文章编号:1004-0609(2011)10-2650-09

原位生长碳纳米管及其在SiCf/SiC复合材料中的应用

周新贵,余金山,孙 科,赵 爽

(国防科学技术大学 新型陶瓷纤维及其复合材料国家重点实验室,长沙 410073)

摘 要:采用碳纳米管改善纤维与基体间的界面结合,同时利用碳纳米管自身的优异性能对碳化硅纤维增强碳化硅复合材料(SiCf/SiC)进行二次增强。通过化学气相沉积工艺(CVD)在SiC纤维编织件内原位生长碳纳米管,优化碳纳米管原位生长过程中的碳源流量、反应温度和反应时间等工艺参数,对碳纳米管的原位生长工艺及机理进行系统分析,并结合先驱体浸渍裂解工艺(PIP)制备CNTs-SiCf/SiC复合材料,探讨原位生长碳纳米管的引入对复合材料力学性能的影响。结果表明,优化后的工艺参数如下:反应温度750 ℃,C2H2、H2和N2流量比1/1/3,C2H2流量100~150 mL/min,反应时间60 min;碳纳米管的引入使SiCf/SiC复合材料的弯曲强度、弯曲模量和断裂韧性分别提高了16.3%、90.4%和106.3%。

关键词:SiCf/SiC复合材料;碳纳米管;化学气相沉积;原位生长;浸渍;裂解

中图分类号:TB323 文献标志码:A

In-situ grown carbon nanotubes and their applications for SiCf/SiC composites

ZHOU Xin-gui, YU Jin-shan, SUN Ke, ZHAO Shuang

(State Key Laboratory of Advanced Ceramic Fibers and Composites, National University of Defense Technology, Changsha 410073, China)

Abstract: Carbon nanotubes (CNTs) were incorporated in the matrices to change the surface microstructure of SiC fiber and ameliorate the interfacial bonding between SiC fiber and SiC matrix, as well as acting as a bridge to secondly reinforce SiCf/SiC composites. CNTs-SiCf/SiC composites were successfully fabricated by in-situ growing CNTs directly in the composite performs via a chemical vapor deposition(CVD) process followed by polymer impregnation and pyrolysis (PIP) routes densification. The effects of carbon resource (C2H2) flux, reaction temperature and reaction time on properties of CNTs were studied, the technics and growth mechanism of CNTs were investigated. Finally the effect of in-situ grown CNTs introduction on the mechanical properties of the CNTs-SiCf/SiC composite was discussed. The results indicate that optimized parameters for CNTs growing are as follows: reaction temperature 750 ℃, reaction time 60 min, flux ratio of C2H2 to H2 to N2 1/1/3 and C2H2 flux 100-150 mL/min. As a result of the introduction of CNTs, flexural strength, flexural modulus and fracture toughness of SiCf/SiC composites are increased by 16.3%, 90.4% and 106.3%, respectively.

Key words: SiCf/SiC composites; carbon nanotubes; chemical vapor deposition; in-situ growth; impregnation; pyrolysis

连续碳化硅纤维增强碳化硅基复合材料(SiCf/SiC)具有密度低、比强度高、比模量高、耐高温、抗热震等优异性能,在航空航天领域有着广泛的应用[1-5]。同时,SiCf/SiC复合材料还具有伪塑性行为、较低氚渗透率和较优的辐照稳定性,被认为是理想的聚变堆候选材料[6-8]。随着SiCf/SiC复合材料应用领域的不断拓展,人们对其力学性能提出了更高的要求。众所周知,纤维-基体界面对复合材料的性能具有重要影响,因此,界面优化是改善SiCf/SiC复合材料力学性能的重要手段之一。

碳纳米管(CNTs)具有很高的轴向强度和刚度以及良好的韧性,近年来,国内外关于碳纳米管作为复合材料一维增强相的研究[9-12]越来越多,部分研究已取得了较好的效果。VINOD等[13]在2D的SiC平纹布上得到定向排列的碳纳米管,叠层后制备了环氧树脂基复合材料,其断裂韧性提高了348%,弯曲强度提高了240%;LI等[14]在Fe2O3/HA(羟基磷灰石)混合粉末中原位生长碳纳米管,再采用粉末冶金法制备了CNTs(Fe)/HA复合材料,其断裂韧性提高了2倍多。这些研究显示了采用碳纳米管来增强复合材料的广泛应用前景。目前,在SiCf/SiC复合材料中引入碳纳米管作为二次增强相的研究尚未见报道。

为此,本文作者首先通过化学气相沉积工艺(CVD)在SiC纤维编织件中原位生长碳纳米管,优化碳纳米管原位生长过程中的碳源流量、反应温度和反应时间等工艺参数,研究SiC纤维编织件上碳纳米管的形貌结构及其原位生长机理;然后,通过先驱体浸渍裂解工艺(PIP)制备CNTs-SiCf/SiC复合材料;最后,分析CNTs-SiCf/SiC复合材料的结构性能以及碳纳米管的增韧机理。

1 实验

1.1 原料

所用增强纤维为国防科学技术大学生产的KD-I型SiC纤维。编织件采用三维四向编织结构,纤维的体积分数为49.1%。先驱体为聚碳硅烷(PCS),由国防科学技术大学新型陶瓷纤维及其复合材料重点实验室制备。

1.2 碳纳米管的原位生长

采用文献[15]中提供的催化剂配比配制Ni-La-Al硝酸盐的乙醇溶液作为催化剂先驱体,通过真空浸渍法在SiC纤维编织件中引入催化剂,晾干后置于石英管中,450 ℃下在H2与N2的流量均为100 mL/min气氛中还原60 min,之后在N2保护下升温,最后在C2H2、H2和N2的流量比为1/1/3的气氛中保温原位生长碳纳米管。

1.3 CNTs-SiCf/SiC复合材料的制备

首先,将SiC编织件和生长了碳纳米管的SiC编织件真空浸渍先驱体溶液;然后,热模压固化;之后,在高纯N2保护下升温至1 100 ℃使先驱体裂解转化为SiC陶瓷。重复浸渍裂解过程直至质量增加率小于1%,即得到原位生长碳纳米管SiCf/SiC复合材料。

1.4 分析测试

采用排水法测试材料的密度ρ和开孔率θ。在WDW-100型电子万能试样机上测试材料的弯曲强度、模量和断裂韧性。采用日本JSM-5600LV(JEOL)型扫描电子显微镜和HITACHIS-4800场发射扫描电镜观察编织件上原位生长碳纳米管以及SiCf/SiC复合材料的断口形貌。采用JEOL-2010F型透射电镜分别观察编织件上碳纳米管和SiCf/SiC复合材料的显微组织;采用SDT Q600热分析仪得到样品的热重曲线;利用VERTEX 70型Raman光谱测试仪得到样品的激光拉曼光谱。

2 结果和分析

2.1 CVD法原位生长碳纳米管工艺

2.1.1 碳源流量对碳纳米管生长的影响

图1所示为反应温度为750 ℃、反应时间为60 min及4种不同碳源(C2H2)流量条件下得到的碳纳米管形貌。由图1可知,随着C2H2流量的增大,碳纳米管的直径分布范围增大,管壁变得粗糙,缺陷增多,碳纤维成分相应增加。当碳源流量为50、100及150 mL/min时,得到的碳纳米管表面较为干净;当碳源流量增大至200 mL/min时,产物中观察到较多的沉积碳,碳纳米管表面有明显的沉积碳包覆,表明在该流量条件下,活性碳原子的供给速度超过析出速度,催化剂过早失活,不利于碳纳米管的生长。

表1所列为不同碳源流量条件下产物的热分析及Raman光谱结果。其中:ti表示样品开始发生质量损失时的温度,代表碳纳米管的纯净度;to表示样品质量损失最大时的温度,代表碳纳米管的质量,如碳纳米管的晶型结构,石墨层壁上的缺陷程度等;Re表示剩余产物的质量分数,Re越小,表示产物中碳沉积量越大,说明催化剂的活性越高[16]。Raman光谱中D峰与G峰的谱峰强度强度比值ID/IG能够反映出碳管纳米管壁外无序碳的多少即表层结晶度,比值越小,表面无序碳和非晶碳越少,可以认为碳纳米管质量越 好[17]。由表1可以看出,随着碳源流量的增加,产物放热峰的峰温明显向低温区移动,同时Re值变大,D峰和G峰的线宽增大,ID/IG由0.773增大至0.977,表明催化剂的存活时间逐渐变短,产物中无定形碳含量逐渐增加,碳纳米管质量和纯度均随之下降,与SEM的观察结果(图1)相符。

图1 反应温度为750 ℃、反应时间为60 min、不同碳源流量下制备的碳纳米管的形貌

Fig.1 Morphologies of CNTs at reaction temperature 750 ℃, reaction time 60 min and different C2H2 fluxes: (a) 50 mL/min; (b) 100 mL/min; (c) 150 mL/min; (d) 200 mL/min

表1 不同碳源流量情况下产物热分析及Raman光谱结果

Table 1 Thermal analysis and Raman spectrum results of CNTs under different C2H2 fluxes

2.1.2 反应温度对碳纳米管生长的影响

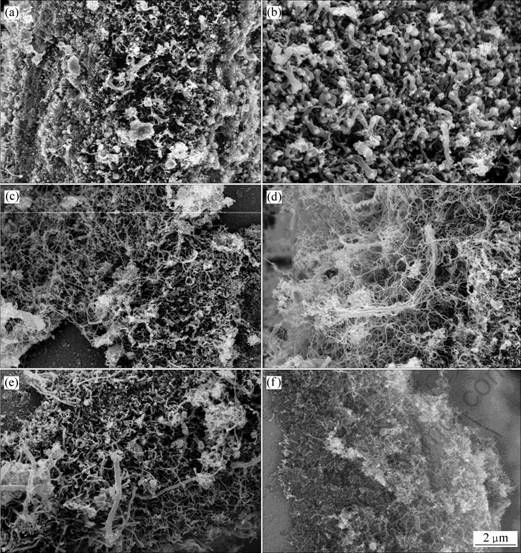

图2所示为碳源流量为100 mL/min、反应时间为60 min及不同反应温度下得到的碳纳米管形貌。由图2可以看出,反应温度对碳纳米管形貌的影响很大,不同温度下制备的碳纳米管形貌存在很大差别。在较低温度(600 ℃)下,几乎无产物生成,得到的少量碳纳米管生长不完全,管径较粗,长径比很小,并混有很多非晶碳(见图2(a))。当温度高于600 ℃时,开始有碳纳米管生长;随着温度的进一步升高,产物明显增多,非晶碳的比例降低,碳纳米管的生长密度逐渐提高,碳纳米管较长,管壁相对光滑,大多数稍有弯曲,也有少部分碳纳米管曲率较大,发生缠绕,且碳纳米管的直径分布范围随着温度的升高而变窄,分别为 650 ℃的80~100 nm、700 ℃的60~80 nm和750 ℃的40~50 nm(分别见图2(b)、(c)、(d))。但是,当反应温度超过800 ℃后,产物中非晶碳的比例逐渐增大,长出的碳纳米管表面有沉积碳覆盖,直径增大(见图2(e));当温度上升至850 ℃时,几乎无碳纳米管生成,沉积物多为无定形碳(见图2(f))。

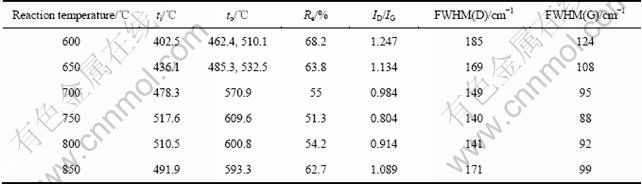

表2所列为不同反应温度下制备的碳纳米管粗产品的热分析及Raman光谱结果。由表2可知,600 ℃和650 ℃时产物均存在两个明显的放热峰,产物中无定形碳含量很高;随着反应温度的升高,产物放热峰的峰温逐渐向高温移动,同时Re值逐渐减小,D峰线宽变窄,ID/IG变小,所生成的碳纳米管的石墨化程度逐渐增加;当温度超过800 ℃后,产物放热峰再次向低温区移动,Re增大,ID/IG变大,碳纳米管质量下降。

2.1.3 反应时间对碳纳米管生长的影响

图3所示为碳源流量为100 mL/min、反应温度为750 ℃及不同反应时间条件下得到的碳纳米管的形貌。反应前60 min内,碳纳米管从聚集在催化剂表面的短棒逐渐生长完全,长径比增大且相互缠绕(见图3(a)、(b)、(c)),之后随着反应时间延长,碳纳米管直径变大,表面开始出现不同程度的沉积碳包覆,反应120 min后,已经出现直径超过100 nm的粗管,管表面的积碳现象已比较明显(见图3(d))。

表3所列为不同反应时间下产物热分析及Raman光谱结果。从表3中的热分析数据看,在前60 min内,随着反应时间的延长,产物的ti和to下降,Re值也随之减小,这是由于时间较短时,碳纳米管的产率较低;60 min后,产物的放热峰继续向低温区移动,同时Re值略有增加。在Raman谱图数据中,随着时间的延长,产物特征峰线宽增大,ID/IG由0.746增大至0.925,碳纳米管的表层结晶度逐渐下降。

2.2 原位生长碳纳米管形貌与结构

图4所示为C2H2流量为100 mL/min、反应温度为750 ℃、反应时间为60 min条件下原位生长碳纳米管后SiC纤维的表面形貌,样品从编织件内部随机取得。由图4可以看出,SiC纤维表面生长着非常浓密的碳纳米管,长度均在数微米,局部弯曲且相互缠绕,形成一种可称之为“森林”状的碳纳米管层。碳纳米管的这种“森林”状分布可能是由于两种原因引起的:一方面,催化剂颗粒的催化活性是由其外部晶面和颗粒的形态决定的,而催化剂通常表现为各向异性,这样,催化剂颗粒四周管壁的生长速率不同,从而导致碳纳米管向生长速率小的那个方向弯曲;另一方面,当气体流经空隙在微米级三维结构的纤维编织件内部时,气流方向可能发生改变而在空隙内形成若干的局部“扰流”,高温下刚生长出来的碳纳米管直径很小(约40 nm),其生长方向会由于气流和重力的共同作用发生一定的偏转直至发生弯曲来达到整体平衡。此外,相互间的吸引力将使碳纳米管相互缠绕在一起,因此,宏观上碳纳米管在SiC纤维表面形成三维多孔网状结构。

图2 碳源流量为100 mL/min、反应时间为60 min及不同反应温度下生长的碳纳米管形貌

Fig.2 Morphologies of CNTs at C2H2 flux of 100 mL/min, reaction time of 60 min and different reaction temperatures: (a) 600 ℃; (b) 650 ℃; (c) 700 ℃; (d) 750 ℃; (e) 800 ℃; (f) 850 ℃

表2 不同反应温度下产物热分析及Raman光谱结果

Table 2 Thermal analysis and Raman spectrum results of CNTs at different reaction temperatures

图3 碳源流量为100 mL/min、反应温度为750 ℃及不同反应时间生长的碳纳米管形貌

Fig.3 Morphologies of CNTs at C2H2 flux of 100 mL/min, reaction temperature of 750 ℃ and different reaction times: (a) 15 min; (b) 30 min; (c) 60 min; (d) 120 min

表3 不同反应时间下产物热分析及Raman光谱结果

Table 3 Thermal analysis and Raman spectrum results of CNTs at different reaction times

图4 SiC纤维表面原位生长碳纳米管形貌

Fig.4 Morphologies of in-situ grown CNTs on SiC fiber surface: (a) Overall view; (b) Enlargement of area A; (c) Enlargement of area B

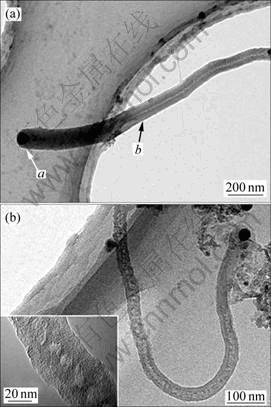

图5所示为原位生长碳纳米管的TEM像。由图5(a)可见,所得碳纳米管顶端包覆有直径约为30 nm的圆形催化剂颗粒,说明碳纳米管的生长是采取顶端模式,析出的碳将催化剂颗粒向远离基底的方向顶出,生长一段时间后,催化剂颗粒被析出的碳所包覆而逐渐失去催化活性,最后停止生长。由图5(b)可见,碳纳米管为中空管状结构,内、外径分别约为15 nm和30 nm,管内每隔20~30 nm会出现一段“节”,而外径一直保持不变,整个碳纳米管呈现一种“竹节”状结构。这主要是由于碳纳米管在生长过程中,催化剂颗粒固液共存,碳原子簇在催化剂颗粒表面和内部扩散速率不同引起的,碳纳米管的生长驱动力来自催化剂颗粒前后碳的浓度差和温度差。

图5 碳纳米管的TEM像

Fig.5 TEM images of CNTs: (a) CNTs with catalyst particle; (b) Bamboo-like CNTs

2.3 CNTs-SiCf/SiC复合材料的力学性能与微观结构

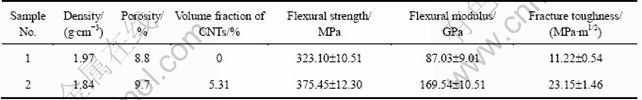

表4所列为原位生长碳纳米管前后复合材料密度和力学性能的变化。样品1为未加入碳纳米管的SiCf/SiC复合材料,其弯曲强度和弯曲模量分别为323.10 MPa和87.03 GPa,断裂韧性为11.22 MPa·m1/2。样品2为原位生长碳纳米管后的复合材料,其各项力学性能均有不同程度的提高,材料的弯曲强度提高了16.3%,而弯曲模量和断裂韧性则分别提高了90.4%和106.3%,说明碳纳米管的加入对复合材料起到了显著的增韧效果。

表4 碳纳米管对SiCf/SiC复合材料密度和力学性能的影响

Table 4 Effects of CNTs on density and mechanical properties of SiCf/SiC composites

图6所示为SiCf/SiC复合材料试样的断口形貌。图6(a)中,未加入碳纳米管的SiCf/SiC复合材料断口较为平整,纤维均为成束整齐断裂,几乎不存在纤维拔出情况,说明在未经任何处理的情况下,SiC纤维与SiC基体界面结合很强,裂纹扩展时得不到偏转和阻碍,使得裂纹很容易将纤维“冲断”,贯穿整个材料,造成低应力下类似于单相陶瓷材料的脆断裂;图6(b)中,加入碳纳米管的SiCf/SiC复合材料断口可以观察

图6 SiCf/SiC复合材料试样的断口形貌

Fig.6 Fracture morphologies of SiCf/SiC composites: (a) SiCf/SiC composites without CNTs; (b) CNTs-SiCf/SiC composites

到明显的纤维拔出现象,断口起伏不平,表明碳纳米管的引入改善了纤维与基体间的强界面结合,复合材料的韧性得以大幅提高。

图7所示为引入碳纳米管后复合材料断口处纤维与基体间的界面形貌。由图7可以观察到位于开裂的基体内部的碳纳米管(图中Ⅰ号白色箭头处),在图7中Ⅱ号箭头处,同样可以观察到白色的点状突起,可以认为,编织件内微米级的SiC纤维与纤维之间间隙很小,而碳纳米管长度均在5 ?m以上,因此,原位生长的碳纳米管可以在两根纤维之间以及两束纤维之间起到“搭桥”的作用,将这两种增强体结合起来,形成一种天然的微米-纳米混合增强结构。复合材料微裂纹在陶瓷基体内部的扩展和增殖。与一般的纤维致密成型后基体内部包裹着大量的碳纳米管,陶瓷基复合材料失效初期一般源于微裂纹在陶瓷基体内部的扩展和增殖,微米级碳纳米管的存在能有效阻止这种增强的复合材料相比,复合材料断裂时,部分碳纳米管的断裂和拔出行为可增加材料的断裂功,同时,基体开裂后,包裹在基体内部的碳纳米管承受外加载荷,并在基体的裂纹面之间架桥。桥联的碳纳米管会对基体产生使裂纹闭合的力,进一步提高了材料的韧性。

图7 CNTs-SiCf/SiC复合材料断口处的碳纳米管拔出

Fig.7 Pullouts of CNTs at fracture surface of CNTs-SiCf/SiC composites: (a) Overall view; (b) Interface area

3 结论

1) 对化学气相沉积工艺原位生长碳纳米管的工艺参数进行了优化,在本实验条件下,当C2H2流量为100 mL/min、反应温度为750 ℃、反应时间为60 min时,碳纳米管的生长效果最佳。

2) 通过化学气相沉积工艺在SiC纤维编织件上原位生长了碳纳米管。碳纳米管呈竹节状结构,遵循顶端生长模式,在SiC纤维表面呈“森林”状分布。

3) 采用先驱体浸渍裂解工艺制备了CNTs-SiCf/ SiC复合材料,与未生长碳纳米管的SiCf/SiC复合材料相比,断裂模式由脆性断裂转变为伪塑性断裂,碳纳米管通过拔出、裂纹扩展受阻、裂纹偏转和碳纳米管桥联等机制提高了SiCf/SiC复合材料的韧性。

REFERENCES

[1] ALAIN L, PATRICK S, ALAIN A, ERIC B, GEORGES H. Ceramic matrix composites to make breakthroughs in aircraft engine performance[C]//Proceedings of the 50th AIAA/ASME/ ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference. Palm Springs: American Institute of Aeronautics and Astronautics, Inc,2009: 1-11.

[2] DICARLO J A, YUN H M, MORSCHER G N, BHATT R T. SiC/SiC composites for 1 200 ℃ and above[R]. Washington: NASA Center for AeroSpace Information, 2004.

[3] PAPPU L N M, NOEL N N, DAVID N B, SUBODH M. Probabilistic analysis of a SiC/SiC ceramic matrix composite turbine vane[R]. Washington: NASA Center for AeroSpace Information, 2004.

[4] ROY R G, KASHALIKAR U K, MAJI A. Lightweight and cost-effective SiC optical structures[C]//Proceedings of the Space 2004 Conference and Exhibit. San Diego: American Institute of Aeronautics and Astronautics, Inc, 2004: 1-8.

[5] 胡海峰, 张玉娣, 邹世钦, 周新贵, 张长瑞. SiC/SiC复合材料及其在航空发动机上的应用[J]. 航空制造技术, 2010, 6: 90-91.

HU Hai-feng, ZHANG Yu-di, ZOU Shi-qin, ZHOU Xin-gui, ZHANG Chang-rui. SiC/SiC composites and its application on aero-engine[J]. Aeronautical Manufacturing Technology, 2010, 6: 90-91.

[6] KATOH Y, SNEAD L L, HENAGER C H, HASEGAWA A, KOHYAMA A, RICCARDI B, HEGEMAN H. Current status and critical issues for development of SiC composites for fusion applications[J]. Journal of Nuclear Materials, 2007, 367/370: 659-671.

[7] KOHYAMA A, SEKI M, ABE K, MUROGA T, MATSUI H, JITSUKAWA S, MATSUDA S. Interactions between fusion materials R&D and other technologies[J]. Journal of Nuclear Materials, 2000, 283/287: 20-27.

[8] ZHAO S, ZHOU X G, YU H J, WANG H L, WU Y C, HUANG Q Y, ZHU Z Q, HUANG Z L. Compatibility of SiCf/SiC with LiPb at 700 ℃[J]. Fusion Engineering and Design, 2010, 85: 1624-1626.

[9] ENRIQUE J G, BRIAN L W. Fabrication and multifunctional properties of a hybrid laminate with aligned carbon nanotubes grown in situ[J]. Composites Science and Technology, 2008, 68: 2034-2041.

[10] MATHUR R B. Growth of carbon nanotubes on carbon fiber substrates to produce hybrid/pjenolic composites with improved mechanical properties[J]. Composites Science and Technology, 2008, 68: 1608-1615.

[11] KEPPLEA K L, SANBORN G P. Improved fracture toughness of carbon ?ber composite functionalized with multi walled carbon nanotubes[J]. Carbon, 2008, 46: 2026-2033.

[12] HUNG K H, KUO W S, KO T H, TZENG S S, YAN C F. Processing and tensile characterization of composites composed of carbon nanotube-grown carbon ?bers[J]. Composites: Part A, 2009, 40: 1299-1304.

[13] VINOD P V, ANYUAN C, LI X, MA K, SOLDANO C, KAR S, AJAYAN P M, GHASEMI-NEJHAD M N. Multifunctional composites using reinforced laminae with carbon-nanotube forests[J]. Nature Materials, 2006, 5: 457-462.

[14] LI H, ZHAO N, LIU Y, LIANG C, SHI C, X DUA, LI J. Fabrication and properties of carbon nanotubes reinforced Fe/hydroxyapatite composites by in situ chemical vapor deposition[J]. Composites: Part A, 2008, 39: 1128-1132.

[15] 居 艳, 李风仪, 魏任重. 镍基催化剂上催化裂解甲烷生长碳纳米管[J]. 合肥工业大学学报: 自然科学版, 2004, 27(12): 1528-1531.

JU Yan, LI Feng-yi, WEI Ren-zhong. Catalytic decomposition of methane over nickel-based catalysts to grow carbon nanotubes[J]. Journal of Hefei University of Technology: Natural Science, 2004, 27(12): 1528-1531.

[16] PORWAL D, MUKHOPADHYAY K, RAM K, MATHUR G N. Investigation of the synthesis strategy of CNTs from CCVD by thermal analysis[J]. Thermochimica Acta, 2227, 463: 53-59.

[17] HIURA H, EBBESEN T, TANIGAKI K, TAKAHASHI H. Raman studies of carbon nanotubes[J]. Chem Phys Lett, 1993, 202: 509-512.

(编辑 陈卫萍)

基金项目:国家自然科学基金资助项目(51072228)

收稿日期:2011-04-22;修订日期:2011-07-28

通信作者:周新贵,教授,博士;电话:0731-84573162;E-mail: zhouxinguilmy@163.com

周新贵教授简介

周新贵,1968年9月出生,博士,英国布里斯托大学访问学者。现任国防科技大学航天与材料工程学院新型陶瓷纤维及其复合材料国防科技重点实验室教授(2004年)、博士生导师(2006年),材料科学与工程学科学术带头人。先后完成10余项国防重大型号、“973”国家安全重大基础研究、国防科技预研、国家自然科学基金等项目的研究工作,获国家科技进步二等奖1项,国防科工委科技进步一、二等奖2项。目前作为课题和项目负责人,承担了军口“973”、“863”、国家自然科学基金等多项课题。出版学术专著2部,发表学术论文80余篇,获国家发明专利10余项。