文章编号:1004-0609(2010)S1-s0284-05

钢-铝轧制复合界面化合物的抑制机理

王 平,谢佩佩

(东北大学 电磁材料过程研究教育部重点实验室,沈阳 110004)

摘 要:采用扫描电镜和金相显微镜研究钢-铝轧制复合界面化合物的合金化抑制机理。结果表明:通过在铝中加入合金元素硅, 界面化合物的生成受到明显的抑制, 特别是当硅含量达到6.0%(质量分数)时, 抑制作用更强,即使在560 ℃加热时, 界面层的厚度也仅为2~3 μm, 且主要是Fe2Al5;由于Fe和Al扩散均匀,界面化合物在界面处呈等宽连续分布。通过热力学原理阐述界面化合物的生成规律。

关键词:轧制复合; 界面化合物; 抑制作用; 生成规律

中图分类号:TG335.81 文献标志码:A

Restraining mechanism of compound of

steel-aluminum rolling bonding composite board

WANG Ping, XIE Pei-pei

(Key Laboratory of Electromagnetic Processing of Materials, Ministry of Education,

Northeastern University, Shenyang 110004, China)

Abstract: Through scanning electron microscopy and metallograph microscopy, the restraining mechanism of steel aluminum rolling bonding interfacial high temperature compound building was investigated. The results show that, by adding alloying element Si to aluminium and nitrogen to steel, the interfacial compound building is obviously restrained. Besides, the more the Si element added is, the stronger the restraining effect is. When the mass fraction of Si is 6.0%, the restraining action is the stronger. Even when the heating temperature is 560 ℃, the thickness of the interfacial compound is 2-3 ?m and mostly the portion is Fe2Al5. Because Fe and Al diffuse, the same width of continuous interfacial compound is built. In conclusion, Si evidently restrains the interfacial compound building. The interfacial compound of mechanism is clarified by thermodynamics theory building.

Key words: rolling bonding; interfacial compound; restrain; formation rule

钢-铝复合材料具有钢的高强度、韧性和耐磨性以及铝的低密度和耐腐蚀性等特点, 可以满足许多特殊使用要求, 为此, 人们进行大量的研究工作, 并已获得许多有价值的结果[1-4]。杨连发等[5]分别介绍了用于制造钢-铝层叠复合材料的可行的复合技术,并对各复合方法的工艺特点,主要工艺参数及技术要点进行分析与比较。但钢-铝轧制复合后, 其界面间相互作用形成化合物层, 化合物层是影响双金属复合材料性能的关键因素, 是界面处产生开裂的主要原因, 特别是对于高温下复合材料的应用尤显重要。因此, 要获得高品质的复合材料, 必须抑制化合物层的产生。这是复合材料能否广泛应用的关键问题, 也是目前尚没有解决的问题。2007年,宋群玲等[6]等通过在钢-铝复合材料界面添加Si、Zn、Mn、Ni微量合金元素来增强钢/铝界面的结合强度, 提高钢-铝复合材料的应用性能。对合金化界面进行剥离强度的测试, 并用XRD检测了结合界面的微观结构。结果表明,Si和Zn界面微合金化处理能显著提高钢/铝复合板界面性能。本文作者以轧制复合的钢-铝复合材料为例,通过在铝中加入不同量的合金元素硅,研究其在高温时界面化合物的生成规律及其抑制机理, 目的是探索硅对复合板间化合物生成所起到的抑制作用,以期为 钢-铝复合材料在高温下的应用奠定基础。

1 实验

合金以工业纯铝(含99.65% Al,质量分数)、金属硅、45#钢为原料。首先将纯铝和金属硅配比成含硅量分别为1.0%、1.5%、6.0%、10.0%(质量分数)的合金,之后在高温电阻炉中熔化,熔化温度设置为750 ℃。经过除气、精炼、扒渣,制成铝硅合金锭坯。铝硅合金锭坯再经过热轧机轧制成18 mm厚的薄板带。

合金板带与45#钢板经打磨后,在冷轧机上进行轧制复合(按照铝中硅元素含量, 分别标号为样品1、2、3、4), 成品复合材料厚度为2.0 mm,钢板和铝板的变形量在50%和70%之间,为比较硅元素对复合层界面化合物的影响,也同时制备了纯铝和45#钢的复合板,厚度也为2.0 mm, 标号为样品0。

轧制好的板带剪成100 mm×200 mm小块材料,在电阻炉中进行退火处理。退火为分级退火,即先在室温加热1 h到300 ℃,再加热30 min达到500、560、610 ℃, 并保温1 h。用光学显微镜观察分析界面化合物的数量和形貌,并采用扫描电镜进行界面化合物的物相分析。

2 结果与分析

2.1 界面金相组织

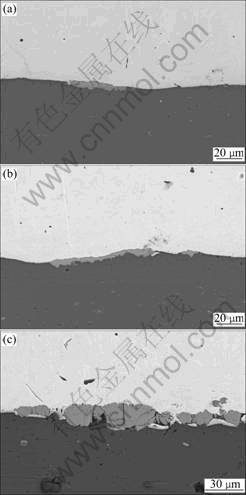

图1所示为纯铝和45#钢的复合板界面的显微组织。由图1可以看出,界面化合物生长随温度的变化规律, 界面处产生的化合物尺度随温度的升高而变长,且温度升高的速度越快,化合物生成的速度也会越快[2]。温度越高,原子运动越剧烈,铝和铁原子的扩散增强,因此在界面生成的化合物增多。在界面没有阻止铝铁扩散的因素,所以铝铁原子快速扩散,生成很厚的不连续的化合物层,严重影响界面结合强度。

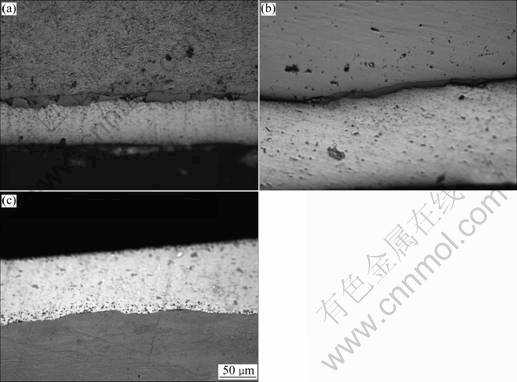

图2所示为560 ℃下退火不同硅含量钢-铝复合界面的显微组织。由图2可以看出, 在560 ℃下退火, 随硅含量的增多, 界面化合物生成的数量在减少。所以,Si明显地抑制界面化合物的生成,并在高温情况下,成功阻碍铁-铝之间的扩散。Si对保证钢-铝复合材料在较高温度下退火处理发挥了很大的作用,进而改善钢-铝复合材料的结合性能[3]。在500和610 ℃时,硅元素与铝形成化合物,并且生成的铝硅化合物对铁-铝之间的扩散起到阻碍作用。随硅含量的增多,生成的铝硅化合物增多,阻碍作用增强,有效抑制了界面化合物的生成。但如果硅含量过多(超过10.0%,质量分数),生成大量的铝硅化合物,并达到饱和,使铝硅化合物层变厚,并且容易脆化,那么不但不会使界面的高温结合强度增加,反而会使界面的结合强度减弱。

图1 不同温度时钢-铝复合界面显微组织

Fig.1 Microstructures of steel-aluminum composite interfacial at different temperatures: (a) 500 ℃; (b) 560 ℃; (c) 610 ℃

2.2 扫描电镜分析结果

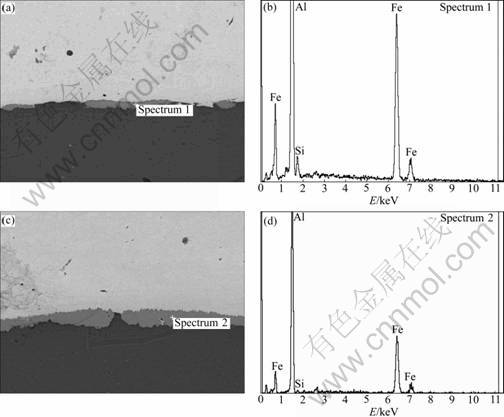

为了确定界面化合物的主要成分,对含Si量为1.5%不同温度下的退火界面组织分析, 如图3所示。

图2 560 ℃时不同Si含量的钢-铝复合界面的显微组织

Fig.2 Microstructures of steel-aluminum composite interfacial with different Si contents: (a) 1.0%; (b) 1.5%; (c) 6.0%

图3 含硅量1.5%时不同温度下退火复合界面的SEM像及EDS谱

Fig.3 SEM images ((a), (c)) and EDS patterns ((b), (d)) of component interface with 1.5% Si annealed at different temperatures: (a), (b) 560 ℃;(c), (d) 610 ℃

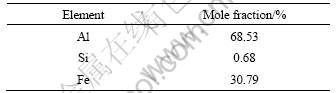

由图3可以看出, 在铝合金与钢复合并在一定温度退火后,它们的界面化合物的成分是Al、Fe和Si元素等形成的化合物。在表1中(560 ℃时),摩尔比为n(Fe):n(Al):n(Si)=11:30:1。则生成的化合物化学式为 (FeAl3)10(FeSi),则可以确定生成FeAl3和FeSi。这是因为在富铝区铁在铝中的固溶度很小,铁在650 ℃以下在铝中的扩散速率仅是铝在铁中扩散速率的万分之一[7]。因此,铝原子扩散的速率要比铁原子快的多,当温度达到560 ℃时,通过共晶反应形成FeAl3。在表2中,当温度在610 ℃,n(Fe):n(Al)≈2:5时,钛在富铝区铁的固溶度略微变大,铁原子有较高的能量穿过Fe-Si化合物层与铝形成Fe2Al5相。通过比较可以看出,Si在560 ℃以下时, 成功地抑制界面化合物的生长;当温度升高到610 ℃时, Si的抑制作用就明显变弱, 使界面生成的化合物主要为Fe2Al5相。

表1 含1.5%Si复合界面经560 ℃退火后的成分分析

Table 1 Component analyses of component interface with 1.5% Si after annealing at 560 ℃

表2 含1.5%Si复合界面经610 ℃退火后的成分分析

Table 2 Component analyses of component interface with 1.5% Si after annealing at 610 ℃

2.3 界面化合物生成的机理分析

在铝原子饱和的状态下,在钢与铝复合的反应扩散过程中最先形成的Fe-Al系化合物应当是FeAl相,其次是FeAl2和Fe2Al5相[8-12]。而Fe3Al相在温度高于500 ℃以上是不可能形成,因为,这时Fe3Al相的生成自由能为正值。其中FeAl2为亚稳态,它在与铝复合的过程中生成的可能性很小。当提高温度时,它将按下列反应式分解:

3FeAl2=Fe2Al5+FeAl ,  -5 191.63 J

-5 191.63 J

因此, 综合以上分析, 各种化合物的生成顺序是FeAl、FeAl2和Fe2Al5。所以,最终生成的界面化合物应该是Fe2Al5。但是,由于硅元素的加入,且 Fe-Si化合物的生成自由能比任何的Fe-Al化合物的生成自由能值负得多[13]。因此,在钢铝界面处最先形成的是Fe-Si化合物,Fe-Si化合物层有可能成为铁铝原子相互扩 散的障碍。

3 结论

1) 界面化合物的生成顺序依次是FeAl、FeAl2和 Fe2Al5。

2) 硅元素的加入有效抑制界面铁铝化合物的生成,阻碍了铁、铝之间的互相扩散,可以延缓或阻止Fe2Al5相的生成,在高温下仍保持较高的界面结合强度。

REFERENCES

[1] 于九明, 孝云祯, 王群骄, 方晓英, 崔光洙. 金属层状复合技术及其新进展[J]. 材料研究学报, 2000, 14(1): 1-5.

YU Jiu-ming, XIAO Yun-zhen, WANG Qun-jiao, FANG Xiao-ying, CUI Guang-zhu. New development of technology of clad metal [J]. Chinese Journal of Materials Research, 2000, 14(1): 1-5.

[2] 王建民, 朱 锡, 刘润泉. 铝/钢爆炸复合界面的显微分析[J]. 材料工程, 2006, 11: 1-5.

WANG Jian-min, ZHU Xi, LIU Run-quan. Aluminum/steel composite interface of microscopic analysis [J]. Journal of Materials Engineering, 2006, 11: 1-5.

[3] VENDRA L J, RABIEI A. A study on aluminum-steel composite metal foam processed by casting [J]. Materials Science and Engineering A, 2007, 465(1/2): 59-67.

[4] 张 伟, 范志康, 郭献军. 热浸镀铝钢渗铝层的微观组织及其形成机理研究现状[M]. 机械工程材料, 2006, 30(1): 1-4.

ZHANG Wei, FAN Zhi-kang, GUO Xian-jun. Summary of coating formation mechanism and microstructuring hot dip aluminizing on steel [M]. Materials and Mechanical Engineering, 2006, 30(1): 1-4.

[5] 杨连发. 钢-铝层叠复合材料固态复合技术及应用[J].桂林电子工业学院学报, 2004, 24(3): 91-94.

YANG Lian-fa. The solid union technology for manufacturing laminated composite materials of aluminum and steel [J]. Journal of Guilin University of Electronic Technology, 2004, 24(3): 91-94.

[6] 宋群玲, 马 娟, 胡日博, 张文莉, 全 红. 界面微合金化对钢/铝复合板性能影响的研究[J]. 昆明冶金高等专科学校学报, 2007, 23(1): 1-5.

SONG Qun-ling, MA Juan, HU Yue-bo, ZHANG Wen-li, QUAN Hong. Towards influence of interfacial microalloy on the capacity of St-Al bimetallic plate [J]. Journal of Kunming Metallurgy College, 2007, 23(1): 1-5.

[7] 冯伟年, 刘光曙. 金属与合金的电化学热处理[M]. 北京: 机械工业出版社, 1989.

FENG Wei-nian, LIU Xian-shu. Electrochemical heat treatment of the metal and alloy [M]. Beijing: China Machine Press, 1989.

[8] 高海燕, 贺跃辉, 沈培智, 江 垚, 黄伯云, 徐南平. Fe-Al系金属间化合物多孔材料的制备及也结构表征[M]. 粉末冶金材料科学与工程, 2009, 14(4): 1-6.

GAO Hai-yan, HE Yue-hui, SHEN Pei-zhi, JIANG Yao, HUANG Bo-yun, XU Nan-ping. Fabrication and pore structure characteristics of porous Fe-Al intermetallics [M]. Materials Science and Engineering of Powder Metallurgy, 2009, 14(4): 1-6.

[9] BAY N. Cold welding [J]. Journal of Engineer for Industry, 1997, 101(2): 121-127.

[10] SINGER A R E. The principle of spray rolling of metal [J]. Met and Mat, 1970, 4: 246-252.

[11] MCKAMEY C G. A review of recent developments in Fe3Al-based alloys [J]. J Mater Res, 1991, 6(8): 1779-1788.

[12] LESZCYNSKI T. Structure and property of St41/A1 cladding joint [J]. Biuletyn Instytutu Spawalnictwa, 1991, 35(2/3): 36-40.

[13] 刘邦津. 钢材的热浸镀铝[M].冶金工业出版社, 1995: 6-24.

LIU Bang-jin. Steel products of the hot-dip aluminizing [M]. Metallurgical Industry Press, 1995: 6-24.

(编辑 李艳红)

基金项目:国家高技术研究发展计划资助项目(2009AA03Z534); 国家重点基础研究发展计划资助项目(2005CB623707); 辽宁省自然科学基金资助项目(20082036); 高等学校学科创新引智计划资助项目(B07015)

通信作者:王 平,教授, 博士;电话:13304049002;E-mail: wping@epm.neu.edu.cn