文章编号:1004-0609(2011)07-1632-07

热等静压法制备高立方织构的镍基合金复合基带

邱火勤1, 索红莉1, 寇生中1, 2, 马 麟1, 田 辉1, 刘 敏1, 袁冬梅1, 王营霞1

(1. 北京工业大学 材料科学与工程学院,北京 100124;

2. 兰州理工大学 材料科学与工程学院,兰州 730050)

摘 要:采用热等静压(HIP)法制备芯层为Ni-12%W(Ni12W,摩尔分数)合金、外层为Ni-5%W(Ni5W,摩尔分数)合金的Ni5W/Ni12W/Ni5W 3层复合初始坯锭;采用压延辅助双轴织构技术(RABiTSTM)通过直接冷轧及再结晶退火获得Ni5W/Ni12W/Ni5W复合基带;采用X射线四环衍射技术(XRD)及背散射电子衍射技术(EBSD)对复合基带表面冷轧及再结晶织构进行分析。结果表明:冷轧复合基带表面形成较强的铜型形变织构,再结晶退火后复合基带表面形成锐利的立方织构,其立方织构含量达到99.1%(≤10°),与商业用Ni5W合金基带水平相当。

关键词:镍基复合基带;热等静压;铜型织构;立方织构

中图分类号:TM 26 文献标志码:A

Fabrication of Ni-based alloy composite substrate with

high cube texture using hot isostatic presses method

QIU Huo-qin1, SUO Hong-li1, KOU Sheng-zhong1, 2, MA Lin1,

TIAN Hui1, LIU Min1, YUAN Dong-mei1, WANG Ying-xia1

(1. College of Materials Science and Engineering, Beijing University of Technology, Beijing 100124, China;

2. College of Materials Science and Engineering, Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: A tri-layer composite alloy ingot was fabricated by hot isostatic presses (HIP) method, in which the outer layer is Ni-5%W(Ni5W, mole fraction) alloy and the inner layer is Ni-12%W(Ni12W, mole fraction) alloy. The composite ingot was cold-rolled using the process of rolling assisted biaxially textured substrate (RABiTSTM) technology and annealed to obtain the Ni5W/Ni12W/Ni5W composite substrate with high cube texture. The cold rolling and the recrystallization textures on the surface of the as-obtained composite substrate were studied systematically by X-ray and EBSD measurements. The results show that a strong deformation copper-type texture is obtained in the cold rolled composite substrate, and a sharp cube texture is formed on the surface of Ni5W/Ni12W/Ni5W composite substrate after a recrystallization annealing process. The percentage of the cube orientated grain within a misorientation angle of 10° is as high as 99.1%, which is in the same level as that of the commercial Ni5W tape.

Key words: Ni-based composite substrate; hot isostatic press; copper-type texture; cube texture

1996年,美国橡树岭国家实验室(ORNL)的NORTON[1]等发现,金属纯镍(Ni)通过压延辅助双轴织构技术(RABiTSTM)能够形成锐利的立方织构。但是,由于其具有铁磁性(273 K时饱和磁化强度为0.575 A·m2/g)[2]、屈服强度低(300 K 时为34 MPa)以及退火后晶界较深等无法克服的本征缺陷,因此,无法满足工业化发展的要求。而获得高强度、低磁性及高立方织构的金属基带是制备高性能高温涂层超导体的前提。为了解决纯Ni基带存在的本征问题,近几年来,复合基带引起了人们的广泛关注,并成为研究的热点。在复合基带中采用易获得强立方织构的合金作为外层材料,而将高强度、无(或低)磁性的合金作为芯层材料[3-4]。制备复合基带的技术核心是控制条件使得内、外层具有相近的再结晶温度和相似的力学变形性能,保证复合基带的外层织构度、连接性以及良好的表面形貌[5]。目前,制备多层复合基带的方法主要有套管法[6-7]、共轧制法[8]和复合坯锭法[9-12]。复合坯锭法的核心思路如下:首先制备具有多层结构且内、外层界面结合良好的复合坯锭,然后经大变形量的轧制及再结晶退火工艺,获得复合基带。与套管法及共轧制法相比,采用复合坯锭法制备复合基带避免了轧制加工过程中的热轧过程,一方面能大幅降低对轧机的要求,另一方面能避免热轧中不稳定因素的影响。采用复合坯锭法制备的复合基带表层具有锐利的立方织构,磁性及力学性能都有较大程度的提高,能很好地满足涂层导体的应用要求。

目前,获得复合坯锭的方法主要有熔炼法、常规无压烧结法及先进的放电等离子体烧结法。研究发现,在采用上述3种现有方法制备复合基带时,直接冷轧过程中都可能存在一定的开裂现象,特别是制备大尺寸的复合坯锭来大规模制备复合长带时,更易出现开裂现象。这是由于复合坯锭的外层与芯层间元素无法得到充分扩散或扩散不均匀,导致复合坯锭界面层间结合力较弱。另外,采用常规无压烧结法得到的复合坯锭的本征缺陷(如气孔、溶质在晶界偏析等)较多,加工性能差,如果提高烧结温度或延长烧结时间,初始坯锭的晶粒将异常长大,导致脆性,这些都将导致后期轧制过程中开裂现象。同时,晶粒的异常长大对后续再结晶立方织构的形成也有一定影响。目前,为了获得均匀而细化的组织,许多粉末冶金制品的生产采用热等静压工艺进行成型及致密化。热等静压工艺是将制品置于密闭容器中,向制品施加各向同等压力,同时施以高温,在高温、高压的作用下,使得制品能够快速地烧结和致密化[13-15]。因此,本文作者首先采用热等静压法制备出外层与芯层间界面结合良好、本征缺陷较少、晶粒尺寸较小的复合初始坯锭,然后通过RABiTSTM技术制备外层为Ni5W合金、芯层为Ni12W合金的强立方织构的Ni基合金复合基带,并对复合基带表面的冷轧织构及再结晶退火织构进行分析与表征。

1 实验

将Ni粉和W粉(纯度为99.9%)按Ni-5%W(摩尔分数)及Ni-12%W(摩尔分数)进行称量配比,再分别采用高能球磨机混合成Ni5W和Ni12W两种混合粉末;将充分球磨后的混合粉末分别按Ni5W/Ni12W/ Ni5W(各层厚度比约为1?1?1)的顺序逐次放入冷等静压橡胶模具中,用冷等静压成型(压力为250 MPa,保压5 min);采用热等静压法压制烧结(烧结工艺:温度1 200 ℃,压力120 MPa,保温保压时间6 h,工作介质为纯Ar)得到初始厚度约为10 mm的复合坯锭;再将此复合坯锭通过直接冷轧工艺得到厚度约为95 μm的复合基带(道次变形量小于5%,最终形变量约为99%);将冷轧复合基带在Ar-4%H2气氛中进行再结晶退火处理,得到具有强立方织构的Ni5W/Ni12W/Ni5W复合基带。退火工艺采用两步退火工艺[16],即在750 ℃保温0.5 h,然后再升温到1 250 ℃保温2 h。

用布鲁克Advanced D-8 X射线衍射仪对冷轧复合基带形变织构进行测量与分析。用配备EBSD附件的场发射扫描电镜(JEOL JSM6500F)对再结晶退火后复合基带表面进行微取向表征,对其晶粒取向分布和晶界特征等信息进行采集与分析。

2 结果与讨论

2.1 冷轧基带表面形变织构分析

研究表明:高层错能的面心立方金属(FCC)经大形变量轧制后,可获得冷轧形变织构(包括Copper(112) á111?和S(123) á634? 型形变取向)﹑Brass(011) á211?取向及Goss(011) á100?取向。其中,铜型形变织构(Copper和S型形变取向)的存在是金属经再结晶退火工艺后能够形成锐利立方织构的主要原因[17]。一般认为,大变形后的金属板材经再结晶退火后,立方晶粒的形核容易发生在C取向基体中,并与基体形成大角度晶界。这是由于Copper取向基体中具有较高的形变储能,因此,立方晶核的长大能够消耗C组织,使其储能得到充分的释放。同时,根据取向生长原 理[18-19],再结晶晶核与基体接近某一有利的取向关系时,其晶界迁移率较高,能够迅速长大,对最终再结晶织构起决定性作用。 经统计与理论计算证明,在FCC金属中,当再结晶晶核与基体存在40°á111?取向关系时,其晶界迁移率较快,能够迅速长大。而相关研究证明,在FCC金属合金形变冷轧织构中,S取向与立方织构取向之间存在沿着á111?晶轴转动40°的关系。综上所述,冷轧基带中的铜型形变织构是金属基带再结晶退火后获得立方织构的主要因素之一。

本文作者采用X射线衍射技术对获得的冷轧基带表面形变织构进行宏观表征。图1(a)所示为冷轧Ni5W/Ni12W/Ni5W复合基带的(111)面极图。将其与标准冷轧铜型形变织构(见图1(b) [20])进行对比可以看出,该冷轧复合基带表面形成了很强的铜型织构。

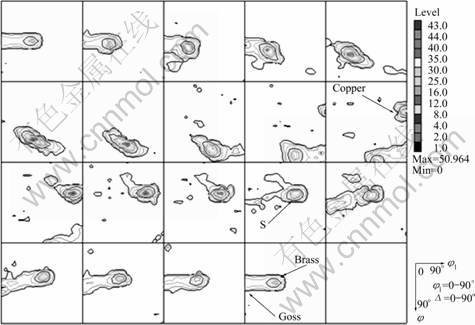

利用取向分布函数图(ODF)可以从三维欧拉空间更准确地判断各取向线的强度变化,图2所示为沿φ2从0?到90?,每隔5?取截面,绘制出冷轧Ni5W/Ni12W/Ni5W复合基带的ODF截面图。在(φ1,φ,φ2)为(90?,35°,45°)的Copper取向、(φ1,φ,φ2)为(59?,37°,63°)的S取向及(φ1,φ,φ2)为(35?,45°,0°)的Brass取向处,从等高线可看出,相应的织构强度较高;而在(φ1,φ,φ2)为(0?,45°,0°)的Goss取向处,强度较弱,说明其Goss取向织构含量较低。冷轧复合基带表面各个取向织构的体积分数见表1。由表1可知:对后续再结晶退火获得锐利立方织构有利的Copper及S取向的含量分别达到了17.99% 和38.36%,而不利于再结晶立方织构形成的Goss取向织构仅为6.99%。

图1 冷轧Ni5W/Ni12W/Ni5W复合基带的(111)面极图及冷轧铜型织构(111)面极图[20]

Fig.1 (111) pole figure of cold rolled Ni5W/Ni12W/Ni5W composite tape (a) and (111) pole figure for Cu-type rolling texture(b)[20]

图2 冷轧Ni5W/Ni12W/Ni5W复合基带的ODF图

Fig.2 ODF maps of cold-rolled Ni5W/Ni12W/Ni5W composite tape

表1 冷轧Ni5W/Ni12W/Ni5W复合基带各取向的体积分数

Table 1 Orientation and volume fractions of components for cold-rolled Ni5W/Ni12W/Ni5W composite tape

综上所述,采用本研究方法制备的Ni基复合初始坯锭,经直接冷轧后所得的冷轧复合基带表面形成了很强的铜型织构,这为其后续采用优化的再结晶退火工艺获得较强立方织构提供了必要的前提条件。

2.2 复合基带再结晶织构分析

基于“外延”生长的机理[1]要求采用RABiTSTM技术制备的金属基带表面晶粒能形成锐利的立方织构取向,即{001}á100?取向。因此,对涂层导体用复合基带的再结晶织构取向分析是表征基带性能优劣的一个重要方法。本文作者采用配备EBSD附件的场发射扫描电镜(JEOL JSM6500F)对所制备的复合基带经再结晶退火后的表面进行微取向表征,并对其晶粒取向分布及晶界特征等信息进行采集与分析。

2.2.1 复合基带表面晶粒微取向信息

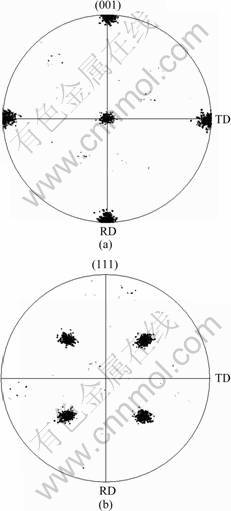

图3所示为根据背散射菊池花样计算得出的复合基带表面的(001)面和(111)面极图。由图3可以看出,其背底很干净,表明该复合基带表面形成了锐利的再结晶立方织构。

图4所示为复合基带表面的EBSD微取向晶粒分布。图4中用灰色到黑色标记与标准立方取向偏离10°以内的晶粒,超过10°的用白色标记,所有晶粒取向与立方织构均由计算机软件(Orientation image micrograph,OIM)自动采集和计算得出。由图3及4可知,大部分晶粒为立方织构,与标准的立方织构偏离10°以内的晶粒占总面积的99.1%,表现出良好的择优取向生长特性。

图5所示为再结晶织构与理想立方取向偏离角度分布图。它表示与理想立方取向偏离一定角度的再结晶晶粒所占面积的百分比。横坐标表示其与理想立方晶粒偏离的角度,纵坐标表示对应的晶粒面积占所有晶粒面积的百分比。其中,图5(b)所示为由图5 (a)的曲线积分所得。从图5(b)可以看出,当假设与理想立方取向偏离10°以内为立方织构时,则立方晶粒所占的面积达到99.1%。此外,再结晶取向分布曲线存在明显峰值,这说明与理想立方取向偏离角为4.25°的晶粒比例最高。

图3 再结晶复合基带表面的(001)面和(111)面极图

Fig.3 (001) (a) and (111) (b) pole figures of Ni5W/ Ni12W/Ni5W composite tape after recrystallization

图4 退火后Ni5W/Ni12W/Ni5W复合基带的EBSD图

Fig.4 EBSD map of annealed Ni5W/Ni12W/Ni5W composite tape

相关研究表明,在FCC金属合金中,要使其在再结晶退火后获得强立方织构,可以通过控制初始坯锭的晶粒长大来提高基带在再结晶后其立方晶粒的含量[21]。因此,相比常规无压烧结法,本实验中采用边加压、边烧结的热等静压制坯工艺从一定程度上缩短了压块的均匀化保温时间,因此,采用热等静压法能得到晶粒尺寸较小的复合初始坯锭。复合初始坯锭通过后续的优化轧制及再结晶退火工艺后能获得锐利立方织构的Ni5W/Ni12W/Ni5W复合基带。

图5 Ni5W/Ni12W/Ni5W复合基带的再结晶织构与理想立方取向偏离角度分布及立方晶粒分布曲线

Fig.5 Cube texture as function of deviation angle of Ni5W/Ni12W/Ni5W composite tape(a) and distribution curve of cube grains in Ni5W/Ni12W/Ni5W composite tape (b)

2.2.2 复合基带的表面晶界分布特征

钇钡铜氧(YBCO)超导材料具有晶界弱连接的特性,因此,YBCO薄膜的临界电流受晶界夹角的影响很大。DIMOS等[22]研究发现,如果YBCO薄膜的ab面内存在大角度晶界,则超导材料的临界电流密度不可能提高。因此,晶界(GBs)特征是表征基带性能的另一个重要指标。

图6所示为复合基带不同角度的晶界分布图。图中采用不同的灰度值及线条粗细代表不同角度的 晶界。

图6 Ni5W/Ni12W/Ni5W复合基带不同角度的晶界分布

Fig.6 Grain boundary distribution Ni5W/Ni12W/Ni5W composite tape with different misorientation angles

图7所示为复合基带晶界随微取向角的变化曲线,即不同角度晶界含量的定量分布曲线。从图6与7可以看出,采用热等静压制坯法制备的复合基带在10°以下小角度晶界的含量达到89.9%,且其峰值为6.33°。综上所述,此复合基带具有很好的晶界特性,能很好地满足后续过渡层及超导层外延生长的需求。

图7 Ni5W/Ni12W/Ni5W复合基带晶界随微取向角变化 曲线

Fig.7 Grain boundary as function of misorientation angle of Ni5W/Ni12W/Ni5W composite tape

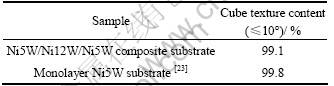

表2所列为本文作者制备的Ni基复合基带与德国EICKEMEYER等[23]实验室制备的单层Ni5W 基带的结果。由表2可知,采用本研究提出的工艺路线,可获得再结晶立方织构含量很高的Ni基复合基带。特别是采用本文作者提出的热等静压法制坯技术,可以获得较高立方织构含量的NiW复合基带,而且有望通过下一步的研究阐明热等静压法在制备初始坯锭上所特有的优势,进一步优化制备工艺,获得更高立方织构的NiW复合基带。

表2 Ni5W/Ni12W/Ni5W复合基带与单层Ni5W 基带[23]的比较

Table 2 Comparison of home-prepared Ni5W/Ni12W/ Ni5W composite substrate and monolayer Ni5W substrates[23]

3 结论

1) 采用热等静压制坯法制备出Ni5W/Ni12W/Ni5W复合合金初始坯锭,经直接冷轧和再结晶退火工艺获得了锐利立方织构的Ni5W/Ni12W/Ni5W复合金属基带。

2) Ni5W/Ni12W/Ni5W冷轧复合基带形成了很强的铜型形变织构,其中Copper(112)á111?与S(123) á634?的含量分别达到17.99%和38.66%,为后续再结晶退火后形成强立方织构提供了必要的前提条件。

3) Ni5W/Ni12W/Ni5W复合基带的再结晶立方织构含量(与理想立方织构偏离角≤10°)达到99.1%;小于10°的小角度晶界占总晶界长度的89.9%。表明制备的复合基带具有锐利立方织构,可以满足进一步制备高性能涂层导体的要求。

REFERENCES

[1] NORTON D P, GOYAL A, BUDAR J D, CHRISTEN D K, SPECHTE E D, HE Q, SAFFIAN B, PARANTHAMAN M, KLABUNDE C E, LEE D F, SALES B C, LIST F A. Epitaxial YBa2Cu3O7 on biaxially textured nickel (001): An approach to superconducting tapes with high critical current density [J]. Science, 1996, 274: 755-757.

[2] IJADUOLA A O, THOMPSON J R, GOYAL A, THIEME C L H, MARKEN K. Magnetism and ferromagnetic loss in Ni-W textured substrates for coated conductors [J]. Physica C, 2004, 403: 163-171.

[3] SHI D Q, DOU S X, KO R K, CHUNG J K, KIM H S, HA H S, SONG K J, PARK C. YBCO coated conductor using biaxially textured clad composite Ni-Mn/Ni-Cr substrate [J]. Superconductor Science and Technology, 2005, 18: 1045-1049.

[4] SUBRAMANYA SARMA V, de BOER B, EICKEMEYER J, HOLZAPFEL B. On the development of high strength and biaxially textured Ni-3%W/Ni-10%Cr-1.5%Al composite substrate for coated conductor application [J]. Scripta Materialia, 2003, 48(8): 1167-1171.

[5] 赵 跃, 索红莉, 刘 敏, 何 东, 祝永华, 高忙忙, 周美玲. 涂层导体金属基带的研究进展[J]. 中国有色金属学报, 2008, 18(3): 457-464.

ZHAO Yue, SUO Hong-li, LIU Min, HE Dong, ZHU Yong-hua, GAO Mang-mang, ZHOU Mei-ling. A review of metal substrates for coated conductors [J].The Chinese Journal of Nonferrous Metals, 2008, 18(3): 457-464.

[6] WATANABE T, MATSUMOTO K, TANIGAWA T, MAEDE T, HIRABAYASHI I. Surface-oxidation epitaxy of Ni-clad Ni-20wt%Cr and Ni-clad austenitic stainless steel tapes for Y-Ba-Cu-O coated conductors [J]. IEEE Transactions on Applied Superconductivity, 2001, 11(1): 3134-3137.

[7] MIYOSHI K, NAGASU Y, OHASHI Y, SAKAMOTO H, MIMURA M, FUKUSHIM H. Development of textured substrates with high strength and weak magnetism [J]. Physica C, 2006, 445/448: 614-619.

[8] GOYAL A. Preparation of biaxially textured coated article having cube texture, involves plastically deforming and recrystallizing coated metal article preform to form biaxial texture that exhibit specific X-ray diffraction peak: US, 6375768- B1[P]. 2002-04-23.

[9] ZHAO Yue, SUO Hong-li, LIU Min, HE Dong, ZHANG Ying-xiao, MA Lin, ZHOU Mei-ling. Highly reinforced and cube textured Ni alloy composite substrates by a hybrid route [J]. Acta Materialia, 2007, 55: 2609-2614.

[10] LIU Min, SUO Hong-li, ZHAO Yue, HE Dong, ZHANG Ying-xiao, MA Lin, FAN Rui-fen, ZHOU Mei-ling. A novel technique for developing composite substrates used in YBCO coated conductors [J]. Scripta Materialia, 2007, 56: 129-131.

[11] SUO Hong-li, ZHAO Yue, LIU Min, ZHANG Ying-xiao, HE Dong, MA Lin, JI Yuan, ZHOU Mei-ling. Technique for developing highly strengthened and biaxially textured composite substrates for coated superconductor tapes [J]. Acta Materialia, 2008, 56: 23-30.

[12] 何 东, 索红莉, 赵 跃, 刘 敏, 周 婕, 张迎肖, 马 麟, 李亚明, 周美玲. 用放电等离子技术(SPS)制备高性能的Ni基合金复合基带[J]. 功能材料, 2006, 37: 290-293.

HE Dong, SUO Hong-li, ZHAO Yue, LIU Min, ZHOU Jie, ZHANG Ying-xiao, MA Lin, LI Ya-ming, ZHOU Mei-ling. Fabrication of Ni based composite substrate with high performances for coated conductors using sparking plasmas method [J]. Function Materials, 2006, 37: 290-293.

[13] KIM M T, KIM D S, OH O Y. Effect of γ′ precipitation during hot isostatic pressing on the mechanical property of a nickel-based superalloy [J]. Materials Science and Engineering A, 2008, 480: 218-225.

[14] KIM M T, CHANG S Y, WON J B, PARK H W. Effect of hot isostatic pressing on the microstructure and mechanical properties of vitreous enamel coatings on low carbon steel [J]. Surface and Coatings Technology, 2006, 201: 3281-3288.

[15] SU?REZ M, FERN?NDEZ A, MEN?NDEZ J L, NYGREN M, TORRECILLAS R, ZHAO Z. Hot isostatic pressing of optically active Nd:YAG powders doped by a colloidal processing route [J]. Journal of the European Ceramic Society, 2010, 30: 1489-1494.

[16] ZHAO Yue, SUO Hong-li, LIU Min, LIU Dan-min, ZHANG Ying-xiao, ZHOU Mei-ling. Development of cube textured Ni-5at.%W alloy substrates for coated conductor application using a melting process [J]. Physica C, 2006, 440: 10-16.

[17] HIRSCH J, L?CKE K. Mechanism of deformation and development of rolling textures in polycrystalline fcc metals. I: Description of rolling texture development in homogeneous CuZn alloys [J]. Acta Metallurgica, 1988, 36(11): 2863-2882.

[18] DUGGAN B J, SINDEL M, K?HLHOFF G D, L?CKE K. Oriented nucleation, oriented growth and twinning in cube texture formation [J]. Acta Metallurgica et Materialia, 1990, 38(1): 103-111.

[19] HUMPHREYS F J, HATHERLY M. Recrystallization and related annealing phenomena [M]. 2nd ed. New York: Elsevier, 2004: 379-413.

[20] DOHERTY R D, HUGHES D A, HUMPHREYS F J, JONAS J J, JUUL JENSEN D, KASSNER M E, KING W E, MCNELLEY T R, MCQUEEN H J, ROLLETT A D. Current issues in recrystallization: A review [J]. Materials Science and Engineering A, 1997, 238: 219-274.

[21] SUO H L, GENOUD J Y, TRISCONE G, WALLKER E, SCHINDL M, PASSERINI R, CLETON F, ZHOU M, FLUKIGER R. Preparation and characterization of {001}á100? cube textured Ag substrates for in-plane orientation HTS tapes [J]. Superconductor Science and Technology, 1999, 12: 624-632.

[22] DIMOS D, CHAUDHARI P, MANNHART J. Superconducting transport-properties of grain-boundaries in YBa2Cu3O7 bicrystals [J]. Physical Review B, 1990, 41: 4038-4049.

[23] EICKEMEYER J, SELBMANN D, OPITZ R, de BOER B, HOLZAPFEL B, SCHULTZ L, MILLER U. Nickel-refractory metal substrate tapes with high cube texture stability [J]. Superconductor Science and Technology, 2001, 14: 152-159.

(编辑 陈卫萍)

基金项目:国家重点基础研究发展计划资助项目(2006CB601005);国家高技术研究发展计划资助项目(2009AA032401);国家自然科学基金资助项目(50771003,50802004);北京市自然科学基金资助项目(2092006);教育部新世纪优秀人才资助项目(39009001201002)

收稿日期:2010-07-05;修订日期:2010-11-18

通信作者:索红莉,教授,博士;电话:010-67392947;E-mail: honglisuo@bjut.edu.cn