文章编号:1004-0609(2016)-06-1198-06

模具温度和保护气体对Zr50Cu50非晶态形成的影响

党一纵1,宫声凯1,薛云飞2,王 鲁2

(1. 北京航空航天大学 材料科学与工程学院,北京,100191;

2. 北京理工大学 材料科学与工程学院,北京,100081)

摘 要:利用铜模铸造法制备Zr50Cu50二元非晶合金,并研究铜模温度、保护气体对Zr50Cu50合金非晶形成的影响。熔液的冷却速率是由铜模温度以及保护气性质共同决定的,相比于氩、氦作为保护性气体不但有效提高熔液的冷却速率,而且在超低温制备环境下仍能保持样品表面光滑。在此研究基础上,利用氦作为保护气,在液氮作为铜模冷却介质的超低温环境下(79 K),制备出表面光滑、直径为2.5 mm的Zr50Cu50大块非晶合金,该尺寸超越了之前所报道的Zr50Cu50非晶合金的最大尺寸(2 mm)。

关键词:非晶合金;模具温度;保护气体;冷却速度;非晶形成能力

中图分类号:TG146.2 文献标志码:A

由于非晶合金具有独特的原子无序排布结构,相比于晶态合金表现出高强度[1]、高弹性极限[2]、极强的耐腐蚀性能[3],在基础科学研究和工程应用领域受到了广泛关注。非晶合金的形成能力一直是非晶研究的重点方向[4],提高合金的非晶形成能力主要有两个方面:1)调整非晶合金的成分;2) 改善合金的制备工艺[5-6]。其中制备工艺的选择与控制对非晶合金的上述性能密切相关,即使同种合金成分在不同的制备工艺下所形成的微观结构也有着明显的差异[7-8]。系统研究制备工艺对非晶形成的影响,对新型非晶合金的开发具有重要意义。TURNBULL等[9]和COHEN等[10]认为,只要冷却速率足够高,任何成分的合金甚至纯金属都可以形成非晶结构。近些年,发展出多种非晶合金制备方法,如真空吸铸法[11]、铜模铸造法[12]、熔融压铸法[13]和单向熔化法[14]等,这些制备方法实质上都是通过提高合金熔液凝固速率来获得非晶合金。其中铜模铸造法应用最为广泛,铜模铸造法完全依靠纯铜的高传热性能来获得高冷却速率进而制备出大块非晶。Zr-Cu二元合金的具有一定的非晶形成能力,通过添加合适的元素还可以进一步提高非晶形成能力与综合性能,成为极具应用前景的非晶结构材料[15-16]。本文作者利用铜模铸造法制备Zr50Cu50二元非晶合金,并系统研究制备过程中铜模温度和保护气体对冷却速率及非晶形成的影响。在此基础上,通过改进铜模铸造工艺,提高Zr50Cu50非晶合金的极限尺寸,为大尺寸非晶合金的制备提供新的途径与方法。

1 实验

首先,在磁控钨极真空电弧炉内熔配Cu、Zr纯金属。其中,Cu、Zr的纯度为99.98%(质量分数),按照Zr50Cu50的成分比例进行称量配比。熔配前,先将电弧炉抽真空至2.0×10-3 Pa以下,充入高纯氩气,作为熔配过程中保护气体。为了保证得到成分均匀的Zr50Cu50母合金,在熔炼过程中,采用电磁搅拌的方式,并反复熔炼5次,最终获得Zr50Cu50合金纽扣锭。将合金纽扣锭进行破碎并在真空喷铸炉内,制备Zr50Cu50柱形非晶合金。在非晶制备过程中炉内的保护气体分别采用氩气和氦气,铜模温度分别采用液氮、冰水混合物、室温空气以及外加热源4种方式进行控制,喷射压力差为2.5×10-3 Pa。在之前的研究中发现喷铸温度对合金的微观组织形态有着重要的影响[17]。为了最大限度地消除这一影响,在所有样品的制备中,通过红外线测温仪将浇铸温度控制在1570K。制备得到的Ⅰ~Ⅷ号合金样品所采用的制备方法如表1所列。

表1 不同保护气氛中合金样品Ⅰ~Ⅷ的制备方法

样品非晶特征采用X射线衍射(X-ray diffraction,XRD)和透射电镜(Transmission electron microscope,TEM)分析。晶化温度以及合金的熔化行为采用差热式扫描量热仪(Differential scanning calorimetry, DSC),在高纯氩保护下进行热分析。DSC测试时的升温速度5 K/min,测试样品的质量均控制在10 mg。样品的外观形貌采用扫描电镜(Scanning electronic microscopy, SEM)进行观测。此外,为防止测试样品在加工过程中因受热发生晶化影响测试结果,样品的切割均在慢速锯加工平台上完成。

2 结果与分析

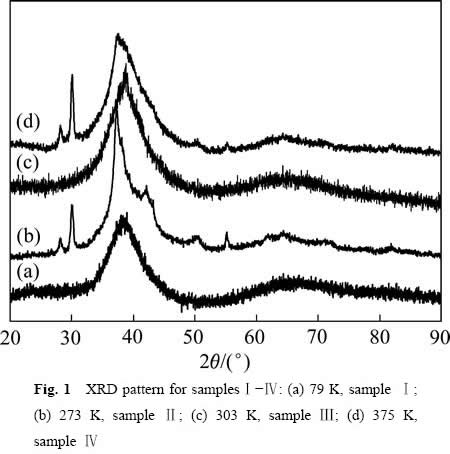

图1所示为Zr50Cu50合金样品Ⅰ~Ⅳ的XRD谱,这4种样品的直径为1.5 mm,皆利用氩气作为保护气体,模具冷却介质及温度分别为液氮(79 K)、冰水混合物(273 K)、室温(303 K)、外加热源(375 K)。从图1中可以看出,样品Ⅰ的XRD谱表现出明显的漫散射峰,表明样品Ⅰ是拥有大量短程有序结构的非晶态合金;样品Ⅱ、Ⅲ和Ⅳ的XRD谱都存在强度不等的尖锐谱峰,说明这3种样品内部不同程度上析出了晶体。

图2所示为样品Ⅰ~Ⅳ的DSC曲线。从图2中可以看出,4种样品都表现出明显的非晶态转变和晶化转变,图中显示了各合金样品的非晶态转变温度Tg和晶化转变温度Tx。通过计算晶化放热焓(简称“晶化焓)可以对比出各种样品的非晶化程度。一般认为,同种成分合金晶化焓越大,其非晶化程度越高。晶化焓可以通过计算DSC曲线中晶化反应放热峰面积得到。通过对比4种样品的晶化焓ΔHc可知,样品Ⅰ(ΔHc=42.31J/g)的非晶化程度最为明显,样品Ⅱ(ΔHc=22.48J/g)的非晶化程度最低,低于样品Ⅲ(ΔHc=36.91J/g)和Ⅳ(ΔHc=30.06J/g)的非晶化程度。

图1 Ⅰ~Ⅳ合金样品的XRD谱

图2 Ⅰ~Ⅳ样品的DSC曲线

根据热传导方程,在其他传热条件相同的前提下,当熔液和模具之间温度梯度越大,熔液的冷却速率也就越快。在金属熔体温度相同的情况下,模具温度越低就意味着温度梯度越大,冷却速率越高,那么非晶化程度也就越高。但通过对比样品Ⅱ、Ⅲ和Ⅳ晶化焓值发现,虽然样品Ⅱ的温度梯度高于样品Ⅲ和Ⅳ的,但其非晶化程度却低于样品Ⅲ和Ⅳ的。这表明在实际的制备过程中,不能仅仅依靠增加熔液与模具之间的温度梯度来提高合金熔液的冷却速率,同时这也说明还有其他因素影响着熔液的冷却速率。

对于形状简单的柱体铸件,凝固时间一般通过式(1)计算[18]:

(1)

(1)

式中: 是铸件的密度;H是熔化焓;V为铸造件体积;h为合金熔液与模具之间的传热系数;T为合金铸件浇铸时的熔液温度;T0为模具温度;A为铸件表面积。

是铸件的密度;H是熔化焓;V为铸造件体积;h为合金熔液与模具之间的传热系数;T为合金铸件浇铸时的熔液温度;T0为模具温度;A为铸件表面积。

根据式(1)可以认为,对于相同材质的模具、相同材料及尺寸的铸件而言, 、H、V/A可以看作是不变的,因此可以认为,冷却速率是由合金熔液与模具之间的传热系数h和合金熔液与模具之间的温度梯度(T-T0)共同作用的结果,前面已分析了温度梯度的影响。理论上在模具材质相同、合金熔液成分相同的情况下,h值也应该被认为是相同的。但在实际制备过程中需要注意的是,由于炉体中并不是真空状态,而是通入氩气作为保护性气体。根据HOLMAN[19]的简化热交换公式来表示合金熔液和模具之间的平均热交互系数h为

、H、V/A可以看作是不变的,因此可以认为,冷却速率是由合金熔液与模具之间的传热系数h和合金熔液与模具之间的温度梯度(T-T0)共同作用的结果,前面已分析了温度梯度的影响。理论上在模具材质相同、合金熔液成分相同的情况下,h值也应该被认为是相同的。但在实际制备过程中需要注意的是,由于炉体中并不是真空状态,而是通入氩气作为保护性气体。根据HOLMAN[19]的简化热交换公式来表示合金熔液和模具之间的平均热交互系数h为

(2)

(2)

式中:At为熔液和模具之间直接接触的面积;A为熔液表面积; 为界面间隙厚度;Aut为铸件和模具内壁之间非接触面积;km、kM和kg分别为铸件、模具和界面间气体的热导率。可认为A、km、kM和kg是常量。气体吸附量与系统内的压力和温度成函数关系。在系统压力不变时,模具的温度降低导致模具型腔壁上的氩气吸附量将会增加,这也意味着熔液与模具型腔壁之间的气体薄膜或间隙变大[20]。在式(2)中,即随着温度下降,

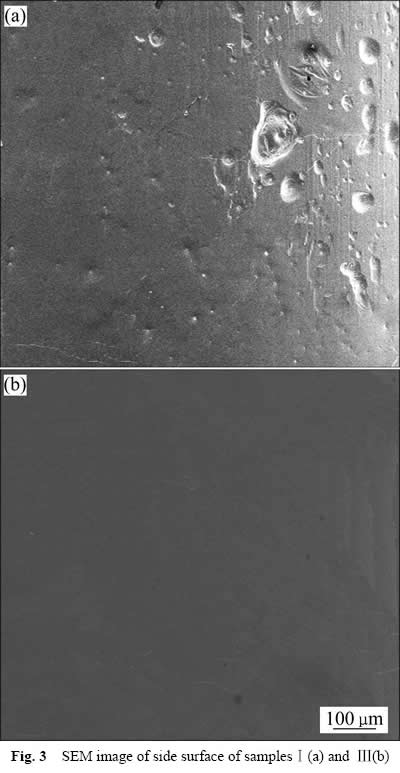

为界面间隙厚度;Aut为铸件和模具内壁之间非接触面积;km、kM和kg分别为铸件、模具和界面间气体的热导率。可认为A、km、kM和kg是常量。气体吸附量与系统内的压力和温度成函数关系。在系统压力不变时,模具的温度降低导致模具型腔壁上的氩气吸附量将会增加,这也意味着熔液与模具型腔壁之间的气体薄膜或间隙变大[20]。在式(2)中,即随着温度下降, 将增大,并降低了h值,最终导致熔液的冷却速率变小。这也是样品Ⅱ的非晶化程度低于样品Ⅲ和Ⅳ的重要原因之一。另一方面,如果将模具冷却至极低的温度,扩大熔液与模具之间的温度梯度是可以抵消由于气体吸附对非晶形成所带来的负面影响的。这也就解释了样品Ⅰ仍获得了非晶态结构,但样品I的表面布满了大量的孔洞,如图3(a)所示。相比之下,样品Ⅲ的表面非常光滑平整,如图3(b)所示。这可能是由于氩气的沸点为87.3 K,当模具温度降低到79 K时,炉体内靠近模具的氩气极易发生凝结,并以液滴的形式吸附在模具的型腔内壁上。当合金熔液快速注入到模具的型腔中时,氩液滴气化但却不易排出,致使样品表面出现大量孔洞。相比之下,在制备样品Ⅲ时,磨具温度较高,氩气的流动性强,吸附在模具型腔内壁的量较少,样品Ⅲ表面光滑整洁无明显孔洞。一般认为样品的表面孔洞易引起应力集中,将会大大降低样品的力学性能,在样品制备过程中应尽量保证样品的表面质量。

将增大,并降低了h值,最终导致熔液的冷却速率变小。这也是样品Ⅱ的非晶化程度低于样品Ⅲ和Ⅳ的重要原因之一。另一方面,如果将模具冷却至极低的温度,扩大熔液与模具之间的温度梯度是可以抵消由于气体吸附对非晶形成所带来的负面影响的。这也就解释了样品Ⅰ仍获得了非晶态结构,但样品I的表面布满了大量的孔洞,如图3(a)所示。相比之下,样品Ⅲ的表面非常光滑平整,如图3(b)所示。这可能是由于氩气的沸点为87.3 K,当模具温度降低到79 K时,炉体内靠近模具的氩气极易发生凝结,并以液滴的形式吸附在模具的型腔内壁上。当合金熔液快速注入到模具的型腔中时,氩液滴气化但却不易排出,致使样品表面出现大量孔洞。相比之下,在制备样品Ⅲ时,磨具温度较高,氩气的流动性强,吸附在模具型腔内壁的量较少,样品Ⅲ表面光滑整洁无明显孔洞。一般认为样品的表面孔洞易引起应力集中,将会大大降低样品的力学性能,在样品制备过程中应尽量保证样品的表面质量。

图3 样品Ⅰ和Ⅲ侧面的SEM像

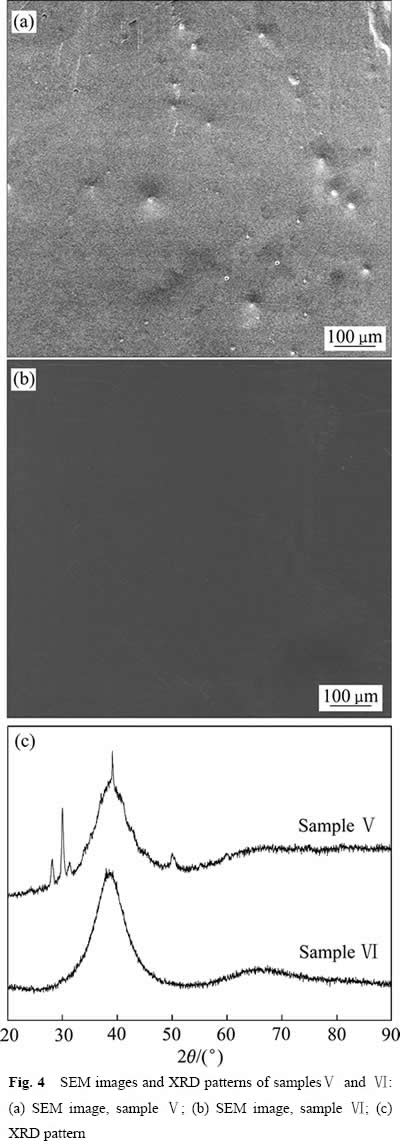

基于以上分析,本文作者又选用了沸点极低的氦(氦沸点温度为4.1 K)作为保护气体进行对比实验。在其他制备条件相同的情况下,分别利用氩和氦作为保护气体,制备了直径为2 mm的样品Ⅴ和Ⅵ。对样品Ⅴ和Ⅵ的表面进行SEM观察,其中样品Ⅴ的表面仍然布满了大量的气孔,其表面形态与样品I的相近,如图4(a)所示。样品Ⅵ的SEM图像如图4(b)所示,样品Ⅵ的表面光滑无明显的孔洞。图4(c)为样品Ⅴ、Ⅵ号的XRD谱。从图4(c)中可知,样品Ⅴ析出了晶体相,而样品Ⅵ仍为非晶相。这表明在其它制备条件相同的前提下,由于氦气的低沸点,使得氦气在低温下仍能保持很好的流动性,有效降低气体在模具型腔壁上的吸附量,提高铸件与模具之间的传热系数h的值,提高冷却速率,有利于Zr50Cu50合金非晶态的形成,同时也保证了样品表面光滑。

本文作者采用液氮作为铜模冷却介质、氦气作为保护气体,又分别制备了直径为2.5 mm(样品Ⅶ)和3 mm(样品Ⅷ)两种不同尺寸的Zr50Cu50棒状合金样品。图5(a)所示为样品Ⅶ、Ⅷ的XRD谱。图5(b)、(c)所示为样品Ⅶ和Ⅷ的TEM像。从图5可看出,样品Ⅶ仍保持组织结构均匀的非晶态,对应的选区电子衍射也表现出非晶独有的衍射环,样品Ⅷ则析出了细小的晶体相,对应的选区电子衍射压表现出明显的衍射斑点。在之前的研究报道中,利用传统铜模铸造法制备的Zr50Cu50非晶合金棒,其极限制备尺寸为d 2 mm[21-22]。在现有条件下通过改进制备方法,将Zr50Cu50非晶合金的尺寸提高到d 2.5 mm。

图4 样品Ⅴ和Ⅵ侧面的SEM像和XRD谱

图5 样品Ⅶ、Ⅷ的XRD谱和显微组织

3 结论

1) 在Zr50Cu50非晶合金的实际制备过程中,降低模具温度,扩大熔液与模具的温度梯度,提高冷却速率有利于合金非晶相的形成;降低模具温度,增加保护气体吸附量,降低熔液与模具之间的传热系数,从而降低冷却速率不利于合金非晶相的形成。

2) 氩作为保护气,由于其具有相对较高的沸点,在液氮作为铜模冷却介质的超低温制备环境下极易形成液滴吸附在模具型腔壁上。这不但降低合金熔液的冷却速率,而且还严重影响合金样品的表面质量。

3) 相比于氩,氦具有极低的沸点,在同样的超低温条件下仍能保持良好的流动性,因此,氦能够有效地提高熔液与模具之间的传热系数,进而增加熔液的冷却速率;在超低温环境下,仍能保证合金样品表面质量。

4) 采用液氮作为冷却介质,氦作为保护气进行铜模铸造,在现有实验条件下制备出直径为2.5mm、组织均匀、表面光滑的Zr50Cu50非晶合金柱形样品。这一方法将Zr50Cu50非晶形成能力提高了25%。

REFERENCES

[1] KATO H, CHEN H S, INOUE A. Relationship between thermal expansion coefficient and glass transition temperature in metallic glasses[J]. Scripta Materialia, 2008, 58(12): 1106-1109.

[2] GREER A L, MA E. Bulk metallic glasses: At the cutting edge of metals research[J]. MRS Bulletin, 2007, 32(8): 285-301.

[3] GAO J H, GUAN S K, REN Z W, SUN Y F, ZHU S J, WANG B. Homogeneous corrosion of high pressure torsion treated Mg-Zn-Ca alloy in simulated body fluid[J]. Materials Letters, 2011, 65: 691-693.

[4] 邱克强, 杨君宝, 尤俊华, 任英磊. Mg-Zn-Ca 合金的非晶形成能力及力学性能[J]. 中国有色金属学报, 2011, 28(8): 1828-1833.

QIU Ke-qiang, YANG Jun-bao, YOU Jun-hua, REN Ying-lei. Glass-forming ability and mechanical properties for Mg-Zn-Ca alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 28(8): 1828-1833.

[5] FU H M, ZHANG H F, WANG H, HU Z Q. Cu-based bulk amorphous alloy with larger glass-forming ability and supercooled liquid region[J]. Journal ofAlloysand Compounds, 2008, 458(1/2): 390-393.

[6] 杨 伟, 陈寿辉, 张守银, 余 欢, 严青松, 蔡长春. 冷却速率对 AZ91D 镁合金非平衡凝固组织的影响[J]. 中国有色金属学报, 2014, 24(3): 593-599.

YANG Wei, CHEN Shou-hui, ZHANG Shou-yin, YU Huan, YAN Qing-song, CAI Chang-chun. Effect of cooling rate on non-equilibrium solidified microstructure of AZ91D magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(3): 593-599.

[7] ZHANG J, PANG S J, ZHANG T. Effect of cooling rate on plastic deformability of Zr-based bulk metallic glasses[J]. Science China Physics, Mechanics and Astronomy, 2010, 53(3): 415-418.

[8] LIU Y H, LIU C T, WANG W H, INOUE A, SAKURAI T, CHEN M W. Thermodynamic origins of shear band formation and the universal scaling law of metallic glass strength[J]. Physical Review Letters, 2009, 103(6): 065504.

[9] TURNBULL D, COHEN M H. Concerning reconstructive transformation and formation of glass[J]. Journal of Chemical Physics, 1958, 29(5): 1049-1051.

[10] COHEN M H, TURNBULL D. Molecular transport in liquids and glasses[J]. Journal of Chemical Physics, 1959, 31(5): 1164-1167.

[11] 白 琴, 满 华, 唐永军, 郝彦斐, 徐 晖, 夏 爽, 胡业旻. 铜模吸铸法制备Fe-Nd-Al-B-Dy 合金的结构和磁性能[J]. 中国有色金属学报, 2011, 21(5): 1118-1122.

BAI Qin, MAN Hua, TANG Yong-jun, HAO Yan-pei, XU Hui, XIA Shuang, HU Ye-min. Structure and magnetic properties of Fe-Nd-Al-B-Dy alloys by suction casting[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(5): 1118-1122.

[12] 杨 伟, 张燕龙, 余 欢, 陈寿辉, 卢百平, 汪志太. 冷却速率对 Cu70Zr30 合金初生相及包晶转变的影响[J]. 中国有色金属学报, 2014, 24(9): 2295-2301.

YANG Wei, ZHANG Yan-long, YU Huan, CHEN Shou-hui, LU Bai-ping, WANG Zhi-tai. Effects of cooling rate on primary phase and peritectic transformation in Cu70Zr30 alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(9): 2295-2301.

[13] KONOVALOV I I, KOMISSAROV V A, MASLOV A A, ORLOV V K. Bulk amorphous plate production by a casting process[J]. Journal of Non-crystalline Solids, 1996, 205(96): 536-539.

[14] INOUE A, YOKOYAMA Y, SHINOHARA Y, MASUMOTO T. Preparation of bulky Zr-based amorphous alloys by a zone melting method[J]. Materials Transactions, JIM, 1994, 35(12): 923-926.

[15] 潘 冶, 纪秀林, 皮锦红, 张 露. 微量元素对Cu-Zr-Al 块体金属玻璃形成能力及力学性能的影响[J]. 中国有色金属学报, 2011, 21(3): 583-587.

PAN Ye, JI Xiu-lin, PI Jing-hong, ZHANG Lu. Effects of minor alloying additions on glass forming ability and mechanical properties of Cu-Zr-Al bulk metallic glasses[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(3): 583-587.

[16] DEO L P, MENDES M A B, COSTA A M S, CAMPOS N N D, de OLIVEIRA M F. Applying a new criterion to predict glass forming alloys in the Zr-Ni-Cu ternary system[J]. Journal of Alloys and Compounds, 2013, 553: 212-215.

[17] ZHU Z W, ZHENG S J, ZHANG H F, DING B Z, HU Z Q, LIAW P K, WANG Y D, REN Y. Plasticity of bulk metallic glasses improved by controlling the solidification condition[J]. Journal of Materials Research, 2008, 23(4): 941-948.

[18] FLEMINGS M. Solidification processing[M]. New York: McGraw Hill, 1974.

[19] HOLMAN J. Heat transfer[M]. New York: McGraw Hill, 1990: 1.

[20] MAO J, ZHANG H F, FU H M, WANG A M, LI H, HU Z Q. A new way to improve glass-forming ability by controlling the preparation conditions of bulk metallic glass[J]. Advanced Engineering Materials, 2010, 12(3): 170-175.

[21] YANG L, GE T, GUO G Q, HUANG C L, MENG X F, WEI S H, CHEN D, CHEN L Y. Atomic and cluster level dense packing contributes to the high glass-forming ability in metallic glasses[J]. Intermetallics, 2012, 34: 106-111.

[22] WANG W H, LEWANDOWKI J J, GREER A L. Understanding the glass-forming ability of Cu50Zr50 alloys in terms of a metastable eutectic[J]. Journal of Materials Research, 2005, 20(9): 2307-2313.

Effect of mold temperature and protective gas on glass forming of Zr50Cu50 metallic glasses

DANG Yi-zong1, GONG Sheng-kai1, XUE Yun-fei2, WANG Lu2

(1. School of Materials Science and Engineering, Beihang University, Beijing 100191, China;

2. School of Materials Science and Engineering, Beijing Institute of Technology, Beijing 100081, China)

Abstract: The Zr50Cu50 binary bulk metallic glasses were prepared using cooper mold casting. The effects of cooper mold temperature and protective gas on the glass-forming ability were studied. The cooling rate of alloy melt was controlled by cooper mold temperature and protective gas properties. Compared with Ar, He as protective gas speeds up the cooling rate, at the same time, it can improve the smoothness of alloy samples surface under ultra low temperature. The fully amorphous alloy with diameter of 2.5 mm can be cast for Zr50Cu50 by using He as protective gas and liquid nitrogen as cooling medium under ultra low temperature environment (79 K). The size of Zr50Cu50 binary bulk metallic glasses exceeds the maximum dimension of 2 mm.

Key words: metallic glasses; mold temperature; protective gas; cooling rate; glasses forming ability

Foundation item: Project(10872032) supported by the National Natural Science Foundation of China

Received date: 2015-08-11; Accepted date: 2015-12-26

Corresponding author: DANG Yi-zong; Tel: +86-10-82339256; E-mail: dangyizong@163.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(10872032)

收稿日期:2015-08-11;修订日期:2015-12-26

通信作者:党一纵,高级工程师,博士;电话:010-82339256;E-mail: dangyizong@163.com