热轧工艺对X80管线钢组织及低温韧性的影响

王秉新1, 2,连景宝1,刘相华2,王国栋2

(1. 辽宁石油化工大学 机械工程学院,辽宁 抚顺,113001;

2. 东北大学 轧制技术及连轧自动化国家重点实验室,辽宁 沈阳,110004)

摘要:利用D450试验轧机,对X80管线钢开展控轧控冷实验。采用光学显微镜、透射电镜、扫描电镜以及电子背散射衍射技术分析不同TMCP工艺条件下的管线钢组织结构,研究形变热处理工艺对管线钢组织及低温韧性的影响。研究结果表明:在较高压下率及较大冷速条件下,管线钢组织以细小的针状铁素体作为主要组元,奥氏体/马氏体(M/A)组元数量较少,粒径较小;相反,在低压下率及较小冷速情况下,管线钢组织主要是由粒径较大的准多边形铁素体构成,M/A组元数量多,粒径大;与准多边形铁素体为主的组织相比,以针状铁素体作为主要组元的管线钢由于具有细小的有效晶粒粒径、高的大角度晶界比例以及细小的M/A组元,表现出良好的低温韧性。

关键词:高强管线钢;工艺参数;韧脆转变;有效晶粒尺寸;奥氏体/马氏体组元;电子背散射衍射

中图分类号:TG113.25 文献标志码:A 文章编号:1672-7207(2014)11-3786-06

Effect of hot-rolling processes on microstructures and low-temperature toughness in X80 grade pipe-line steel

WANG Bingxin1, 2, LIAN Jingbao1, LIU Xianghua2, WANG Guodong2

(1. College of Mechanical Engineering, Liaoning Shihua University, Fushun 113001, China;

2. State Key Laboratory of Rolling & Automation, Northeastern University, Shenyang 110004, China)

Abstract: Using a pilot rolling mill with twin rolls of 450 mm in diameter, thermo-mechanical controlled processing (TMCP) experiments were performed in X80 grade pipe-line steel. The microstructural characteristics for different TMCP conditions were analyzed by means of optical microscope (OM), transmission electron microscope (TEM), scanning electron microscope (SEM) as well as electron back-scatter diffraction (EBSD), and the effect of TMCP conditions on microstructures and low-temperature toughness was investigated. The results show that during higher reduction in austenite non-recrystallization region and faster cooling rate during accelerated cooling, the microstructure is dominated by acicular ferrite (AF) accompanied with small amount of fine martensite/austenite (M/A) constituents. In contrast, lower reduction and slower cooling rate lead to a predominantly quasi-polygonal ferrite (QF) microstructure with coarse M/A islands. Compared with the microstructure mainly consisting of QF, the pipe-line steel with the microstructure primarily characterized by AF exhibits excellent low-temperature toughness because of its fine effective grain size, high fraction of high angle grain boundaries and fine M/A islands.

Key words: high strength pipe-line steel; rolling parameters; ductile-brittle transition; effective grain size; martensite/ austenite constituent; electron back-scatter diffraction

管线运输是长距离输送石油、天然气最经济合理的运输方式。为提高输送效率,降低能耗和减少投资,管线用钢向高强度、优良焊接性能的方向发展[1-2]。随着高寒地带油气田的开发,管线的服役环境更加恶劣,对输送管线用钢的低温韧性也提出了更高要求。高强管线钢在不同TMCP条件下,组织中存在多边形铁素体、准多边形铁素体、针状铁素体、板条状贝氏体以及马氏体/奥氏体岛等多种不同组织组元,构成了一个复杂的混合组织,组元类型、各组元比例等结构特征对管线钢低温韧性均具有显著的影响[3]。目前对高强管线钢热轧工艺、组织结构以及与低温性能的关系已有一些研究[4-7],但由于高强管线钢组织的复杂性,进一步分析上述关系,对优化高强管线钢热轧工艺及组织结构设计,提高管线钢综合力学性能仍具有重要意义。本文作者针对X80高强管线钢,通过调整控轧控冷工艺参数,获得具有不同特征的组织结构,分析组织特征对低温性能的影响。

1 试验材料及方法

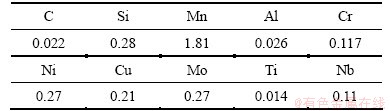

实验材料为X80高强管线钢,其化学成分如表1所示。采用箱式加热炉将断面长×宽为100 mm×100 mm的板坯加热到1 200 ℃保温1 h,利用D450试验轧机,采用奥氏体再结晶区和非再结晶区两阶段轧制,轧制7道次,最终钢板厚度为12 mm,轧后立即采用水幕冷却方式进行加速冷却到终冷温度,然后进行空冷到室温。

表1 X80管线钢化学成分(质量分数)

Table 1 Chemical compositions of X80 steel %

根据奥氏体再结晶区与未再结晶区压下率分配及轧后冷速不同,采用2种TMCP工艺。工艺A和B的工艺参数见表2。

根据ASTM E23-2002a标准[8],沿钢板横向切取试样,加工成标准夏比V型缺口冲击试样,冲击试验温度为20~-196 ℃。用双曲正切函数[9]对冲击功-温度实验数据回归分析,确定韧脆转变温度(DBTT)。利用FEI Quanta 600型扫描电镜(SEM)观察断裂试样侧表面,以分析低温下断裂时解理断裂裂纹扩展情况。

在钢板上取样用于光学显微镜(OM)、透射电镜(TEM)以及电子背散射花样(EBSD)分析,检验面为轧制钢板的横断面。试样经过磨制、抛光后,分别用体积分数为4%硝酸酒精溶液以及LePera试剂[10]进行腐蚀,使用Leica DMIRM型图像仪分析管线钢的金相组织及奥氏体/马氏体(M/A)组元。切割薄片试样,经机械减薄和电解双喷减薄,制备薄膜样品,使用JEM2000EX型透射电镜观察管线钢组织的精细结构,加速电压为200 kV。使用配备EDAX-TSL取向成像系统的FEI Quanta 600型扫描电镜对管线钢进行EBSD分析。采用电解抛光制备EBSD试样,抛光液组成(体积比)为V(高氯酸):V(酒精):V(水)=2:13:1,抛光电压为35 V。

2 试验结果

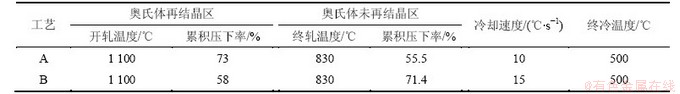

图1所示为2种TMCP工艺条件下管线钢的金相组织。由图1可知:管线钢在不同TMCP条件下,组织均含有AF和QF。但TMCP工艺不同,各组织组成物相对含量不同。工艺A条件下的管线钢的组织基本是由尺寸较大的QF构成,其形貌特征为边界呈不规则锯齿状或波浪状,犹如一块无特征的碎片。相反,工艺B下的组织主要是由细小的AF构成,这些铁素体呈独特的不规则非等轴晶形貌。

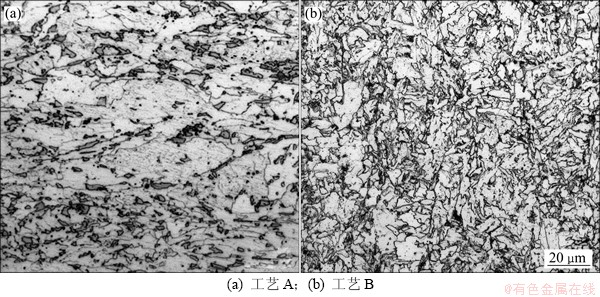

此外,不同TMCP工艺下,管线钢的组织中M/A组元尺寸、数量也存在差异。为了清楚地显示2种TMCP工艺中M/A组元的特征,对上述试样重新抛光,用LePera试剂腐蚀,其组织如图2所示。在用LePera试剂腐蚀的组织中,M/A组元呈白亮色,而针状铁素体(AF),准多边形铁素体(QF)呈灰色。从图2可以看出:在工艺A条件下,M/A岛尺寸较大,数量较多;而在工艺B条件下,MA岛细小,数量较少。

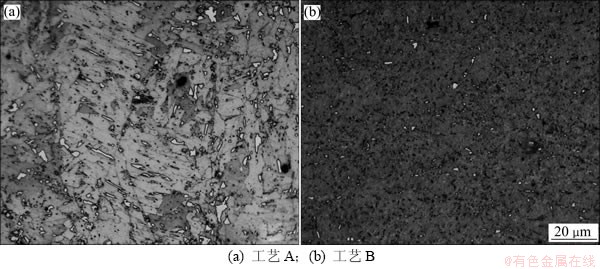

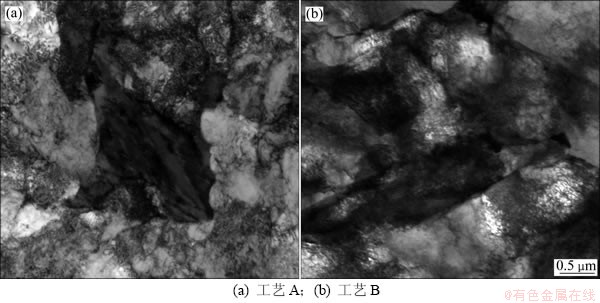

2种TMCP工艺下管线钢组织TEM结构如图3所示。准多边形铁素体与多边形铁素体不同,在其内部含有较高密度的位错,这些位错相互缠结,形成位错墙及胞状亚结构,如图3(a)所示。此外,还可以看出,在准多边形铁素体内部存在一个巨大的块状M/A岛,其长度超过2 μm。从图3(b)可知,针状铁素呈非平行的针片状结构,互相交错,而且在针状铁素体板条间分布着十分细小的M/A岛。

表2 控轧控冷工艺参数

Table 2 TMCP parameters for hot rolling processes

图1 不同TMCP工艺管线钢金相组织

Fig. 1 Optical microstructures for pipe-line steels obtained by different TMCP conditions

图2 不同TMCP工艺M/A组元特征(LePera试剂腐蚀)

Fig. 2 M/A component characteristics under different TMCP conditions (etched in LePera reagent)

图3 不同TMCP工艺管线钢组织的TEM形貌

Fig. 3 TEM images for pipe-line steels obtained by different TMCP conditions

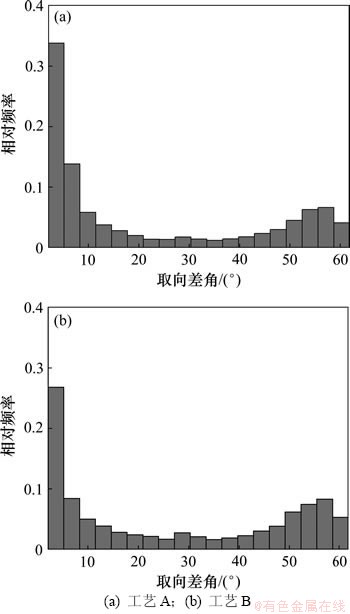

为了分析2种TMCP工艺管线钢组织的晶界结构、有效晶粒大小等组织特征,对管线钢进行EBSD分析,其结果分别如图4和图5所示。文献[11]指出,相邻晶粒取向差≥15°的大角度晶界,能改变裂纹扩展方向,可有效地阻碍解理裂纹的扩展。从图4可知,工艺A条件下,管线钢组织中大角度晶界(15°)所占比例为40.9%,比工艺B条件下的(56.2%)低。

图4 不同TMCP工艺晶界取向差分布

Fig. 4 Distributions of grain boundary misorientation under different TMCP conditions

文献[11]将取向差≥15°(即起始角为15°)晶界作为决定组织有效晶粒尺寸的一个主要晶体学参数。图5所示为起始角为15°的EBSD晶界取向差,表明2种TMCP工艺条件下的管线钢组织有效晶粒粒径。由EBSD分析可得工艺A、工艺B组织的有效晶粒尺寸分别为6.32 μm及3.28 μm,说明工艺B条件下管线钢有效晶粒粒径比工艺A的小。

图5 不同TMCP工艺管线钢晶界取向差图

Fig. 5 Misorientation maps at tolerance angle of 15° under different TMCP conditions

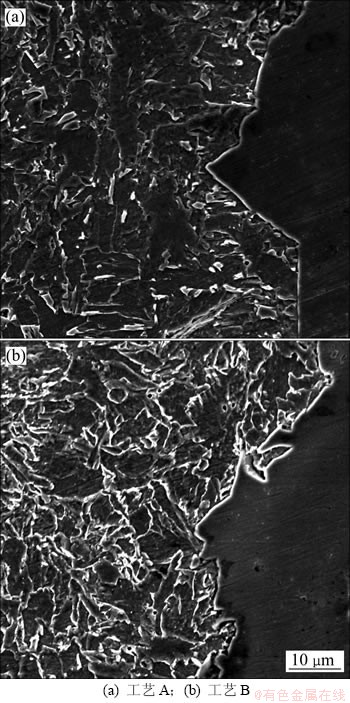

图6所示为解理裂纹扩展情况。相比于工艺A组织,工艺B管线钢解理裂纹断裂路径更加曲折。这是因为工艺B管线钢具有较细小的有效晶粒尺寸,使得其拥有较多的大角度晶界,导致解理裂纹更加频繁地改变其扩展方向。

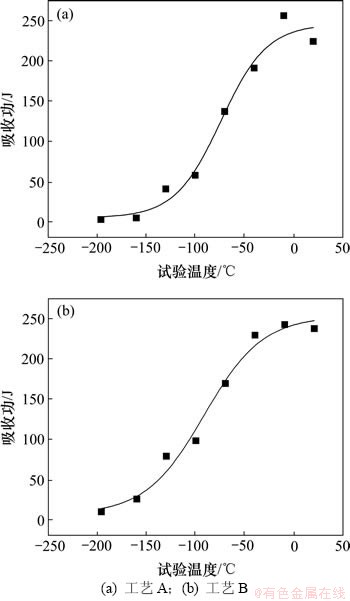

为减小误差,用双曲正切函数对冲击功-温度实验数据回归分析,建立韧脆转变曲线。根据冲击功-温度曲线,按照能量法确定韧脆转变温度,即将高阶能与低阶能的平均值所对应的温度作为韧脆转变温度,则2种TMCP工艺管线钢的DBTT如图7所示。由图7可见:工艺B条件下管线钢的DBTT为-91.7 ℃,比工艺A条件下的(-73.8 ℃)低,表明前者的低温韧性较后者的更优。

图6 -196 ℃时断裂试样断口侧表面的SEM图

Fig. 6 SEM images of side view of fracture surfaces for impact specimens fractured at -196 ℃

3 分析与讨论

相对于工艺A,工艺B在奥氏体未再结晶区累积压下率较大,在变形奥氏体内形成了高密度的可作为AF形核点的位错及形变带,促进了AF相变[12]。QF又称块状铁素体(MF)[4],其转变是由界面扩散控制的形核-长大型相变,在相变过程中,间隙原子以及置换原子在迁移界面上进行再分配,相变受界面上的短程扩散所控制[13]。工艺B终轧后,冷却速度较大,降低了包括碳在内的合金元素的扩散,QF相变受到抑制。因此,虽然2种工艺条件下,管线钢组织均含AF以及QF,但TMCP工艺不同,2种组织组成物相对含量不同,工艺A管线钢组织含有较多的QF,而工艺B组织则是以AF为主。

TMCP工艺除使管线钢产生上述不同的组织特征外,对组织中M/A组元尺寸、数量也存在着显著的影响。在固态相变动力学中,把固态相变驱动力简化成2部分:一是由过冷引起的相变驱动力;二是由储存在晶体中的形变能而形成的相变驱动力。相比于工艺A,工艺B未再结晶区累积压下率以及轧后加速冷速大,使得由过冷以及形变能引起的相变驱动力增大,促进了中温相变,提高了中温相变产物转变量,导致工艺B条件下的管线钢组织中M/A组元数量降低,粒径减小。

图7 管线钢在不同TMCP工艺条件的韧脆转变曲线

Fig. 7 Ductile-brittle transition curves for pipe-line steels under different TMCP conditions

由于在工艺B条件下,管线钢具有细小的有效晶粒粒径,使其具有良好的低温性能。体心立方金属材料的韧脆转变现象是解理断裂强度与屈服强度相互竞争的结果[14]。晶粒细化导致材料的屈服强度及解理断裂强度增加,但对断裂强度的作用程度明显大于屈服强度[15]。因此,细化晶粒使断裂强度显著提高,最终导致韧脆转变温度降低。

在工艺B条件下,管线钢具有高的大角度晶界比例,这样裂纹传播过程中频繁改变断裂路径,裂纹扩展路径变得更加曲折,如图6所示。这样不利于裂纹的传播,在断裂过程中可吸收更多的能量,提高材料抵抗解理断裂能力[16]。

在工艺A条件下,管线钢组织中大量的粗大M/A组元分布在铁素体基体上(QF及AF),由于这2种组织屈服强度、硬度不同,受外力作用时在M-A/铁素体界面处产生应力集中现象而容易诱发显微裂纹,降低材料的吸收冲击功[17-18],而工艺B组织中由于M/A组元数量少、粒径小,对低温韧性恶化程度低[19]。

因此,通过增加未再结晶区累积压下率以及轧后加速冷却速度,使X80管线钢获得以AF为主+少量粒径细小的M/A组元的混合组织,能够提高管线钢低温韧性。

4 结论

1) 在较高的未再结晶区压下率及较大的冷速条件下,X80管线钢组织以AF作为主要组元,M/A岛数量较少,粒径较小;相反,在低压下率及较小冷速情况下,管线钢组织主要是由粒径较大的QF构成,M/A岛数量多,粒径大。

2) 以AF为主的管线钢由于具有细小的有效晶粒粒径、高的大角度晶界比例以及少量细小M/A组元第二相,表现出良好的低温韧性。

参考文献:

[1] 郑磊, 傅俊岩. 高等级管线钢的发展现状[J]. 钢铁, 2006, 41(10): 1-10.

ZHENG Lei, FU Junyan. Recent development of high performance pipeline steel[J]. Iron and Steel, 2006, 41(10): 1-10.

[2] Bott I S, Souza L F G, Teixeira J C G, et al. High-strength steel development for pipelines: A Brazilian perspective[J]. Metallurgical and Materials Transactions A, 2005, 36A(2): 443-454.

[3] Han S Y, Shin S Y, Lee S, et al. Effects of cooling conditions on tensile and charpy impact properties of API X80 linepipe steels[J]. Metallurgical and Materials Transactions A, 2010, 41A(2): 329-340.

[4] WANG Wei, YAN Wei, ZHU Lin, et al. Relation among rolling parameters, microstructures and mechanical properties in an acicular ferrite pipeline steel[J]. Materials and Design, 2009, 30(9): 3436-3443.

[5] Shin S Y, Hwang B C, Lee S H, et al. Correlation of microstructure and charpy impact properties in API X70 and X80 line-pipe steels[J]. Materials Science and Engineering A, 2007, 458(1/2): 281-289.

[6] 焦多田, 蔡庆伍, 武会宾. 轧后冷却制度对X80级抗大变形管线钢组织和屈强比的影响[J]. 金属学报, 2009, 45(9): 1111-1116.

JIAO Duotian, CAI Qingwu, WU Huibin. Effects of cooling process after rolling on microstructure and yield ratio of high-strain pipeline steel X80[J]. Acta Metallurgica Sinica, 2009, 45(9): 1111-1116.

[7] 孟德亮, 康永林, 郑晓飞, 等. 两阶段控制冷却工艺对含钼X80抗大变形管线钢组织与性能的影响[J]. 北京科技大学学报, 2011, 33(7): 834-840.

MENG Deliang, KANG Yonglin, ZHENG Xiaofei, et al. Effect of two-stage controlled cooling on the microstructure and properties of Mo-containing X80 high-deformability pipeline steel[J]. Journal of University of Science and Technology Beijing, 2011, 33(7): 834-840.

[8] ASTM Standard E23—2002a, Standard test methods for notched bar impact testing of metallic materials[S].

[9] Cao L W, Wu S J, Flewitt P E J. Comparison of ductile-to-brittle transition curve fitting approaches[J]. International Journal of Pressure Vessels and Piping, 2012, 93/94: 12-16.

[10] Lepera F S. Improved etching technique for the determination of percent martensite in high-strength dual-phase steels[J]. Metallography, 1979, 12(3): 263-268.

[11] Diaz-Fuentes M, Iza-Mendia A, Gutierrez I. Analysis of different acicular ferrite microstructures in low-carbon steels by electron backscattered diffraction. Study of their toughness behavior[J]. Metallurgical and Materials Transactions A, 2003, 34A(11): 2505-2516.

[12] Tang Z H, Waldo S. The role of molybdenum additions and prior deformation on acicular ferrite formation in microalloyed Nb-Ti low-carbon line-pipe steels[J]. Materials Characterization, 2008, 59(6): 717-728.

[13] Hillert M. Thermodynamics of the massive transformation[J]. Metallurgical Transactions A, 1984, 15A(3): 411-419.

[14] Hanamura T, Yin F, Nagai K. Ductile-brittle transition temperature of ultrafine ferrite/cementite microstructure in a low carbon steel controlled by effective grain size[J]. ISIJ international, 2004, 44(3): 610-617.

[15] Inoue T, Yin F, Kimura Y, et al. Delamination effect on impact properties of ultrafine-grained low-carbon steel processed by warm caliber rolling[J]. Metallurgical and Materials Transactions A, 2010, 41A(2): 341-355.

[16] WANG Wei, SHAN Yiyin, YANG Ke. Study of high strength pipeline steels with different microstructures[J]. Materials Science and Engineering A, 2009, 502(1/2): 38-44.

[17] Chen J H, Kikuta Y, Araki T, et al. Micro-fracture behaviour induced by M-A constituent (Island Martensite) in simulated welding heat affected zone of HT80 high strength low alloyed steel[J]. Acta Metallurgica, 1984, 32(10): 1779-1788.

[18] LAN Liangyun, QIU Chunlin, ZHAO Dewen, et al. Analysis of martensite-austenite constituent and its effect on toughness in submerged arc welded joint of low carbon bainitic steel[J]. Journal of Materials Science, 2012, 47(11): 4732-4742.

[19] LI Chaowen, WANG Yong, CHEN Yuhua. Influence of peak temperature during in-service welding of API X70 pipeline steels on microstructure and fracture energy of the reheated coarse grain heat-affected zones[J]. Journal of Materials Science, 2011, 46(19): 6424-6431.

(编辑 赵俊)

收稿日期:2013-12-10;修回日期:2014-03-12

基金项目(Foundation item):辽宁省教育厅项目(L2012132) (Project(L2012132) supported by Education Department of Liaoning Province, China)

通信作者:王秉新(1966-),男,辽宁抚顺人,博士,副教授,从事金属材料制备及组织性能表征;电话:024-56865042;E-mail: wangbingxin@163.com