氧化铝种分过程浓度及质量比模型的研究

张家元1,李永清1,2,付明辉1,刘斌1,李黎1

(1. 中南大学 能源科学与工程学院,湖南 长沙,410083;

2. 湖南工业大学 冶金工程学院,湖南 株洲,412007)

摘要:从种分过程的动力学机理出发,结合实验室实验和生产现场的工业试验,以铝酸钠溶液分解过程的动力学方程为数学模型,利用Simulink软件包建立种分过程的浓度变化的动态模型对种分过程进行模拟,预测不同工艺条件下连续分解槽的氧化铝浓度变化。基于分解槽浓度变化直接影响铝酸钠溶液的分解率,利用模型来研究不同工艺制度下种分过程分解率的变化,同时建立连续分解槽的质量比(Rp)模型,通过Rp模型预测不同工艺条件下种分过程的分解率。研究结果表明:降低初温和降低末温有利于提高分解率;实际生产过程的温度是波动变化的,温度异相位波动比同相位波动对分解率影响更大,故可根据天气状况及时调整种分工艺条件,为分解工艺参数的调整和优化提供一定的参考依据。

关键词:氧化铝;种分过程;模型;浓度;分解率

中图分类号:TF803.22 文献标志码:A 文章编号:1672-7207(2011)06-1543-06

Concentration and mass ratio model of gibbsite precipitation process in alumina production

ZHANG Jia-yuan1, LI Yong-qing1, 2, FU Ming-hui1, LIU Bin1, LI Li1

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. School of Metallurgical Engineering, Hunan University of Technology, Zhuzhou 412007, China)

Abstract: The kinetic mechanism, laboratory experiments and industrial tests of the gibbsite precipitation process were employed. On the basis of the dynamic model of decomposition of sodium aluminate solution, a combined dynamic model of Al2O3 concentration was developed with the simulink package to simulate the gibbsite precipitation process, and the Al2O3 concentration was predicted in continuous decomposer tank in different conditions. Because the change of Al2O3 concentration affects the decomposition rate of sodium aluminates solution directly, so the mode can be used to study the value ranges of decomposition rate in different conditions. The mass ratio (Rp) model of the continuous decomposition tank was established, and the decomposition rate of the gibbsite precipitation process in different conditions was predicted. The results show that if the beginning and end temperatures reduce, the decomposition rate will be improved. In practical process, the temperature is fluctuant, and compared with the same-phase fluctuation of the temperature, iso-phase fluctuation has greater impact on the decomposition rate. The technology conditions can be adjusted according to weather conditions to guide the production process and provide reference for the adjustment and optimization of the decomposition parameters.

Key words: alumina; gibbsite precipitation process; model; concentration; decomposition rate

氧化铝的晶种分解过程是精制的过饱和铝酸钠溶液在添加氢氧化铝晶种、降低分解温度和不断搅拌的条件下分解析出 Al(OH)3的过程,简称种分过程。它是拜耳法生产氧化铝的关键工序之一,不仅影响产品氧化铝的数量和质量,而且直接影响循环效率及其他工序。过饱和铝酸钠溶液表现出与一般无机盐的过饱和溶液很不相同的性质,而且其结构和性质由于浓度、分子比及温度等条件不同有很大的差别,铝酸钠溶液的晶种分解结晶过程也不同于一般无机盐溶液的分解结晶过程[1]。种分过程包括晶核形成过程和晶体生长过程[2],而过饱和度直接影响晶核形成过程和晶体生长过程的速度,这2个过程的速度又影响着结晶产品中晶体的粒度及粒度分布[3],因此,过饱和度是考虑结晶问题的一个极其重要的因素。不少研究人员对于氧化铝种分过程进行了大量的研究,提出了氧化铝浓度及Na2O与Al2O3的质量比(Rp)计算模型,但由于实验条件的限制,没有得到合理求解结果。在此,本文作者根据分解动力学方程建立铝酸钠溶液分解过程浓度变化模型,同时在实验基础上对浓度及质量比(Rp)方程进行求解,并用Rp模型来预测不同实验条件或者生产工艺下种分过程的分解率。

1 氧化铝在纯氢氧化钠溶液中的溶解度求解

分解反应的推动力与溶液的溶解度有关。方敬东等对氧化铝在纯氢氧化钠溶液中的溶解度进行研究,得到溶解度与温度的关系[4]:

(1)

(1)

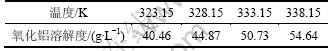

其中:ρ*为Al2O3在铝酸钠溶液的溶解度,g/L;T为热力学温度,K;A和B为常系数,与具体的实验条件有关。因此,首先必须通过实验测定不同温度下氧化铝在反应溶液中的溶解度。实验中溶解度测定都是在分解反应达到平衡状态之后进行(实验持续时间72 h)。测得氧化铝在纯氢氧化钠溶液中的溶解度如表1所示。

将表1中实验数据代入式(1)得:A=12.34,B= -2 083。

表1 氧化铝在纯氢氧化钠溶液中的溶解度

Table 1 Solubility of alumina in pure sodium hydroxide solution

2 动力学模型方程

铝酸钠溶液分解反应的化学方程式如下:

NaAlO2+2H2O→Al(OH)3↓+NaOH

许多研究者对上述反应进行了研究[4-5],并总结出许多相近的动力学模型方程。铝酸钠溶液分解反应具有以下特点:

(1) 铝酸钠溶液的分解反应是溶质在晶种表面的结晶反应。在工业生产的温度范围内,其控制步骤为表面反应控制,即反应速率与搅拌强度无关。

(2) 分解反应的推动力为溶液的过饱和度。Steemson等[7]认为应以(ρ-ρ*)/ρ*作为推动力项的表达式;

(3) 表面反应为二级反应。通过铝酸钠溶液分解反应的反应特性,对连续种分槽建立如下动力学模型方程:

(2)

(2)

其中:ρ和ρ0分别为Al2O3瞬时和初始时的质量浓度,g/L;t和tres分别为分解反应时间和停留时间(即晶体生长时间),h;R为理想气体常数,8.314 J/(mol·K);K为溶液分解反应的指前因子,g/(h·m2);S为单位体积溶液晶种的比表面积,m2/L;ρ*为铝酸钠溶液的溶解度,g/L;E为分解反应活化能,J/mol;T为反应温度,K。

在不同时间测定50~66 ℃时连续分解各槽铝酸钠溶液浓度,通过实验结果对式(2)进行拟合和处理,关联得到动力学模型式(2)中的参数:K=1.166 4×1012 g/(h·m2),E=83.35 kJ/mol,S=17 m2/L。

从而得到连续分解槽铝酸钠溶液分解反应的动力学方程:

(3)

(3)

3 基于Simulink软件浓度模型的建立和求解

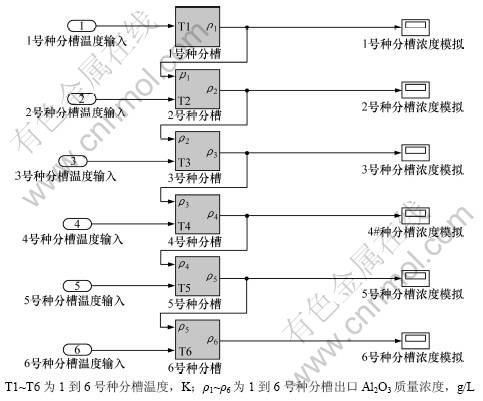

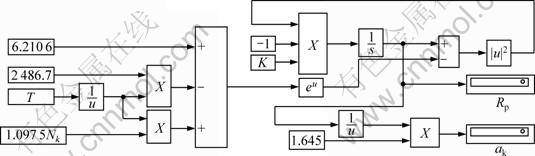

以铝酸钠溶液分解过程的动力学方程(3)为数学模型,利用Simulink软件包建立种分过程浓度变化模型,如图1所示。

该模型将每个种分槽设计成1个子系统,从Matlab的工作空间中输入各个种分槽的参数,将上一槽的浓度实时地输入到下一槽。设定每个种分槽的反应时间、输入种分槽的温度、浓度等初始工艺条件,运行模型进行计算,可以求得在不同温度下不同种分槽的氧化铝质量浓度随时间的变化情况。

图1 浓度变化模型

Fig.1 Concentration model

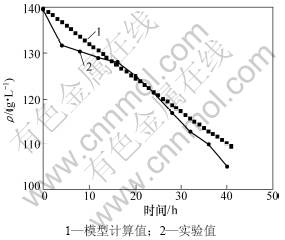

在工艺条件1(首槽温度为62.3 ℃,末槽温度为54.5 ℃,中间槽采用线性降温,首槽氧化铝初始质量浓度为139.6 g/L)下,用该浓度模型对种分过程的浓度变化进行计算,模型计算值与实验值的比较如图2所示。由图2可知:浓度模型的计算值与实验值比较接近(相对误差在5%以内),能满足生产上的要求。

图2 分解温度为62.3~54.5 ℃时模型计算值与实验值比较

Fig.2 Comparison of simulation and experimental results at decomposition temperature of 62.3-54.5 ℃

4 Rp模型的建立和求解

前面所建立的种分过程中氧化铝质量浓度变化的动力学模型中,对于现场实际生产,分解过程中Na2O与Al2O3的质量比(Rp),也是种分过程中重要的参数。Rp的定义式如下:

(4)

(4)

因此,求得分解后的Rp就可以得到分解后的χk,进一步就能求得种分过程的分解率。对于实验室的间歇槽实验,Rp的动力学模型如下[6-7]:

(5)

(5)

其中:t为分解反应时间,h;K为反应动力学常数,与具体的实验条件有关;Rpeq为反应平衡时的质量比,它既是1个热力学概念量,又是1个动力学参数,与种分反应平衡及反应速率等有很大关系[6-7]。在生产过程中,产品质量、分解率、分解槽单位产能等指标均与Rpeq有关。

Farhadi等[8]对氢氧化铝晶体生长的机理进行了研究,得到Rpeq的求取方法如下:

(6)

(6)

其中:ρ为苛碱质量浓度,g/L。

可以建立实验室间歇槽Rp的动力学模型Rp:

(7)

(7)

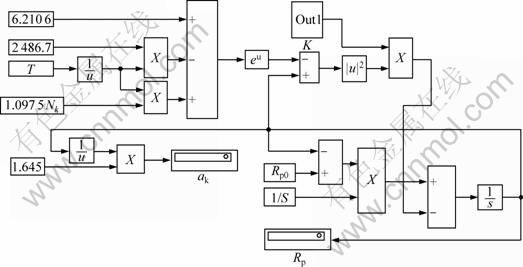

模型中的动力学常数K可以通过下面的方法求取:先假设不同实验条件下的K,建立以上动力学Simulink模型,如图3所示。通过不同实验条件下对应的K,可以得出K与实验条件的关系式,经非线性拟合得到:

(8)

(8)

其中:χk为物质的量比;Nk为苛碱质量浓度,g/L;vt为搅拌速率,r/min;ρg为固体质量浓度,g/L。

得到K与实验条件的关系式后就可以建立连续种分槽的Rp模型,从而预测分解反应后的αk。对于生产上的连续种分槽,其 Simulink模型如图4所示。

(9)

(9)

其中:Rp0和Rpeq分别初始Rp和分解反应平衡时的Rp;tres为停留时间。

图3 实验室Rp模型

Fig.3 Layout of Rp experimental model

图4 预测计算Rp模型

Fig.4 Layout of Rp prediction model

5 分解率的计算和预测

分解率是衡量种分过程结果的重要标准之一[9]。建立分解槽浓度动态模型的重要目的是对不同工艺条件下种分过程的分解率进行计算和预测。分解率是指铝酸钠溶液中氧化铝析出的含量,与分解首槽和末槽的χk(物质的量比)有关。分解率η通常通过下式计算:

(10)

(10)

其中:χk,0为精液的摩尔比;χk,m为母液的摩尔比。

在种分过程中,苛碱质量浓度变化很小,氧化铝质量浓度的变化直接影响到溶液摩尔比χk的变化,从而影响分解率[10-11]。从动力学方程式(3)和建立的浓度模型可以看出[12-13]:分解温度特别是分解首槽的温度是影响种分过程最为关键因素之一,当分解原液的成分一定时,确定和控制好适宜的温度至关重要。现场对于种分过程的控制和种分工艺的调整也往往从调节分解首槽和分解末槽的温度入手。下面讨论分解首槽和末槽的温度变化对氧化铝质量浓度的影响。

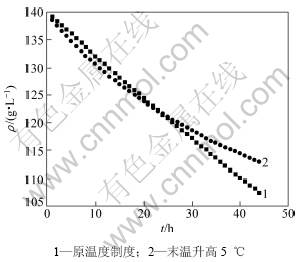

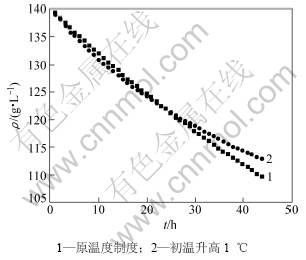

以工艺条件1下的种分过程为研究对象。分解首槽质量浓度保持不变,中间槽采取线性降温。当分解末槽温度不变而分解初温升高1 ℃时,模型计算得到的种分槽质量浓度与原温度制度下的质量浓度的比较如图5所示。当分解首槽温度不变而分解末温升高5 ℃时,模型计算得到的种分槽质量浓度与原温度制度的质量浓度的比较如图6所示。由图5和图6可知:

图5 初温升高对分解槽质量浓度的影响

Fig.5 Effect of beginning temperature on decomposition concentration

图6 末温升高对分解槽质量浓度的影响

Fig.6 Effect of end temperature on decomposition concentration

(1) 当终温相同时,提高分解初温会使分解末期的氧化铝质量浓度增大,从而使铝酸钠溶液末期的χk降低,分解率下降。

(2) 当初温相同时,提高分解终温也会使分解末期的氧化铝质量浓度增大,从而导致铝酸钠溶液末期的χk降低,分解率也会降低。

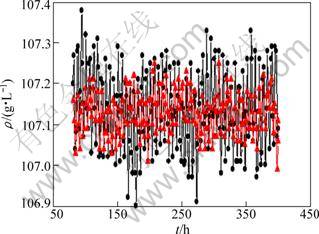

实际的种分过程往往还受到一些其他因素如天气状况(主要是气温变化)的影响,各种分槽的实际温度往往在某一范围内波动(但应控制温度使其温度波动不超过-0.5~0.5 ℃)[14-16]。仍以工艺条件1下的种分过程为研究对象,当浓度模型的温度输入加入异相位波动2sin (t+π/2i)时,模型计算得到分解末槽的浓度波动如图7所示。研究结果表明:温度异相位波动比同相位波动对氧化铝质量浓度的影响更大,从而对种分过

图7 输入温度有波动的情况下分解槽的质量浓度波动

Fig.7 Fluctuation of decomposer’concentration in case of input temperature’ fluctuation

程分解率的影响也更大。

6 结论

(1) 根据种分过程中的动力学机理和方程建立了种分过程质量浓度变化模型,可利用该模型来研究不同分解条件下的种分过程中Al2O3质量浓度的变化。

(2) 降低分解初温和分解末温有利于提高分解率。

(3) 实际生产过程的温度是波动变化的,温度异相位波动比同相位波动对分解率影响更大,这对生产过程有直接的指导作用,可根据天气状况及时调整种分工艺条件,从而稳定种分生产。

(4) 可以通过Rp模型来预测不同工艺条件下种分过程的分解率,为分解工艺参数的调整和优化提供一些参考依据。

参考文献:

[1] 毕诗文, 于海燕. 氧化铝生产工艺[M]. 北京: 化学工业出版社, 2006: 5-7.

BI Shi-wen, YU Hai-yan. Alumina production technology[M]. Beijing: Chemistry Industrial Press, 2006: 5-7.

[2] 白万全. 拜耳法种分附聚动力学初步研究[J]. 轻金属, 2004(10): 11-14.

BAI Wan-quan. Preliminary study of agglomeration dynamics on crystalline particles in Bayer process[J]. Light Metals, 2004(10): 11-14.

[3] 张江峰, 李旺兴, 尹周澜. 铝酸钠溶液晶种分解附聚过程主要影响因素研究[J]. 轻金属, 2004(9): 17-19.

ZHANG Jiang-feng, LI Wang-xing, YIN Zhou-lan. Study of agglo meration during the precipitation of sodium aluminate solution[J]. Light Metals, 2004(9): 17-19.

[4] Sweeger C, et al. Morphology, evolution and other characteristics of gibbsite crystals grown from pure and impure aqueous sodium aluminate solutions[J]. Journal of Crystal Growth, 2001, 233(3): 567-582.

[5] Yamada K. Crystallization of aluminum trihydroxide form sodium aluminate solution[J]. Light Metals, 1978(9): 19-38.

[6] Steemson M, White E T, Milne D. A graphical construction for predicting the yield from continuous precipitator trains[J]. Light Metals, 1984, 9(6): 237-253.

[7] 尹周澜, 刘吉波, 张平民, 等. 氧化铝生产种分过程Rpeq的测定及其与降温制度的关系[J]. 中国有色金属学报, 2001, 11(6): 1136-1137.

YIN Zhou-lan, LIU Ji-bo, ZHONG Ping-ming, et al. The measurement of Rpeq and the relationship with the cooling system in gibbsite precipitation process during alumina production[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(6): 1136-1137.

[8] Farhadi T. Masoud bahrami babaheidary. mechanism and estimation of Al(OH)3 crystal growth[J]. Journal of Crystal Growth, 2002, 234(4): 721-730.

[9] 谭军, 陈启元, 尹周澜, 等. 分形在砂状氧化铝强度研究中的应用[J]. 中南大学学报: 自然科学版, 2005, 36(5): 834-836.

TAN Jun, CHEN Qi-yuan, YIN Zhou-lan, et al. Application of fractal theory to studying strength of sandy alumina[J]. Journal of Central South University: Science and Technology, 2005, 36(5): 834-836.

[10] Ginter D M, Loyalka S K. Apparent size-dependent growth in aggregation crystallizers[J]. Chemical engineering Science, 1996, 51(14): 3685-3695.

[11] 吴若琼, 朱敏, 刘今. 氧化铝生产中氢氧化铝絮凝剂的研究[J]. 中南大学学报: 自然科学版, 1996, 27(4): 428-431.

WU Ruo-qiong, ZHU Min, LIU Jin. A study on flocculants for aluminium hydroxide settling in the process of alumina manufacture[J]. Journal of Central South University: Science and Technology, 1996, 27(4): 428-431.

[12] GOMEZ M J. Crystal size distribution of hydroxyapatite precipitated in a MSMPR reactor[J]. Cryst Res Technol, 2001, 36(8/9/10): 1065-1074.

[13] Davidov I V, Liapunov A N, Shmorgunenko N S, et al. Optimization of temperature condition of the aluminate liquor decomposition process[J]. Light Metals, 1978(9): 19-38.

[14] 刘斌, 刘吉波, 张家元, 等. 氧化铝种分过程的粒度分析[J]. 有色金属: 冶炼部分, 2006(5): 25-27.

LIU Bin, LIU Ji-bo, ZHANG Jia-yuan, et al. Analysis of particle size distribution during seed precipitation process of alumina[J]. Nonferrous Metal: Extractive Metallurgy, 2006(5): 25-27.

[15] 吴玉胜, 毕诗文, 李文成. 分解过程氢氧化铝产品粒度变化机理及规律[J]. 中国有色金属学报, 2005, 15(12): 2061-2065.

WU Yu-sheng, BI Shi-wen, LI Wen-cheng. Mechanism and rule of Al(OH)3 particles variation in seed precipitation[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(12): 2061-2065.

[16] Grootscholtem P A M. Industrial crystallization[M]. Delft University Press D. Reidel Publishing Company, 1984: 70-74.

(编辑 陈灿华)

收稿日期:2010-05-11;修回日期:2010-08-10

基金项目:中国博士后基金资助项目(291054)

通信作者:张家元(1968-),男,湖北浠水人,博士,教授,从事热能与动力工程研究;电话:0731-88876111; E-mail:zjyzhq@mail.csu.edu.cn