28CrMnMoV钢过冷奥氏体连续冷却转变研究

李红英1,李阳华1, 2,王晓峰2,谢凯意2,苏阳2

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 衡阳华菱钢管有限公司 技术中心,湖南 衡阳,421001)

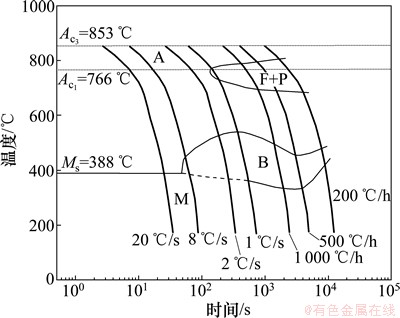

摘要:利用Gleeble-3500热模拟机测量28CrMnMoV钢以不同速度连续冷却时的膨胀曲线,结合差热分析法和金相-硬度法,确定临界点及相变温度点,绘制、分析、应用过冷奥氏体的连续冷却曲线(CCT图),研究实验钢连续冷却时的奥氏体转变。研究结果表明:实验钢过冷奥氏体在高温区可能发生铁素体转变和珠光体转变,中温区可能发生贝氏体转变,低温区可能发生马氏体转变,当冷却速度为0.05~0.5 ℃/s时,转变产物为多边形铁素体、珠光体和少量贝氏体的混合组织,在1~5 ℃/s的冷却速度范围内,转变产物为贝氏体,当冷却速度大于5 ℃/s时,转变产物为马氏体。较低的含碳量提高了马氏体转变温度,合金元素Cr,Mo和V有抑制奥氏体扩散分解的作用,以低于1 ℃/s的速度冷却才会有先共析铁素体和珠光体,较高的锰含量对贝氏体转变起到了明显的促进作用,在0.05~10 ℃/s 的较宽冷却速度范围内连续冷却都会发生贝氏体转变。根据测得的CCT图指导28CrMnMoV钢的分级控冷工艺,为V150油套管的高强高韧性提供保障。

关键词:28CrMnMoV钢;连续冷却;CCT图;相变

中图分类号:TG151.2;TG151.3 文献标志码:A 文章编号:1672-7207(2014)10-3363-10

Continuous cooling transformation of undercooling austenite about 28CrMnMoV steel

LI Hongying1, LI Yanghua1, 2, WANG Xiaofeng2, XIE Kaiyi2, SU Yang2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Technology Center of Hengyang Valin Steel Tube Co. Ltd., Hengyang 421001, China)

Abstract: The dilatometric curves of 28CrMnMoV steel during continuous cooling process at different cooling rates were measured on Gleeble-3500 thermal mechanical simulator. According to differential scanning calorimetry(DSC) analysis and microstructure observation combined with hardness test, the critical temperatures and phase transformation temperatures were determined from the dilatometric curves, which were used to determine the continuous cooling transformation (CCT) diagram of 28CrMnMoV steel. The results show that ferrite (or pearlite) can be formed in supercooled austenite of tested steel at higher temperature intervals, and bainite transformation and martensite transformation can occur at intermedium temperature and low temperature zones, respectively. The massive morphology of ferrite and pearlite can be easily formed when the cooling rate is in the range of 0.05-0.5 ℃/s. The bainite appears when the cooling rate is in the temperature interval of 1-5 ℃/s, and the martensitic transformation occurs when the cooling rate is greater than 5 ℃/s. Lower carbon content increases the martensite transformation temperature. Because the alloy elements of Cr, Mo and V can inhibit the decomposition of austenite, pro-eutectoid ferrite and pearlite can be formed only in the condition of cooling rate below 1 ℃/s. However, higher manganese content can greatly accelerate the bainite transformation. Therefore, bainite can be easily formed during the continuous cooling process for a large range of cooling rate(0.05-10℃). The developed CCT diagram can be used to guide the multiple controlled cooling process,which can provide guarantee for the excellent combination of high strength and toughness of V150 tubing and casing.

Key words: 28CrMnMoV steel; continuous cooling; continuous cooling transformation diagram; phase transformation

在勘探开发石油和天然气时,油套管起固井作用,用量大、花费高,服役性能和质量出现问题将导致整口油井报废,开发安全可靠、使用寿命长的油套管对油井的寿命乃至油田的发展至关重要[1]。油套管的服役环境十分恶劣,套管柱通常要承受几百甚至上千大气压的内压或外压、千牛顿的拉伸载荷,还有高温及腐蚀介质作用[2]。随着地质和环境条件苛刻的油气田相继投入开发,以及钻井和完井新技术、新工艺陆续投入使用,油井管的服役条件更加复杂和严酷[3]。“十二五”期间,我国要开钻一批深井和超深井,随着井深增加,井内温度、压力相应提高,必须采用V140和V150钢级的油套管,为了确保油井的运行安全,油套管要兼具高强度和高韧性[4]。英国能源部规定高钢级油套管的横向最低冲击韧性≥σy/10,强度在150 ksi (1 034 MPa)级别的钢管,夏比冲击功必须超过100 J,塔里木油田甚至要求所使用的V150油套管横向0 ℃全尺寸试样冲击功超过110 J[5]。但是,一般材料在强度提高的同时,韧性会有一定程度的削弱,特别是当屈服强度达到1 034 MPa钢级时,韧性不足问题更为突出,良好强韧性匹配涉及多项材料强韧化技术的综合运用,因此,超深井用超高强度套管的开发难度较大,被称为世界性的技术难题[6]。采用中碳铬钼钢,加入适量Mn,V,Si,Cu和Ni元素,通过微合金化结合连铸连轧工艺及适当的调质工艺,有望获得高强高韧的油套管。调质处理是提高油套管强韧性最为关键的技术手段,国内外生产企业都对其给予了极大关注,由于水淬的冷却速度较快,钢管在淬火时淬裂和淬弯的倾向较大,水淬的核心技术已成为生产高强高韧油套管的瓶颈[7-8]。微合金钢的过冷奥氏体连续冷却转变是一个极为复杂的过程,在不同冷却条件和不同温度下,奥氏体会发生不同的转变,可能得到铁素体、珠光体、贝氏体、马氏体及残余奥氏体等不同的室温组织。连续冷却转变曲线(CCT图)可以用来分析不同冷却速度下过冷奥氏体的转变产物和硬度的变化情况,从而达到通过控制冷却速度来控制过冷奥氏体转变的目标。本研究用膨胀法结合金相-硬度法和差热分析法测定28CrMnMoV钢的CCT图,为制订V150油套管的高强韧性调质工艺提供依据,根据CCT图确定分级控冷工艺,可实现奥氏体尽量转变成马氏体的同时减少淬火应力。

1 实验材料及实验方法

实验材料为工厂生产的28CrMnMoV热轧无缝钢管,直径为139.70 mm,长度为12.70 mm,化学成分(质量分数,%)为: 0.26~0.30 C, 0.90~1.20 Cr, 0.50~ 0.80 Mo,0.80~1.10 Mn,0.06~0.15 V,0.30~0.50 Si。

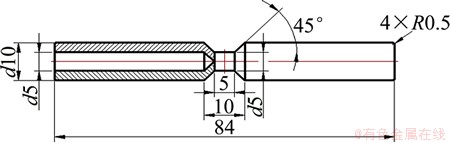

采用热分析法(DSC)、膨胀法并结合金相-硬度法,测试临界点Ac1,Ac3及Ac1点至Ms点之间的过冷奥氏体以不同速度连续冷却的相变点[9]。以10 ℃/min的速度将试样升温到1 000 ℃,获得升温DSC曲线,确定其临界点Ac1和Ac3。从钢管上切取直径为6 mm,长度为70 mm的试样,在真空状态下,以20 ℃/s 的速率升到900 ℃奥氏体化,保温10 min,分别以0.05,0.1,0.2,0.5,1,2,5,10,15,20,30和50 ℃/s的速度冷却至室温,利用Gleeble-3500热模拟机获取不同冷却速度的膨胀曲线,再由膨胀曲线确定相变温度点。以喷水冷却(冷却速度约400 ℃/s)测定其Ms点,图1所示为喷水冷却试样及尺寸示意图,沿钢管轴向在壁厚中间取样。

图1 喷水试样示意图(单位: mm)

Fig. 1 Schematic diagram of water-cooled samples

用常规的机械研磨及抛光方法制备金相样品,用4%(质量分数)硝酸酒精浸蚀,利用POLYVAR-MET金相显微镜观察组织和测量显微硬度(HV2)。利用QUANTA 200型扫描电镜观察淬火组织。

2 实验结果与分析

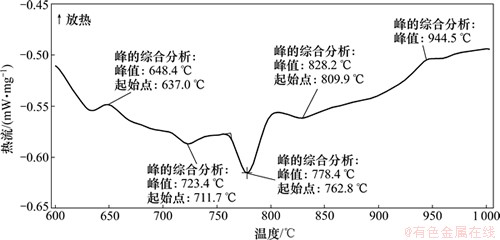

图2所示为28CrMnMoV钢的DSC曲线,采用峰值综合分析法得到临界温度点,Ac1=778 ℃,Ac3=828 ℃。

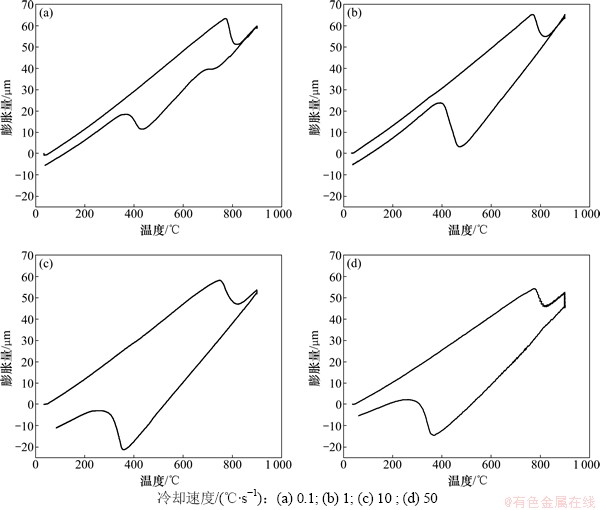

当钢发生固态相变时,由于新旧两相结构、比热容不同,材料的体积将发生不连续变化,因而,热膨胀曲线在发生相变的温度出现拐点,采用切线法可以确定各种相变点。图3所示为以0.1,1,10和50 ℃/s速度冷却实验钢的膨胀曲线,以0.1 ℃/s的速度连续冷却时,出现4个拐点,表明发生了2种相变。当冷却速度为1,10和50 ℃/s时,均只出现2个拐点,表明连续冷却过程中只发生了1种相变。图3(b)对应的相变开始点高于500 ℃,为中温相变,而图3(c)和3(d)对应的相变起止温度大致相同,均在400 ℃以下的低温区,相应的相变类型为马氏体转变。

图2 10 K/min时实验钢的升温DSC曲线

Fig. 2 DSC curve of experimental steel at 10 K/min

图3 过冷奥氏体的膨胀曲线

Fig. 3 Dilatometric curves of supercooled austenite

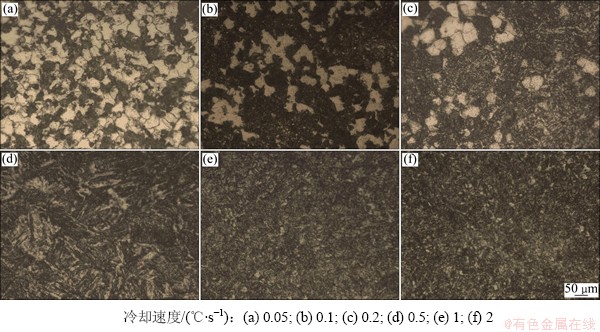

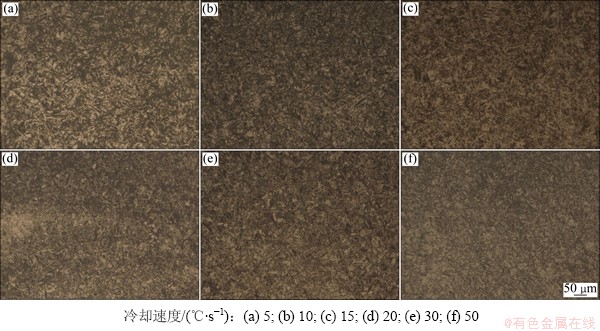

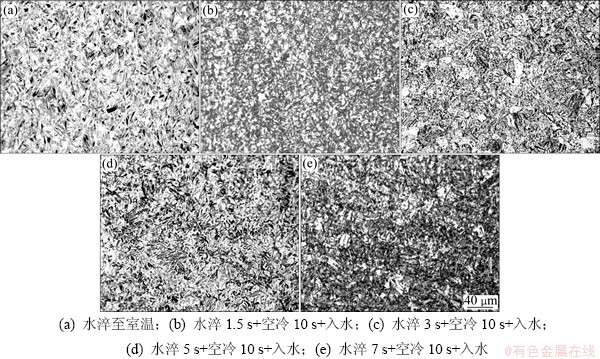

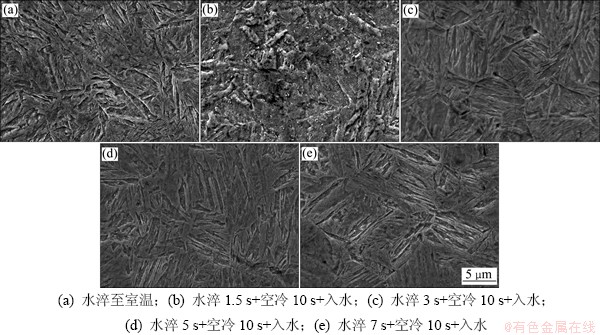

图4和图5所示为实验钢以不同速度冷却到室温的显微组织。当冷却速度为0.05~0.2 ℃/s时,转变产物为多边形铁素体、珠光体和少量贝氏体的混合组织,且随着冷却速度的增加,铁素体数量逐渐减少,贝氏体逐渐增多。在0.5~2 ℃/s的冷却速度范围内,转变产物基本为贝氏体组织,鲜有铁素体出现,仅在0.5 ℃/s冷速对应金相组织的个别视场发现极少量的铁素体。当冷却速度增加到5~50 ℃/s时,为淬火马氏体组织,随着冷却速度增加,马氏体数量逐渐增多。

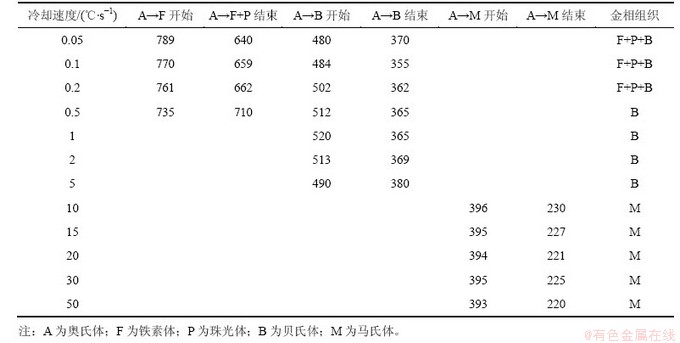

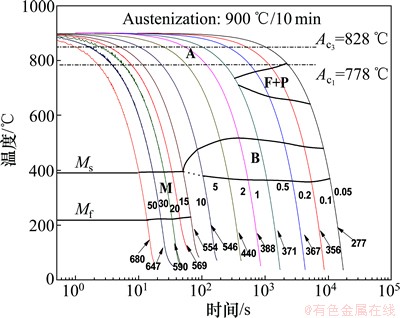

根据不同冷却速度膨胀曲线上的拐点(切点),结合显微组织观察和显微硬度测量,确定相变温度。表1所示为测得的不同冷却速度对应的相变温度,表2所示为不同速度冷却试样的维氏硬度。

图4 以不同速度连续冷却转变后的金相组织

Fig. 4 Microstructure of steel after continuous cooling at different cooling rates

图5 以不同速度连续冷却转变后的金相组织

Fig. 5 Microstructure of steel after continuous cooling at different cooling rates

表1 不同冷却速度对应的相变点温度

Table 1 Phase transformation temperatures corresponding to different cooling rates ℃

表2 不同速度冷却试样的维氏硬度

Table 2 Vickers hardness of samples for different cooling rates

根据膨胀曲线,当冷却速度大于0.5 ℃/s 时,连续冷却不会出现铁素体转变;当冷却速度大于5 ℃/s时,连续冷却只有马氏体转变。由图4(e)和图5(b)可以看出:1 ℃/s冷速对应组织为贝氏体组织,10 ℃/s冷速对应组织为淬火马氏体,因此,1 ℃/s可以视为不发生铁素体转变的临界冷却速度,10 ℃/s为发生马氏体转变的临界冷却速度。

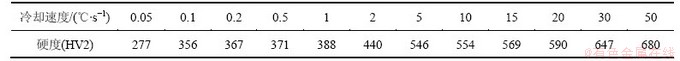

3 CCT图的绘制及分析

将表1中的相变点绘制到温度-时间半对数坐标上,将各物理意义相同的点连接起来,同时在该坐标上标出Ac1和Ac3,绘出如图6所示的CCT图,冷却曲线右边的数字为对应的冷却速度,下端的数字为以此速度冷却至室温的维氏硬度值。结合显微组织分析可知:高温区有铁素体转变和珠光体转变,中温区有贝氏体转变,低温区有马氏体转变;当冷却速度为0.05~0.5 ℃/s时,转变产物为多边形铁素体、珠光体和少量贝氏体,在1~5 ℃/s的速度范围连续冷却,转变产物为贝氏体;当冷却速度大于5 ℃/s时,转变产物为马氏体。

图6 28CrMnMoV钢的CCT图

Fig. 6 CCT diagram of 28CrMnMoV Steel

图7所示为已发表的29CrMo44钢的CCT图[10],测得的实验钢CCT图的相转变曲线与其有相似性,但因为两者的成分有细微差别,导致CCT图也有一定的差别,表明相变产物的生成与钢中合金元素的作用也密切相关。

图7 29CrMo44钢的CCT图

Fig. 7 CCT diagram of 29CrMo44 Steel

29CrMo44钢C质量分数比实验钢的稍高,Cr,Mo,Mn,Si和Ni元素含量均低于实验钢中的含量,不含V,合金元素从热力学和动力学2方面影响过冷奥氏体的转变,一方面改变新旧相的自由能差,使相变温度发生变化,另一方面影响相变产物的形核与长大过程。实验钢较低的含碳量降低了其淬透性,提高了过冷奥氏体的马氏体转变温度,马氏体转变开始温度为395 ℃,29CrMo44钢的马氏体转变温度为388 ℃。实验钢有较高的Cr,Mo和V等强碳化物形成元素,这些元素在奥氏体中的扩散速度较慢,同时提高C在奥氏体中的扩散激活能,强烈阻碍碳的扩散,从而推迟过冷奥氏体的扩散分解过程,降低珠光体和贝氏体的转变速度[11],当冷却速度稍大于0.5 ℃/s时实验钢就没有先共析铁素体和珠光体生成,而在较低冷却速度下有贝氏体转变。发生铁素体转变时,C要重新分布;发生珠光体转变时,Mo元素要重新分布, 发生贝氏体转变时,Mo元素不需要重新分布:因此,Mo推迟和减慢铁素体转变和珠光体转变,而对贝氏体转变速度影响较小,只是扩大了贝氏体转变的冷却速率范围[12]。受碳元素影响,V微量溶于铁素体中,当温度足以使钒碳化物完全分解而溶入奥氏体中时,V降低碳的扩散速度,增加过冷奥氏体稳定性,抑制珠光体转变,极易出现贝氏体组织[13],因此,含V的实验钢有着明显的中温转变区。实验钢的Cr含量较高,Cr抑制奥氏体转变,降低钢的临界冷却速度,推迟贝氏体转变的作用大于推迟珠光体转变的作用,在一般情况下,Cr降低钢的Ms温度,但是,当Cr以碳化物形式存在于奥氏体中时,反而使钢的Ms温度升高,淬火时Cr在奥氏体中的实际浓度决定Ms点。Mn,Si和Ni等弱碳化物或非碳化物形成元素,不同程度降低珠光体和贝氏体的转变速度,实验钢Mn含量较高,在0.05~10 ℃/s 的较宽冷却速度范围内连续冷却都会发生贝氏体转变。

4 CCT图的应用和验证

得到完全马氏体组织是钢管实现高强度的基础,必须以较快速度绕过高温转变和中温转变区,但是,钢管在水中发生马氏体转变时,内外温差导致较大热应力,体积膨胀产生较大组织应力,在组织应力和热应力同时作用下,容易产生淬火裂纹,降低钢管韧性[14]。工业生产高强度无缝钢管在淬火过程中极易开裂,为了减缓淬火应力,提高钢管韧性,降低脆裂概率[15],充分实现马氏体转变,可以利用CCT图来指导制定分级控冷工艺。为了避免贝氏体转变,控制钢管在水中的停留时间,温降到Bf点以下出水空冷,使钢管温度场尽可能均匀,然后再次入水完成马氏体转变,可以降低淬火应力,提高钢管的韧性。

热处理过程是一个温度、应力、相变相互影响的高度非线性问题,其中温度的变化会引起相变和热胀冷缩,导致应力应变。相变潜热和应变会影响温度场,而应力应变又会诱发相变,要在理论上对热处理温度场、组织场和应力场耦合求解较困难[16];另一方面,无法在线原位测量连续冷却试样的温度、组织、应力,只能在冷却到室温状态观察组织和残余应力分布情况,难以得到与实际生产相适应的结果。国内外学者综合数值计算方法、计算传热学、热弹塑性理论、相变动力学、计算流体力学等与热处理相关学科,为热处理过程的计算机模拟和仿真技术的发展奠定了坚实的基础[17]。

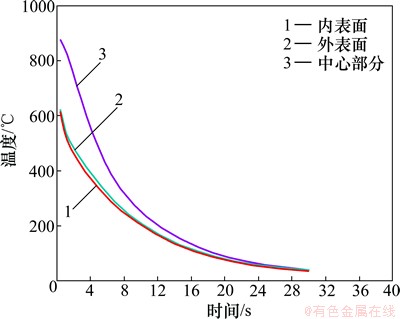

针对直径为139.70 mm、壁厚为12.70 mm的热轧管,模拟实际淬火冷却工艺,由890 ℃直接淬入20 ℃水,假设管材内外初始温度均匀。由于钢管具有对称性,可取其横截面的1/4建立几何模型,壁厚为12.70 mm,外径为69.85 mm,根据计算精度和网格规整性的要求,共划分成2 400个单元,沿径向20等分,沿圆周120等分。假设内外表面对流换热系数相同,内外表面的冷却速度相同,水淬对流换热系数参照29CrMo44V钢 [18],空冷的对流换热系数取45 W/(m2·℃),热物性参数参照25号钢[19]。图8所示为计算得到的中心部和表面节点的冷却曲线,淬入水中1~3 s,钢管内外表面和中心部的温差很大,随着停留时间延长,温差逐渐缩小。

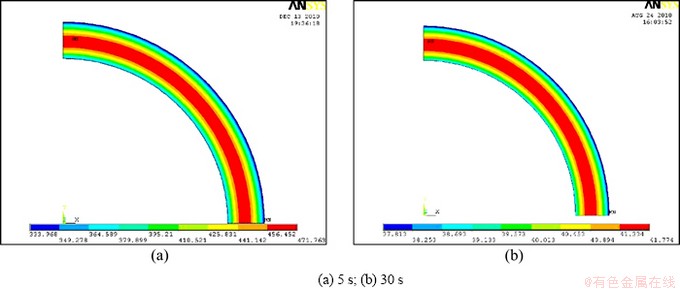

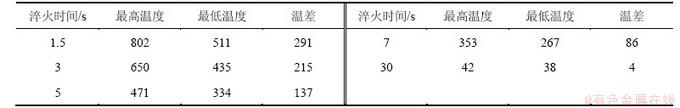

图9所示为钢管在水中停留5 s和30 s后横断面温度分布云图。从图9可以看出:钢管表面温度最低,心部温度最高,内外温差随着在水中停留时间延长而缩小,停留30 s出水后,横断面的温差为仅4 ℃。表3所示为在水中停留不同时间后钢管横断面的最高温度和最低温度。

进行5组淬火实验验证不同冷却方案的组织,分别为:1,水淬至室温;2,水淬1.5 s+空冷10 s+入水;3,水淬3 s+空冷10 s+入水;4,水淬5 s+空冷10 s+入水;5,水淬7 s+空冷10 s+入水。淬火温度为890 ℃,水温为20 ℃。淬火后截取金相样进行组织观察,结果如图10和图11所示。

根据测得的CCT图和表3可以分析钢管在水中停留不同时间的组织。淬火1.5 s出水时,最高温度为802℃,最低温度为511℃,根据CCT图推断,会发生铁素体转变和贝氏体转变,再入水发生马氏体转变。图10(b)表明该冷却方案对应的组织为铁素体、马氏体、少量贝氏体和部分碳化物。水淬3 s出水时,最高温度为650 ℃,最低温度为435 ℃,空冷主要发生贝氏体转变,再入水发生马氏体转变,实际组织为板条状马氏体、块状铁素体、少量下贝氏体。水淬5 s出水时最高温度为471 ℃,最低温度为334 ℃,发生贝氏体转变和马氏体转变,再入水发生马氏体转变,实际组织由贝氏体、板条状马氏体和少量孪晶马氏体。水淬7 s出水时,钢管的最高温度为353 ℃,最低温度为267 ℃,出水空冷不会有贝氏体转变,实际组织为孪晶马氏体和板条状马氏体。综上分析可知:由CCT图推断出的组织基本上与实际淬火组织一致,表明所测CCT图较准确,可用于指导高强高韧油套管的淬火。

图8 钢管淬火的冷却曲线

Fig. 8 Temperature-time curves of quenching-steel pipe

图9 不同淬水时间钢管横断面的温度分布云图

Fig. 9 Temperature distribution of steel pipe cross section for different water quenching time

表3 不同淬火时间钢管横断面的最高温度和最低温度

Table 3 Maximum and minimum temperatures of steel pipe cross section for different quenching time ℃

图10 不同冷却方案对应的金相微观组织

Fig. 10 Optical microstructure for different cooling scheme

图11 不同冷却方案对应的SEM微观组织

Fig. 11 SEM microstructure for different cooling scheme

在工业生产中,一般采用从奥氏体化温度直接水冷至室温的冷却方式。从图10(a)和图11(a)可以看出:直接水淬到室温的组织由板条马氏体+孪晶马氏体组成,其中孪晶马氏体的含量略多。马氏体中的孪晶界易于造成位错塞积,使孪晶界产生应力集中而出现微裂纹,与此同时,马氏体快速长大会导致互成一定角度的孪晶马氏体片相互碰撞,马氏体片尖端可能冲击原奥氏体晶界,降低材料的韧性。采用入水5 s+空冷10 s+再入水的冷却方案,提高马氏体转变前钢管横断面温度的均匀性,会对减小钢管淬火应力产生很好的效果,获得下贝氏体/马氏体复相组织,为V150油套管的高韧性提供组织基础,高温回火后可以获得较好的强韧性配合。

5 结论

1) 用膨胀法结合金相-硬度法和差热分析法测得了28CrMnMoV钢的CCT图,Ac1=778 ℃,Ac3=828 ℃,在高温区主要发生铁素体转变和珠光体转变,中温区发生贝氏体转变,低温区发生马氏体转变。当冷却速度为0.05~0.5 ℃/s时,转变产物为多边形铁素体、珠光体和少量贝氏体的混合组织,在1~5 ℃/s的冷却速度范围内,转变产物为贝氏体;当冷却速度大于5 ℃/s时,转变产物为马氏体。

2) 实验钢为低碳铬钼合金钢,较低的含碳量提高了马氏体转变温度,合金元素Cr,Mo和V有推迟奥氏体扩散分解的作用,只有以低于1 ℃/s的速度冷却才会有先共析铁素体和珠光体生成,较高的锰含量对贝氏体转变起到了明显的促进作用,在0.05~10 ℃/s 的较宽冷却速度范围内连续冷却都会发生贝氏体转变。

3) 所测CCT图可为28CrMnMoV钢的分级控冷工艺提供依据,采用入水5 s+空冷10 s+再入水的冷却方案,会对减小钢管淬火应力产生很好的效果,获得的下贝氏体/马氏体复相组织为V150油套管的高韧性提供组织基础,高温回火后可以获得较好的强韧性配合。

参考文献:

[1] 丰振军, 曹峰, 杨力能, 等. 中国油井管研究进展[J]. 石油工业技术监督, 2010, 26(7): 52-53.

FENG Zhenjun, CAO Feng, YANG Lineng, et al. Development of the study on the oil well tubes[J]. Technology Supervision in Petroleum Industry, 2010, 26(7): 52-53.

[2] 杨秀琴. 中国油井管的供求现状与发展[J]. 金属世界, 2012(3): 1-10.

YANG Xiuqin. Present status on supply and demand of oil country tubular goods and its development in China[J]. Metal World, 2012(3): 1-10.

[3] 李鹤林, 韩礼红, 张文利. 高性能油井管的需求与发展[J]. 钢管, 2009, 38(1): 1-9.

LI Helin, HAN Lihong, ZHANG Wenli. Demand for and development of hi-performance OCTG[J]. Steel Pipe, 2009, 38(1): 1-9.

[4] 李鹤林, 田伟. 面向 “十二五” 的油井管[J]. 钢管, 2012, 41(1): 1-6.

LI Helin, TIAN Wei. Development situation of OCTG industry and market in 12th FYP period[J]. Steel Pipe, 2012, 41(1): 1-6.

[5] 李鹤林, 张亚平, 韩礼红. 油井管发展动向及高性能油井管国产化(上)[J]. 钢管, 2007, 36(6): 1-6.

LI Helin, ZHANG Yaping, HAN Lihong. Development situation of OCTG and production localization of hi-grade OCTGPart (Ⅰ)[J]. Steel Pipe, 2007, 36(6): 1-6.

[6] 李鹤林, 田伟, 邝献任. 油井管供需形势分析与对策[J]. 钢管, 2010, 39(1): 1-7.

LI Helin, TIAN Wei, KUANG Xianren. OCTG supply-demand situation and countermeasures[J]. Steel Pipe, 2010, 39(1): 1-7.

[7] Janez G, Slavko B, Martin Z. Influence of quenching process parameters on residual stresses in steel[J]. Journal of Materials Processing Technology, 2001, 114(1): 57-70.

[8] Puschmann F, Specht E. Transient measurement of heat transfer in metal quenching with atomized sprays[J]. Experimental Thermal and Fluid Science, 2004, 28(6): 607-615.

[9] 李红英, 林武, 宾杰, 等. 低碳微合金管线钢过冷奥氏体连续冷却转变[J]. 中南大学学报(自然科学版), 2010, 41(3): 923- 929.

LI Hongying, LIN Wu, BIN Jie, et al. Continuous cooling transformation of undercooling austenite for lowcarbon microalloyed pipeline steel[J]. Journal of Central South University (Science and Technology), 2010, 41(3): 923-929.

[10] 刘江成, 张传友, 付继成, 等. 超深井用 V150 级高强高韧套管开发[C]//第七届中国钢铁年会大会论文集 (中). 北京, 2009: 490-496.

LIU Jiangcheng, ZHANG Chuanyou, FU Jicheng, et al. Development of grade V150 casing with high strength and high toughness for ultra-deep well service[C]//The 7th CSM annual meeting proceeding (Part Ⅱ). Beijing, 2009: 490-496.

[11] Podder A S, Bhadeshia H K. Thermal stability of austenite retained in bainitic steels[J]. Materials Science and Engineering A, 2010, 527(7/8): 2121-2128.

[12] 杨静, 李桂艳, 韩鹏, 等. 钼对高强度船板钢变形后连续冷却转变的影响[J]. 机械工程材料, 2009(8): 10-12.

YANG Jing, LI Guiyan, HAN Peng, et al. Effect of molybdenum on continuous cooling transformation of ship plate steel with high strength[J]. Materials For Mechanical Engineering, 2009(8): 10-12.

[13] Pan T,Yang C,Ma Y, et al. Chemistry and process optimization of V-microalloyed N80-class seamless casing tube[J]. Journal of Iron and Steel Research, 2010, 17(3): 72-78.

[14] Bergeon N, Kajiwara S, Kikuchi T. Atomic force microscope study of stress-induced martensite formation and its reverse transformation in a thermomechanically treated Fe–Mn–Si–Cr– Ni alloy[J]. Acta Materialia, 2000, 481(6): 4053-4064.

[15] 李亚欣, 刘雅政, 周乐育, 等. 石油套管淬火过程中残余应力场的数值模拟[J]. 北京科技大学学报, 2010, 32(11): 1440- 1446.

LI Yaxin, LIU Yazheng, ZHOU Leyu, et al. Numerical simulation of residual stress field in an oil casing during quenching process[J]. Journal of University of Science and Technology Beijing, 2010, 32(11): 1440-1446.

[16] 姚灿阳. 7050 铝合金厚板淬火温度场及内应力场的数值模拟研究[D]. 长沙: 中南大学机电工程学院, 2007: 18-22.

YAO Canyang. A study on the numerical simulation of distribution of temperature and stress in quenching process of aluminum alloy 7050[D]. Changsha: Central South University. School of Mechanical and Electrical Engineering, 2007: 18-22.

[17] Mackerle J. Finite element analysis and simulation of quenching and other heat treatment processes: A bibliography (1976–2001)[J]. Computational Materials Science, 2003, 27(3): 313-332.

[18] 武斌斌, 温殿英, 李连进, 等. 热轧高强度无缝钢管淬火工艺温度场有限元模拟[J]. 天津理工大学学报, 2007, 22(6): 28-31.

WU Binbin, WEN Dianying, LI Lianjin, et al. Simulation of temperature field of quenching process of hot-rolled high-strength seamless pipe by FEM[J]. Journal of Tianjin University of technology, 2007, 22(6): 28-31.

[19] 干勇, 田志凌, 董瀚, 等. 中国材料工程大典[M]. 北京: 化学工业出版社, 2006: 552.

GAN Yong, TIAN Zhining, DONG Han, et al. Chinese material engineering dictionary[M]. Beijing: Chemical Industry, 2006: 552.

(编辑 何运斌)

收稿日期:2013-12-27;修回日期:2014-04-24

基金项目:湖南省重大科技专项资助项目(2008FJ1003) (Foundation item: Project (2008FJ1003) supported by Major Science and Technology Program of Hunan Province)

通信作者:李红英(1963-),女,湖南湘乡人,博士,教授,博士生导师,从事金属及合金的强韧化研究;电话:0731-88836328;E-mail: lhying@csu.edu.cn