矿热炉塌料过程中烟尘扩散的数值模拟

李立清,黄贵杰,祝培旺,胡蔷,何锁盈,刘峥

(中南大学 能源科学与工程学院,湖南 长沙,410083)

摘要:以铁合金生产车间为研究对象,利用Fluent软件对车间内矿热炉生产过程中塌料事故的烟尘扩散规律进行非稳态的数值模拟。对连续相和离散相,分别采用标准k~ε模型和DPM模型,分析不同风速和风向的烟尘扩散规律。研究结果表明:当风速在2 m/s以下时,南风能更有效地排除烟尘,并且风速越大,清洁作用越明显;当塌料事故结束时,不论何种风速或风向,车间内烟尘污染面积达到最大;在300 s且无风时最大烟尘质量浓度是风速为4 m/s时的36.6倍;车间内的死角是烟尘最难排出的地方,北风风速为0.2 m/s的最大停留时间长达4 800 s。

关键词:矿热炉;塌料;Fluent软件;烟尘扩散;非稳态

中图分类号:X511;X513 文献标志码:A 文章编号:1672-7207(2012)01-0356-10

Numerical simulation of dust dispersion in process of slag surge of ferroalloy furnace

LI Li-qing, HUANG Gui-jie, ZHU Pei-wang, HU Qiang, HE Suo-ying, LIU Zheng

(School of Energy Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Taking ferroalloy plant as example, the fluent software was used to simulate the unsteady flow of particle dispersion in the workshop when slag surge occurs in the electric furnace. Standard k-ε equation was adopted for continuous phase and particle stochastic trajectory model for discrete phase. At different wind speeds and in different directions, the flow field distribution of gas phase and trajectory of particle phase were obtained through computation. The results show that with low wind speed (less than 2 m/s), the south wind is more effective to remove the dust, and the greater the wind speed, the better the cleaning effect. Besides, regardless of wind speed or wind direction, when the slag surge is over, the dust pollution area is the biggest in the workshop. The maximum concentration of dust without wind is 36.6 times than that of wind speed of 4 m/s at 300 s. Corners of the workshop are the most difficult places for dust to clear up. The maximum residence time at north wind of 0.2 m/s is 4 800 s.

Key words: ferroalloy furnace; slag surge; Fluent software; dispersion of dust; unsteady

铁合金矿热炉在冶炼过程中,由于金属熔融物料矿热炉因搭桥作用而发生悬料。若悬料质量过大,物料会塌陷。塌陷的物料压缩矿热炉内气体,使气压高于环境压力,从而导致烟尘和可燃气体外泄,并可能导致炉内局部区域的可燃气体与空气混合比例处于爆炸范围,可燃气体迅速燃烧,即可能发生爆炸事故。矿热炉运行过程中发生塌料、爆炸事故严重影响正常生产作业[1]。事故不仅可能造成设备损坏,延长热停炉时间,而且由于塌料时矿热炉内瞬时变为正压,有大量含尘有毒烟气从缝隙处喷出,甚至出现过炽热熔体喷出炉外,还会危及到职工的人身安全[2-3]。因而了解塌料事故情况下的烟尘扩散规律,对于安全生产有重要的指导意义。随着计算机技术的不断发展,计算流体力学(Computational fluid dynamic,CFD)已成为研究三维流动的重要手段[4]。与试验研究相比,数值模拟时间较少,精度较高[5],因此,Fluent软件被广泛地用于评价室内空气质量。Cheong等[6]利用RNG k~ε模型模拟了办公室内的污染物扩散问题;Khan等[7]利用两相流模型研究了室内通风口的位置对室内污染物扩散的影响;荆俊山[8]对生产车间内纳米二氧化钛粉尘的扩散进行了模拟和分析。然而,目前的研究很少考虑室内污染物非稳态输入情况下的扩散问题。在此,本文作者应用Fluent软件对铁合金矿热炉塌料事故状态下的非稳态烟尘扩散问题进行研究,以便分析塌料时烟尘排放的非稳态扩散规律,为厂房内除尘提供依据。

1 物理模型

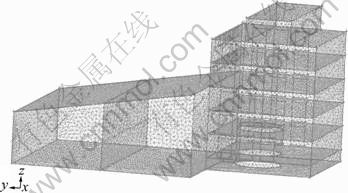

生产车间及网格划分如图1所示。车间右侧矿热炉间尺寸(x方向长度×y方向长度)为36 m×28 m,第1层高3 m,其余每层均高6 m;左边铸造间尺寸(x方向长度×y方向长度)为54 m×48 m,最高处21 m,最低处14 m,且南北向无外墙(x轴正方向为南向);右边矿热炉间五六层西侧有8个3.6 m×2.4 m的窗户,第2~6层南北向共有30个3.6 m×4.8 m的窗户;矿热炉间内(x=36 m,y=18 m)处有1个半径为6 m、高9 m的圆柱形矿热炉。

由于非结构化网格生成相对简单,可疏密控制,具有较好的可调性和可控制性[9],研究采用非结构化的网格划分方法,并对局部区域进行加密,尤其是进风口、出风口区域以及矿热炉表面。经gambit软件处理后,将物理模型划分成306 719个体元,所有网格的扭曲度均小于0.8,其中90%的网格扭曲度小于0.6。

图1 物理模型及网格划分

Fig.1 Structure of physical model and mesh

2 数学模型

在生产车间的两相流场中,颗粒物的体积分数小于10%,故将气相作为连续相考虑,颗粒相作为离散相考虑[5]。气相采用欧拉法描述,湍流模型为标准k~ε模型,在近壁处采用标准壁面函数法。而对于颗粒相,选用拉格朗日法离散相模型(DPM)。颗粒相湍流扩散采用随机轨道模型,并考虑两相之间的耦合[10]。

2.1 连续相的数学模型

流体流动要受物理守恒定律的支配,基本的守恒定律包括质量守恒、动量守恒和能量守恒。因车间高大空旷,假定温度均匀,暂不考虑能量方程。由于气相处于湍流状标准,要使方程封闭,还需给出雷诺应力项。研究选用k~ε模型[11]。

质量守恒方程为:

(1)

(1)

动量守恒方程为:

(2)

(2)

应力张量 由下式表示:

由下式表示:

(3)

(3)

式中: 为密度,kg/m3;t为时间,s;u,v和w为速度矢量在x,y和z方向的分量,m/s;p为静压,Pa;μ为动力黏性系数,Pa·s;Fi包含了其他的模型相关源项,如多孔介质和自定义源项。

为密度,kg/m3;t为时间,s;u,v和w为速度矢量在x,y和z方向的分量,m/s;p为静压,Pa;μ为动力黏性系数,Pa·s;Fi包含了其他的模型相关源项,如多孔介质和自定义源项。

k~ε模型用于提供时均流动变量的雷诺平均的Navier-Stokes(RANS)模型。

湍流动能k方程为:

(4)

(4)

耗散率ε方程为:

(5)

(5)

其中:

(6)

(6)

(7)

(7)

式中:k为湍流动能,m2/s2; 为湍流动能耗散率,m2/s3;

为湍流动能耗散率,m2/s3; 和

和 分别为层流和湍流动力黏性系数,Pa·s;

分别为层流和湍流动力黏性系数,Pa·s; 为湍能体积生成率,kg/(s3·m)。

为湍能体积生成率,kg/(s3·m)。

C1ε,C2ε,σk,σε和Cμ为模型中常数,其取值分别为1.44,1.92,1.00,1.30和0.09。

2.2 离散相的数学模型

颗粒作为离散相被注入,而在拉格朗日体系下,通过指定独立颗粒的初始位置、速度,就可以模拟这一离散相[12]。计算时选定随机游走模型,考虑两相之间的耦合。房间中的颗粒物可能会受到如下几种作用力:曳力、重力以及虚质量力、热泳力、布朗力、霍夫曼升力、流体压差引起的作用力等其他作用力。但对于空气中密度较大的细颗粒,只有曳力的作用非常大[13],这里仅考虑曳力和重力。

用DPM方法描述粒径小的颗粒物在车间内的运动,不考虑颗粒的碰撞。假定所有颗粒为球形,颗粒的运动方程为:

(8)

(8)

式中:upi为颗粒在i方向的速度,m/s;uj为流体速度,m/s;μ为流体分子的动力黏性系数,Pa·s;dp为颗粒直径,m;ρp为颗粒密度,kg/m3,研究取ρp= 2 360 kg/m3;gi为i方向上的重力加速度,m/s2。Cc为Stokes曳力公式的Cunningham修正系数,其计算公式为:

(9)

(9)

式中: 为气体分子平均自由程,由本文所给条件求得Cc=1.19。

为气体分子平均自由程,由本文所给条件求得Cc=1.19。

3 数值计算和讨论

3.1 边界条件和初始条件

边界条件设置:(1) 入口为速度入口,出口为压力出口;(2) 给定无滑移壁面边界条件,近壁处采用壁面函数修正;(3) 假定颗粒物接触时发生完全弹性碰撞,遇到楼板则被捕捉和到达出口边界或者进口边界为逃逸,终止轨道计算。

矿热炉塌料时炉内压力变成正压,矿热炉外表面观察孔、泄爆门以及第3~6层内的烟囱连接处存在缝隙,存在污染物泄漏,为污染排放源。塌料污染物泄漏时间为厂方多次测量值的平均值。计算中所用颗粒物参数如下:烟尘总泄漏强度[14]为1.33×10-5 kg/s,泄漏时间为300 s,烟尘初始速度[15]为3 m/s。

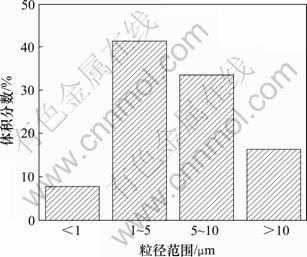

使用JL-1155型激光粒度分布测试仪对生产现场的矿热炉烟尘进行分析,得出烟尘颗粒物粒径分布如图2所示。粒径范围在1~5 μm的颗粒体积分数占41.2%,而且粒径在 3.5 μm以下的颗粒物能被吸入人的支气管和肺泡中并沉积下来,引起或加重呼吸系统的疾病。采用1~5 μm 的中间粒径dp=3 μm的颗粒作为研究对象。

图2 烟尘颗粒物粒径分布

Fig.2 Particle size distribution of dust

湍流模型采用k~ε方程、一阶精度、非稳态计算;对于涉及时间相离散的非稳态流动,通常采用压力隐式分裂算法(Pressure implicit split operation,PISO)[16];对控制方程进行基于微元中心有限体积元离散,迭代求解,其收敛条件为小于10-3。

3.2 无风情景

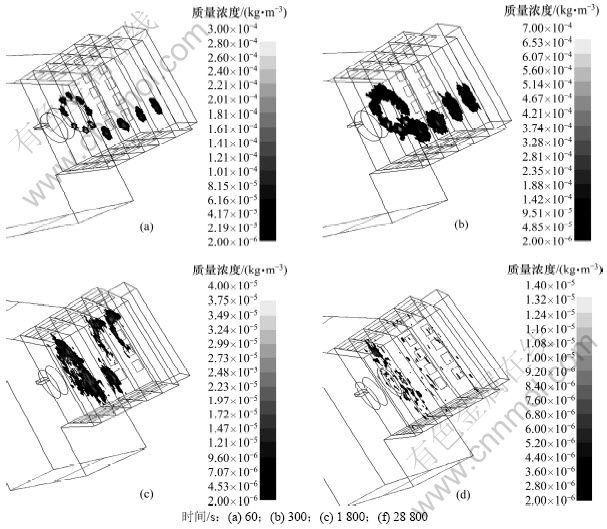

图3所示是在无风条件下,距每层楼板高1.5 m(人体呼吸高度)截面(即z=10.5,16.5,22.5,28.5 m)上的烟尘质量浓度分布图。从图3可知:在塌料事故过程中烟尘持续从矿热炉外表面观察孔、泄爆门以及烟囱连接缝隙处泄漏,车间内烟尘污染面积不断增大;300 s后,塌料事故结束,由于烟尘的扩散,烟尘污染面积随着时间的增加先达到最大值,然后逐渐减小,在28 800 s(8 h)后,仍有烟尘存在于车间内。

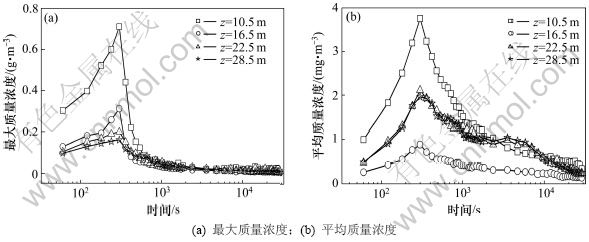

图4所示是无风时车间内选取截面上的最大质量浓度和平均质量浓度随时间的变化。由图4可知:在矿热炉间z=16.5 m截面处,由于矿热炉泄漏源较多,强度大,故在大部分时间里,其最大质量浓度和平均质量浓度都比其他截面的大;从塌料开始到结束,烟尘不断排放,车间内烟尘质量浓度不断增大;在300 s时最大质量浓度和平均质量浓度均达到最大值,此时,z为10.5,16.5,22.5和28.5 m时的截面最大质量浓度分别为最高容许质量浓度的353,157,100和80倍[17];300 s后,各截面烟尘最大质量浓度和平均质量浓度逐渐减小,烟尘颗粒逐步向车间各处扩散,从通风口扩散出去。直到28 800 s(8 h),烟尘仍未全部扩散出去,矿热炉间内的最大烟尘质量浓度为14.3 mg/m3,仍为最高容许质量浓度的7.15倍[17]。在无风工况下,烟尘很难从车间排放出去,将严重影响工人的身体健康,设计有效的通风手段显得非常重要。

图3 无风条件下不同时间车间内烟尘质量浓度分布

Fig.3 Mass concentration distributions of dust in workshop at different moments under no wind

图4 无风条件下选定截面上最大质量浓度和平均质量浓度随时间变化曲线

Fig.4 Relationships among maximal, average mass concentration and time at selected cross sections under no wind

3.3 有风情景

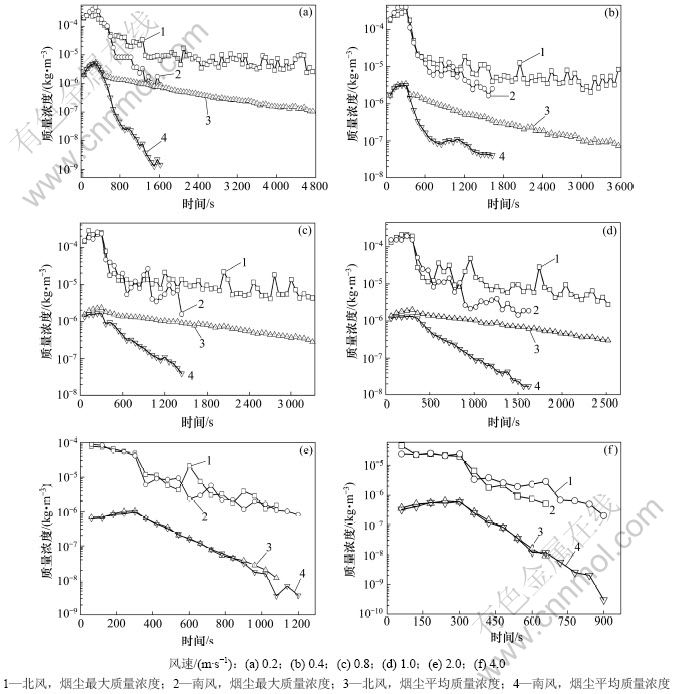

在高大厂房内自然通风是一种经济、有效的节能措施,不消耗动力,又能获得满意换气排尘的效果。模拟讨论不同风速、风向条件对烟尘扩散的影响。设定风速为0.2,0.4,0.8,1.0,2.0和4.0 m/s 6种,风向选南北两向,共12种工况,结果见图5。

由图5可知:无论风向和风速如何,选定截面上烟尘平均质量浓度随时间变化都呈现出同样的规律性;当风速小于1 m/s时,南风的烟尘平均质量浓度比北风的小;而当风速大于1 m/s时,两者随时间的变化曲线几乎相同。分时间段考虑,在300 s前,塌料事故造成烟尘的持续排放,烟尘的平均质量浓度随时间增加而增大;在300 s时,烟尘平均质量浓度达到最大值;而在300 s之后,由于塌料事故结束和风力的清洁作用,车间内烟尘的平均质量浓度随着时间的增大而减小,并且风速越大,平均质量浓度降低得越快。通风形成湍流,烟尘跟随气流一起湍动,使得所选截面上烟尘最大质量浓度变得无规律,但可知在300 s时烟尘最大质量浓度达到最大值,当风速为0.2,0.4,0.8,1.0,2.0和4.0 m/s时,烟尘最大质量浓度分别是最高容许质量浓度的121,149,122,96,25和10倍[17](对于北风)以及237,198,115,77,21和12倍[17](对于南风)。此时烟尘最大质量浓度、平均质量浓度均和污染区域与无风时的相比均明显降低。

图5 不同风速时烟尘最大质量浓度和平均质量浓度随时间变化曲线

Fig.5 Relationships between dust mass concentration in workshop and time at different wind speeds

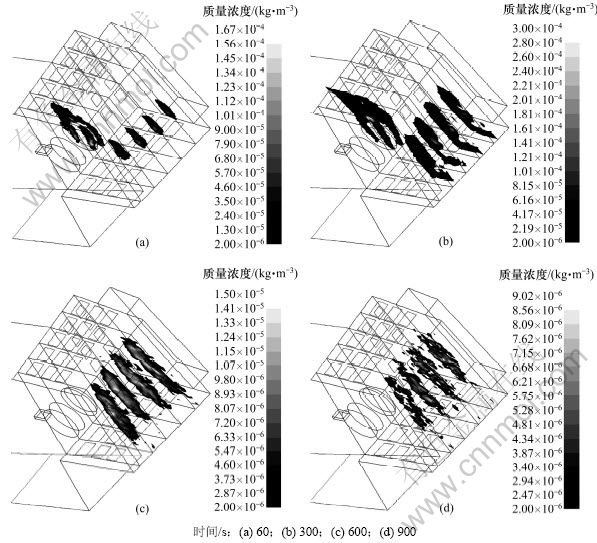

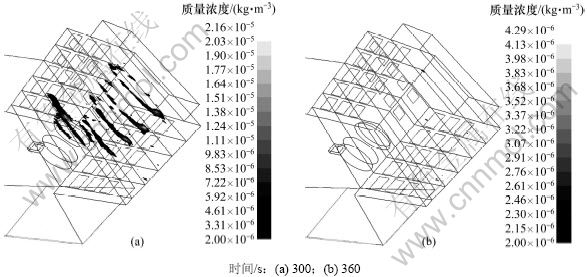

图6~9所示分别是风速为0.4 m/s(低风速)和4 m/s(高风速)时,南北风向车间内烟尘质量浓度分布图。从图6和图8可知:低风速时,从塌料事故开始到结束,车间内烟尘污染面积不断增大,且在300 s达到最大值,之后烟尘污染面积逐渐减小。从图7和图9可知:高风速的排污效果相当明显,当塌料事故结束后的60 s(即360 s时),除了部分区域形成涡旋,出现死角之外,风已将烟尘颗粒物几乎全部排出车间。

比较图6~9可知:低风速比高风速的排污能力较弱,颗粒染污物影响的范围较广,排污时间较长;南风烟尘污染面积比北风的小,排污效果较北风的效果明显;另外,烟囱缝隙泄漏的烟尘与矿热炉观察孔、泄爆门泄漏的烟尘相比,虽然在前者的烟尘泄露量比较少,但需要更长时间把烟尘从车间排放出去。因为厂房的设计使得在矿热炉的位置形成穿堂风,污染物很快从车间排出;而在烟囱缝隙附近形成了漩涡,产生死角,导致烟尘在车间内长时间停留,烟尘难以从车间排出。

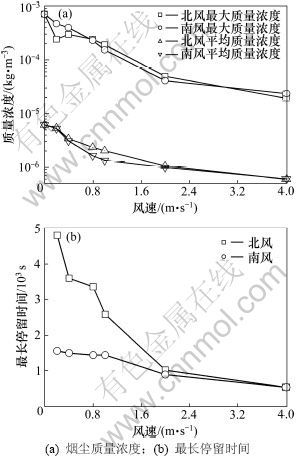

3.4 风速对烟尘质量浓度和停留时间的影响

风速和风向对烟尘扩散的影响见图10。从图10可知:烟尘最大质量浓度随风速的变化呈现一定的波动性,但总的趋势是随着风速的增大逐渐减小;烟尘平均质量浓度随着风速的增大而逐渐变小。烟尘在车间内的最长停留时间随着风速的增大而减小。这是因为通风使得靠近西外墙的地方形成涡旋,产生死角,低风速时导致烟尘在此堆积,长时间无法排除。当风速小于2 m/s时,南风的烟尘平均质量浓度和最长停留时间比北风的小。这说明风速在2 m/s以下时,南风的清洁作用比北风的清洁作用明显;而当风速在2 m/s以上时,风速对烟尘最大质量浓度、平均质量浓度和最长停留时间的影响已不明显;南北风烟尘平均质量浓度和最长停留时间几乎一样,说明此时2种风向具有几乎一样的清洁效果。总之,南风比北风的清洁效果明显,这是由厂房的结构决定的,因为烟囱位于车间的西北角,一旦北风吹来,这里便形成涡旋,使得刚泄露的烟尘在涡旋内流动,因此,烟尘更难扩散出去。

图6 南风风速为0.4 m/s时烟尘质量浓度分布

Fig.6 Mass concentration distributions of dust at south wind speed of 0.4 m/s

图7 南风风速为4 m/s时烟尘的质量浓度分布

Fig.7 Mass concentration distributions of dust at south wind speed of 4 m/s

图8 北风风速为0.4 m/s时烟尘的质量浓度分布

Fig.8 Mass concentration distributions of dust at north wind speed of 0.4 m/s

图9 北风风速为4 m/s时烟尘的质量浓度分布

Fig.9 Mass concentration distributions of dust at north wind speed of 4 m/s

3.5 风速对排出颗粒和沉降颗粒的影响

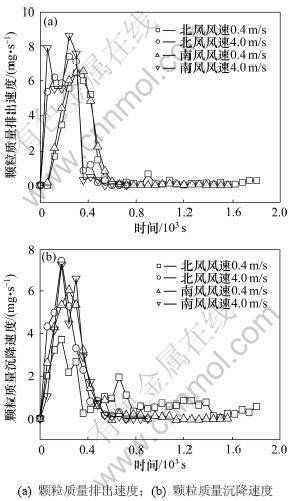

图11所示为风速与风向和颗粒质量排出、沉降速度之间的关系。从图11(a)可以看出:随着风速增大,颗粒质量排出速度的峰值向前推移,高风速峰值出现在240 s左右,而低风速出现在360 s左右;风速越小排出颗粒所需要的时间越长,高风速基本上在900 s之后已无颗粒物排出,而低风速在1 800 s之后,还有颗粒物排出。从图11(b)可以看出:颗粒质量沉降速度在180 s左右达到峰值,风速小时,由于颗粒物在室内停留时间短,在900 s之后还有颗粒物沉降。比较图11(a)和图11(b)可以看出:颗粒物质量排出速度与颗粒物质量沉降速度相当。

4 模型验证

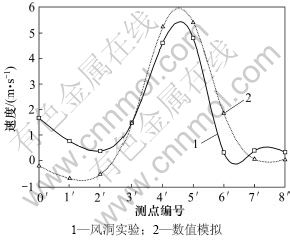

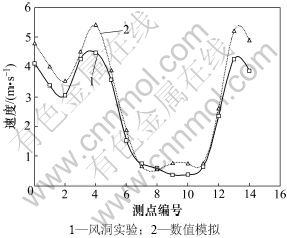

由于室外风速不稳定性,并且厂房高大空旷,进行室内流场测量存在一定的困难,但可以通过风洞实验进行流场测试。通过相似原理把实物缩小成一定比例的模型,将该模型在风洞中进行实验,测出相关参数。将本文物理模型的数值模拟值与王怡等[18]的实验测量值比较,风洞实验值和数值模拟的结果如图12~13所示。从图12~13可以看出:单区间模型的风洞实验值与数值模拟值较吻合。

图10 不同风速和风向对烟尘质量浓度和最长停留时间的影响

Fig.10 Influence of different wind speeds and wind directions on dust concentration and maximal residence time

图11 不同风速和风向对排出和沉降颗粒质量的影响

Fig.11 Influence of different wind speeds and wind directions on eduction and sedimentation of partial mass

图12 x=1.8 cm时单区间模型各测点处速度

Fig.12 Velocity of test points of single zone at x=1.8 cm

图13 y=0 cm时单区间模型各测点处速度

Fig.13 Velocity of test points of single zone at y=0 cm

5 结论

(1) 无风时,300 s时车间内的烟尘平均质量浓度均达到最大值,在z=10.5 m处截面的最大质量浓度比最高容许质量浓度大353倍,28 800 s时仍比最高容许质量浓度大7.15倍。

(2) 通风形成的涡旋使得塌料时由烟囱缝隙泄漏烟尘在车间的角落附近大量堆积,并且当风速越小时,烟尘的堆积量越多,最长停留时间越长。

(3) 有风时,300 s时车间内的烟尘平均质量浓度均达到最大值,以当地年平均风速2 m/s为例,北风和南风的最大质量浓度是最高容许质量浓度的25倍和21倍。

(4) 不同的风向对烟尘在车间内的扩散也有一定影响。当风速在2 m/s以下时,南风能更有效地排除烟尘;当风速在2 m/s以上时,2种风向具有近乎一样的清洁效果。排出颗粒物质量和沉降颗粒物质量相当。

参考文献:

[1] Austin P R, Nogami H, Yagi J. Analysis of actual blast furnace operations and evaluation of static liquid holdup effects by the four fluid mode[J]. ISIJ International, 1998, 38(3): 246-255.

[2] Hobbesland A, Kjuus H, Thelle D S. A study of mortality among 14 730 male workers in 12 Norwegian ferroalloy plants: Cohort characteristics and the main causes of death[J]. Occup-Environ-Med, 1996, 53(8): 540-546.

[3] Kjuus H, Andersen A, Langard S, et al. Cancer incidence among workers in the Norwegian ferroalloy industry[J]. British J Ind Med, 1986, 43(4): 227-236.

[4] Bernardo S, Mori M, Peres A P, et al. 3-D computational fluid dynamics for gas and gas-particle flows in a cyclone with different inlet section angles[J]. Powder Technology, 2006, 162(3): 190-200.

[5] 王福军. 计算流体动力学分析[M]. 北京: 清华大学出版社, 2004: 1-6.

WANG Fu-jun. Analysis of computational fluid dynamic[M]. Beijing: Tsinghua University Press, 2004: 1-6.

[6] Cheong K, Djunaedy E, Poh T, et al. Measurements and computations of contaminant’s distribution in an office environment[J]. Building and Environment, 2003, 38(1): 135-145.

[7] Khan J, Feigley C, Lee E, et al. Effects of inlet and exhaust locations and emitted gas density on indoor air contaminant concentrations[J]. Building and Environment, 2006, 41(7): 851-863.

[8] 荆俊山. 生产车间内纳米二氧化钛粉尘扩散的数值模拟研究[D]. 青岛: 中国海洋大学气象学专业, 2009: 22-49.

JING Jun-shan. Numerical simulation of titanium dioxide dispersion in the production workshop[D]. Qingdao: Ocean University of China. Department of Marine Meteorology, 2009: 22-49.

[9] 韩占忠, 王敬, 兰小平. FLUENT流体工程仿真计算实例与应用[M]. 北京: 北京理工大学出版社, 2005: 18-122.

HAN Zhan-zhong, WANG Jing, LAN Xiao-ping. Calculation samples and applications of fluid engineering simulated by Fluent[M]. Beijing: Beijing Institute of Technology Press, 2005: 18-122.

[10] Van Wachem B G M, Almsted A E. Methods for multiphase computational fluid dynamics[J]. Chemical Engineering Journal, 2003, 96(1/3): 81-89.

[11] 熊莉芳, 林源, 李世武. k-ε湍流模型及其在FLUENT软件中的应用[J]. 工业加热, 2007, 36(4): 13-15.

XIONG Li-fang, LIN Yuan, LI Shi-wu. k-ε turbulence model and its application in Fluent software[J]. Industrial Heating, 2007, 36(4): 13-15.

[12] Baxter L L, Smith P J. Turbulent dispersion of particles: the STP model[J]. Energy Fuels, 1993, 7(6): 852-859.

[13] LIU Jun-jie, WANG Meng, XU Bin, et al. An experimental method to determine enzyme particle emission rate in workplace[J]. Building and Environment, 2009, 44(12): 2327-2334.

[14] 王文勇. 铁合金电炉烟尘治理技术分析[J]. 四川环境, 2003, 22(4): 56-59.

WANG Wen-yong. Technology analysis of collection fine particulates emitted from ferro-alloy furnace[J]. Sichuan Environment, 2003, 22(4): 56-59.

[15] 储少军, 曾世林, 黄祖诚, 等. 矿热炉塌料、爆炸事故的成因浅析[J]. 铁合金, 2009(2): 13-17.

CHU Shao-jun, ZENG Shi-lin, HUANG Zu-cheng, et al. Cause of the accident on the slag surge and the interior explosion of the ferroalloy furnace[J]. Ferro-alloys, 2009(2): 13-17.

[16] 任玉新, 陈海昕. 计算流体力学基础[M]. 北京: 清华大学出版社, 2006: 184-199.

REN Yu-xin, CHEN Hai-xin. Basic of computational fluid dynamic[M]. Beijing: Tsinghua University Press, 2006: 184-199.

[17] TJ 36—79, 工业企业设计卫生标准[S].

TJ 36—79, Industrial enterprise design sanitary standard[S].

[18] 王怡, 文福, 刘加平. 大开口自然通风实验研究及数值模拟分析[J]. 太阳能学报, 2010, 31(4): 432-436.

WANG Yi, WEN Fu, LIU Jia-ping. Research on natural ventilation through large opening and numerical simulation analysis[J]. Acta Energiae Solaris Sinica, 2010, 31(4): 432-436.

(编辑 陈灿华)

收稿日期:2011-01-25;修回日期:2011-03-01

基金项目:国家自然科学基金资助项目(20976200);湖南省节能减排重大专项(08SK1003,2009FJ1009)

通信作者:李立清(1966-),男,湖南郴州人,教授,博士生导师,从事空气品质与空气污染控制研究;电话:13807483619;E-mail: liqingli@hotmail.com