Al-8.0Zn-2.0Mg-1.6Cu铝合金的淬透性

万里1, 2,邓运来1,张云崖1,张新明1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中国·精美铝业有限公司,浙江 缙江,321400)

摘要:通过末端淬火、差示扫描量热仪(DSC)、扫描电镜(SEM)、透射电镜(TEM)、X线衍射仪(XRD)、光学显微镜(OM)和硬度等分析测试方法研究Al-8.0Zn-2.0Mg-1.6Cu铝合金的淬透性及淬火冷却过程中的微观组织演变。研究结果表明:随着冷却速度的降低,试样的硬度显著下降,其淬透深度约为40 mm,临界冷却速度约为3.8 ℃/s;淬火冷却过程中平衡态MgZn2(η)相析出是影响该合金淬透性的主要因素,其析出温度区间为438~215 ℃;平衡态MgZn2相在淬火冷却时先后经历晶界与晶粒内部2个过程的析出,析出峰值温度分别为387 ℃和342 ℃。

关键词:Al-Zn-Mg-Cu;末端淬火;淬透性;平衡态MgZn2相

中图分类号:TG166.3 文献标志码:A 文章编号:1672-7207(2011)11-3289-07

Hardenability of Al-8.0Zn-2.0Mg-1.6Cu aluminum alloy

WAN Li1, 2, DENG Yun-lai1, ZHANG Yun-ya1, ZHANG Xin-ming1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. China Jingmei Aluminium Industry Company Limited, Jinyun 321400, China)

Abstract: The hardenability and structures on Al-8.0Zn-2.0Mg-1.6Cu aluminum alloy were determined by end-quench test, differential scanning calorimetry (DSC), scanning electron microscopy (SEM), transmission electron microscopy (TEM), X-ray diffraction (XRD), optical microscopy (OM) and hardness. The result shows that with the decrease of cooling rate the hardness decreases significantly, and the quenched depth is about 40 mm with critical cooling velocity 3.8 ℃/s. The precipitation of MgZn2 (η) phases precipitating in 438-215 ℃ interval is the primary factor that affects the hardenability of this alloy during the quenching. The equilibrium state MgZn2 phases precipitate as two paths successively during the quenching: grain boundaries and inside the grains, with the peak temperature 387 ℃ and 342 ℃ respectively.

Key word: Al-Zn-Mg-Cu; end-quench test; hardenability; equilibrium MgZn2 phase

在航空航天工业迅速发展的今天,整体结构件的应用可以显著降低构件质量,并减少其装配成本,因此,采用具有优越力学与耐蚀性能的7000系铝合金厚板制造大型整体构件越来越受到重视[1-3]。但7000系铝合金具有较强的淬火敏感性,在淬火时效后产品表层与心部力学性能有显著差异[4-8],严重制约了该系铝合金厚截面材料应用的迅速发展。针对该系合金的这种现状,美国Alcoa公司在7075的基础上先后研制了7050和7150应用于波音757,767和777客机[9-10]。并且在2003年,Alcoa公司研制出具有高强高韧和高淬透性的7085铝合金,并被A380等先进飞行器所采用[11]。已有大量文献[4, 11-16]报道了影响该系合金淬火敏感性的因素。而研究铝合金淬火敏感性一般采用温度-时间-性能(TTP)图来表征,但TTP图很难获得淬透性的定量数据。本文作者以实验室制备的Al-Zn-Mg-Cu系铝合金为对象,采用前期设计的末端淬火装置[17-18]在获得淬透性数据的同时,深入研究淬火冷却过程中影响该系铝合金淬透性的因素及微观组织的演变。为开发新一代高强高韧和高淬透性铝合金提供了一定的实验基础。

1 实验材料与方法

采用高纯铝、纯锌、纯镁和铝-铜、铝-锆中间合金配料,晶粒细化剂采用Al-5Ti-B。在石墨坩埚电阻炉内进行熔炼,熔炼温度为750~780 ℃,精炼温度为730~750 ℃,铸造温度为710~720 ℃,除气剂采用C2Cl6。将铝合金熔体浇入铁模中获得尺寸(长×宽×高)为40 mm×80 mm×120 mm的铸锭,铸锭的名义化学成分(质量分数)如表1所示。将获得的铸锭采用(400 ℃, 12 h)+( 470 ℃, 12 h)的制度进行均匀化热处理。考虑铸锭法制备铝合金特厚板(如厚度180 mm以上)时,由于受铸锭厚度和轧机开口度的限制,其轧制变形的压下量一般约为70%,为了与工业生产条件下能实现的特厚板轧制总变形量相近,本文采用的热轧总压下量为70%。热轧的开轧温度为420 ℃,轧制前将轧辊预热到约300 ℃,以避免轧制过程中轧辊引起的试样温度降低。沿板材轧向截取尺寸(直径×高)为10 mm×140 mm的圆柱体作为末端淬火试验的试样棒,使轧向平行于圆柱试样的轴向。试样置于箱式空气炉中保温进行固溶处理(475 ℃, 4 h),固溶处理后喷射压力和流量分别为15 kPa和1 000 L/h的室温水进行末端淬火试验[17-18],喷射时间为10 min。淬火后将试样置于箱式空气炉中进行121 ℃, 24 h人工时效。将所得淬火试样棒从中间剖出一块厚度为3 mm的试样片,剖分面平行于板材的轧制面,并沿温度梯度方向进行硬度测试,得到硬度与离淬火端面距离的曲线,即淬透性曲线。

表1 试验所用Al-Zn-Mg-Cu合金的名义化学成分(质量分数)

Table 1 Chemical composition of investigated Al-Zn-Mg-Cu alloy %

在试样上距离淬火端面的头部(5 mm)、中部(40 mm)、尾部(80 mm)处截取薄片进行透射样品的制备,透射样品分析在TECNAIG2 20型透射电镜上进行,加速电压为200 kV。用XJP-6A型金相显微镜进行光学金相观察,试样腐蚀试剂(Keller)成分为1 mL HF+ 1.5 mL HCl+2.5 mL HNO3+95 mL蒸馏水。用HV-5型小负荷维氏硬度计进行硬度测试,载荷为30 N,保载时间为15 s。X线衍射(XRD)物相分析采用Rigaku D/Max 2500型衍射仪。示差扫描量热(DSC)分析采用NET2SCH-200 F3热分析仪,降温速度为5 ℃/min。

2 结果与讨论

2.1 淬透性曲线

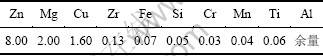

实验测得末端淬火过程中距淬火端面不同距离的连续冷却曲线如图1(a)所示。在末端淬火过程中接近淬火端面温度下降十分迅速,而随着距淬火端面距离的增加温度下降逐渐趋于平缓,且在接近淬火试样末端温度曲线十分接近。试样的淬透性曲线如图1(b)所示。从图1(b)可以看出:随着距淬火端面距离的增加,其硬度也随之降低,但是到达一定距离(60 mm)后其硬度保持不变。如果以试样本身硬度最大值下降10%处的距离来评价其淬透性的话,该试样淬透深度约为40 mm。

图1 试样距淬火端面不同距离在淬火时的连续冷却曲线和淬透性曲线

Fig.1 Continuous cooling curves and hardenability curve during end-quench test and hardenability of sample

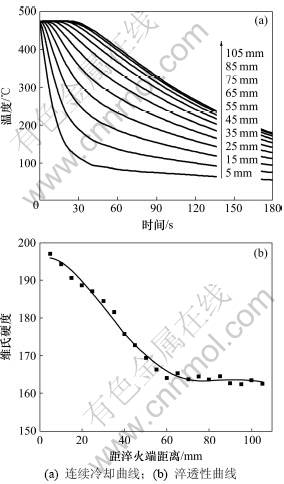

为深入研究淬火冷却过程中影响该合金淬透性的因素,从热轧板上截取一块质量约为20 mg、直径为5 mm的圆片加热到475 ℃保温4 h后进行DSC降温分析,降温速度为5 ℃/min,实验所得DSC测试曲线如图2(a)所示。从图2(a)可以看出:试样拥有2个相互重叠的放热效应B和C,说明在相应温度区间有第二相粒子析出。同时效应B与效应C相比,其发生时间靠前,放热程度相对较弱。对热处理可强化铝合金而言,淬火的目的是获得高的过饱和固溶度。如果在淬火冷却过程中有第二相的大量析出,其必定会降低基体的过饱和程度,这将减少时效过程中强化相粒子的析出数量,从而造成其力学性能的下降。而对于厚板材料而言,其意味着淬透性的变差,淬透深度的降低。因此,试样淬火冷却过程中应保持较高的冷却速度,减少其在第二相粒子析出开始至结束温度区间(AD)停留的时间,从而避免在淬火过程中第二相粒子的大量析出,以保证试样最终的力学性能。图2(a)中第二相析出的开始温度、峰值温度和结束温度如表2所示。同时结合图1(a)的冷却曲线得到了试样距淬火端面各点在第二相粒子析出温度区间的冷却速度,如图2(b)所示。随着距淬火端面距离的增加,冷却速度开始急剧下降,随后其变化放缓,最后趋于不变,和末端淬火试样的淬透性曲线变化规律十分吻合。

图2 试样在降温过程中的DSC曲线和末端淬火时经过析出温度区间的冷却速度

Fig.2 DSC curve of sample during cooling process and cooling rates during end-quench test

表2 图2(a)中第二相粒子析出的开始温度、峰值温度和结束温度

Table 2 Starting, peak, and end temperature of precipitates in Fig.2(a) ℃

图1与图2的结果表明:试样在淬火过程中经过第二相粒子析出温度区间的冷却速度对材料淬透性的影响非常敏感。当距淬火端面距离小于40 mm时,随着距淬火端面距离的增加,冷却速度急剧下降,淬火通过第二相粒子析出温度区间的时间变长。由于各温度下合金元素的固溶度不同,试样将在此过程中动态析出固溶原子,从而在淬火后基体的固溶程度减小,以至于在随后的时效过程中不能大量弥散析出有助于提高合金性能的强化相,使其硬度降低。当距离大于40 mm时,随着距淬火端面距离的增加,冷却速度下降放缓,并逐渐趋于一致。由于冷却速度很小,此时淬火通过第二相粒子析出温度区间的时间十分漫长。大量第二相粒子在此过程中动态析出,使得材料的力学性能大大恶化。在本实验条件下,其临界冷却速度约为3.8 ℃/s。

2.2 试样微结构

试样时效状态下沿冷却速度方向不同距离的立体金相照片如图3所示。从图3(a)可以看出:在本实验固溶处理加热过程中没有发生显著的再结晶现象,淬火端面晶粒仍保持沿轧制方向被拉长的条状形变组织。随着淬火冷却速度降低,可以从距淬火试样端面40 mm及80 mm处金相组织中看到再结晶和非再结晶区域,因为试样在淬火过程中随着冷却速度的降低,大量第二相粒子将会在有大量缺陷存在的晶界与亚晶界处形核析出,从而在金相制备过程中晶界与亚晶界优先被腐蚀。如图3(b)和3(c)所示,金相照片中亮色部分为尺寸相对较大的再结晶区域,而暗色部分则为尺寸小于10 μm的亚晶组织。

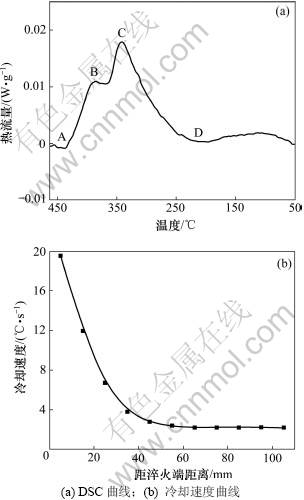

试样距淬火端面5,40和80 mm处析出相如图4所示。本时效状态下淬火端面晶粒内部析出的强化相为非平衡态MgZn2(η′)相,其尺寸细小、分布弥散(图4(a))。随着距淬火端面距离的增加以及冷却速度的降低,其尺寸有一定的粗化(图4(b))。且当冷却速度小于临界冷却速度时,已有部分与基体成一定位相关系的棒状平衡态η相析出(图4(c))。这种平衡态η相的析出对基体强度没有太大贡献,且其析出大大降低了强化相η′的析出数量。这可能是造成图1(b)中随着冷却速度的降低,淬透性曲线下降的原因之一。图4(d)~(f)所示为基体中粗大平衡态析出相情况,从图4(d)可以看出:本实验条件下淬火端面晶界处的析出相为非连续的平衡态η相。而随着距离淬火端面距离的增加,当达到40 mm处时,其晶界上大量析出与基体有一定位相关系的平衡态η相,且其尺寸显然较淬火端面的更加粗大(图4(e))。值得注意的是与此同时,晶粒内部已有少量的平衡态η相开始析出。而随着距离淬火端面距离的继续增加,当达到80 mm处时,晶界上析出的平衡态η相粒子数量增多且尺寸增大,同时在晶粒内部,特别是再结晶晶粒内部有粗大平衡态η相以非共格、平衡态Al3Zr粒子为核心异质形核析出(图4(f))。从而使强化相η′的析出数量继续减少。这可能是造成图1(b)中随着冷却速度的降低,淬透性曲线下降的又一原因。

图3 试样距淬火端面不同距离处的金相照片

Fig.3 Optical micrographs of sample with different distances from hardening face

图4 试样距淬火端面不同距离处析出相TEM像

Fig.4 TEM images of sample with different distances from hardening face

2.3 析出动力学行为

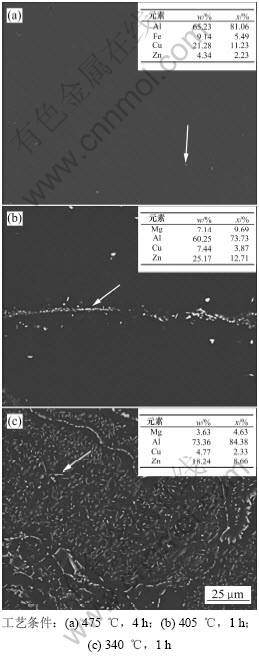

为了进一步探明图2(a)中各放热效应析出粒子的物相,将试样在相应的放热效应内保温后进行微观组织观察,考虑到DSC曲线上2个放热相应相互叠加,同时保温时间较DSC降温时间长,将第1个效应的保温温度提高但仍处于其析出温度区间,以避免第2个效应在此过程中的影响。图5所示为试样在不同温度保温后的金相组织。从图5可以看出:淬火态试样保持形变组织,晶粒沿轧制方向拉长。淬火态试样晶界细小、晶粒内部十分干净,说明固溶处理过程第二相粒子已充分溶解到基体中形成了过饱和固溶体,并且在淬火过程中没有明显的第二相粒子析出。经405 ℃保温1 h处理后的组织中晶粒内部仍然保持相对干净,但是晶界有明显的第二相粒子析出,并且呈断续分布。而经过340 ℃保温1 h处理后的组织中,不但晶界有明显的第二相粒子断续分布,而且晶粒内部已不再干净,有大量的粒子析出。

图6所示为试样在不同温度保温后的试样的SEM像。从图6可见:淬火态样品在固溶处理过程中几乎所有的第二相粒子都溶入到基体形成过饱和固溶体了,基体显得十分干净,与图5(a)中的金相组织保持一致。基体组织中只有稀疏的几颗尺寸为1~2 μm的白色粒子(图6(a))。结合扫描电镜附件能谱仪(EDX)半定量分析发现其为Fe-Rich相粒子,由于其尺寸较小使得在统计过程中难免会吸收基体的信号,其化学计量比接近于Al7Cu2Fe粒子。在本系合金中应严格控制此粒子的数量及尺寸,因为其十分稳定,一般认为其在本系列合金均匀化和固溶过程中均无法将其完全溶解,其最终溶解必定伴随着本合金基体的熔化,该粒子严重影响合金的力学性能。经405 ℃保温1 h处理后的组织中可发现大角度晶界及亚晶界有明显的第二相粒子析出(图6(b)),综合能谱及图4(d)~(f)的TEM像表明其主要为平衡态η相粒子。并且能谱发现该粒子上Cu原子的含量远高于基体的1.6%(质量分数),说明η相粒子在晶界析出的同时有Cu原子向晶界处扩散。而晶粒内部很少有粒子析出,而经340 ℃保温1 h处理后的组织不仅晶界处有大量的η相粒子析出,再结晶和亚晶晶粒内部也同样大量析出η相粒子(图6(c))。由此可见冷却过程中η相粒子在晶界处析出的析出激活能较晶粒内部低。其析出现象与图5中金相照片所示现象十分吻合。

图5 试样在不同温度保温后的显微组织

Fig.5 Optical micrographs of samples at different temperatures

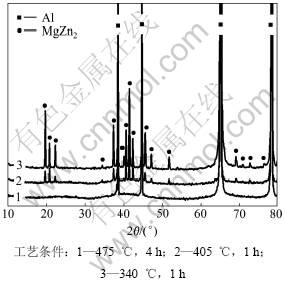

图7所示为试样在不同温度保温后的XRD谱。淬火态中扫描电镜中发现的Al7Cu2Fe粒子由于其数量较少其并没有被XRD检测出来,样品的扫描曲线中也没有探测到其余物相的衍射峰。经405 ℃保温1 h处理后基体中有η相粒子存在,经340 ℃保温1 h处理后基体中有η相粒子存在的同时其衍射强度较经405 ℃保温1 h处理后更强。说明此状态下基体中析出的η相粒子更多,这与由图5和6所观察到的现象一致。

图6 试样在不同温度保温后的SEM像

Fig.6 SEM images of samples at different temperatures

综上所述,在冷却过程中析出相的数量、尺寸及其分布受其析出行为的影响。当冷却速度很快时,其迅速通过析出区间,从而避开了平衡态η相粒子析出(图4(d))。而随着距淬火端面距离的增加,冷却速度逐渐下降,其冷却过程中无法避开析出区间但其经过时间较短时,由于晶界处析出激活能较晶粒内部低,所以,晶界处平衡态η相粒子析出较为明显,晶粒内部数量较少(图4(e))。随着距淬火端面距离的继续增加,冷却速度继续下降,其在冷却过程中经过析出温度区间的时间大大增加,所以,在晶界处平衡态η相粒子增多并粗化的同时,晶粒内部,特别是再结晶晶粒内部,大量析出粗大的平衡态η相粒子(图4(f))。这是淬火敏感性增加及淬透性恶化的直接原因。

图7 试样在不同温度保温后的XRD谱

Fig.7 XRD patterns of samples at different temperatures

3 结论

(1) Al-8.0Zn-2.0Mg-1.6Cu合金在淬火冷却过程中,随着距淬火端面距离的增加,试样的硬度显著下降,之后趋于平缓,变化规律与试样各点冷却速率曲线变化规律一致,其淬透深度约为40 mm,临界冷却速度约为3.8 ℃/s。

(2) 淬火冷却过程中平衡态MgZn2(η)相析出是影响该合金淬透性的主要因素,其析出温度区间为438~215 ℃。

(3) 平衡态MgZn2(η)相在淬火冷却时先后经历晶界与晶粒内部2个过程的析出,析出峰值温度分别为387 ℃和342 ℃。

参考文献:

[1] Heinza A, Haszler A, Keidel C, et al. Recent development in aluminium alloys for aerospace applications[J]. Materials Science and Engineering A, 2000, 280(1): 102-107.

[2] Fridlyander I N. Russian aluminum alloys for aerospace and transport applications[J]. Materials Science Forum, 2000, 921: 331-337.

[3] Williams J C, Starke E A. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51(19): 5775-5799.

[4] Conserva M, Fiorini P. Interpretation of quench-sensitivity in Al-Zn-Mg-Cu alloys[J]. Metallurgical and Materials Transactions B, 1973, 4(3): 857-862.

[5] Thompson D S, Subramanya B S, Levy S A. Quench rate effects in Al-Zn-Mg-Cu alloys[J]. Metallurgical Transactions, 1971, 2(4): 1149-1159.

[6] Robinson J S, Cudd R L, Tanner D A, et al. Quench sensitivity and tensile property inhomogeneity in 7010 forgings[J]. Journal of Materials Processing Technology, 2001, 119(1/3): 261-267.

[7] Liu S D, Zhang X M, Chen M A, et al. Influence of aging on quench sensitivity effect of 7055 aluminum alloy[J]. Materials Characterization, 2008, 59(1): 53-60.

[8] Godard D, Archambault P, Aeby-Gautier E, et al. Precipitation sequences during quenching of the AA 7010 alloy[J]. Acta Materialia, 2002, 50(9): 2319-2329

[9] Srivatsan T S. The low-cycle fatigue and cyclic fracture behaviour of 7150 aluminium alloy[J]. International Journal of Fatigue, 1991, 13(4): 313-321.

[10] Smith B. The Boeing 777: The development of the Boeing 777 was made possible by the development of breakthrough materials that allowed reductions in structural weight while maintaining affordability[J]. Advanced Materials and Processes, 2003, 9: 41-44.

[11] Chakrabarti D J, Liu J, Sawtell R R, et al. New generation high strength high damage tolerance 7085 thick alloy product with low quench sensitivity[J]. Materials Forum, 2004, 28: 969-974.

[12] Conserva M, Di-Russo E, Caloni O. Comparison of the influence of chromium and zirconium on the quench sensitivity of Al-Zn-Mg-Cu alloys[J]. Metallurgical and Materials Transactions B, 1971, 2(4): 1227-1232.

[13] Liu S D, Zhong Q M, Zhang Y, et al. Investigation of quench sensitivity of high strength Al-Zn-Mg-Cu alloys by time-temperature-properties diagrams[J]. Materials Design, 2010, 31(6): 3116-3120.

[14] Liu J. Advanced aluminum and hybrid aerostructures for future aircraft[J]. Materials Science Forum, 2006, 519/512: 1233-1238.

[15] 刘胜胆, 张新明, 黄振宝, 等. 7055铝合金的淬火敏感性研究[J]. 中南大学学报: 自然科学版, 2006, 37(5): 846-849.

LIU Sheng-dan, ZHANG Xin-ming, HUANG Zheng-bao, et al. Quench sensitivity of 7055 aluminum alloy[J]. Journal of Central South University: Science and Technology, 2006, 37(5): 846-849.

[16] 张勇, 邓运来, 张新明, 等. 7050铝合金热轧板的淬火敏感性[J]. 中国有色金属学报, 2008, 18(10): 1788-1794.

ZHANG Yong, DENG Yun-lai, ZHANG Xin-ming, et al. Quenching sensitivity of 7050 aluminum alloy hot-rolled plate[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(10): 1788-1794.

[17] 张新明, 邓运来, 张勇, 等. 测量铝合金材料淬透深度的装置及方法: 中国, 200710034410.8[P]. 2007-08-08.

ZHANG Xin-ming, DENG Yun-lai, ZHANG Yong, et al. Measurement device and method of quenched depth for aluminum alloy: CN, 200710034410.8[P]. 2007-08-08.

[18] 张新明, 邓运来, 万里, 等. 一种测量铝合金材料淬透深度的淬火试棒: 中国, 200920063828.6[P]. 2009-03-27.

ZHANG Xin-ming, DENG Yun-lai, WAN Li, et al. Measurement bar of quenched depth for aluminum alloy: CN, 200920063828.6[P]. 2009-03-27.

(编辑 陈爱华)

收稿日期:2010-09-04;修回日期:2010-12-26

基金项目:国家重点基础研究发展计划(“973”计划)项目(2010CB731700)

通信作者:邓运来(1969-),男,湖南常德人,教授,从事材料组织性能及加工研究;电话:0731-88876913;E-mail: dengylcsu@126.com