利用微泡浮选柱从浮选尾矿中回收微细粒级白钨矿

黄光耀,冯其明,欧乐明,卢毅屏,张国范

(中南大学 资源加工与生物工程学院,湖南 长沙,410083)

摘 要:针对湖南安化湘安钨业公司白钨浮选尾矿中微细粒级未能在浮选机中有效分选的特点,研究开发一种微泡浮选柱,该浮选柱采用微孔材质发泡,并利用专家系统控制浮选柱关键工作参数。半工业试验获得了较适宜的柱浮选工作参数:表观矿浆速率为0.27 cm/s,表观气体速率为1.35 cm/s。工业试验获得的精矿品位可达24.52%,回收率为43.41%,富集比达35.03。水析试验结果表明:5~10,10~19和19~38 μm 3个粒级的回收率均达到65%以上。试验测得的浮选柱内气泡的Sauter直径为400 μm,仅为机械搅拌浮选机气泡的1/3,气泡直径减小促使浮选速率常数k显著增大,这是浮选柱能有效回收微细粒级白钨矿的主要原因。

关键词:微细矿物;浮选柱;白钨矿;浮选尾矿;二次资源利用

中图分类号:TD923 文献标识码:A 文章编号:1672-7207(2009)02-0263-05

Recovery of fine scheelites from flotation tailings by flotation column

HUANG Guang-yao, FENG Qi-ming, OU Le-ming, LU Yi-ping, ZHANG Guo-fan

(School of Resources Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: In order to recover fine scheelites from flotation tailings of cleaner circuit, a novel flotation column, which using microcellular material as bubble generator and using expert system to control key work parameters of the column, was manufactured. Pilot and full scale column flotation experiments were carried out, and interrelated work parameters of the column were obtained. The optimum work parameters are as follows: the superficial velocity of the feed 0.27 cm/s and the superficial velocity of air 1.57 cm/s. The recovery of WO3 reaches 43.41% with an average grade of 24.52%, and the enrichment ratio reaches 35.03. The recoveries of three different size fraction, 5-10 μm, 10-19 μm and 19-38 μm, all reach 65%. Sauter diameter of the bubbles in the column is about 400 μm, and smaller diameter make the flotation rate constant k increases greatly, improving flotation performance, which is the key reason that fine scheelites can be recovered.

Key words: fine particles; flotation column; scheelite; flotation tailings; recycling

钨是一种高熔点稀有金属,钨及其合金是现代工业、国防及高新技术应用中极为重要的功能材料之一。我国是钨资源大国,钨矿储量极其丰富,截至2005 年底,我国共有钨基础储量26.046 Mt(以WO3计算)。在钨矿查明资源储量中,黑钨矿约占20.8%,白钨矿约占69.6%,混合钨矿约占9.6%。我国钨矿现有生产规模按采选综合回收率58.4%计算,现有钨矿基础储量只能满足开采23 a的需要,即到2028年,我国钨矿基础储量将耗竭[1]。因此,面对国内钨矿资源面临枯竭的严峻形势,如何高效利用现有钨矿资源,实现钨业的可持续发展,是当前一项重要的研究课题。从钨尾矿中回收钨资源,是合理高效利用钨资源的一个重要方面,其不仅具有巨大的经济效益,而且具有重大的战略意义。

从钨尾矿中回收钨,技术上的难点是微细粒级颗粒中有用矿物的高效回收。对于微细粒级颗粒的回收,可以采用的有效途径主要有调药、调粒、调泡3种[2-5],即寻找高效的浮选药剂、选择合理的工艺参数、开发针对微细粒级颗粒浮选的浮选设备。微泡浮选柱被认为是一种能高效回收微细粒的浮选设备,在煤炭和黑色金属行业都得到了广泛应用[6-12]。微泡浮选柱技术特点是利用特殊的发泡材料产生小直径气泡,从而提高浮选速率常数,强化捕收;同时,通过泡沫区淋洗水来减少脉石矿物夹杂,从而提高精矿品位[13]。目前的研究表明,结合微泡浮选柱在微细粒级回收方面的优势,能实现资源的高效利用[14-15]。为进一步改善微泡浮选柱回收微细粒级性能,本文作者研制一种采用微孔材料发泡的浮选柱(CMPT),并进行半工业试验和工业试验,从钨浮选尾矿中回收微细粒级白钨,并对相关机理进行探讨。

1 试验方法

1.1 浮选机浮选试验

采用XFD型浮选机进行浮选试验。试验样品为湘安钨矿生产现场的精选尾矿,WO3含量为0.39%。实验所用油酸、水玻璃、氧化石蜡皂731、氧化石蜡皂733和氧化矿捕收剂(代号为OL)为工业品,新型捕收剂(代号为KL)为实验室合成品,浮选用水为工业 用水。

1.2 浮选柱半工业和工业试验

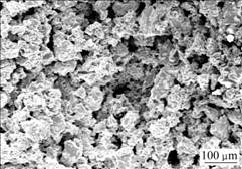

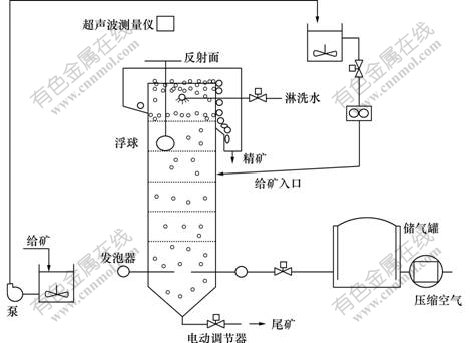

浮选柱浮选的药剂制度为:工业油酸40 g/t,水玻璃2 kg/t。半工业试验使用浮选柱规格为直径 140 mm,长3 m;工业试验使用浮选柱规格为直径600 mm,长6.5 m。浮选柱利用压缩空气通过微孔材质发泡,图1所示为浮选柱微孔材质发泡器的扫描电镜(SEM)照片,发泡器孔径大小和形状不均匀,最大接近100 ?m,最小为1 ?m,其平均孔径为10 ?m。图2所示为浮选柱半工业和工业试验时设备联系示意图。

图1 微孔材质发泡器SEM照片

Fig.1 SEM image of microcellular material

图2 浮选柱试验示意图

Fig.2 Schematic diagram of experimental apparatus

2 结果与讨论

2.1 浮选机浮选试验

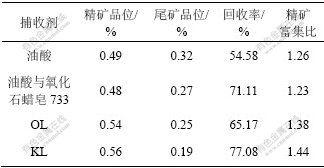

分别用油酸、油酸与氧化石蜡皂733(1?1)、OL与KL药剂作捕收剂,进行浮选试验。试验条件为:药剂用量120 g/t,pH=10,水玻璃作抑制剂,用量为2 kg/t。试验结果如表1所示。

表1 不同种类捕收剂试验结果

Table 1 Flotation results under different collectors

从表1可以看出,采用机械搅拌式浮选机,富集比小于1.5,这表明机械搅拌式浮选机未能对微细粒级进行选择性回收,加之机械搅拌浮选机存在一定的脉石夹杂效应,导致它不能有效地从精选尾矿中回收微细粒级(5~19 ?m)白钨。

2.2 微泡浮选柱半工业试验

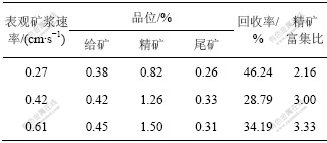

2.2.1 表观矿浆速率

表观矿浆速率决定了矿浆在浮选柱内的浮选时间,表观矿浆速率大,矿浆在浮选柱的浮选时间较短,而浮选时间对浮选效果有直接影响,故而表观矿浆速率会影响浮选效果。表2所示为不同表观矿浆速率的试验结果。从表2可以看出,合适的表观矿浆速率为0.27 cm/s,在后续的试验中表观矿浆速度控制在0.27 cm/s。

表2 表观矿浆速率对浮选的影响

Table 2 Effect of superficial velocity of feed on flotation performance

2.2.2 表观气体速率

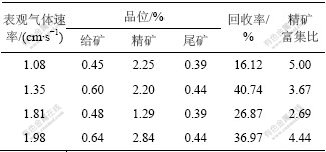

在不补加精矿冲洗水的条件下,进行了表观气体速率试验,结果见表3。从表3可以看出,当表观气体速率为1.35 cm/s时,可得到最大的回收率,故合适的表观气体速率为1.35 cm/s,后续试验表观气体速率控制在1.35 cm/s。

表3 表观气体速率对浮选的影响

Table 3 Effect of superficial velocity of air on flotation performance

2.2.3 精矿泡沫区淋洗水

表4所示为精矿泡沫区添加淋洗水试验结果。从表4可以看出,精矿泡沫区添加淋洗水可明显减少非目的矿物夹杂,提高精矿品位,实现较高的富集比,但淋洗水过大会使回收率降低。

表4 精矿泡沫区淋洗水对浮选的影响

Table 4 Effect of wash water on flotation performance

2.2.4 添加充填材料方式

柱内充填材料的布置方式,也会影响浮选效果,表5所示为充填材料试验结果,从表5可以看出,充填层同一方向排列时,可获得较高的回收率,但精矿质量较低;充填层呈相互垂直方向排列时,可获得较高的精矿质量,但回收率有所降低。

表5 充填材料方式对浮选的影响

Table 5 Effect of baffle on flotation performance

2.3 微泡浮选柱工业试验

工业试验条件为:泡沫层厚度控制在500 mm左右,精矿淋洗水控制在0.04 cm/s,表观气体速率控制在1.0~1.5 cm/s,尾矿处理量为1.5 t/h。

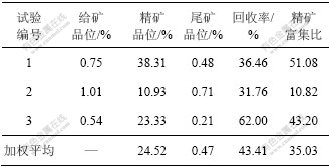

工业试验部分结果如表6所示。从表6可以看出,最高的精矿品位可达38%左右,最大的精矿富集比可达51左右,平均精矿品位为24.52%,平均精矿富集比为35.03%,工业试验数据波动较大,主要原因是给矿条件(现场精选作业尾矿)变化较大,部分工艺参数被调整。工业试验及后续工业生产实践表明采用该浮选柱能有效地从精选尾矿中回收白钨。

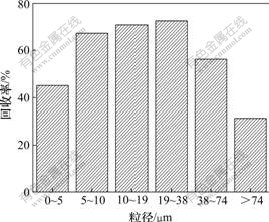

对浮选柱给矿、精矿、尾矿进行标准沉降水析试验,计算了粒级回收率,结果如图3所示。由图3可以看出,5~10,10~19和19~38 μm 3个粒级的回收率均可达到65%以上,表明微细粒颗粒得到有效回收。

表6 浮选柱工业试验部分结果

Table 6 Results of full scale column flotation

图3 粒级回收率

Fig.3 Recovery of different size fraction

2.4 微泡浮选柱回收微细粒级的机理

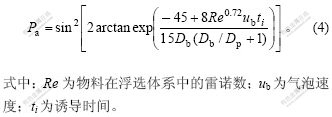

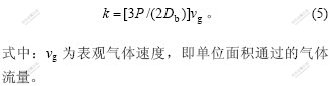

根据经典浮选理论,在浮选矿浆体系中矿物颗粒被气泡捕捉的可能性P为:

对微细矿物颗粒,其与气泡碰撞的Pd较小,可以忽略,故

; (2)

; (2)

Pa随着矿物颗粒直径和气泡直径的减小而增大。

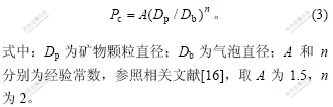

浮选速率常数k为:

结合式(3),(4)和(5)可以推出:

。 (6)

。 (6)

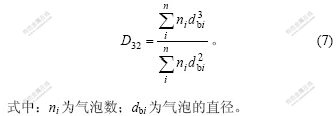

浮选速率常数k随着气泡直径的减小成几何级数增加。试验室用佳能数码相机A610捕捉了浮选柱产生的微泡,采用数字图像技术计算,得到气泡的Sauter 直径(D32)为0.40 mm。

Grau等[17]测量了试验室机械浮选机产生气泡的直径,其气泡Sauter直径D32为1.2~2.9 mm,本研究中浮选柱内气泡Sauter直径为0.40 mm,仅为该值的1/3,故与机械搅拌浮选机相比,浮选速率常数k呈几何级数增加,因为微粒粒级白钨矿浮选速率常数增加,所以它能够在精矿产品中得到富集,这是微细粒级白钨矿能被回收的主要原因。此外,柱浮选采用的泡沫区精矿淋洗水减少脉石矿物夹杂,可以实现较高的富集比。

3 结 论

a. 采用本文研制的新型微泡浮选柱,能有效回收尾矿中的微细粒级白钨,回收率达43.41%,精矿品位24.52%,精矿富集比可达35.03。

b. 浮选柱内气泡的Sauter直径为400 ?m,使微细粒级白钨矿的浮选速率常数显著增加,这是微细粒级白钨矿回收的主要原因。同时,粒级分析结果表明,5~10,10~19和19~38 μm 3个粒级的回收率均达到65%,也表明微细粒级白钨矿得到了有效回收。

参考文献:

[1] 吴荣庆, 张燕如. 关于对钨矿行业实行宏观调控的政策建议[J]. 中国钨业, 2006, 21(6): 5-9.

WU Rong-qing, ZHANG Yan-ru. On macroscopic control to China’s tungsten industry[J]. China Tungsten Industry, 2006, 21(6): 5-9.

[2] 王淀佐. 浮选理论的新进展[M]. 北京: 科学出版社, 1992: 220-221.

WANG Dian-zuo. New development in flotation theory[M]. Beijing: Science Press, 1992: 220-221

[3] 刘文刚, 魏德洲, 周东琴, 等. 螯合捕收剂在浮选中的应用[J]. 国外金属矿选矿, 2006, 43(7): 4-8.

LIU Wen-gang, WEI De-zhou, ZHOU Dong-qing, et al. An application of chelating agents as collectors in flotation processing[J]. Metallic Ore Dressing Abroad, 2006, 43(7): 4-8.

[4] Liu Q, Wannas D, Peng Y J. Exploiting the dual functions of polymer depressants in fine particle flotation[J]. Int J Miner Process, 2006, 80(2/4): 244-254.

[5] Rubio J, Capponi F, Rodrigues R T, et al. Enhanced flotation of sulfide fines using the emulsified oil extender technique[J]. Int J Miner Process, 2007, 84(1/4): 41-50.

[6] Demir U, Yamik A, Kelebek S, et al. Characterization and column flotation of bottom ashes from Tuncbilek power plant[J]. Fuel, 2008, 87(6): 666-672.

[7] Eisele T C, Kawatra K S. Reverse column flotation of iron ore[J]. Minerals & Metallurgical Processing, 2007, 24(1): 61-65.

[8] Banisi S, Finch J A. Testing a flotation column at the sarcheshmeh copper mine[J]. Minerals Engineering, 2001, 14(7): 785-789.

[9] Günry A, ?nal G, ?elik M S. A new flowsheet for processing chromite fines by column flotation and the collector adsorption mechanism[J]. Minerals Engineering, 1999, 12(9): 1041-1049.

[10] Valderrama L, Rubio J. Unconventional column flotation of low-grade gold fine particles from tailings[J]. Int J Miner Process, 2008, 86(1/4): 75-84.

[11] Tao D, Luttrell G H, Yoon R H. A parametric study of froth stability and its effect on column flotation of fine particles[J]. Int J Miner Process, 2000, 59(1): 25-43.

[12] Yianatos J B, Bergh L G, Cortés G A. Forth zone modeling of an industrial flotation column[J]. Minerals Engineering, 1998, 11(5): 423-435.

[13] Ireland P, Cunningham R, Jameson G J. The behaviour of wash water injected into a froth[J]. Int J Miner Process, 2007, 84(1/4): 99-107.

[14] 欧乐明, 冯其明, 张国范, 等. 颗粒表面电化学反应电荷传递模型及其浮选意义[J]. 中南大学学报: 自然科学版, 2005, 36(3): 402-406.

OU Le-ming, FENG Qi-ming, ZHANG Guo-fan, et al. Model of electrochemical reaction charge transferring on surface of mineral grain and its flotation significance[J]. Journal of Central South University: Science and Technology, 2005, 36(3): 402-406.

[15] 冯其明, 穆 枭, 张国范, 等. 铝土矿浮选泡沫消泡研究[J]. 中南大学学报: 自然科学版, 2005, 36(6): 955-959.

FENG Qi-ming, MU Xiao, ZHANG Guo-fan, et al. Investigation on antifoaming of flotation bauxite[J]. Journal of Central South University: Science and Technology, 2005, 36(6): 955-959.

[16] Yoon R H. Microbubble flotation[J]. Minerals Engineering, 1993, 6(6): 619-630.

[17] Grau R A, Heiskanen K. Bubble size distribution in laboratory scale flotation cells[J]. Minerals Engineering, 2005, 18(12): 1164-1172.

收稿日期:2008-06-11;修回日期:2008-09-19

基金项目:国家重点基础研究发展计划资助项目(2007CB13602);国家自然科学基金资助项目(50574101)

通信作者: 冯其明(1962-),男,湖北天门人,教授,博士生导师,从事微细粒浮选与二次资源再生研究;电话:0731-8836817;E-mail: qmf@mail.csu.edu.cn