DOI: 10.11817/j.issn.1672-7207.2016.12.004

超快冷对含Nb钢相变行为的影响

周晓光,徐少华,王福祥,杨浩,王斌,刘振宇,吴迪,王国栋

(东北大学 轧制技术及连轧自动化国家重点实验室,辽宁 沈阳,110819)

摘要:为揭示超快冷对含Nb钢相变行为的影响机制,利用MMS-300热/力模拟试验机研究超快冷+层流冷却条件下含Nb钢的相变行为。研究结果表明:实验钢于680 ℃处于铁素体相变区;当冷却速度大于20 ℃/s时,实验钢于600 ℃处于针状铁素体和贝氏体相变区。实验钢变形后冷却至铁素体相区后,随着保温时间的延长,铁素体含量逐渐增加;当保温时间超过76.5 s时,超快冷工艺下的铁素体含量高于层流冷却工艺下的铁素体含量。当前段冷却速度达到30 ℃/s时,组织中出现硬相组织,继续增大冷却速度,对最终相变组织影响不大。

关键词:超快冷;含Nb钢;相变;冷却速度;显微组织

中图分类号:TG335.11 文献标志码:A 文章编号:1672-7207(2016)12-3989-06

Effect of ultra fast cooling on phase transformation behavior for Nb bearing steel

ZHOU Xiaoguang, XU Shaohua, WANG Fuxiang, YANG Hao, WANG Bin,

LIU Zhenyu, WU Di, WANG Guodong

(State Key Laboratory of Rolling Technology and Automation, Northeastern University, Shenyang 110819, China)

Abstract: In order to reveal the effect mechanism of ultra fast cooling on phase transformation behavior of Nb bearing steel, phase transformation behavior of Nb bearing steel was investigated under ultra fast cooling added laminar cooling conditions by using MMS-300 thermomechanical simulator. The results show that the experimental steel at 680 ℃ is in ferrite phase zone and the experimental steel at 600 ℃ is in acicular ferrite and bainite phase zone when the cooling rate is higher than 20 ℃/s. When the deformed experimental steel is cooled to ferrite phase zone, ferrite fraction increases with the increase of holding time. Ferrite fraction under ultra fast cooling conditions is higher than that under laminar cooling conditions when the holding time is more than 76.5 s. When the forepart cooling rate reaches 30 ℃/s, the hard phase microstructure is generated. The microstructure keeps unchanged with the further increase of forepart cooling rate.

Key words: ultra fast cooling; Nb bearing steel; phase transformation; cooling rate; microstructure

随着我国基础设施建设的不断发展,含Nb钢已广泛应用于汽车、造船、管线、桥梁等诸多领域。Nb作为一种微合金元素,其细晶强化、固溶强化、析出强化以及相变强化等优点尚没有任何一种微合金元素可以替代,因此,含Nb钢的开发一直是科研院所竞相研究的热点之一[1-12]。随着Nb的广泛应用,Nb铁的价格也越来越高,已经达到30万元/t。近年来,为了更好地发挥Nb在钢中的作用或者减少Nb的使用量进而降低生产成本,东北大学将超快速冷却(简称“超快冷”)应用于含Nb钢的开发并取得了显著的效果[13-18]。超快冷的冷却能力一般为层流冷却的2~5倍,含Nb钢轧后立即进入超快冷并在合适的相变区终止冷却,除了更好地发挥细晶强化、析出强化等强化机制外[14, 17],其相变强化效果也是不容忽视的。通过控制超快冷终冷温度在实现相变组织多样化控制的同时,其相变过程与传统层流冷却也发生了较大的变化。为了更好地将超快冷应用于含Nb钢的生产,有必要对超快冷条件下的相变行为进行研究。本文作者以某典型含Nb钢为研究对象,通过热模拟实验研究了前置式超快冷工艺条件下,超快冷对相变行为的影响机制,同时给出了实现相变强化所需超快冷的最低临界冷却速度,为开发低成本含Nb钢提供参考。

1 实验

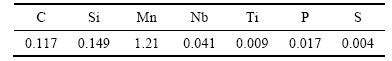

实验所用低C含Nb钢来自国内某钢厂,其化学成分如表1所示。

表1 实验钢的化学成分(质量分数)

Table 1 Chemical composition of experimental steel %

将实验坯料在实验室直径×长度为450 mm×450 mm二辊可逆式轧机上轧成12 mm厚的板材,然后机械加工成直径×长度为8 mm×15 mm的圆柱形热模拟试样。实验在MMS-300热力模拟实验机上进行。采用两阶段变形。第一阶段变形模拟粗轧阶段的再结晶区轧制;第二阶段变形模拟精轧阶段的未再结晶区轧制。具体实验方案如下。

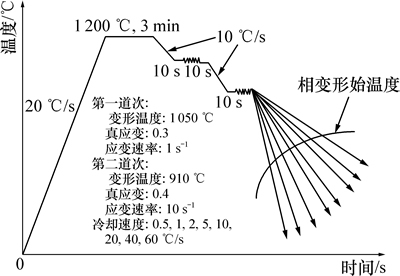

1.1 实验钢连续冷却转变(CCT)曲线的确定

实验目的:研究变形后的奥氏体在不同的冷却速度条件下的相变行为及显微组织, 获得实验钢的动态CCT曲线,为冷却工艺制度的制订提供依据。

将试样以20 ℃/s加热到1 200 ℃,保温3 min,然后以10 ℃/s的冷却速度冷却到1 050 ℃,保温10 s后进行压缩,真应变为0.3,应变速率为1 s-1,变形后保温10 s;然后以10 ℃/s冷至910 ℃,保温10 s后进行压缩,真应变为0.4,应变速率为10 s-1,再以不同的冷却速度(分别为0.5,1,2,5,10,20,40和60 ℃/s)冷却至室温,记录试样冷却过程中的膨胀 量-温度曲线。热模拟实验工艺如图1所示。

图1 动态CCT曲线实验示意图

Fig. 1 Experimental schematic illustration of dynamic CCT curves

实验后切取金相试样,研磨、抛光后采用体积分数为4%的硝酸酒精溶液进行腐蚀,在金相显微镜下观察组织,并结合膨胀曲线确定实验钢的相变温度,绘制动态CCT曲线。

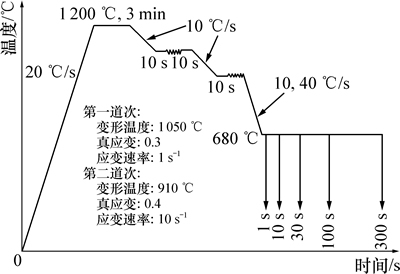

1.2 超快冷和层流冷却对含Nb钢相变的影响研究

实验目的:结合CCT曲线的结果,实验钢在变形后改变冷却速度分别模拟超快冷和层流冷却,探索超快冷技术在实验钢相变过程中所起的作用。

实验钢的加热及变形工艺同图1。试样变形结束后分别以40 ℃/s(模拟超快冷)和10 ℃/s(模拟层流冷却)冷却至680 ℃进行保温,保温不同时间(1 s,10 s,30 s,100 s,300 s)之后淬火。实验后制作金相试样,用金相显微镜观察组织。热模拟实验工艺如图2所示。

图2 不同冷却条件下相变实验示意图

Fig. 2 Experimental schematic illustration of phase transformation experiment under different cooling conditions

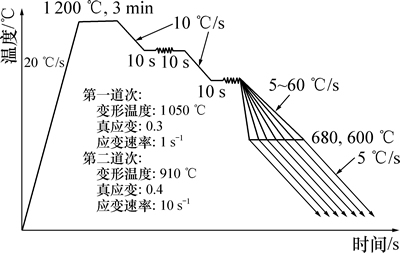

1.3 临界冷却速度的确定

实验目的:确定超快冷可发挥强化作用所需要的最低冷却速度。通过模拟两段式冷却过程,研究前段冷却速率及冷却终止温度对室温组织的影响。

实验钢的加热及变形工艺同图1。试样变形后先以不同的冷却速度(分别为5,10,20,30,40,50和60 ℃/s)冷却至680 ℃和600 ℃,然后再以5 ℃/s的冷却速度冷却至室温。实验后制作金相试样,观察显微组织并测试其宏观维氏硬度。热模拟实验工艺如图3所示。

图3 两段式冷却实验示意图

Fig. 3 Experimental schematic illustration of two-stage cooling experiment

2 实验结果与讨论

2.1 动态CCT曲线的绘制

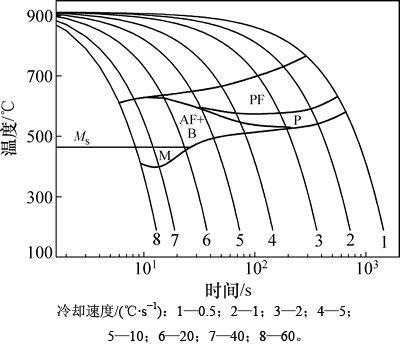

图4给出了实验钢的动态CCT曲线。由图4可以看出:实验钢相变区域可分为三部分:高温相变产物主要是先共析多边形铁素体(PF)和珠光体(P);中温相变产物是针状铁素体(AF)和贝氏体(B);低温相变产物为马氏体(M)。实验钢于680 ℃处于多边形铁素体相变区间;而当冷却速度大于20 ℃/s时,实验钢于 600 ℃处于针状铁素体+贝氏体相变区间。

图4 实验钢动态CCT曲线

Fig. 4 Dynamic CCT diagrams for experimental steel

2.2 2种冷却方式下的相变行为

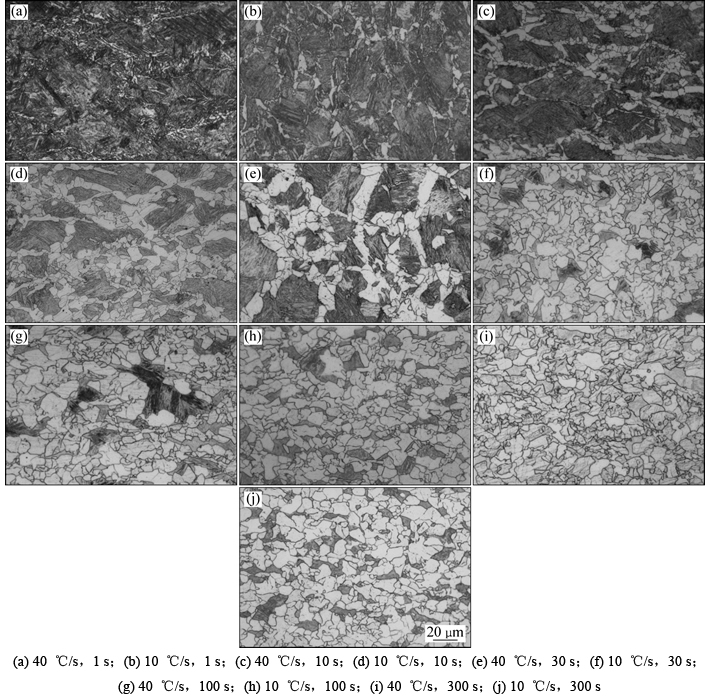

图5给出了变形后分别以40 ℃/s和10 ℃/s冷却至680 ℃保温不同时间淬火的金相组织照片。

从图5可以看出:随着保温时间的延长,铁素体含量逐渐增加,马氏体含量逐渐减少。

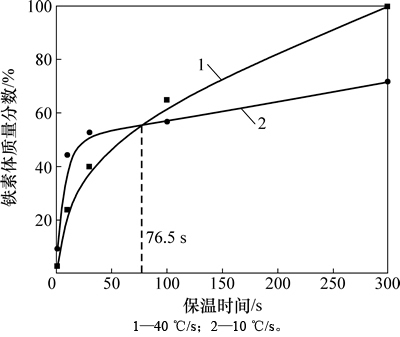

在同一坐标系下绘制铁素体质量分数随保温时间的变化关系图,如图6所示。由图6可以看出:在保温时间为1,10和30 s时,10 ℃/s冷却条件下得到的组织中铁素体含量要高于40 ℃/s冷却时的铁素体含量,而保温100 s和300 s时恰恰相反;大约在保温 76.5 s时二者铁素体含量相同,2条曲线交于1点。并且可以看出:在40 ℃/s冷却条件下,铁素体含量增加较快,且在保温300 s时相变全部完成;而在10 ℃/s冷却条件下,铁素体含量增加较慢,在保温300 s时铁素体相变只完成了72%左右。

这可以解释为:在奥氏体变形后冷却到保温温度的过程中,小冷却速度条件下经历的冷却时间要长 (10 ℃/s冷却时间为23 s,40 ℃/s冷却时间为5.75 s),因此,冷却过程中生成的铁素体较多,从而在保温时间较短时,总的铁素体含量要多于大冷却速度条件下的含量。但是,由于在大冷却速度条件下过冷度大,形核驱动力大,并且较大的冷却速度可以将变形后的奥氏体保留至相变之前,为铁素体相变提供更多的形核点,从而铁素体形核率要远远大于小冷却速度条件下的形核率。因此,随着保温时间的继续延长,大冷却速度对相变的促进作用开始凸显,使得铁素体含量迅速增加,并且较早完成相变过程。

2.3 前段临界冷却速度的确定

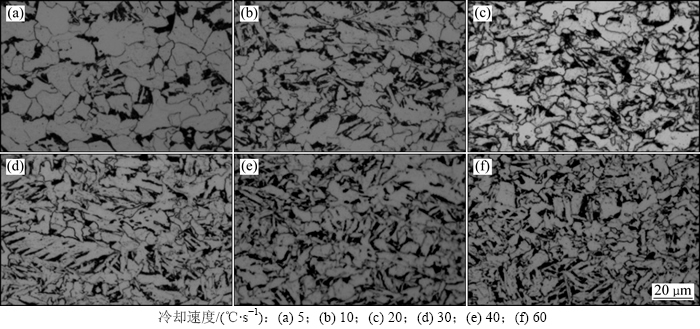

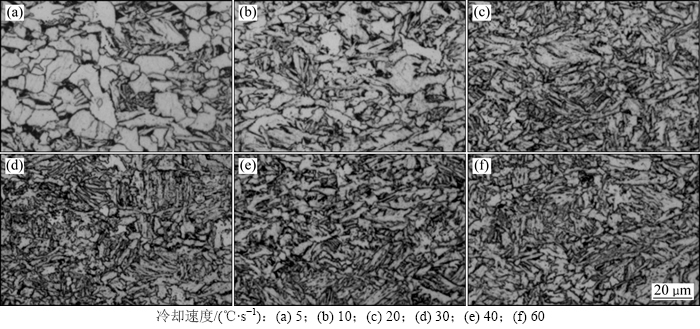

在实际生产过程中,采用两阶段冷却可以获得不同的相变组织。前段冷却速率及冷却终止温度对相变过程均有一定的影响。图7和图8所示为不同前段冷却条件下的部分金相组织。

由图7和图8可以看出:当前段冷却终冷温度为680 ℃时,在前段冷却速率较小时(5~20 ℃/s),得到组织为多边形铁素体、珠光体以及少量针状铁素体,随冷却速度增大铁素体含量逐渐减少;当冷却速度达到30 ℃/s时,针状铁素体含量显著增加;当冷却速度继续增大时,组织变化不明显,为针状铁素体、少量准多边形铁素体和珠光体的混合组织。当前段冷却终冷温度为600 ℃时,随着前段冷却速度的增加,组织也有类似的变化趋势。当冷却速度大于30 ℃/s时,组织变化不明显,以针状铁素体和贝氏体为主。

图5 680 ℃下保温不同时间后淬火的金相组织

Fig. 5 Quenching microstructure after different holding time at 680 ℃

图6 铁素体质量分数随保温时间的变化

Fig. 6 Variation of ferrite mass fraction with holding time

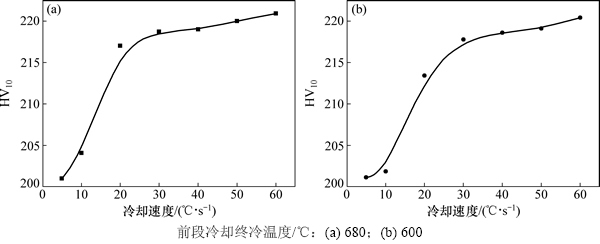

用KB3000BVRZ-SA型万能硬度计测定各试样的硬度,绘制冷却速度-维氏硬度曲线,如图9所示。由图9可以看出:在2种工艺条件下,当冷却速度从5 ℃/s增加到30 ℃/s时,硬度均增加较快,之后虽然冷却速度继续增大,硬度基本不变。这与分析金相组织得到的结论是一致的。

实验钢变形后采用超快冷+层流冷却的冷却模式时,超快冷的平均冷却速度必须大于30 ℃/s,更大的冷却速度对相变的影响不大。

图7 不同前段冷却条件下的金相组织(前段冷却终冷温度680 ℃)

Fig. 7 Microstructures of different forepart cooling conditions

图8 不同前段冷却条件下的金相组织(前段冷却终冷温度600 ℃)

Fig. 8 Microstructures of different forepart cooling conditions

图9 维氏硬度HV10随冷却速度的变化

Fig. 9 Variation of Vickers-hardness with cooling rates

3 结论

1) 确定了实验钢的动态CCT曲线,实验钢于680 ℃处于铁素体相变区;当冷却速度大于20 ℃/s时,实验钢于600 ℃处于针状铁素体和贝氏体相变区。

2) 采用层流冷却(10 ℃/s)和超快冷(40 ℃/s)冷却至铁素体相区(680 ℃)保温发现,随保温时间延长,多边形铁素体含量均增多,当保温时间达到约76.5 s时,多边形铁素体含量相当,且超快冷工艺下多边形铁素体含量增加较快。

3) 实验钢变形后采用两段式冷却,当前段冷却终止温度为680 ℃和600 ℃,冷却速度达到30 ℃/s时,组织中出现了针状铁素体等硬相组织,继续增大冷却速度,对最终相变组织影响不大。

参考文献:

[1] EGHBALI B, ABDOLLAH-ZADEH A. Influence of deformation temperature on the ferrite grain refinement in a low carbon Nb-Ti microalloyed steel[J]. Journal of Materials Processing Technology, 2006, 180(1/2/3): 44-48.

[2] OKAMOTO R, BORGENSTAM A, AGREN J. Interphase precipitation in niobium-microalloyed steels[J]. Acta Materialia, 2010, 58(14): 4783-4790.

[3] OGAWA T, SUGIURA N, MARUYAMA N, et al. Influence of state of Nb on recrystallization temperature during annealing in cold-rolled low-carbon steels[J]. Materials Science & Engineering A, 2013, 564: 42-45.

[4] CHALLA V S A, ZHOU W H, MISRA R D K, et al. The effect of coiling temperature on the microstructure and mechanical properties of a niobium-titanium microalloyed steel processed via thin slab casting[J]. Materials Science & Engineering A, 2014, 595: 143-153.

[5] PRIADI D, NAPITUPULU R A M, SIRADJ E S. Austenite grain growth calculation of 0.028% Nb steel[J]. Journal of Mining and Metallurgy, Section B: Metallurgy, 2011, 47(2): 199-209.

[6] MISRA R D K, ZHENG H, WU K M, et al. Niobium-containing quenching and partitioning processed ultrahigh strength martensite-austenite dual phase steels[J]. Materials Science & Engineer A, 2013, 579: 188-193.

[7] LAN L Y, QIU C L, ZHAO D W, et al. Dynamic and static recrystallization behavior of low carbon high niobium microalloyed steel[J]. Journal of Iron and Steel Research International, 2011, 18(1): 55-60.

[8] SHANMUGAM S, MISRA R D K, HARTMANN J, et al. Microstructure of high strength niobium-containing pipeline steel[J] Materials Science & Engineering A, 2006, 441(1): 215-229.

[9] EGHBALI B, ABDOLLAH-ZADEH A. Deformation-induced ferrite transformation in a low carbon Nb-Ti microalloyed steel[J]. Materials and Design, 2007, 28(3): 1021-1026.

[10] PIETRZYK M, ROUCOULES C, HODGSON P D. Modelling the thermomechanical and microstructural evolution during rolling of a Nb HSLA steel[J]. ISIJ International, 1995, 35(5): 531-541.

[11] MEDINA S F. The influence of niobium on the static recrystallization of hot deformation austenite and on strain induced precipitation kinetics[J], Scripta Metallurgica et Materialia, 1995, 32(1): 43-48.

[12] OKAGUCHI S, HASHIMOTO T. Computer model for prediction of carbonitride precipitation during hot working in Nb-Ti bearing HSLA steels[J]. ISIJ International, 1992, 32(3): 283-290.

[13] 王国栋. 以超快冷为核心的新一代TMCP技术[J]. 上海金属, 2008, 30(2): 1-5.

WANG Guodong. The new generation TMCP with the key technology of ultra fast cooling[J]. Shanghai Metals, 2008, 30(2): 1-5

[14] 王国栋. 新一代控制轧制和控制冷却技术与创新的热轧过程[J]. 东北大学学报(自然科学版), 2009, 30(7): 913-922.

WANG Guodong. New generation TMCP and innovative hot rolling process[J]. Journal of Northeastern University (Natural Science), 2009, 30(7): 913-922.

[15] AURELIE L, PIERRE S, GUILLAUME B, et al. Metallurgical aspects of ultra fast cooling in front of the down-coiler[J]. Steel Research International, 2004, 75(2): 139-146.

[16] HERMAN J C. Impact of new rolling and cooling technologies on thermomechanically processed steels[J]. Ironmaking and Steelmaking, 2001, 28(2): 159-163.

[17] WANG Bin, LIU Zhenyu, ZHOU Xiaoguang, et al. Precipitation behavior of nanoscale cementite in hypoeutectoid steels during ultra fast cooling(UFC) and their strengthening effects[J]. Materials Science & Engineering A, 2013, 575:189-198.

[18] TANG S, LIU Z Y, WANG G D, et al. Microstructural evolution and mechanical properties of high strength microalloyed steels: ultra fast cooling(UFC) versus accelerated cooling(ACC)[J]. Materials Science & Engineering A, 2013, 580: 257-265.

(编辑 杨幼平)

收稿日期:2015-12-18;修回日期:2016-03-23

基金项目(Foundation item):国家自然科学基金资助项目(51004037);辽宁省自然科学基金资助项目(2015020180);中央高校基本科研业务费专项资金资助项目(N140704002,N130307001)(Project(51004037) supported by the National Natural Science Foundation of China; Project(2015020180) supported by the Natural Science Foundation of Liaoning Province, China; Projects(N140704002, N130307001) supported by the Fundamental Research Funds for the Central Universities)

通信作者:周晓光,博士,副教授,从事钢铁材料组织性能控制与预测等研究;E-mail:xiaoguangzhou@126.com