晶界处存在许多气孔;当第2步烧结时间为25 h时,除晶界处存在少量气孔之外,坯体几乎完全烧结致密,且平均晶粒尺寸为2.25 μm。

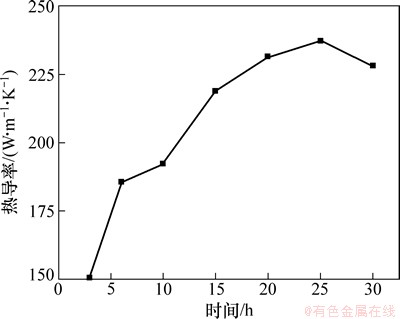

图10所示为采用二步烧结工艺TSS3烧结的样品的热导率。由图10可见:热导率随着第2步烧结时间的延长而逐渐增加。如前所述,BeO陶瓷的导热机理为声子传导,所以样品相对密度是影响热导率的主要因素。而相对密度随着二步烧结工艺TSS3的进行增加(图8),因此热导率存在相同的变化趋势。由图10还可知:实验所得BeO陶瓷的最高热导率为237 W/(m×K),该值远低于相同相对密度(96.6%)的BeO陶瓷的理论热导率300 W/(m×K)。其原因为气孔的存在使陶瓷的热导率下降。Enloe等[19]关于AlN陶瓷的研究表明当气孔率高于2%时其对热导率的影响很大。除气孔的作用之外,BeO陶瓷的晶界也起到很重要的作用。声子通过晶界时产生散射现象,因此,声子传输速率降低,热导率下降。Buhr等[20]的研究也表明晶界和气孔的存在会降低陶瓷的热导率。但是关于晶界对热导率的影响还存在分歧。Watari等[21-22]认为晶界数量(晶粒尺寸)对热导率的影响不大。

图9 按二步烧结工艺TSS3烧结样品不同时间的微观组织结构

Fig. 9 Microstructures of specimens sintered by TSS3 process for different times

图10 按二步烧结工艺TSS3烧结的样品的热导率

Fig. 10 Thermal conductivities of samples sintered by TSS3 process

2.4 纳米BeO粉体的烧结机理

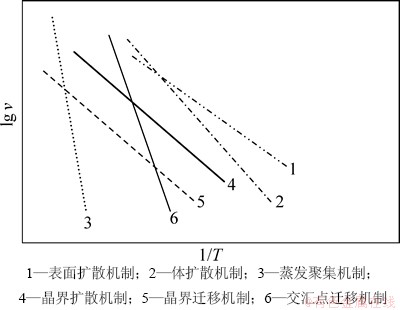

烧结理论[6, 12, 17]表明粉体在烧结过程中存在6种主要的烧结机制:(1) 表面扩散机制。物质由颗粒凸表面向凹表面进行迁移。(2) 体扩散机制。(3) 蒸发聚集机制。物质(原子)由颗粒表面蒸发通过孔洞中的气相迁移并凝聚在颈部凹表面。(4) 晶界扩散机制。物质通过晶界进行扩散迁移。(5) 晶界迁移机制。晶界直接进行迁移。(6) 交汇点迁移机制。烧结过程中出现的二面晶界与孔洞或者多个晶界的交汇点直接发生迁移。其中,交汇点迁移机制是一种类似于溶质原子拖拽的有效抑制晶粒生长的机制[23-25]。Czubayko等[24]在研究高纯锌时观察到这种机制,他们发现:当温度较低时晶界拖拽着二面角小于120°的三角晶界交汇点移动,而当温度较高时二面角大于120°的三角晶界交汇点对晶界移动的拖拽作用很低。

烧结过程中各种烧结机制都存在一定的作用,但是何种机制起主要作用与坯体的烧结时期和烧结条件等有关。在烧结初期(特别是当坯体相对密度较低时)表面扩散机制起主导作用,但是在烧结末期晶界扩散为主要烧结机制[26]。当烧结温度较高时,热激活作用较强,晶界迁移机制和交汇点迁移机制起作用[6]。如果烧结温度足以使物质产生高于外界的气压,那么蒸发聚集机制起作用[27]。Mazaheri等[12]的研究表明:当温度高于1 100 ℃之后纳米ZnO的烧结机制为蒸发聚集机制。实际上,何种烧结机制起主要作用是由其激活能决定的。图11所示为激活能不同的各机制的阿伦尼乌斯曲线,其中:v为晶界迁移速度;T为热力学温度。

对纳米BeO粉体进行常规烧结时,在烧结初期(坯体孔隙率较高晶界数量较少),表面扩散机制起主导作用[17],物质向烧结颈发生迁移,烧结颈长大且较小晶粒快速长大,但是该过程对致密化几乎没有贡献[27];随着烧结的进行,体积扩散机制和晶界扩散机制的作用逐渐突出,坯体发生致密化,气孔数量减少且形成部分闭合气孔(晶粒生长速率不同造成),同时晶界数量增加;在烧结末期,晶界迁移机制也产生作用,从而坯体致密化的同时晶粒长大,最后所获得的微观组织特征为晶粒尺寸较大且少量尺寸异常大、晶内存在大量闭合气孔(图5(d))[4]。Wang等[4]的前期研究也表明:当烧结温度较高时晶界迁移机制等加速晶粒长大的机制所起的作用更为突出,所以增加烧结温度也不能解决问题。因此,采用常规工艺烧结纳米BeO粉体很难获得致密陶瓷。

为获得细晶致密陶瓷,表面扩散、晶界迁移和交汇点迁移等易于晶粒生长的机制必须被抑制,同时晶界扩散和体扩散等利于致密化的机制还必须存在。图11表明:当烧结温度较低时,表面扩散机制和体扩散机制起主要作用。如前所述,当坯体相对密度较高(烧结末期)时表面扩散被晶界扩散所代替。因此,提高坯体初始相对密度可降低表面扩散的作用。这正是二步烧结中在第1步烧结后要求坯体相对密度高于75%的主要原因之一。Wang等[6]的研究也表明相对密度高于某一临界值之后烧结机制发生转变。图11还表明:若烧结温度过高,则晶界迁移和交汇点迁移等机制容易被激活。因此,二步烧结中的第2步烧结工艺在合适的温度(t2)下进行时,其主导机制为晶界扩散和体扩散等机制。

图11 各种机制的阿伦尼乌斯曲线示意图[6, 27]

Fig. 11 Schematic representation of Arrhenius plot for sintering mechanisms[6, 27]

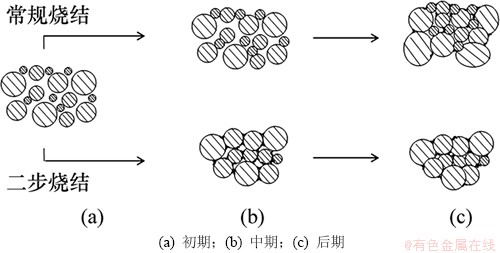

二步烧结的微观组织结构变化过程与常规烧结的不同。在二步烧结过程中,坯体经过预热处理(第1步烧结)后,除相对密度升高之外,较小的纳米晶已经长大(所有的晶粒尺寸相差不大,从而可以避免后期因长大速率不一致而造成陶瓷内晶粒尺寸分布不均匀)。颗粒接触点(气孔边缘)已经变得圆滑[28]。此外,具有拖拽晶界迁移的交汇点也已经形成,且较高温度(t1)下形成的交汇点的激活能较高,因此其在较低温度(t2)下对晶界的钉扎作用较强[23-26, 28]。在第2步烧结过程中,因为烧结温度(t2)较低,扩散速率较低(图11),同时晶界、气孔表明和交汇点等地方的缺陷需要较长的时间才能够达到平衡,所以第2步烧结的初期虽然相对密度增加但晶粒尺寸变化不大或增长十分缓慢,即存在“孕育期”(TSS3;图8)。随后相对密度继续增加,晶粒在交汇点的拖拽下逐渐长大,最后获得晶粒细小的致密陶瓷。图12所示为常规烧结与二步烧结的微观组织结构演变示意图。

图12 常规烧结与二步烧结的微观组织结构演变示意图

Fig. 12 Schematic diagram illustrating microstructure evolvement during conventional sintering and two-step sintering

3 结论

(1) 纳米BeO粉体二步烧结的温度范围为:第1步烧结温度t1:1 450 ℃≤t1≤1 500 ℃,第2步烧结温度t2:1 300 ℃≤t2≤1 400 ℃。

(2) 采用纳米级粉体制备BeO陶瓷较合适的二步烧结工艺为:(1 450 ℃,1 min)+(1 400 ℃,25 h),该工艺下所得陶瓷的微观组织结构较均匀,致密度和热导率均较高,分别为96.6%和237 W/(m×K)。

(3) 在纳米BeO粉体的二步烧结过程中,表面扩散、晶界迁移和交汇点迁移等易于晶粒生长的机制被抑制,晶界扩散和体扩散等利于致密化的机制起主要作用。

参考文献:

[1] 高陇桥. 氧化铍陶瓷[M]. 北京: 冶金工业出版社, 2006: 1-8.

GAO Longqiao. BeO ceramic[M]. Beijing: Metallurgical Industry Press, 2006: 1-8.

[2] Sommer M, Jan A, Henniger J. Beryllium oxide as optically stimulated luminescence dosimeter[J]. Radiation Measurements, 2008, 43(2/3/4/5/6): 353-356.

[3] 钟朝伟, 钟朝位, 张树人, 等. 高纯高导热BeO 陶瓷材料烧结工艺研究[J]. 压电与声光, 2007, 29(6): 726-728.

ZHONG Chaowei, ZHANG Shuren, LI Zhigang, et al. Studies on the sintering process of high pure BeO ceramics with high thermal conductivity[J]. Piezoel Ectectrics & Acoustooptics, 2007, 29(6): 726-728.

[4] Wang X Y, Wang R C, Peng C C, et al. Synthesis and sintering of BeO nanopowders[J]. Progress in Natural Science-Materials International, 2010, 20(1): 81-86.

[5] Chen I W, Wang X H. Sintering dense nanocrystalline ceramic without final-stage grain growth[J]. Nature, 2000, 404: 168-171.

[6] Wang X H, Chen P L, Chen I W. Two-step sintering of ceramics with constant grain-size, I: Y2O3[J]. Journal of the American Ceramic Society, 2006, 89(2): 431-437.

[7] Li J, Ye Y. Densification and grain growth of Al2O3 nanoceramics during pressureless sintering[J]. Journal of the American Ceramic Society, 2006, 89(1): 139-143.

[8]  P, Galusek D, et al. Two-stage sintering of alumina with submicrometer grain size[J]. Journal of the American Ceramic Society, 2007, 90(1): 330-332.

P, Galusek D, et al. Two-stage sintering of alumina with submicrometer grain size[J]. Journal of the American Ceramic Society, 2007, 90(1): 330-332.

[9] Binner J, Annapoorani K, Paul A, et al. Dense nanocrystructured zirconia by two stages conventional/hybrid microwave sintering[J]. Journal of the European Ceramic Society, 2007, 28(5): 973-976.

[10] Mazaheri M, Valefi M, Hesabi Z R, et al. Two-step sintering of nanocrystalline 8Y2O3 stabilized ZrO2 synthesized by glycine nitrate process[J]. Ceramics International, 2009, 35(1): 13-20.

[11]  P, Capel F, Tartaj J, et al. A strategic two-stage low temperature thermal processing leading to fully dense and fine-grained doped-ZnO varistors[J]. Advance Materials, 2002, 14(2): 137-141.

P, Capel F, Tartaj J, et al. A strategic two-stage low temperature thermal processing leading to fully dense and fine-grained doped-ZnO varistors[J]. Advance Materials, 2002, 14(2): 137-141.

[12] Mazaheri M, Zahedi A M, Sadrnezhaad S K. Two-step sintering of nanocrystalline ZnO compacts: Effect of temperature on densification and grain growth[J]. Journal of the American Ceramic Society, 2008, 91(1): 56-63.

[13] Kim H D, Han B D, Park D S, et al. Novel two-step sintering process to obtain a bimodal microstructure in silicon nitride[J]. Journal of the American Ceramic Society, 2002, 85(1): 245-252.

[14] Mohammadhossein E, Mohammadhossein F, Mahdi A. The effect of the two-step sintering process on consolidation of fluoridated hydroxyapatite and its mechanical properties and bioactivity[J]. International Journal of Applied Ceramic Technology, 2014, 11(1): 47-56.

[15] Huan Y, Wang X, Fang J, et al. Grain size effects on piezoelectric properties and domain structure of BaTiO3 ceramics prepared by two-step sintering[J]. Journal of the American Ceramic Society, 2013, 96(11): 3369-3371.

[16] Wang X, Wang R, Peng C, et al. Growth of BeO nanograins synthesized by polyacrylamide gel route[J]. Journal of Materials Science and Technology, 2011, 27(2): 147-152.

[17] 果世驹. 粉末烧结理论[M]. 北京: 冶金工业出版社, 2002: 15.

GUO Shiju. Powder sintering principles[M]. Beijing: Metallurgical Industry Press, 2002: 15.

[18] Wang C J, Huang C Y, Wu Y C. Two-step sintering of fine alumina-zirconia ceramics[J]. Ceramic International, 2009, 35(4): 146-1472.

[19] Enloe J H, Rice R W, Lau J W, et al. Microstructural effects on the thermal conductivity of polycrystalline aluminum nitride[J]. Journal of the American Ceramic Society, 1991, 74(9): 2214-2219.

[20] Buhr H, Müller G. Microstructure and thermal conductivity of AlN(Y2O3) ceramics sintered in different atmospheres[J]. Journal of the European Ceramic Society, 1993, 12(4): 271-277.

[21] Watari K, Ishizaki K, Fujikawa T. Thermal conduction mechanism of aluminium nitride ceramics[J]. Journal of Materials Science, 1992, 27(10): 2627-2630.

[22] Virkar A V, Jackson T B, Cutler R A. Thermodynamic and kinetic effects of oxygen removal on the thermal conductivity of aluminum nitride[J]. Journal of the American Ceramic Society, 1989, 72(11): 2031-2042.

[23] Chen P L, Chen I W. Grain growth in CeO2: Dopant effects, defect mechanisms, and solute drag[J]. Journal of the American Ceramic Society, 1996, 79(7): 1793-1800.

[24] Czubayko L, Sursaeva V G, Gottstein G, et al. Influence of triple junctions on grain boundary motion[J]. Acta Materialia, 1998, 46(16): 5863-5871.

[25] Gottstein G, Shvindlerman L S. Triple junction dragging and von Neumann–Mullins relation[J]. Scripta Materialia, 1998, 38(10): 1541-1547.

[26] Kingery W D, Berg M. Study of initial stages of sintering solid by viscous flow, evaporation-condensation and self-diffusion[J]. Journal of Apply Physicals, 1955, 26 (10): 1205-1212.

[27] Rahaman M N. Ceramic processing and sintering[M]. New York: Marcel Dekker, 1995: 540-619.

[28] Lin F J T, Jonghe L C D, Rahaman M N. Microstructure refinement of sintered alumina by a two-step sintering technique[J]. Journal of the American Ceramic Society, 1997, 80(9): 2269-2277.

(编辑 杨幼平)

收稿日期:2013-05-25;修回日期:2013-09-10

基金项目:国家青年自然科学基金资助项目(51202296);中南大学博士后基金资助项目(2012年)

通信作者:王日初(1965-),男,广东河源人,博士,教授,从事水激活电池阳极材料和电子封装陶瓷等研究;电话:0731-88836638;E-mail:wrc@csu.edu.cn