文章编号:1004-0609(2008)11-2014-06

摩擦条件对铝合金挤压变形流动行为的影响

李 峰1,刘晓晶1,苑世剑2

(1. 哈尔滨理工大学 材料科学与工程学院,哈尔滨 150040;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001)

摘 要:通过有限元模拟和实验,对不同摩擦挤压过程中铝合金变形流动行为的机理进行分析,并利用罗德系数和应力偏量不变量(J2)等特征量进行变形分区。结果表明:采用积极摩擦可使挤压时的“死区”缺陷完全消失,且塑性区内材料的应变类型由3种变为均一的拉伸类变化,显著地提高了挤压过程中坯料横断面上金属流速的均匀性,更利于金属的挤出成形。

关键词:挤压;摩擦条件;数值模拟;应变类型;金属流动行为

中图分类号:TG 376 文献标识码:A

Effect of friction condition on flow behavior of

aluminum alloys during extrusion

LI Feng1, LIU Xiao-jing1, YUAN Shi-jian2

(1. School of Materials Science and Engineering, Harbin University of Science and Technology, Harbin 150040, China;

2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China)

Abstract: The mechanical mechanism of the flow behavior of aluminum alloys during extrusion process with active friction was investigated by numerical simulations and experiments. The characteristic quantities such as the second invariant of the Lode parameter (μ) and deviatoric stress tensor (J2) were employed for the division of deformation area. The results show that when extruded with active friction, no metal flow interface forms at the container bottom, the dead metal zone completely disappears, the deformation types of the metal in the plastic deformation area change from three types to one type of tension. The homogeneity of the deformation as well as the metal flow is apparently improved, which will be helpful for extruding and promoting the quality of extrudates.

Key words: extrusion; friction condition; numerical simulations; deformation types; metal flow behavior

挤压成形过程中金属处于强烈的三向压应力状态,可充分发挥其塑性,获得较大变形量,特别适合一些低塑性难变形材料的加工成形。因此,挤压成形在航空航天、机械冶金等领域结构件的制造中获得广泛的应用[1?3]。

影响挤压过程中金属变形流动的因素很多,如摩擦与润滑条件、模具结构及坯料温度等。其中,摩擦是决定挤出制品性能的重要边界条件之一[4]。以正挤压为例,摩擦起阻碍作用,极易引起成形过程中产生流动缺陷,且消耗大量的挤压能。为了减小或消除摩擦阻力的影响,反向挤压、静液挤压等方法随之产生,但这些方法自身也存在着难以克服的弱点。因此,研究者通过大量研究发现,改变摩擦力的方向,可使其起积极作用[5?7]。在反挤压的基础上,M?LLER[8]提出使摩擦起积极作用的ISA法,利用该方法通过改善与优化挤压条件,能显著提高挤出制品的均匀性和力学性能。

尽管长期以来,挤压成形中的摩擦问题一直是大量研究的主题[9?10],但目前的研究仅限于工艺条件变化的影响和模型化的验证[11?13],对摩擦改变挤压成形过程中金属流动行为的本质机理则鲜有论述。针对以上不足,本文作者对不同摩擦的挤压过程进行实验研究,并利用罗德系数和应力偏量不变量等应力场特征量对成形过程进行了变形分区,进而对摩擦条件改变金属变形流动行为的力学机理进行对比分析。

1 实验

1.1 摩擦的作用方式

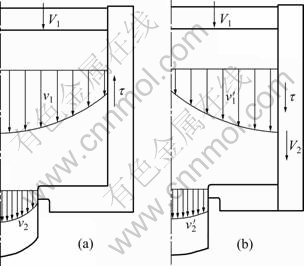

除模具结构形式外,摩擦与润滑也是影响挤压过程中金属流动行为的重要边界条件之一。其中,摩擦力的大小及方向对成形过程中金属的变形流动行为均产生较大影响,如图1所示。其中,τ为摩擦力的方向;V1为坯料所受端部作用力的方向;V2为凹模的运动方向;v1型腔内金属的流速分布;v2型腔入口部位金属的流速分布。

图1 摩擦的作用方式与金属流动行为的关系

Fig.1 Relationship between friction pattern and metal flow behavior: (a) Baffling effect; (b) Active effect

由图1可知,在冲头作用下金属逐渐向型腔内充填流动,凹模静止不动,其受模腔侧壁摩擦力的作用方向与金属的充填流动方向相反,因阻碍作用将引起模腔内金属流动行为沿径向的不均匀分布。其中,轴心处金属的流速较快,靠近模腔侧壁处材料的流速较慢。成形过程中坯料的形状尽管会发生显著改变,但仍为一连续整体。如果润滑条件较差,则两处金属流速的差异将随之增加,金属变形流动不均匀的趋势将显著加剧。

为了减小或消除摩擦阻力的影响,可通过改变成形过程中摩擦力的作用方向,使其起积极作用,如图1(b)所示。即在变形过程进行的同时,通过对模具施加与加载方向相同的运动,可使型腔中模壁处金属的流速显著提高,这样能有效地平衡模口处摩擦力的阻碍作用,显著提高充填时金属变形流动的均匀性。

1.2 工艺过程

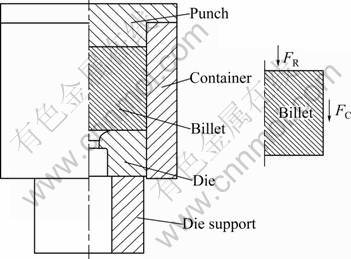

为了改善成形过程中摩擦阻力的不良影响,使其成为有助于金属发生塑性变形和改善流动的条件,在此设计了可实现带积极摩擦作用的成形装置,其原理如图2所示。

图2 工艺原理及受力分析示意图

Fig.2 Schematic diagram of technological principle and force analysis

图2中成形力FE = FR+FC。其中,FR为冲头作用力,FC为模腔的辅助摩擦力。由于FC的作用,使坯料外层金属的流动速度加快,与轴心部分速度相近,从而消除了充填成形过程中坯料横断面金属流速不均的影响。这种结构的设计,可实现冲头与成形方向相同的运动,同时省去模具与设备间的固定装置且不需考虑导向结构,使实验变得简便易行。

1.3 工艺方案

为了便于对比分析,本文作者分别对有、无润滑剂和积极摩擦等变形过程进行了研究,并通过圆环的热压缩实验测得有、无润滑剂时的摩擦因子分别为0.3和0.5,其他实验条件均与前述相同。冲头的速度为 1 mm/s,挤压温度为435 ℃,挤压比为9.8。

2 金属变形流动行为

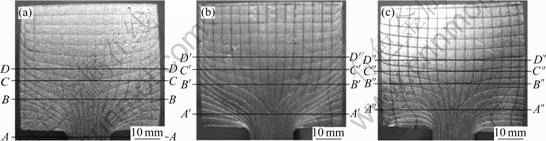

当压下量为20 mm时不同摩擦条件下坯料断面网格变形的分布如图3所示。

图3 坯料断面上的网格变形对比

Fig.3 Comparison of grids deformation patterns on billet section: (a) Without lubrication; (b) With lubrication; (c) With active friction

由图3(a)可以看出,在无润滑成形过程中,靠近模腔底角部金属由于受摩擦条件的影响,此处网格几乎不发生变化。因此,成形过程中该处金属较难以发生变形流动。从径向流线分布情况可以看出,模壁与轴心处金属变形流动的差异较大,由于受侧壁摩擦阻力的影响,该处金属的变形流动明显滞后于轴心部位;当使用润滑剂后,如图3(b)所示,模腔底角部难变形区的范围显著缩小,从径向流线的分布对比可知,模壁与轴心处金属的流速差异也明显降低。采用积极摩擦成形时,如图3(c)所示,坯料断面上网格流线的分布变得相对均匀。即使是靠近模腔底角部,剖面上轴向的网格流线也有明显地向型腔模口弯曲的趋势。由此可见,当采用该方式进行成形时,变形金属较易向型腔模口内均匀地充填流动,显著降低产生流动缺陷的可能性。

成形过程中金属变形流动的均匀性对锻件品质性能有着重要影响,因此,分别取原始位置相同的4个截面上各点变形后的轴向相对位移进行对比。为了便于测量分析,以变形后最远点作截面,所取截面位置如图3所示。

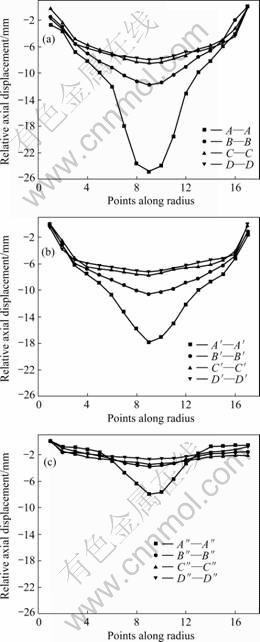

图4所示为变形后不同截面上各点轴向相对位移量的数值分布对比。由图4可知,不同变形过程中4个截面上各点的轴向相对位移量几乎都是沿着轴线呈对称分布。随着离轴心距离的减小,其绝对值逐渐增大,由此可知,充填过程中轴心处金属的变形流速最快。

图4 轴向相对位移量的对比

Fig.4 Comparison of axial relative displacements: (a) Without lubrication; (b) With lubrication; (c) With active friction

通过轴向相对位移量的对比可知,无润滑成形时因受凹模侧壁摩擦阻力的影响较大,不同截面上各点的轴向相对位移量的差别较大。其中,A—A截面上轴心处点的相对位移量为24.92 mm;采用润滑剂后,与A—A截面原始位置相同的A′—A′ 截面上,轴心处点的相对位移量仍为最大值,但其数值减小到17.76 mm;采用积极摩擦成形时,A″—A″ 截面上轴心处点的相对位移量与前两种挤压过程相比,其数值明显地降低,仅为7.98 mm,其余截面上各点的轴向相对位移量差别也显著减小。因此,采用积极摩擦可使挤压过程中塑性区内金属变形流动的均匀性明显增大,更利于提高挤压制品的质量。

3 挤压过程的应力应变

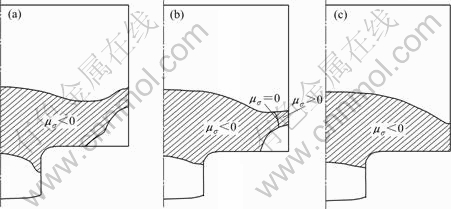

为了对不同摩擦条件下挤压过程的力学机理进行分析,利用应力偏张量第二不变量J2、Lode系数μ等特征量[14?15]对挤压过程进行变形分区,并对塑性区内的应力应变分布进行分析。图5所示为不同摩擦条件下的变形分区结果对比。

图5 不同摩擦条件下的变形分区对比

Fig.5 Comparison of deformations division under different friction conditions: (a) Without lubrication; (b) With lubrication; (c) With active friction

由图5(a)可以看出,无润滑成形过程中,模腔内发生塑性变形的金属均分布在型腔模口的附近。靠近凸模端部和已经充填进型腔的材料均处于刚性区,在其底角部存在部分难以满足塑性条件的区域,即“死区”。因塑性区内罗德系数的数值都为负,因此,该区内的材料均处于伸长类变化。当采用润滑剂后,模腔内塑性区的范围明显扩大,模腔底部难变形区的范围则相对缩小,如图5(b)所示。处于塑性区内材料的应变类型也发生了显著地改变,由罗德系数的分布可以看出,此处材料的应变类型是伸长类、平面应变及压缩类3种共存的。其中,塑性区内靠近模腔侧壁的部分材料应变类型为压缩类,模腔内塑性区里大部分材料的应变类型为伸长类变化,罗德系数为零的材料处于平面应变类变化。

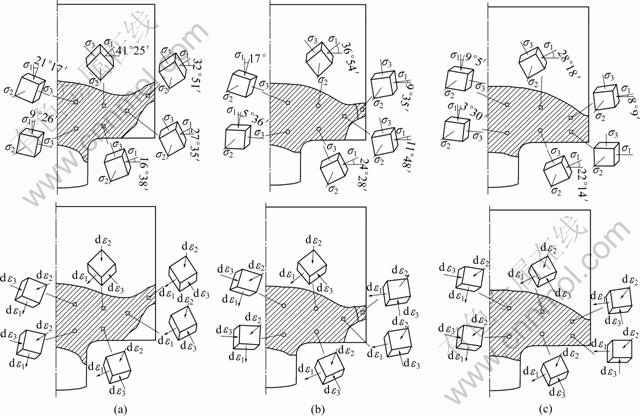

但积极摩擦成形过程中,金属的变形流动状况发生显著地改变,如图5(c)所示。其中,模腔底部区域内的材料,均因满足屈服条件而发生塑性变形并无死区产生。塑性区内材料的应变类型为均一的伸长类,因此与前两种情况相比,模腔内塑性区的范围则显著扩大,其变形流动也更加均匀。不同摩擦条件成形过程中塑性区内典型点的应力应变状态分布如图6所示。图中箭头的方向分别代表拉为正、压为负。

由图6可以看出,不同挤压过程中塑性区内各点的应力状态均为三向压应力,其最大主应力均朝着模口方向分布。但对于不同部位点的应力状态而言,其方向差异却很大。以靠近轴心处材料的应力状态为例进行说明,无润滑成形时,随着离模口距离的增加,最大主应力的分布与轴线发生较大的偏转;有润滑成形时该处各点最大主应力与轴线方向偏转角则明显减小;当采用积极摩擦后,偏转角的数值则显著地降低,该处各点最大主应力与轴线方向近似为一致。

从应变分布可以看出,无润滑成形过程中塑性区材料均处于伸长类变化。其最大主应变增量几乎都是向着模口方向呈伸长趋势变化,另两向呈缩短趋势变化。因此,该区内金属较易向模口方向充填流动,但因模腔内塑性区的范围相对较小,所以,成形过程中向型腔充填流动的金属量较小。

有润滑剂挤压过程中塑性区内材料均处于伸长类变化,应变变化趋势与前者相同;靠近侧壁处于压缩类变形的材料,除了沿径向发生较大的伸长变形外,沿环向的中间主应变也呈显著地伸长趋势变化,说明该区内金属除部分向模口流出外,另一少部分将逐渐留在模腔内而不易成形。当积极摩擦成形时,如图6(c)所示,塑性区内所有材料的应变类型均为伸长类,其最大主应变增量几乎都是沿着模口方向呈伸长趋势变化,另两个方向应变增量呈缩短趋势。因此,与前面两种成形过程相比,积极摩擦更利于金属的挤出成形。

图6 成形过程中应力应变状态的矢量分布

Fig.6 Vector distributions of stress and strain state: (a) Without lubrication; (b) With lubrication; (c) With active friction

4 结论

1) 采用积极摩擦挤压时,塑性区范围显著地扩大,模底处不存在难变形的区域。塑性区内材料的应变类型由3种变为均一的伸长类,显著地提高金属挤压变形流动的均匀性。

2) 无润滑挤压时,随着离模口距离的增加,最大主应力的分布与轴线方向发生较大偏转;采用积极摩擦后,该处各点最大主应力与轴线方向的偏转角则显著减小。

3) 无润滑剂时,轴心处点的相对位移量为最大值,采用润滑剂和积极摩擦成形后,该值分别降低28.7%和69.7%,因此,积极摩擦类挤压显著降低坯料横断面金属流速的不均性,有利于挤出制品质量的提高。

REFERENCES

[1] LI L, ZHOU J, DUSZCZYK J. Prediction of temperature evolution during the extrusion of 7075 aluminium alloy at various ram speeds by means of 3D FEM simulation[J]. J Mater Process Technol, 2004, 145(3): 360?370.

[2] QAMAR S Z, ARIF A F M, SHEIKH A K. A new definition of shape complexity for metal extrusion[J]. J Mater Process Technol, 2004, 151/156: 1734?1739.

[3] BAKHSHI-JOOYBARI M. A theoretical and experimental study of friction in metal forming by the use of the forward extrusion process[J]. J Mater Process Technol, 2004, 125/126: 369?374.

[4] HSU T C, HUANG C C. The friction modeling of different tribological interfaces in extrusion process[J]. J Mater Process Technol, 2003, 140(1/3): 49?53.

[5] BEREZHNOI V L, MOROZ B. Moskova[J]. WILS, 1976: 259?276.

[6] SAHA P K. Thermodyamics and tribology in aluminium extrusion[J]. Wear, 1998, 218(2): 179?190.

[7] LI F, YUAN S J, LIU G, HE Z B. Effect of friction on metal flow behavior during extrusion process[J]. J Mater Eng Perf, 2008, 17(1): 7?14.

[8] M?LLER K B. Advanced Technology of plasticity 2002[C]//KIUCHI M, NISHIMURA H, YANAGIMOTO J. Proceedings of the 7th ICTP, Japan, 2002: 427?432.

[9] HAO M. BAKHSHI-JOOYBARI. A theoretical and experimental study of friction in metal forming by the use of the forward extrusion process[J]. J Mater Process Technol, 2004, 125/126: 369?374.

[10] DAMODARAN D, SHIVPURI R. Prediction and control of part distortion during the hot extrusion of titanium alloys[J]. J Mater Process Technol, 2004, 150(1/2): 70?75.

[11] TAN Xin-cai. Comparisons of friction models in bulk metal forming[J]. Tribology International, 2002, 35(6): 385?393.

[12] 邓小民, 孙中建, 李胜祗, 方木云, 曹 杰. 铝合金挤压时的摩擦与摩擦因数[J]. 中国有色金属学报, 2003, 13(3): 599?605.

DENG Xiao-min, SUN Zhong-jian, LI Sheng-zhi, FANG Mu-yun, CAO Jie. Friction and friction coefficient for aluminium alloy extrusion[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(3): 599?605.

[13] RUDKINS N T, HARTLEY P, PILLINGER I, et al. Friction modeling and experimental observations in hot ring compression tests[J]. J Mater Process Technol, 1996, 60(3): 349?353.

[14] HU W L, HE Z B, FANG Y. Uniform principle on stress, strain and yield locus for analyzing metal forming processes: the contribution of Prof. Z.R. Wang[J]. J Mater Process Technol, 2004, 151(1/3): 27?32.

[15] WANG Z R. A consistent relationship between the stress- and strain-components and its application for analyzing the plane-stress forming process[J]. J Mater Process Technol, 1995, 55(1): 1?4.

基金项目:国家重点基础研究计划资助项目(5131903ZT2)

收稿日期:2008-03-11;修订日期:2008-09-03

通讯作者:李 峰,博士;电话:13199563940;E-mail: hitlif@126.com

(编辑 龙怀中)