铝电解金属陶瓷惰性阳极气体及电解质流场仿真

张红亮,王志刚,李劼,赖延清

(中南大学 冶金科学与工程学院,湖南 长沙,410083)

摘 要:采用有限体积法仿真计算惰性阳极气体运动及其带动下的电解质流动,并研究工艺及结构参数对阳极气体和电解质流场的影响。研究结果表明:电解质沿阳极中心呈对称循环流动,距离阳极气体越近,电解质流速越大;气体流速随气泡直径的增大而增加,电解质流速先下降后增加,气泡直径控制在3 mm为宜;若电流、电解温度和阳极浸入电解质深度增加,则气体的平均流速降低,电解质平均流速增加,应适当降低电流、电解温度和阳极浸入电解质深度;极距增加,则气体平均流速增加,电解质平均流速降低,可适当增加极距;阳极结构本身对流场结果有一定影响,若阳极半径增加,则气体的平均流速增加,电解质平均流速降低,合理的阳极倒角半径为35~40 mm。

关键词:铝电解;惰性阳极;阳极气体;电解质;流场仿真

中图分类号:TF821 文献标志码:A 文章编号:1672-7207(2010)04-1256-07

Simulation on flow field of anode gas and electrolyte in aluminum electrolysis with cermet inert anodes

ZHANG Hong-liang, WANG Zhi-gang, LI Jie, LAI Yan-qing

(School of Metallurgy Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The anode gas movement and its induced electrolyte flow field were calculated using finite volume method and the effect of structural and technical parameters was also considered. The results show that the electrolyte moves symmetrically and circularly with bigger velocity near the anode gas. The gas velocity increases with the increase of bubble diameter while the electrolyte velocity increases firstly and then decreases, which is beneficial to control the bubble diameter to be 3 mm. With the increase of current, temperature and anode immersion depth, the average velocity of gas reduces while the average velocity of electrolyte increases, so the current, temperature and anode immersion depth should be lowered properly. The anode-cathode distance can be increased properly because increasing anode-cathode distance can accelerate the average velocity of gas and reduce the electrolyte velocity. The anode structure itself has some influence on the flow field, the average velocity of gas and electrolyte increases and reduces respectively with the increase of anode radius, while the reasonable anode chamfer radius is 35-40 mm.

Key words: aluminum electrolysis; inert anode; anode gas; electrolyte; flow field simulation

熔盐电解法生产铝是目前工业炼铝的唯一方 法,电解槽通常采用碳素阳极和阴极,电解槽通入强大的直流电,在阴极析出金属铝,在阳极生成CO2和CO气体。在电解过程中,碳素阳极直接参与化学反应,因而不断消耗,需要定时更换阳极来维持电解生产,由此产生了一系列的问题:(1) 优质碳消耗量大,需要配备庞大的碳素阳极生产工厂,增加了生产成本;(2) 阳极需经常更换,增加了劳动强度;(3) 极距不稳定,需要复杂的机械装置来调整极距;(4) 电解反应产生大量的温室气体CO2和少量的CO以及大量的致癌物质CFn等,给环境造成极大的污染。而使用惰性阳极及相应的电解工艺则可以有效避免这些问题,并具有如下优点:(1) 无需碳素阳极生产工厂,生产成本降低;(2) 阳极不需经常更换,降低了劳动强度;(3) 极距稳定,易于控制;(4) 阳极产品为氧气,避免了环境污染[1]。

本文作者在进行惰性阳极电解试验时发现2种现象:阳极气泡相当细小且无阳极效应发生。而国内外其他学者也有过相关报道,如Cassayre等[2-3]在对析氧阳极(SnO2, Cu, Cu-Ni, Cu-Al)和碳素阳极电解过程的气泡特征的研究中发现惰性阳极的O2气泡细小,析出特征与碳素阳极上CO2气泡析出特征有很大差异;徐君莉等[4]研究了采用金属惰性阳极的铝电解过程中不同电流密度下阳极气泡的成核、长大、汇聚和排放过程,发现阳极气泡细小;Gao等[5]采用透明电解槽观测了惰性阳极和碳素阳极电解过程的气泡析出行为,发现碳素阳极气泡聚集长大后以大气泡析出,而金属阳极上气泡析出过程可分为阳极表面氧化、O2形成和气泡脱附3个阶段。因此,对惰性阳极的气体行为进行研究,能够对惰性电极铝电解新工艺的开发提供理论基础与技术支撑。目前,对阳极气体及其扰动下的电解质流场进行研究主要有物理模型[6-9]、实验室电解槽[10]及数值模拟[11-13]3种方法。近年来,数值模拟的方法越来越多地应用于铝电解工业中,为铝电解槽的结构改造及工艺设计提供了许多参考。数值模拟的优点在于能够方便地了解各参数变化对结果的影响,降低设计成本。此外,数值模拟也使计算结果能更好地可视化。在此,本文作者采用数值模拟方法计算惰性阳极气体及其带动下的电解质流动情况,并考查相关结构及工艺参数对流场的影响。

1 模型及计算方法

1.1 模型简化

铝电解槽中的阳极气体及电解质流动场十分复杂,是典型的多相流动,在进行数值模拟时必须进行相应的简化:

(1) 不考虑电解质中悬浮氧化铝的影响,即简化为两相流模型。

(2) 不考虑电解质中的温度分布不均,认为温度均匀即为电解温度,在求解控制方程时不求解能量方程,只求解连续性方程和动量方程。

(3) 不考虑气泡之间的碰撞和接合。

1.2 基本方程

本文采用欧拉-欧拉多相流计算方法,其连续性方程为:

(1)

(1)

式中: ,ρi和Ui分别表示i相(i为L或G,L表示电解质,G表示气体)的体积分数、密度和平均速度。在求解区域的每个微元内,电解质和氧气共同存在,体积分数之间存在关系:

,ρi和Ui分别表示i相(i为L或G,L表示电解质,G表示气体)的体积分数、密度和平均速度。在求解区域的每个微元内,电解质和氧气共同存在,体积分数之间存在关系:

(2)

(2)

动量方程为:

(3)

(3)

式中:SMi表示质量力;μeff为有效黏度;p为两相压力。Mi(ML= -MG)为两相的动量传递,它是两相相对速度、各相密度、界面密度和曳力系数的函数。曳力系数采用Ishii-Zuber关系式进行计算,

(4)

(4)

式中:Re为相对Reynolds数;Bo为Bond数,

,

,  (5)

(5)

μL为电解质黏度;d为气泡直径;g为重力加速度;σ为气体与电解质之间的表面张力,这里取为0.14 N/m。

对于电解质,湍流模型选为标准k-ε模型;对于气体,湍流模型选为零方程模型[14]。

1.3 模型及边界条件

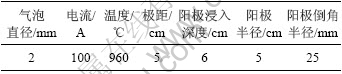

模型初始情况下的结构及工艺参数如表1所示。

表1 初始结构及工艺参数

Table 1 Initial structural and technical parameters

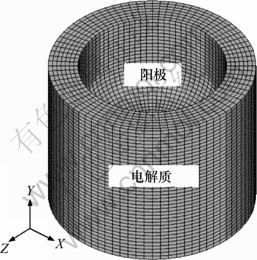

模型在ANSYS中生成并进行网格划分(如图1),然后,输出到CFX中进行边界条件及求解的相关 设定。

图1 模型网格划分

Fig.1 Mesh of model

阳极底部及侧部面设定为Inlet边界,定义气体和电解质的体积分数和速度,电解质的速度定义为0 cm/s,气体的速度采用以下公式计算[15]:

(6)

(6)

式中:I为电流;R为理想气体常数;T为温度;F为法拉第常数;P为压力; 为气体的体积分数;S为浸入电解质中的阳极面积。电解质上表面定义为Outlet中的Degassing边界,其他面设置为Wall边界。

为气体的体积分数;S为浸入电解质中的阳极面积。电解质上表面定义为Outlet中的Degassing边界,其他面设置为Wall边界。

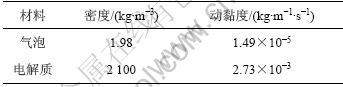

1.4 材料属性

计算中所需的材料属性见表2[14]。

表2 材料属性

Table 2 Material properties

2 结果与讨论

2.1 初始结果分析

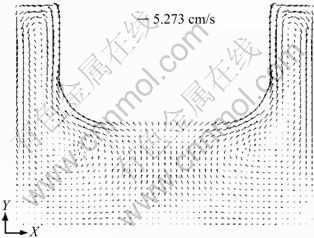

在初始条件下,经计算得到Z=0平面的电解质流速矢量图如图2所示。从图2可见:电解质在阳极气体的作用下随阳极气体上升,遇到空气表面后又返回到电解槽中,整体上形成了2个对称的旋涡;在阳极侧部旋涡更为明显,距离阳极气体越近,电解质流速越大,电解质最大流速为5.273 cm/s。

图2 电解质流速矢量图(Z=0)

Fig.2 Vector of electrolyte velocity (Z=0)

2.2 气泡直径的影响

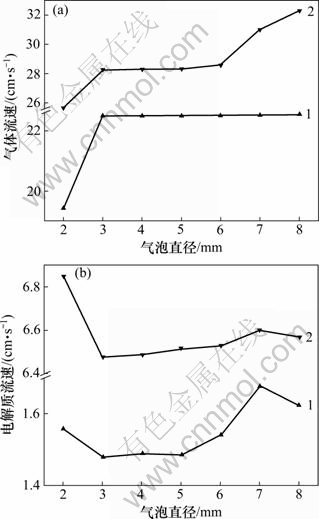

根据电解实验观察,惰性阳极电解时阳极气泡细小,估计直径范围为2~8 mm。当设定气泡直径由2 mm增加至8 mm时,气体流速与电解质流速的相应变化如图3所示。

(a) 气体流速;(b) 电解质流速

1—平均流速;2—最大流速

图3 流速随气泡直径的变化

Fig.3 Velocity variation with bubble diameter

从图3(a)可见:随着气泡直径的增大,气体的平均流速和最大流速都有一定程度的增大,其中气体最大流速增加幅度较大,气泡直径由2 mm增加到8 mm时,气体最大流速由25.661 cm/s增加到32.308 cm/s,增加了25.90%。气体的平均流速在气泡直径由2 mm增加到3 mm时有较大程度的增加,而后随着气泡直径的变化,气体的平均流速变化不明显。图3(b)表明电解质流速在气泡直径由2 mm增加到3 mm时,最大流速和平均流速有所降低,而后随气泡直径增加总体呈上升趋势,平均流速及最大流速均在气泡直径 3 mm时最小。气体的流速越大,气流就能够越快地从电解槽中脱离出去,对电解过程的不良影响就会越小,因此从增大气体流速、降低电解质流速的角度考虑,气泡直径控制在3 mm是比较理想的。

2.3 电流的影响

当电流由70 A增大到130 A时,气体流速与电解质流速的相应变化如图4所示。

从图4(a)可见:随着电流的增加,气体的平均流速略有下降,但下降幅度很小,平均流速仅从19.454 cm/s下降到19.425 cm/s。气体的最大流速随电流的增加而增加,变化较平均流速变化明显,随电流的增加,最大流速由24.685 cm/s增加到26.498 cm/s,增加了7.34%。图4(b)表明:电解质流速随电流的增大而增大,其中平均流速由1.326 cm/s增加到1.759 cm/s,增加了32.65%,最大流速由5.712 cm/s增加到7.862 cm/s,增加了37.64%。电解质流速增加是由于电流越大,气体的生成率越高,单位时间内注入的气体量越多,因此,电解质流速越大。故从增加气体流速、降低电解质流速的角度考虑,电流不宜过大。

(a) 气体流速;(b) 电解质流速

1—平均流速;2—最大流速

图4 流速随电流的变化

Fig.4 Velocity variation with current intensity

2.4 温度的影响

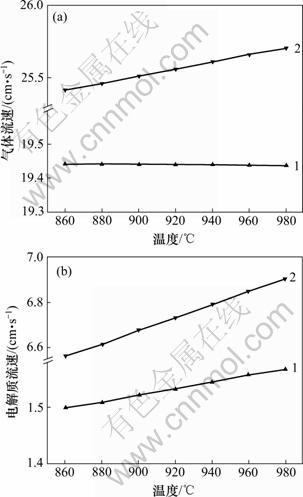

当电解质温度由860 ℃增加到980 ℃时,气体流速与电解质流速的相应变化如图5所示。

(a) 气体流速;(b) 电解质流速

1—平均流速;2—最大流速

图5 流速随温度的变化

Fig.5 Velocity variation with temperature

从图5(a)可见:电解质温度对气体流速的影响与电流的影响相同,随着温度的升高,气体的平均流速略有降低,但降低很小,而气体的最大流速有所增加,增加幅度也同样不大。从图5(b)可见:电解质平均流速和最大流速均随着温度的升高而增大,平均流速由1.499 cm/s增加到1.567 cm/s,增加了4.54%,电解质最大流速增加了5.24%。温度升高,气体生成率增加,因此,电解质流速有所增加。从增大气体流速、降低电解质流速的角度考虑,低温电解更有利于提高电流效率。

2.5 极距的影响

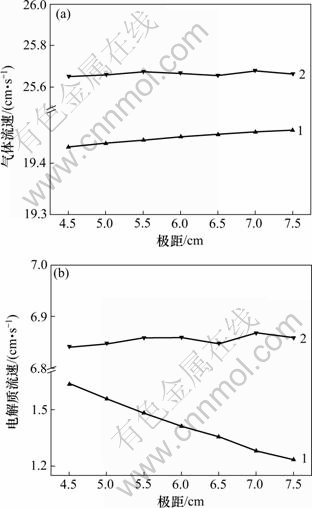

当极距由4.5 cm增加到7.5 cm时,气体流速与电解质流速的相应变化如图6所示。

(a) 气体流速;(b) 电解质流速

1—平均流速;2—最大流速

图6 流速随极距的变化

Fig.6 Velocity variation with anode-cathode distance

从图6(a)可见:气体的平均流速随极距的增加而增加,当极距由4.5 cm增至7.5 cm时,气体的平均流速由19.431 cm/s增加到19.464 cm/s;气体的最大流速随极距的增加基本保持不变。从图6(b)可见:电解质平均流速随极距的增加而下降,当极距由4.5 cm增至 7.5 cm时,电解质平均流速由1.634 cm/s下降至1.236 cm/s,降低了24.36%。电解质最大流速随极距增加没有明显变化。极距增加相当于增加了电解质的体积,在气体生成率不变的情况下,电解质的流速自然会有所降低。从增大气体流速、降低电解质流速的角度考虑,适当增加极距是有利的。

2.6 阳极浸入电解质深度的影响

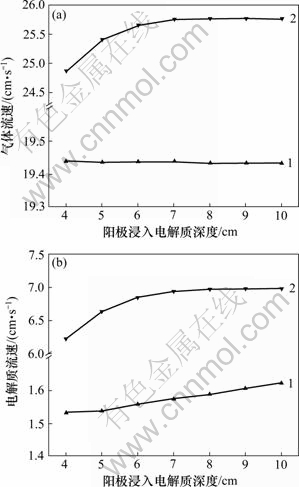

当阳极浸入电解质深度由4 cm增加到10 cm时,气体流速与电解质流速的相应变化如图7所示。

(a) 气体流速;(b) 电解质流速

1—平均流速;2—最大流速

图7 流速随阳极浸入电解质深度的变化

Fig.7 Velocity variation with anode immersion depth

从图7(a)可见:随着阳极浸入电解质深度的增加,气体的平均流速整体呈下降趋势,但变化幅度很小,气体的最大流速呈上升趋势,但增幅同样不大。从图7(b)可见:电解质平均流速及最大流速随着阳极浸入电解质深度的增加基本呈上升趋势,其中电解质的平均流速由1.533cm/s增加到1.623cm/s,增加了5.87%;最大流速由6.225cm/s增加到6.983cm/s,增加了12.18%。从增大气体流速、降低电解质流速的角度考虑,阳极浸入电解质深度取小为宜。

2.7 阳极半径的影响

当阳极半径由4 cm增加到10 cm时,气体流速与电解质流速的相应变化如图8所示。

(a) 气体流速;(b) 电解质流速

1—平均流速;2—最大流速

图8 流速随阳极半径的变化

Fig.8 Velocity variation with anode radius

从图8(a)可见:随着阳极半径的增加,气体的最大流速下降,气体的平均流速基本保持不变,最大流速由26.434 cm/s下降到23.813 cm/s,下降了9.92%。从图8(b)可见:电解质平均流速随阳极半径的增大基本呈下降趋势,只在阳极半径由9 cm增加到10 cm时略有上升;当阳极半径由4 cm增加到8 cm时,电解质平均流速下降较为明显,由1.626 cm/s下降至1.380 cm/s,下降了15.13%,而后阳极半径再增加时,平均流速基本无变化。电解质最大流速随阳极半径的增加而降低,最大流速由7.788 cm/s下降至4.679 cm/s,下降了39.92%。从增大气体流速、降低电解质流速的角度考虑,适当增加阳极半径是有利的。

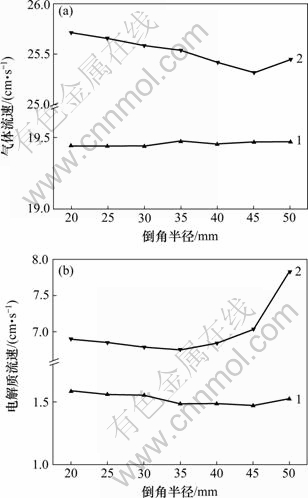

2.8 阳极倒角半径的影响

当阳极倒角半径由20 mm增加到45 mm时,气体流速与电解质流速的相应变化如图9所示。

从图9(a)可见:随着阳极倒角半径的增加,气体的平均流速变化很小;当阳极倒角半径从20 mm增加到45 mm时,气体的最大流速呈降低趋势,而当阳极倒角半径由45 mm增加到50 mm时,气体的最大流速有所增加。从图9(b)可见:电解质的平均流速及最大流速均随着阳极倒角半径的增加而先降低后增加,平均流速在40 mm的倒角半径时取得最小值,最大流速在35 mm的倒角半径时取得最小值,而气体的平均流速在35 mm倒角半径时取得最大值,因此在现有的阳极尺寸下,阳极倒角半径取为35~40 mm为宜。

(a) 气体流速;(b) 电解质流速

1—平均流速;2—最大流速

图9 流速随阳极倒角半径的变化

Fig.9 Velocity variation with anode chamfer radius

3 结论

(1) 在阳极气体的带动下,电解质沿阳极中心呈对称循环流动,距离阳极气体越近,电解质流速越大;随阳极气泡直径的增大,气体流速逐渐增加,电解质流速先下降后增加,气泡直径的最佳值为3 mm。

(2) 电流增加,气体的平均流速降低,气体的最大流速增加,电解质平均及最大流速均增加,电流不宜过大;电解温度增加,气体的平均流速降低,气体的最大流速增加,电解质平均及最大流速均增加,这对低温电解更有利;极距增加,气体平均流速增加,电解质平均流速降低,适当增加极距有利于电解槽操作;阳极浸入电解质深度增加,气体平均流速降低,电解质平均流速增加,阳极浸入深度不宜过大。

(3) 阳极半径增加,气体的平均流速增加,电解质平均流速降低,应适当增加阳极半径;阳极倒角半径对气体及电解质流场有一定影响,合理的阳极倒角半径为35~40 mm。

参考文献:

[1] 王志刚, 黄蔚, 赖延清. 铝电解惰性阳极材料研究新进展[J]. 轻金属, 2007(2): 27-30.

WANG Zhi-gang, HUANG Wei, LAI Yan-qing. New progress of inert anode materials for aluminum electrolysis[J]. Light Metals, 2007(2): 27-30.

[2] Cassayre L, Utigard T A, Bouvet S. Visualizing gas evolution on graphite and oxygen-evolving anodes[J]. Journal of Metals, 2002, 54(5): 41-45.

[3] Cassayre L, Plascencia G, Marin T, et al. Gas evolution on graphite and oxygen-evolving anodes during aluminium electrolysis[C]//Galloway T J. Light Metals. Warrendale: TMS, 2006: 379-383.

[4] 徐君莉, 石忠宁, 高炳亮, 等. 铝电解金属阳极上的气泡析出行为[J]. 中国有色金属学报, 2004, 14(2): 298-301.

XU Jun-li, SHI Zhong-ning, GAO Bing-liang, et al. Bubble behavior on metal anode of aluminum electrolysisp[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(2): 298-301.

[5] GAO Bing-liang, HU Xian-wei, XU Jun-li, et al. Study on bubble behavior on anode in aluminum electrolysis-Part Ⅱ[C]//Galloway T J. Light Metals. Warrendale: TMS, 2006: 467-470.

[6] Shekhar R, Evans J W. Physical modeling studies of electrolyte flow due to gas evolution and some aspects of bubble behavior in advanced Hall cells: Part Ⅰ. Flow in cells with a flat anode[J]. Metallurgical and Materials Transactions B: Process Metallurgy and Materials Processing Science, 1994, 25(3): 333-340.

[7] Shekhar R, Evans J W. Physical modeling studies of electrolyte flow due to gas evolution and some aspects of bubble behavior in advanced Hall cells: Part Ⅱ. Flow and inter-polar resistance in cells with a grooved anode[J]. Metallurgical and Materials Transactions B: Process Metallurgy and Materials Processing Science, 1994, 25(3): 341-349.

[8] Shekhar R, Evans J W. Physical modeling studies of electrolyte flow due to gas evolution and some aspects of bubble behavior in advanced Hall cells: Part Ⅲ. Predicting the performance of advanced Hall cells[J]. Metallurgical and Materials Transactions B: Process Metallurgy and Materials Processing Science, 1996, 27(1): 19-27.

[9] Yang W, Cooksey, M A. Effect of slot height and width on liquid flow in physical models of aluminium reduction cells[C]//Sorlie M. Light Metals. Warrendale: TMS, 2007: 451-456.

[10] Aaberg R J, Ranum V, Williamson K, et al. Gas under anodes in aluminum smelting cells. Part Ⅱ: Gas volume and bubble layer characteristics[C]//Huglen R. Light Metals. Warrendale: TMS, 1997: 341-346.

[11] 夏小霞, 王志奇, 周乃君. 铝电解槽内电解质运动的数值模拟[J]. 过程工程学报, 2007, 7(2): 235-240.

XIA Xiao-xia, WANG Zhi-qi, ZHOU Nai-jun. Numerical simulation of electrolyte flow in aluminum reduction cells[J]. The Chinese Journal of Process Engineering, 2007, 7(2): 235-240.

[12] Feng Y Q, Cooksey M A, Schwarz P. CFD modelling of electrolyte flow in aluminium reduction cells[C]//Sorlie M. Light Metals. Warrendale: TMS, 2007: 339-344.

[13] Kiss L I, Vekony K. Dynamics of the gas emission from aluminum electrolysis cells[C]//Deyoung D H. Light Metals. Warrendale: TMS, 2008: 425-429.

[14] Kiss L I, Perron A L, Poncsak S, et al. The bubble laden layer around inert anodes[C]//Sorlie M. Light Metals. Warrendale: TMS, 2007: 495-500.

[15] Solheim A, Johansen S T, Rolseth S, et al. Gas driven flow in Hall-Heroult cells[C]//Campbell P G. Light Metals. Warrendale: TMS, 1989: 245-252.

收稿日期:2009-09-13;修回日期:2009-12-02

基金项目:国家重点基础研究发展计划项目(2005CB623703);国家高技术研究发展计划项目(2008AA30504);国家自然科学基金资助项目(50874120)

通信作者:王志刚(1981-),男,辽宁阜新人,博士,从事铝电解过程仿真研究;电话:0731-88830474;E-mail:wzg03@163.com

(编辑 任楚威)