FGH4169合金的高温变形行为

王博1, 2,易丹青1, 2,丁学锋1, 2,姚草根3,王斌1, 2,傅上1, 2

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 教育部有色金属材料科学与工程重点实验室,湖南 长沙,410083;

3. 航天材料及工艺研究所,北京,100076)

摘要:利用MMS-200热模拟实验机对FGH4169合金进行高温压缩实验,建立该合金高温变形本构方程。研究结果表明:在变形温度为950~1 050 ℃,应变速率 为0.004~10 s-1的条件下,动态再结晶是该合金的重要软化机制;FGH4169合金在950~1 050 ℃范围内的激活能为430 kJ/mol,该合金的功率耗散效率约比Inconel718合金的功率耗散效率高10%,峰值效率达到57%。并得到FGH4169合金在本实验条件下的加工图;其适合加工工艺如下:变形温度为1 010~1 050 ℃,应变速率为0.01~0.1 s-1,或者变形温度为980 ℃,应变速率为0.004~0.01 s-1。

为0.004~10 s-1的条件下,动态再结晶是该合金的重要软化机制;FGH4169合金在950~1 050 ℃范围内的激活能为430 kJ/mol,该合金的功率耗散效率约比Inconel718合金的功率耗散效率高10%,峰值效率达到57%。并得到FGH4169合金在本实验条件下的加工图;其适合加工工艺如下:变形温度为1 010~1 050 ℃,应变速率为0.01~0.1 s-1,或者变形温度为980 ℃,应变速率为0.004~0.01 s-1。

关键词:FGH4169合金;热压缩;动态再结晶;本构方程

中图分类号:TG111.7 文献标志码:A 文章编号:1672-7207(2013)11-4408-07

Hot deformation behavior of FGH4169 superalloy

WANG Bo1, YI Danqing1, 2, DING Xuefeng1, 2, YAO Caogen3, WANG Bin1, 2, FU Shang1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education, Central South University, Changsha 410083, China;

3. Aerospace Research Institute of Materials & Processing Technology, Beijing 100076, China)

Abstract: The hot deformation behavior of FGH4169 alloy was studied by single-stroke compression test on MMS-200 test machine at the temperature of 920-1 050 ℃ and the strain rate of 0.004-10 s-1. The constitutive equation of the plastic deformation of FGH4169 alloy was obtained by calculation. The results show that flow stress reaches a peak with the increase of strain. Dynamic recrystallization is the main softening mechanism of the hot deformation of FGH4169 alloy, The power dissipation efficiency is 10% higher than that of Inconel718, and the peak efficiency is about 57%. The hot deformation activation energy is calculated about 430 kJ/mol. The suitable deformation condition is at the temperature from 1 010 to 1 050 ℃ with strain rate from 0.01 to 0.1 s-1 or at the temperature of 980 ℃ with the strain rate from 0.004 to 0.01 s-1 according to the processing map.

Key words: FGH4169 alloy; hot deformation; dynamic recrystallization; constitutive equation

粉末冶金高温合金是制造新型航空发动机零部件的最佳材料,主要用于制造涡轮盘等高温承力转动零件[1-2]。FGH4169合金(粉末Inconel 718合金)是以γ'' (Ni3Nb)为主要强化相的镍基时效硬化型高温合金,在650 ℃以下具有较高的强度和塑性、良好的抗疲劳和耐腐蚀性,广泛用于制造涡轮盘、压气机盘、叶片和导向器等关键部件[3-4]。与传统锻造合金相比,粉末高温合金晶粒粒度小、组织均匀,不存在严重的元素或组织偏析,尤其对于FGH4169合金,Nb质量分数较高(5.0%~5.5%),粉末冶金方法可以避免严重的偏析对组织以及性能产生不良影响,同时还具有合金化程度和屈服强度高、疲劳性能好等优点,省去了常规锻造镦粗等一系列中间工艺,降低了成本。GH4169合金在高温塑性变形过程中,对变形温度、变形速率等参数十分敏感,为了获得满意的微观组织和机械性能,需要对其热变形行为进行研究。目前,众多学者对GH4169合金的热变形行为十分关注。Wang等[5]在变形温度为950~1 100 ℃和应变速率在0.001~1 s-1下绘制了δ时效态GH4169的热加工图,并研究了动态再结晶的机理。杨平等[6]研究了δ时效态Inconel 718合金的高温变形行为,并给出了热压缩的本构方程,同时得出在δ时效态该合金的热变形激活能为497.407 kJ/mol。Yuan等[7]分别给出了固溶态和固溶时效态Inconel 718的变形激活能及本构方程,并研究了析出相对热变形的影响。由文献[8]可知,不同成型方法、原始组织结构等都会对合金的热加工参数产生重要影响。GH4169合金的高温变形行为不仅受到变形温度、应变速率、变形量等变形工艺条件的直接控制,同时,不同成型工艺对材料的热加工性能产生很大影响。目前,对GH4169合金的热加工行为的探索已经成为国内外学者研究热点,但对粉末冶金方法制备的FGH4169合金在热加工方面的研究却鲜有报道。为此,本文作者采用粉末热等静压成型法制备FGH4169合金,对合金进行热模拟压缩试验,研究变形工艺参数对FGH4169合金高温变形时的流动应力变化规律,并绘制热加工图,优化出最佳工艺参数,以便为实际生产提供指导。

1 实验材料及方法

试验用热等静压后的FGH4169合金坯料,其主要元素(质量分数)有Ni 50.2%,Al 0.59,Mo 3.05%,Fe 19.0%,Nb 5.5%,Ti 1.3%,Cr 18.3%和Mn 0.029%。将热等静压后的FGH4169合金加工成直径×高为8 mm×12 mm的圆柱体试样,在MMS-200热模拟实验机上进行单道次高温压缩实验。试验机配有微机处理系统的试验机自动采集有关数据,并进行修正和计算,获得应力-应变等参数。压缩总变形量为60%(真应变),变形速率分别为10,0.1,0.01和0.004 s-1,变形温度为950,980,1 010和1 050 ℃。将变形后的试样立即喷水淬火以保持高温变形组织,通过金相显微镜和扫描电镜对变形组织进行观察。

粉末颗粒边界(previous particle boundary, PPB)是热等静压态粉末冶金高温合金最典型的特征,如图1所示。从图1可见:PPB上存在微观孔洞(图1(b)中白色箭头),在颗粒边界及颗粒内部碳化物聚集(图1(b)中黑色箭头)。经电子探针分析可知:碳化物主要为NbC和TiC。Nb元素是形成FGH4169合金强化相的主要元素,因此,Nb以碳化物形式在PPB偏聚,会使基体质量分数降低,不利于合金强化;同时,原始颗粒边界的碳化物形成网状,一旦微裂纹形成,就会很快沿着原始颗粒边界扩展开去,使合金力学性能降低[9]。

图1 热等静压态FGH4169的原始组织

Fig.1 Microstructures of HIPed FGH4169 alloy

2 实验结果及讨论

2.1 合金真应力-真应变曲线

FGH4169合金经过热模拟实验后,不同变形温度和应变速率下的真应力-真应变曲线如图2所示。从图2可以看出:在不同变形温度和应变速率条件下,该合金的流变曲线变化趋势基本一致;在开始阶段,流变应力随着应变的增加,快速增大并达到峰值(即峰值应力),随后,应力随应变的增加缓慢下降或趋于稳定;当应变速率一定时,随着变形温度升高,峰值应力随着温度的升高而降低,如当应变速率为10 s-1、变形温度由950 ℃升高到1 010 ℃时,峰值应力由630 MPa下降到430 MPa。这是由于随着变形温度的升高,热激活作用增强,原子的动能和扩散速率增大,滑移系的临界切应力下降,导致合金的变形抗力下降;同时,高温下也会产生晶界滑动,上述因素促使合金变形抗力下降。当变形温度一定、应变速率不同时,FGH4169合金的峰值应力随着应变速率的升高而升高,如当变形温度为1 010 ℃时,峰值应力由103 MPa升高到430 MPa。这是由于应变速率增加,会使位错运动的速度增大,位错宽度减小,材料临界剪切应力升高,变形抗力也随之增大;同时,在相同的变形程度条件下,应变速率升高,压缩变形时间缩短,在变形过程中产生更多新的位错源,原有位错来不及消除,位错密度总体上升,从而使合金真应力增大。

2.2 变形条件对FGH4169合金显微组织的影响

镍基合金是低层错能金属,其滑移面上的不全位错之间的层错带(扩展位错)较宽,很难汇聚成全位错,因而,在热变形过程中不易发生刃位错的攀移和螺位错的交滑移,故动态再结晶是合金动态软化的主要方式[10]。FGH4169合金在高温压缩变形过程中,当变形温度为1 050 ℃、应变速率为10 s-1时,变形时间短,再结晶形核效率较低,在原始晶界周围产生细小的再结晶晶粒,整个组织内部并没有完全发生再结晶,形成“项链”组织[11],如图3(a)所示(其中黑色箭头所指为未发生再结晶的原始晶粒,白色箭头所指为原始晶粒周围的细小再结晶晶粒)。随着应变速率降低,再结晶程度逐渐提高。当变形温度为1 050 ℃、应变速率为0.1 s-1时,FGH4169合金组织内部再结晶完全,晶粒尚未长大,如图3(b)所示;当变形温度不变、应变速率为0.004 s-1时,再结晶晶粒长大,出现混晶组织,如图3(c)所示。通过与Inconel718合金的变形组织对比可知[12]:在相同的变形温度和应变速率条件下,实验合金的再结晶程度明显大于Inconel718合金的再结晶程度,如在变形温度为1 050 ℃、应变速率为0.1 s-1时(如图3(b)所示),FGH4169合金组织再结晶完全,而在相同变形条件下,Inconel718合金组织部分再结晶,呈现“项链”组织,可见粉末FGH4169合金更易于发生动态再结晶。

图2 FGH4169合金高温压缩变形时的应力-应变曲线

Fig.2 True stress-strain curves of FGH4169 alloy at hot compression at different temperatures

图3 不同变形条件下FGH4169合金的金相组织

Fig.3 Optical microstructures of FGH4169 alloy compressed at different temperatures and strain rates

粉末高温合金动态再结晶易于在原始颗粒边界(PPB)处发生[13]。PPB主要由碳化物组成,呈网状分布于金属粉末表面。其内部存在较多微观孔洞但结构稳定,在热变形中易于造成位错的塞积,形成高储能区,产生优先形核的条件。在高温变形过程中,PPB随变形量的增大而产生畸变,并随着动态再结晶的进行而逐渐破碎、消散,最后,被动态再结晶晶粒完全取代(如图3(d)所示)。

2.3 本构方程

大量研究表明,高温塑性变形是一个受热激活控制的过程。在热变形过程中,其变形行为与应变速率 (s-1)、温度T(K)和流变应力σ(MPa)有关,通常采用式(2)所示的Arrhenius关系表示材料的本构方程[14]:

(s-1)、温度T(K)和流变应力σ(MPa)有关,通常采用式(2)所示的Arrhenius关系表示材料的本构方程[14]:

(1)

(1)

(2)

(2)

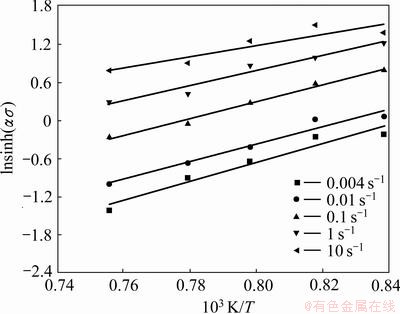

式中:Q为变形激活能,反映了材料热变形的难易程度;R为摩尔气体常数;T为反应热力学温度;A为结构因子;n为应力指数;α为应力水平参数;σ为峰值应力或稳态流变应力;β为应变参数;α与β和n之间满足a=b/n; -

- 的关系如图4所示。

的关系如图4所示。

(3)

(3)

根据图4和图5得到: =9.664×10-3;n=2.107;Q=430 kJ/mol。

=9.664×10-3;n=2.107;Q=430 kJ/mol。

一般认为,金属的热变形激活能与自扩散激活能相近,适合于发生动态回复的情况;对于发生动态再结晶的情况,热变形激活能往往比自扩散激活能大得多[15]。经计算,FGH4169合金在950~1 050 ℃时的热变形激活能为430 kJ/mol,远大于Ni的自扩散激活能(278 kJ/mol)[16]。可以证明:FGH4169在实验条件下的软化机制是动态再结晶;同时,Cr和Fe等合金元素溶入Ni基体,形成固溶体,产生强化效果,同样是热变形激活能大于自扩散激活能的原因之一。FGH4169的热变形激活能小于杨平等[6]得出的Inconel718合金的激活能 (490 kJ/mol)。在相同的变形条件下,FGH4169合金再结晶进行的程度更大,动态再结晶迅速消除加工硬化,使合金的热变形过程更容易实现,从而导致热变形激活能降低;同时,粉末冶金高温合金FGH4169中存在的PPB是优先形核位置,PPB与γ基体之间的界面能也为动态再结晶形核提供了驱动力,从而提高了再结晶程度,增强了再结晶软化作用。

图4 FGH4169合金高温压缩变形峰值应力与应变速率的关系

Fig.4 Relationship between peak flow stress and strain rate in hot deformation of FGH4169

图5 FGH4169合金高温压缩变形峰值应力与变形温度之间的关系

Fig.5 Relationship between peak flow stress and temperature in hot deformation of FGH4169

由式(1)和(2),可得Z和σ之间的关系式为

(4)

(4)

式中:Z为Zener-Hollomon参数,表示温度补偿的变形速率因子。

-

- 关系曲线如图6所示。图6中:截距为

关系曲线如图6所示。图6中:截距为 ,斜率为1/n,可求得A=8.548×1014。

,斜率为1/n,可求得A=8.548×1014。

由此可以得到FGH4169合金高温压缩的本构方程为

图6 FGH4169合金高温压缩峰值应力与Z参数之间的关系

Fig.6 Relationship between peak flow stress and parameter Z in hot deformation of FGH4169

(5)

(5)

2.4 加工图

加工图描述了变形区域微观组织的变形机制,还描绘了加工过程中应该避免的不稳定流变区域,可以对材料的可加工性进行评估,并且可获得优化的可加工温度和应变速率[17]。应变速率敏感指数m可表示为

(6)

(6)

根据应力应变曲线可求得m,从而可以计算出不同温度和变形速率下的功率耗散效率:

(7)

(7)

式中:η为功率耗散因子;J为微观组织演变消耗的能量;Jmax为微观组织演变消耗的最大能量。在变形温度和应变速率的平面内绘制η的等值线,即得到能量耗散效率图。

在动态材料模型中,加工失稳的判据是由Ziegler[18]提出来的,失稳参数 可用下表示:

可用下表示:

(8)

(8)

计算不同温度和应变速率下的 ,并绘制加工失稳图,如图7所示。当

,并绘制加工失稳图,如图7所示。当 <0时,材料在对应的温度和变形速率下变形时,处于失稳状态。最后,将功率耗散图和失稳图合并便可得到FGH4169合金的加工图。

<0时,材料在对应的温度和变形速率下变形时,处于失稳状态。最后,将功率耗散图和失稳图合并便可得到FGH4169合金的加工图。

热等静压态粉末FGH4169合金的失稳区域主要集中在低变形温度、高应变速率的变形条件下,一般认为,材料失稳是由于合金发生了绝热剪切或者局部塑形流变。在低温(950 ℃)和高变形速率(10 s-1)下变形时,该区域功率耗散值很低,表明在这些条件下变形时,合金的加工性能会出现恶化,如图8(a)所示;晶内出现大量相互排列紧密的滑移带,呈现明显的局部变形特征,会导致材料失稳;同时,在该区域变形时,合金表面出现与主应力方向成45°的模糊条带,即绝热剪切带如图8(b)和8(c)所示。因此,应避免在低温高变形速率区域对合金进行加工。

图7 FGH4169合金的加工图

Fig.7 A processing map of FGH4169

通过与Inconel718合金的功率耗散图进行比较可知:在相同的变形温度和应变速率条件下,实验合金的总体耗散效率比Inconel718合金的总体耗散效率大。例如,GH4169合金的峰值耗散效率为46%,实验合金的峰值耗散效率为57%。对于FGH4169合金,有更多能量用于改变合金组织状态,即为再结晶提供的能量更多。结合对变形组织和表观激活能的分析,可以得出粉末冶金高温合金FGH4169的再结晶程度比Inconel718的再结晶程度高。

分析图7可知:在本实验条件下,FGH4169合金功率耗散效率较高的区域是变形温度为980~1 050 ℃和应变速率为0.004~0.1 s-1。在该区域中,功率耗散系数最高达到57%,且不存在失稳现象,是合金的安全加工区域。在此安全加工区域中,功率耗散系数大,表明有更多能量合金用于改变合金组织状态。结合变形组织分析可知:在高温、低应变速率条件下变形,再结晶晶粒部分长大,会出现混晶组织(如图3(c)所示);当变形温度为980 ℃、应变速率过大时,FGH4169合金组织再结晶并不完全。经综合考虑,适宜热加工的工艺如下:变形温度为1 010~1 050 ℃和应变速率为0.01~0.1 s-1,或变形温度为980 ℃和应变速率为0.01~0.004 s-1,如图7中方框所示。FGH4169合金在该适宜条件下变形后,组织均匀细小,PPB完全被消除,碳化物在基体均匀分布,粉末冶金缺陷基本被消除。

图8 FGH4169合金在不同变形条件下的失稳组织

Fig.8 Microstructures of FGH4169 alloy after deformation

3 结论

(1) FGH4169合金在高温变形过程中,流变应力随着应变的增大,快速达到峰值应力;随着变形过程的进行,曲线整体上开始下降,表现为动态软化作用,软化的主要机制是动态再结晶。

(2) 在变形温度较低(950 ℃)、应变速率较高(10 s-1)时,FGH4169合金原始晶粒沿变形方向被严重拉长,沿原始晶界有少量动态再结晶晶粒形成,形成“项链”组织;随着变形温度升高、变形速率降低,变形大晶粒逐渐减少,动态再结晶趋于完全,晶粒明显长大。

(3) FGH4169合金峰值流变应力和变形速率的关系可用如下本构方程描述:

该合金的热变形激活能为430 kJ/mol,与在相同变形条件下变形时,FGH4169合金的再结晶程度更大。该合金的功率耗散效率约高于Inconel718合金功率耗散效率10%,峰值效率达到57%。

(4) FGH4169合金适合的热加工工艺如下:变形温度为1 010~1 050℃,应变速率为0.01~0.1 s-1,以及变形温度为980 ℃,应变速率为0.01~0.004 s-1。

参考文献:

[1] 庄景云, 杜金辉, 邓群. GH4169合金及其锻件晶粒形貌的特点[J]. 钢铁研究学报, 2003, 15(7): 44-48.

ZHUANG Jingyun, DU Jinhui, DENG Qun. Grain morphologies characteristics of alloy GH4169 and forgings[J]. Journal of Iron and Steel Research, 2003, 15(7): 44-48.

[2] 李祖德, 李松林, 赵慕岳. 20世纪中、后期的粉末冶金新技术和新材料(2): 新材料开发的沿革与评价[J]. 粉末冶金材料科学与工程, 2006, 11(6): 315-322.

LI Zude, LI Songlin, ZHAO Muyue. New P/M technologies and materials developed in late-20th century(2): History and evaluation of new materials development[J]. Materials Science and Engineering of Powder Metuallurgy, 2006, 11(6): 315-322.

[3] 师昌绪, 陆达, 荣科. 中国高温合金四十年[M]. 北京: 中国科学技术出版社, 1996: 1-25.

SHI Changxu, LU Da,RONG Ke, Forty years of superalloy R&D in China[M]. Beijing: Chinese Science and Technology Press, 1996: 1-25.

[4] Oblak J M, Pauionis D F, Duvall D S. Coherency strengthening in Ni-base alloys bardened by DO22 precipitates[J]. Metallurgical Transactions A, 1974, 5(1): 143.

[5] Wang Y, Zhen L, Shao W Z, et al. Hot working characteristics and dynamic recrystallization of δ-processed Superalloy718[J]. Journal of Alloys and Compounds, 2009, 474: 341-346.

[6] 杨平, 赵玉涛, 王安东. δ工艺Inconel 718合金热变形条件下的流变行为[J]. 中国有色金属学报, 2012, 22(1): 72-79.

YANG Ping, ZHAO Yutao, WANG Andong, et al. Flow stress behavior of delta-processed Inconel 718 superalloy under hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(1): 72-79.

[7] Yuan H, Liu W C. Effect of the δ phase on the hot deformation behavior of Inconel 718[J]. Materials Science and Engineering A, 2005, 408: 281-289.

[8] 李晨, 李淼泉. 固溶处理GH4169合金的高温变形行为[J]. 航空学报, 2010, 31(2): 368-376.

LI Chen, LI Miaoquan. Deformation behavior of nickel based superalloy GH4169 through solution treatment[J]. Acta Aeronautica et Astronautica Sinica, 2010, 31(2): 368-376.

[9] 刘明东. 张莹. FGH95粉末高温合金原始颗粒边界及其对性能的影响[J]. 粉末冶金工业, 2006, 16(3): 1-5.

LIU Mingdong, ZHANG Ying. Study on the PPB defect of P/M superalloy FGH95[J]. Powder metallurgy Industry, 2006, 16(3): 1-5.

[10] 刘鹏飞, 刘东. GH761合金的热变形行为与动态再结晶模型[J]. 稀有金属材料与工程, 2009, 38(2): 275-281.

LIU Pengfei, LIU Dong. Flow behavior and dynamic recrystallization model for GH761 superalloy during hot deformation[J]. Rare Metal Materials and Engineering, 2009, 38(2): 275-281.

[11] 宁永权, 姚泽坤. FGH4096合金“项链”组织研究[J]. 稀有材料科学与工程, 2009, 38(10): 1783-1786.

NING Yongquan, YAO Zekun. Link microstructure of FGH4096 alloy[J]. Rare Metal Materials and Engineering, 2009, 38(10): 1783-1786.

[12] Wang Y, Shao W Z. Microstructure evolution during dynamic recrystallization of hot deformed superalloy 718[J]. Materials Science and Engineering A, 2008(486): 321-332.

[13] 宁永权, 姚泽坤. 热模锻造+直接时效粉末高温合金的强化机制[J]. 金属学报, 2010, 46(3): 324-328.

NING Yongquan, YAO Zekun. Strengthening mechanism of powder metallurgy superalloy by hot-die forging + direct aging[J]. Acta Metallurgica Sinica, 2010, 46(3): 324-328.

[14] Zener C, Hollomon J H. Effect of strainrate upon the plastic flow of steel[J]. Applied Physics, 1944, 15(1): 22-27.

[15] Kashyap B P, Chaturvedi M C. Activation energy for superplastic deformation of in718 superalloy[J]. Scripta Materialia, 2000(43): 429-433.

[16] Wang K, Li M Q. Effect of the δ phase on the deformation behavior in isothermal compression of superalloy GH4169[J]. Materials Science and Engineering A, 2011, 528: 4723-4731.

[17] 戚延龄, 夏长清. Ti62421s 钛合金的热变形行为及加工图[J]. 中南大学学报: 自然科学版, 2012, 43(5): 1662-1671.

QI Yanling, XIA Changqing. Deformation behavior and processing map of high temperature deformation of Ti62421s alloy[J]. Journal of Central South University: Science and Technology, 2012, 43(5): 1662-1671.

[18] Ziegler H. Progress in solid mechanics[M]. Sneddon I N, Hill R, eds. Amsterdam: North-Holland Publishing, 1965: 91.

(编辑 陈灿华)

收稿日期:2012-11-12;修回日期:2013-01-22

基金项目:国家自然科学基金资助项目(51071177);国家重大基础研究发展规划(“973”计划)项目(2012CB619506)

通信作者:易丹青(1953-),男,湖南湘乡人,教授,从事高性能轻金属材料及粉末冶金新材料研究;电话:0731-88830263;E-mail: yioffice@ csu.edu.cn